Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 views414 Dismantling C2 procedure Rev.01

414 Dismantling C2 procedure Rev.01

Uploaded by

Mohammad MushtaqCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- SB 1289a NavajoDocument7 pagesSB 1289a NavajoDiego LlNo ratings yet

- CP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01Document6 pagesCP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01tarekNo ratings yet

- 31-3 ITP For Welder Qualification Tests - Offshore Pipeline WeldingDocument15 pages31-3 ITP For Welder Qualification Tests - Offshore Pipeline Weldingvenkatesh67% (3)

- Attachment 12.7 - QA - QC Checklist - MCC & CBDocument6 pagesAttachment 12.7 - QA - QC Checklist - MCC & CBehteshamNo ratings yet

- Method Statement For Hot Tapping Rev 0 PDFDocument9 pagesMethod Statement For Hot Tapping Rev 0 PDFsharif339No ratings yet

- ITP Static EquipmentDocument12 pagesITP Static Equipmentaamirapi100% (3)

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- ITP C 006 Concrete SlipformDocument7 pagesITP C 006 Concrete SlipformAnil Pottekkat100% (1)

- 414 Column procedure - Rev 2Document5 pages414 Column procedure - Rev 2Mohammad MushtaqNo ratings yet

- 414 Column procedure - Rev 1Document5 pages414 Column procedure - Rev 1Mohammad MushtaqNo ratings yet

- Procedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectionDocument10 pagesProcedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectiondiptiNo ratings yet

- 414 Column procedure - Rev 3Document8 pages414 Column procedure - Rev 3Mohammad MushtaqNo ratings yet

- Method Statement of Cable InstallationDocument17 pagesMethod Statement of Cable Installationmohammedasheem891No ratings yet

- CHEC CON 00 00 MST 0040 A01 Method Statement of Cable InstallationDocument15 pagesCHEC CON 00 00 MST 0040 A01 Method Statement of Cable Installationmohammedasheem891No ratings yet

- DDDDocument7 pagesDDDmohd as shahiddin jafriNo ratings yet

- Fabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XDocument6 pagesFabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XAbdulrahman EladawyNo ratings yet

- Procedure For FabricationDocument10 pagesProcedure For FabricationKoya ThangalNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BDocument6 pagesHFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BMohamed FarisNo ratings yet

- FCPG 00000 CPP143 00 BA 6070 00022 002 FOC Laying and Testing ProcedureDocument11 pagesFCPG 00000 CPP143 00 BA 6070 00022 002 FOC Laying and Testing Procedurem.rasheed400010No ratings yet

- FCPG-00000-CPP143-00-QA-6050-00012-001 - UT ProcedureDocument19 pagesFCPG-00000-CPP143-00-QA-6050-00012-001 - UT Procedurem.rasheed400010No ratings yet

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocument38 pagesMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNo ratings yet

- Icf MD Spec 252 Cast Steel Side Buffer ArrgtDocument17 pagesIcf MD Spec 252 Cast Steel Side Buffer ArrgtDipak Kumar ChatterjeeNo ratings yet

- 414 Column procedureDocument3 pages414 Column procedureMohammad MushtaqNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- Procedure For Srtuctural Fabrication & ErectionDocument5 pagesProcedure For Srtuctural Fabrication & ErectiondiptiNo ratings yet

- Repair ProceduresDocument5 pagesRepair Proceduresmohd as shahiddin jafriNo ratings yet

- PP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0Document14 pagesPP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0ibrahimNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument15 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Document6 pagesRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Method Statement For Erection of Tank t147 UpdatedDocument22 pagesMethod Statement For Erection of Tank t147 UpdatedAshutosh29% (7)

- 16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)Document7 pages16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)SANDEEPNo ratings yet

- Attachment 12.5 - QA - QC Checklist - SMDBDocument6 pagesAttachment 12.5 - QA - QC Checklist - SMDBehteshamNo ratings yet

- MS - Bored Piling Work PT Chosuk Development Indonesia Rev.03 Nov 2020Document23 pagesMS - Bored Piling Work PT Chosuk Development Indonesia Rev.03 Nov 2020Captain ChickenNo ratings yet

- Inspection and Test Plan For Anode MD5Document7 pagesInspection and Test Plan For Anode MD5congvt93No ratings yet

- Tank Fabrication ProcedureDocument11 pagesTank Fabrication ProcedureNurul100% (2)

- Specific Requirements & Scope of Work For RCC PilingDocument38 pagesSpecific Requirements & Scope of Work For RCC PilingTauqueerAhmadNo ratings yet

- Bolted Flange and Gasket Joints Assembly ProcedureDocument9 pagesBolted Flange and Gasket Joints Assembly ProceduremohdNo ratings yet

- TH THDocument9 pagesTH THP.MannaNo ratings yet

- Itp For Sampling Line (GFT Tank-48360)Document46 pagesItp For Sampling Line (GFT Tank-48360)Nithin GNo ratings yet

