Professional Documents

Culture Documents

MGK149

MGK149

Uploaded by

nallanagulapadhu29Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MGK149

MGK149

Uploaded by

nallanagulapadhu29Copyright:

Available Formats

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

Behavioural Study On Eco-Friendly

Geopolymer Tiles

A.Karthik1, S.Saravanan2, M.Muniyandi2, A.Joshua2 ,P. Pandi Karuppu2

1 Assistant Professor, Department of Civil Engineering, Kamaraj College of Engineering and Technology, Madurai,

Tamilnadu - 625701

2 B.E. Final year student, Department of Civil Engineering, Kamaraj College of Engineering and Technology,

Madurai, Tamilnadu - 625701

Abstract- in 1995 to 2.2 billion tons in 2010. Among the

Geopolymer mortar is an innovative greenhouse gases, CO2 contributes about 65% of global

construction material which is produced by the warming. The cement industry is held responsible for

chemical action of inorganic molecules.In Geopolymer some of the CO2 emissions,because the productionof

mortar, ordinary Portland cement (OPC) is not utilized one ton of Portland cement emits approximately one ton

at all. The recent environmental awareness in of CO2 into the atmosphere. Totally 34 billion tons of

construction industry promotes the use of alternative CO2 emitted globally in 2011 and India contributing

binders to partially or fully replace OPC as its CO2 emission of 6%. Indian cement production

production creates environmental pollution due to capacity is likely to be increased in the year 2020, from

release of CO2 into atmosphere. A great 320 million tons to 550 million tons. On the other hand

developmentaround the world in new types of inorganic one ton Portland cement production involves emission

cement binders in the Geopolymer. This promoted the about one ton of CO2 which is a green house gas

use ofgeopolymer mortar which improves the greenness causing global warming. More over fly ash utilization

of ordinary tiles. In this experimental study, Fly ash, in India is only around 55% of total fly ash generated

Bagasse ash and Rise husk ash are attempted in making quantity of around 133 million tons. Several studies

eco-friendly geopolymer tiles because mechanical and have been carried out to reduce the use of Portland

durability properties of geopolymer tiles will be cement in concrete to address the global warming

enhanced. The geopolymer mortar were kept in tile issues. In this respect, the geopolymer. technology

mould and heated at 60oCfor 1 day and exposed to proposed by shows considerable promise for

room temperature for curing. Comparative study was application in concrete industry as an alternative binder

attempted to study the compression strength, water to the Portland cement. In terms of reducing the global

abrasion, modulus ruptureof Fly ash, Bagasse ash and warming, the geopolymer technology could reduce the

Rise husk ash based geopolymer tiles. CO2 emission to the atmosphere caused by cement and

aggregates industries by about 80%.

Keywords: Geopolymer tile, Fly ash, Bagasse ash,

CHEMICAL COMPOSITION OF GEOPOLYMER

Rise husk ash, Sodium hydroxide, Sodium Silicate

Geopolymers are the member of family of

inorganic polymers and are chained structures formed

INTRODUCTION

on back bone of Al and Si ions.The polymerization

Davidovits [1988] proposed that an alkaline

process carried by the chemical reaction under alkaline

liquid could be used to react with the silicon (Si) and

condition results in a three dimensional polymeric chain

the aluminium (Al) in a source material of geological

consists of Si-O-Al-O bonds.

origin or in by-product materials such as fly ash and

rice husk ash to produce binders.

Mn [-(SiO ) z–AlO ] n. wH O

GEOPOLYMER

Portland cement concrete is one of the most where: M = the alkaline element or cation such

widely used construction materials. As the demand for as potassium, sodium or calcium; the symbol –

concrete as a construction material increases, so also indicates the esence of a bond, n is the degree of

the demand for Portland cement. It is estimated that the polycondensation or polymerisation; z is1, 2, 3

production of cement will increase from 1.5 billion tons ………….32.