- SAIC-P-3004 Rev 7 FinalDocument3 pagesSAIC-P-3004 Rev 7 Finalmustafa abdelshafiNo ratings yet

- Welding Inspection Ass 1Document7 pagesWelding Inspection Ass 1mohd as shahiddin jafriNo ratings yet

- STS QAC SOP 007 Repair Procedure For Carbon SteelDocument6 pagesSTS QAC SOP 007 Repair Procedure For Carbon Steelmohd as shahiddin jafriNo ratings yet

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument4 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- Method Statement - Girth GearDocument15 pagesMethod Statement - Girth GearProjects DepartmentNo ratings yet

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDocument6 pagesQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNo ratings yet

- Qic-Qsp-Uni-Tdr-Cl-0418 (3) Rev001Document3 pagesQic-Qsp-Uni-Tdr-Cl-0418 (3) Rev001Ragab EisaNo ratings yet

- API 510 PC 20 31 Aug05 Bench MarkDocument5 pagesAPI 510 PC 20 31 Aug05 Bench MarkCss SfaxienNo ratings yet

- Bridge Crane & Hoist InstallationDocument7 pagesBridge Crane & Hoist Installationnike_y2kNo ratings yet

- Barracuda and Caratinga Crude Oil Fields Production Facilities ProjectDocument87 pagesBarracuda and Caratinga Crude Oil Fields Production Facilities ProjectneivaprojetosNo ratings yet

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Document17 pagesIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedNo ratings yet

- Drilling and Setting Procedure of Conductor PipesDocument7 pagesDrilling and Setting Procedure of Conductor PipesemadabdelsattarNo ratings yet

- Shic A 0008Document3 pagesShic A 000801095902062ahmedNo ratings yet

- Method Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDocument15 pagesMethod Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDonny Subarja100% (2)

- Cable Connection & Sealing of Sacrificial AnodesDocument5 pagesCable Connection & Sealing of Sacrificial AnodesmandiNo ratings yet

- Installation of T1501 PIPE ProcedureDocument6 pagesInstallation of T1501 PIPE Procedure1339979No ratings yet

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument5 pages5 - Tank Itp - Inspection & Test Plan For TanksmandiNo ratings yet

- NCR Disposition ProposalDocument2 pagesNCR Disposition ProposalKarthik DhayalanNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- 414 Column procedure - Rev 2Document5 pages414 Column procedure - Rev 2Mohammad MushtaqNo ratings yet

- 402-02 FdiDocument5 pages402-02 FdiMohammad MushtaqNo ratings yet

- 402-04 FdiDocument5 pages402-04 FdiMohammad MushtaqNo ratings yet

- 402-01 HydroDocument5 pages402-01 HydroMohammad MushtaqNo ratings yet

- AramcoDocument2 pagesAramcoMohammad MushtaqNo ratings yet

- 402-01 FdiDocument5 pages402-01 FdiMohammad MushtaqNo ratings yet

- Construction Cost in Bangalore A4D - Calculate Cost of Construction in Bangalore 2019 - 18 Residential Construction Cost CalculatorDocument97 pagesConstruction Cost in Bangalore A4D - Calculate Cost of Construction in Bangalore 2019 - 18 Residential Construction Cost CalculatorMohammad MushtaqNo ratings yet

- 488-01 WMDocument1 page488-01 WMMohammad MushtaqNo ratings yet

- About BlankDocument4 pagesAbout BlankMohammad MushtaqNo ratings yet

- CCA - Circular 2023Document2 pagesCCA - Circular 2023Mohammad MushtaqNo ratings yet

- Certification Program For The Year - 2019 Certification Program For The Year - 2019 Certification Program For The Year - 2019Document4 pagesCertification Program For The Year - 2019 Certification Program For The Year - 2019 Certification Program For The Year - 2019Mohammad MushtaqNo ratings yet

- CRM # 4044662347 (Zpec # 5)Document1 pageCRM # 4044662347 (Zpec # 5)Mohammad MushtaqNo ratings yet

- Temper Bead Welding MethodDocument3 pagesTemper Bead Welding MethodMohammad MushtaqNo ratings yet

- House and Bungalow Construction Cost Standard Packages - HapphoDocument9 pagesHouse and Bungalow Construction Cost Standard Packages - HapphoMohammad Mushtaq100% (1)

- Certification Program For The Year - 2019 Certification Program For The Year - 2019Document4 pagesCertification Program For The Year - 2019 Certification Program For The Year - 2019Mohammad MushtaqNo ratings yet

- Welding Engineer Interview Questions and Answers: Free EbookDocument38 pagesWelding Engineer Interview Questions and Answers: Free EbookMohammad MushtaqNo ratings yet

- Api-1169 Pipeline Construction Inspector: Body of KnowledgeDocument9 pagesApi-1169 Pipeline Construction Inspector: Body of KnowledgeMohammad MushtaqNo ratings yet

414 Dismantling C2 procedure Rev.01

414 Dismantling C2 procedure Rev.01

Uploaded by

Mohammad Mushtaq0 ratings0% found this document useful (0 votes)

1 views1 pageCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views1 page414 Dismantling C2 procedure Rev.01

414 Dismantling C2 procedure Rev.01

Uploaded by

Mohammad MushtaqCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

ZPEC DOCUMENT No.