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 1

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

The GP tile specimens were cured at varying drawbacks as detailed below. Another object of the

temperature of 60°, 80° & 90°for the maximum period present invention is to provide a process to produce

of 24 hours with minimum rest period of one hour. The geopolymer tile whereby the cost of production is

influence of alkaline activators with equal dosage of appreciably lowered and the properties of the product is

admixture and elevated temperature in the mechanical improved.

properties of geopolymer concrete has been studied,

48% of sodium hydroxide solution was used as alkaline MATERIALS USED:

activators along with commercial grade sodium silicate ASHES:

at varying mix proportions and varying curing In this study available materials low calcium

temperature for preparing Geopolymer mortar. fly ash, bagasse ash, rice husk ash, obtained from local

industry. The chemical composition of fly ash, bagasse

FIELD OF THE INVENTION ash, rice husk ash used and Ordinary Portland Cement

The present invention relates to a process for were compared and tabulated below in Table 1. It can

the production of self-glazed geopolymer tile from fly be observed in the table 1, that the fly ash, bagasse ash,

ash, rice husk ash, bagasse ash. The invention rice husk ash contains low calcium oxide, the molar

particularly relates to a process for the production of ratio of Si to Al is 2 and Iron oxide content was higher

self-glazed geopolymer tile from fly ash, rice husk ash, than Cement.

bagasse ash, which is waste materials of local available The specific gravity of the fly ash was 2.30

industry. and fineness modulus was 1.38.

The specific gravity of the bagasse ash was

OBJECTIVE OF THE PROJECT 1.8.

The main object of the present investigation is The specific gravity of the rice husk ash was 2.14.

to provide a process for the production of geopolymer

tile using eco-friendly materials which obviates the

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 2

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

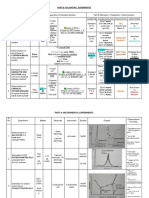

Fly ash

Bagasse ash Rice husk ash

Composition (%) Cement Fly Ash

SiO2 21.0 56.8

Fe2O3 3.4 5.3

Al2O3 5.9 28.2

CaO 64.7 <3

MgO 0.9 5.2

SO3 2.6 0.7

Chloride Content 0.0004 <0.0005

ALKALINE ACTIVATORS: The sodium hydroxide (NaOH) solution was prepared

A combination of sodium silicate solution and by dissolving the pellets in distilled water. Preparation

sodium hydroxide solution were chosen as the alkaline of NaOH solution resulted in emission of heat of 60°C.

liquid. Sodium hydroxide in pellets form with 97% The mass of NaOH solids in a solution in the current

purity and sodium silicate solution of 0.1N were used. study as 8 Molarities.

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 3

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

Fig.3.2 Alkaline activators (Na2SiO3 &NaOH)

SUPER PLASTICIZERS: Easy to use

Cera Concrete tonics 350is a specially formulated dual Fine Aggregate:

purpose admixture for application incorporating The fine aggregate of is obtained from the river

properties of superplasticiser and corrosion inhibitor sand.The physical properties of cement are given in

characteristics based on bi-polar technology. Table 1. The available River sand having bulk density

1.71 kg/m3 was used and the specific gravity is 2.65.

ADVANTAGES:

Substantial reduction in water-cement ratio The Fineness modulus of river sand is 5.24.

The size of the fine aggregate is chosen as it passes

Imparts high degree of corrosion resistance to

concrete through the 4.75mm sieve and retains on the 2.36mm

Compatible with other admixtures sieve.

No adverse effect on workability and strength

It can be used as an admixture to replace sulphate

resisting cement

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 4

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

EXPERIMENTAL INVESTIGATION:

GP mortar mixtures

S.No Mix ID Ash Ash Fine Sodium Sodium Super

kg/m3. Aggregate hydroxide kg/m3 Silicate kg/m3 Plasticizers

kg/m3 kg/m3

1 GP1 Fly ash 774 1052 78 196 12

2 GP2 Bagasse 774 1052 78 196 12

ash

3 GP3 Rice husk 774 1052 78 196 12

ash

4 CM Cement 774 1052 _ _ _

A tile mold of volume 0.3m X 0.3mX 0.012m is calculated to be 0.00108 m3.

S.No Mix ID Ash Ash Fine Sodium Sodium Super

kg/m3. Aggregate hydroxide kg/m3 Silicate kg/m3 Plasticizers

kg/m3 kg/m3

1 GP1 Fly ash 0.836 1.14 0.084 0.217 0.013

2 GP2 Bagasse 0.836 1.14 0.084 0.217 0.013

ash

3 GP3 Rice husk 0.836 1.14 0.084 0.217 0.013

ash

4 CM Cement 0.836 1.14 _ _ _

MANUFACTURING OF GEOPOLYMERIC TILES:

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 5

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

Glazing.

Glazes are used on a wide diversity of ceramic products. While the glaze layer has a negligible

thickness compared to that of the body, its real purpose is to ennoble the product by improving its density, hardness,

gloss, colour, etc.

TESTS ON TILES: The modulus of rupture, also termed bending

strength, which is derived from the magnitude

Modulus of rupture.

breaking strength by a mathematical formula [

Water absorption.

Breaking strength divided by the square of

Moisture Expansion.

minimum thickness at the rupture cross section ].

Compressive strength test

The result of the test, expressed Newtons per

Breaking strength, is a direct relation to the

square millimetre (N/mm2), provides the

load applied on to the tile, with a corrective

approximate mechanical strength of the

coefficient that relates the distance between the

geopolyeric tile independently of tile thickness.

supports and width of the test piece, expressed in

Breaking load, Force necessary to cause the test

newtons (N). the result of the test is a function of

piece to break, expressed in newtons (N)

tile thickness for the same type of material.

according to a pressure gauge reading

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 6

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

Water Absorption reinforced concrete structure, corrosion of the bars took

Water absorption characteristics of the concrete place which results it no cracking and spalling of the

plays an important role for the durability of the concrete and ultimately reduce the life span of the

structure. Ingress of water detoriates concrete and in structure.

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 7

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

% of water absorption

8

4 % of water

6.7 7

5 5.5 absorption

2

0

GP1 GP2 GP3 CM

Compressive strength prepared. At least three of these tiles were tested for

Four geopolymer concrete mixture compressive strength at an age of seven days after

proportions used in laboratory studies. Numerous casting. The unit-weight of specimens was also

batches of these mixtures were manufactured during a determined at the same time. For these numerous

period of four years. For each batch of geopolymer specimens made from Mixture is heat-cured at 600C for

concrete made, 30cm X 30cm tiles specimens were 12 hours.

S.no Geopolymer Mix Compressive strength

attained

(MPa)

1 Fly ash 35.70

2 Bagasse ash 31.45

3 Rise husk ash 30.10

4 Cement 33.65

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 8

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

Moisture Expansion correctly fixed.However, with unsatisfactory fixing

Moisture expansion is the proportional accelerated practices and in certain climatic conditions, natural

expansion that results from subjecting reheated tiles to moisture expansion may aggravate problems, especially

extended immersion in boiling water.The boil time is when tiles are directly fixed to inadequately aged

usually 24 hours.The majority of glazed and unglazed concrete substrates. In these cases, a maximum limit of

tiles have negligible natural moisture expansion that 0.06% moisture expansion is recommended when the

does not contribute to tiling problems when tiles are test is used.

RESULT & DISCUSSION

Result properties of various geopolymer mix

Fly ash

PROPERTIES STANDARDS

Compressive strength 35.70N/mm2

Surface finish Glazed

Bulk density 1.9gm/cc

Water absorption 5%

Bagasse ash

PROPERTIES STANDARDS

Compressive strength 31.45 N/mm2

Surface finish glazed

Water absorption 5.5%

Rise husk ash

PROPERTIES STANDARDS

Compressive strength 30.10 N/mm2

Surface finish glazed

Water absorption 6.7%

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 9

SSRG International Journal of Civil Engineering ( SSRG – IJCE ) – Special Issue ICTER March 2019

Cement

PROPERTIES STANDARDS

Compressive strength 33.65 N/mm2

Surface finish glazed

Water absorption 7%

[2] McCaffrey, R., “Climate Change and the Cement

Industry”, Global Cement and Lime Magazine

ADVANTAGES (Environmental Special Issue), 2002 pp. 15-19.

Manufacturing process of geopolymer tiles is [3] B. Senthil Kumar, V. P. Arunachalam, R. Thenmozhi

simple and easy compared to conventional and T. Senthil VadivelPerformance Analysis of Various

tiles. GeopolymerConcrete Mixes under Elevated

Temperature, Middle-East Journal of Scientific

Geopolymer tiles are cheaper than ceramic Research 24 (2): 287-291, 2016 ISSN 1990-9233

tiles. [4] Davidovits, J, “High-Alkali Cements for 21st Century

Cost of geopolymer tiles mainly depends on Concretes. In Concrete Technology, Past, Present and

sodium silicate solution. Future”, Proceedings of V. Mohan Malhotra

Symposium, Editor: P. Kumar Metha, ACI SP- 144,

Cost of geopolymer tiles can be further 1994, pp.383-397.

reduced by increasing the molarity of NaOH [5] Duxson P, Provis J L, Lukey G C and van Deventer J S

solution instead of increasing (sol/binder). J, “The Role of Inorganic Polymer Technology in the

Automatic surface finish is obtained during Development of Green Concrete”, Cement and

Concrete Research, 37(12), 2007, pp. 1590-1597.

vibration. [6] Gartner E (2004), “Industrially Interesting Approaches

Extra water added to mixture is important to „Low-CO2‟ Cements”, Cement and Concrete

parameter which governs the surface finish. Research, 34(9), 2004, pp.1489-1498.

[7] Davidovits, J, “Soft Mineralogy and Geopolymers”,

Proceedings of the of Geopolymer 88 International

REFERENCES Conference, the Université de Technologie,

[1] Malhotra, V. M., “Making concrete „greener‟ with fly Compiègne, France, 1988.

ash”, ACI Concrete International, 21, 1999, pp 61-66. [8] Gourley, J. T., “Geopolymers; Opportunities for

Environmentally.

ISSN: 2348 – 8352 www.internationaljournalssrg.org Page 10

You might also like

- Methamphetamine SynthesisDocument10 pagesMethamphetamine Synthesisjoejoe6767% (6)

- Chapter 13 Introduction To Polymer (Edited)Document36 pagesChapter 13 Introduction To Polymer (Edited)Clementz WS100% (1)

- Impact of Coal Combustion Fly Ash Used As A Binder in PavementDocument4 pagesImpact of Coal Combustion Fly Ash Used As A Binder in PavementMan ManNo ratings yet

- Final Setting Time and Compressive Strength of Fly Ash and GGBS-Based Geopolymer Paste and MortarDocument8 pagesFinal Setting Time and Compressive Strength of Fly Ash and GGBS-Based Geopolymer Paste and MortarDr. P SWAMY NAGA RATNA GIRINo ratings yet

- Fly AshDocument9 pagesFly AshnicoolNo ratings yet

- Geopolymeric Building Material Using Industrial Waste: Mr. S. C. Dighe & Mr. P. R. GulaveDocument5 pagesGeopolymeric Building Material Using Industrial Waste: Mr. S. C. Dighe & Mr. P. R. GulaveSulakar SalmanNo ratings yet

- Irjet V5i8107Document7 pagesIrjet V5i8107jasimabdNo ratings yet

- Effect of Different Molarities of Sodium Hydroxide Solution On The Strength of Geopolymer ConcreteDocument7 pagesEffect of Different Molarities of Sodium Hydroxide Solution On The Strength of Geopolymer ConcretecyapNo ratings yet

- Fresh and Hardened Properties of Fly AshDocument7 pagesFresh and Hardened Properties of Fly AshdtckulgamNo ratings yet

- An Experimental Investigation On GGBFS and Fly Ash Based Geopolymer ConcreteDocument5 pagesAn Experimental Investigation On GGBFS and Fly Ash Based Geopolymer ConcreteIJSTENo ratings yet

- Evaluation of Compressive Strength Geo-Polymer Foamed Concrete"Document5 pagesEvaluation of Compressive Strength Geo-Polymer Foamed Concrete"Sergio QuirogaNo ratings yet

- Mix Design of Polymeric Concrete IncorpoDocument11 pagesMix Design of Polymeric Concrete Incorpo1limonataNo ratings yet

- Flexural Behaviour of Steel Fiber Reinforced GEO Polymer ConcreteDocument5 pagesFlexural Behaviour of Steel Fiber Reinforced GEO Polymer ConcreteEditor IJTSRDNo ratings yet

- A Preliminary Study of Manufacture of Cement From Rice Husk AshDocument3 pagesA Preliminary Study of Manufacture of Cement From Rice Husk AshGaurav BangarhNo ratings yet

- Experimental Study On Geopolymer Concrete Using Steel FibresDocument4 pagesExperimental Study On Geopolymer Concrete Using Steel FibresAbdullahNo ratings yet

- Eesh Paper PDFDocument4 pagesEesh Paper PDFEesh Kumar TanejaNo ratings yet

- Artikel-1680325787-Effect of FlyDocument9 pagesArtikel-1680325787-Effect of FlyNexar Olaya HidaldoNo ratings yet

- International Journal of Modern EngineerDocument4 pagesInternational Journal of Modern Engineersooperstar330No ratings yet

- Experimental Study On Geopolymer Concrete With Partial Replacement of Fine Aggregate With Foundry SandDocument11 pagesExperimental Study On Geopolymer Concrete With Partial Replacement of Fine Aggregate With Foundry SandkarskotNo ratings yet

- Construction and Building Materials: Lin Yang, Yun Yan, Zhihua Hu, Xiaoli XieDocument6 pagesConstruction and Building Materials: Lin Yang, Yun Yan, Zhihua Hu, Xiaoli XieHeńřÿ ŁøĵæńNo ratings yet

- Role of Alkaline Activator in Development of Eco-FDocument6 pagesRole of Alkaline Activator in Development of Eco-FKarthik MANo ratings yet

- Experimental Investigation On Mineral Content of Fly Bottom Ash and Strength Characteristics of Fly Bottom Ash Bricks - A ReviewDocument8 pagesExperimental Investigation On Mineral Content of Fly Bottom Ash and Strength Characteristics of Fly Bottom Ash Bricks - A ReviewEditor IJTSRDNo ratings yet

- 05 - Chapter 1Document8 pages05 - Chapter 1knight1729No ratings yet

- Performance Evaluation of Cement Stabilized y ash-GBFS Mixes As A Highway Construction MaterialDocument7 pagesPerformance Evaluation of Cement Stabilized y ash-GBFS Mixes As A Highway Construction MaterialHuyNo ratings yet

- Effect of Silica Fume On The Mechanical Properties of FA Based Geopolymer Concrete, Okoye Et Al, 2016 PDFDocument7 pagesEffect of Silica Fume On The Mechanical Properties of FA Based Geopolymer Concrete, Okoye Et Al, 2016 PDFNeeraj VarmaNo ratings yet

- Effect of Alccofines On Setting TimeDocument8 pagesEffect of Alccofines On Setting TimeAvinash PrajapatiNo ratings yet

- 123Document33 pages123kiranNo ratings yet

- Mix Proportion GeoDocument6 pagesMix Proportion Geoअभिषेक महर्षिNo ratings yet

- Experimental Investigation On Flyash Based Geopolymer BricksDocument12 pagesExperimental Investigation On Flyash Based Geopolymer BricksInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Geopolymer ConcereteDocument5 pagesGeopolymer ConcereteMR. ESHAN GHARPURENo ratings yet

- A Case Study On Fly Ash Based Geo-Polymer ConcreteDocument5 pagesA Case Study On Fly Ash Based Geo-Polymer ConcreteBanNo ratings yet

- Gujarat Technological University: Chandkheda, Ahmadabad. AffiliatedDocument14 pagesGujarat Technological University: Chandkheda, Ahmadabad. AffiliatedKaushik MajiNo ratings yet

- E3sconf Icmed2020 01091Document5 pagesE3sconf Icmed2020 0109162Raihan Setyo Nugroho324No ratings yet

- Utilization of Fly Ash For Sustainable Environment ManagementDocument9 pagesUtilization of Fly Ash For Sustainable Environment ManagementEL Hassania EL HERRADINo ratings yet

- Strength Properties of Slag and Fly Ash Blends Activated With Sodium Metasilicate, Sodium Hydroxide and Silica FumeDocument6 pagesStrength Properties of Slag and Fly Ash Blends Activated With Sodium Metasilicate, Sodium Hydroxide and Silica FumeJason BorejszoNo ratings yet

- A Comparative Study On Clay and Red Soil Based Geopolymer MortarDocument6 pagesA Comparative Study On Clay and Red Soil Based Geopolymer MortarIrfan PvNo ratings yet

- Development of Various Curing Effect of Nominal STDocument5 pagesDevelopment of Various Curing Effect of Nominal STAUBREY MAE ERICCA PABINGWITNo ratings yet

- Compressive Strength of Cement & Fly Ash Mortar:-A Case StudyDocument9 pagesCompressive Strength of Cement & Fly Ash Mortar:-A Case StudyOudhai VONGKEONo ratings yet

- 1.1 General: JntuceaDocument40 pages1.1 General: JntuceaKollimarala Srinivasa raoNo ratings yet

- Project Work Phase - 2 18Cvp83Document83 pagesProject Work Phase - 2 18Cvp83naga bhushanNo ratings yet

- Geopolymer ConcreteDocument32 pagesGeopolymer ConcreteTarun MauryaNo ratings yet

- Ijaiem 2016 05 30 44 PDFDocument12 pagesIjaiem 2016 05 30 44 PDFjasimabdNo ratings yet

- Influence of SO3 On The Hydration HeatDocument10 pagesInfluence of SO3 On The Hydration HeatPaknubkNo ratings yet

- Study On Fly Ash and GGBS Based Geopolymer Concrete Under Ambient CuringDocument6 pagesStudy On Fly Ash and GGBS Based Geopolymer Concrete Under Ambient CuringkarskotNo ratings yet

- Paper On Curing Methods of GPCDocument17 pagesPaper On Curing Methods of GPCKUMAR RAJUNo ratings yet

- A Study On Water Absorption and Sorptivity of Geopolymer ConcreteDocument9 pagesA Study On Water Absorption and Sorptivity of Geopolymer ConcreteSajjad AhmadNo ratings yet

- Geopolymer Concrete REPORTDocument15 pagesGeopolymer Concrete REPORTharsha33367% (3)

- Study The Effects of Tobacco Waste Ash and Waste Glass PowderDocument8 pagesStudy The Effects of Tobacco Waste Ash and Waste Glass Powderwidnu wirasetiaNo ratings yet

- Ibraim Overview Influence of Pozzolanic Materials PDFDocument12 pagesIbraim Overview Influence of Pozzolanic Materials PDFrobertsj21No ratings yet

- Fly Ash Class C Geopolymer BrickDocument8 pagesFly Ash Class C Geopolymer BrickSiti AsmahaniNo ratings yet

- GPC Caparison To OpcDocument5 pagesGPC Caparison To Opcabubakarsiddiq118No ratings yet

- Influence of Red Mud As A Partial Replacement of Cement With Hydrated LimeDocument8 pagesInfluence of Red Mud As A Partial Replacement of Cement With Hydrated Limeshivanand hippargaNo ratings yet

- Construction and Building Materials: Wei-Hao Lee, Jhi-Hao Wang, Yung-Chin Ding, Ta-Wui ChengDocument7 pagesConstruction and Building Materials: Wei-Hao Lee, Jhi-Hao Wang, Yung-Chin Ding, Ta-Wui ChengMustafaMahdiNo ratings yet

- Construction and Building MaterialsDocument8 pagesConstruction and Building MaterialsMonicaNo ratings yet

- 44 Utilization of Solid Waste (Fly-Ash) and Rubber Latex Mixed With Clay and Acid Solvent To Produce Concrete Brick Using Solidification ProcessDocument9 pages44 Utilization of Solid Waste (Fly-Ash) and Rubber Latex Mixed With Clay and Acid Solvent To Produce Concrete Brick Using Solidification ProcessMary Joy ManayagaNo ratings yet

- 13 - Flyash Geopolymer - Review###Document32 pages13 - Flyash Geopolymer - Review###fs friedaNo ratings yet

- Construction and Building Materials: N.B. Singh, B. MiddendorfDocument15 pagesConstruction and Building Materials: N.B. Singh, B. MiddendorfHERALDO YAMANDU CRUZ CRUZNo ratings yet

- Fly Ash-Based Geopolymer Concrete 2011 PDFDocument46 pagesFly Ash-Based Geopolymer Concrete 2011 PDFAbdul Hakkim100% (1)

- Dhinesh, Thirugnanasambandam - JETIRZ006059 - 2019Document6 pagesDhinesh, Thirugnanasambandam - JETIRZ006059 - 2019dhavamanidossNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- Cementitious Materials for Nuclear Waste ImmobilizationFrom EverandCementitious Materials for Nuclear Waste ImmobilizationRating: 4 out of 5 stars4/5 (1)

- Mathematical Modeling of The Evacated Solar CollectorDocument10 pagesMathematical Modeling of The Evacated Solar CollectorVedhas WalimbeNo ratings yet

- Module 3 Properties of Liquids and Intermolecular ForcesDocument18 pagesModule 3 Properties of Liquids and Intermolecular ForcesIcarusNo ratings yet

- A Waste Cold Recovery From The Exhausted Cryogenic Nitrogen by Using Thermoelectric Power GeneratorDocument12 pagesA Waste Cold Recovery From The Exhausted Cryogenic Nitrogen by Using Thermoelectric Power GeneratorYin TanNo ratings yet

- Pinch AnalysisDocument6 pagesPinch AnalysisShooeibNo ratings yet

- P RT/ (V - B) - A/v P RT/V V RT/P: Do Problem 40 in Chapter 1Document45 pagesP RT/ (V - B) - A/v P RT/V V RT/P: Do Problem 40 in Chapter 1AleksaNo ratings yet

- Department of Physics, College of Science Mustansiriyah UniversityDocument8 pagesDepartment of Physics, College of Science Mustansiriyah Universityبلسم محمود شاكرNo ratings yet

- Adole CondensationDocument15 pagesAdole CondensationAtif Ahmad AbbasiNo ratings yet

- Heat EnergyDocument18 pagesHeat EnergyCrazzy RamNo ratings yet

- Characterization Catalyst PDFDocument29 pagesCharacterization Catalyst PDFJohn TorrezNo ratings yet

- Formulation and Evaluation of Miconazole Nitrate Nanoemulsion and CreamDocument4 pagesFormulation and Evaluation of Miconazole Nitrate Nanoemulsion and CreamNoon NightNo ratings yet

- Luna Hilic BrochDocument20 pagesLuna Hilic BrochBruna RodriguesNo ratings yet

- Effects of Nitrogen Flow Rates On The Growth Morphology of TiAlN Films Prepared by An Rf-Reactive Sputtering TechniqueDocument5 pagesEffects of Nitrogen Flow Rates On The Growth Morphology of TiAlN Films Prepared by An Rf-Reactive Sputtering TechniquePhysics MPSTMENo ratings yet

- 03 PDFDocument48 pages03 PDFJonathas BritoNo ratings yet

- Exfoliation and Dispersion of Graphene in Ethanol-Water MixturesDocument7 pagesExfoliation and Dispersion of Graphene in Ethanol-Water MixturesHoang Anh NguyenNo ratings yet

- 2-Basic Concepts of Corrosion Science and EngineeringDocument31 pages2-Basic Concepts of Corrosion Science and EngineeringMarwin G CrispinoNo ratings yet

- Organic ChemistryDocument32 pagesOrganic Chemistryj.obriain94No ratings yet

- Chemistry Topic One QuestionsDocument30 pagesChemistry Topic One QuestionsAruba Dhaduk100% (1)

- Raman ReviewDocument13 pagesRaman ReviewApostolis KoutsioukisNo ratings yet

- McCabe-Thiele Method - Mass Transfer Solved Problems - MsubbuDocument2 pagesMcCabe-Thiele Method - Mass Transfer Solved Problems - MsubbuUtkarsh Kapoor100% (2)

- Amino AcidsDocument17 pagesAmino AcidsANAND sNo ratings yet

- AQA Biology A-Level: Required Practical 1Document4 pagesAQA Biology A-Level: Required Practical 1ormattNo ratings yet

- Natural Gas Processing Over ViewDocument5 pagesNatural Gas Processing Over ViewsatishchemengNo ratings yet

- Hc-Ac2-T Advanced Auto Air Cond Demonstration Unit Exp Man Langgeng Indo 9916 PDFDocument122 pagesHc-Ac2-T Advanced Auto Air Cond Demonstration Unit Exp Man Langgeng Indo 9916 PDFJimmy Septariansyah PutraNo ratings yet

- Shs Gen - Chem 1-q1 Mel-6 Week-2Document10 pagesShs Gen - Chem 1-q1 Mel-6 Week-2Kim Francis Beluso Dollete IINo ratings yet

- Fair Use NoticeDocument9 pagesFair Use NoticeAhsan AliNo ratings yet

- ECOMax-HE Brochure - Eco GreenDocument2 pagesECOMax-HE Brochure - Eco GreenMC EstimationNo ratings yet

- Jee Advanced Test On EquilibriaDocument2 pagesJee Advanced Test On EquilibriaprathmfedNo ratings yet

- VTU Chemistry Lab Revision SheetDocument3 pagesVTU Chemistry Lab Revision SheetSHREYAS A HOMBALNo ratings yet