PE-0414-PD-01

METHOD OF STATEMENT

FOR Rev. No. 1

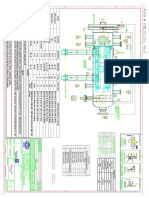

COLUMN LIFTING TRUNIOIN

WELDING FOR DEMOLISHING DATE: 17th Oct 2019

QA/QC

1.0 PURPOSE:

This procedure describes the method of statement for fabrication and welding of Lifting

Trunnion on column C2 for demolishing in Abqaiq North Stabilization area.

2.0 DESCRIPTION OF WORK:

1. Identify the Equipment (Column C2).

2. Fabricate the lifting trunnion and tailing lug as per the drawing ABQAIQ SITE-

110-C-2.

3. Deliver the fabricated items to site with proper support without damaging the

components.

4. Since the lifting trunnion and tailing lug are temporary, it shall be fabricated

from available A36 or equivalent CS material.

5. Identify the suitable location on Column 110-C2 at site for lifting purpose by

lifting team (180 deg apart).

6. Clean the identified area (ie) removal of existing painting and insulation to

ease for welding, Perform PT/MT on the prepared area.

7. Carryout the fitup of fabricated lifting trunnion and tailing lug in the identified

area. Any obstruction on shell to fitup shall be modified accordingly to suit the

site condition.

8. Carryout the Fillet welding between the RF pad and shell on column 110-C2 as

per WPS 0302-M 11 A0-01. Pre heat of 95˚C shall be maintained

9. Perform visual inspection & PT to ensure there is no weld visual & PT defects

of the fillet welding.

Prepared By Reviewed By Approved By

Magdi Abdul Latif P.Asok Kumar D.Hari Kumar

Sr. QA/QC Engineer QA/QC Supervisor QA/QC Superintend

Page 1 of 1

You might also like

- SB 1289a NavajoDocument7 pagesSB 1289a NavajoDiego LlNo ratings yet

- CP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01Document6 pagesCP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01tarekNo ratings yet

- 31-3 ITP For Welder Qualification Tests - Offshore Pipeline WeldingDocument15 pages31-3 ITP For Welder Qualification Tests - Offshore Pipeline Weldingvenkatesh67% (3)

- Attachment 12.7 - QA - QC Checklist - MCC & CBDocument6 pagesAttachment 12.7 - QA - QC Checklist - MCC & CBehteshamNo ratings yet

- Method Statement For Hot Tapping Rev 0 PDFDocument9 pagesMethod Statement For Hot Tapping Rev 0 PDFsharif339No ratings yet

- ITP Static EquipmentDocument12 pagesITP Static Equipmentaamirapi100% (3)

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- ITP C 006 Concrete SlipformDocument7 pagesITP C 006 Concrete SlipformAnil Pottekkat100% (1)

- 414 Column procedure - Rev 2Document5 pages414 Column procedure - Rev 2Mohammad MushtaqNo ratings yet

- 414 Column procedure - Rev 1Document5 pages414 Column procedure - Rev 1Mohammad MushtaqNo ratings yet

- Procedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectionDocument10 pagesProcedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectiondiptiNo ratings yet

- 414 Column procedure - Rev 3Document8 pages414 Column procedure - Rev 3Mohammad MushtaqNo ratings yet

- Method Statement of Cable InstallationDocument17 pagesMethod Statement of Cable Installationmohammedasheem891No ratings yet

- CHEC CON 00 00 MST 0040 A01 Method Statement of Cable InstallationDocument15 pagesCHEC CON 00 00 MST 0040 A01 Method Statement of Cable Installationmohammedasheem891No ratings yet

- DDDDocument7 pagesDDDmohd as shahiddin jafriNo ratings yet

- Fabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XDocument6 pagesFabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XAbdulrahman EladawyNo ratings yet

- Procedure For FabricationDocument10 pagesProcedure For FabricationKoya ThangalNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BDocument6 pagesHFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BMohamed FarisNo ratings yet

- FCPG 00000 CPP143 00 BA 6070 00022 002 FOC Laying and Testing ProcedureDocument11 pagesFCPG 00000 CPP143 00 BA 6070 00022 002 FOC Laying and Testing Procedurem.rasheed400010No ratings yet

- FCPG-00000-CPP143-00-QA-6050-00012-001 - UT ProcedureDocument19 pagesFCPG-00000-CPP143-00-QA-6050-00012-001 - UT Procedurem.rasheed400010No ratings yet

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocument38 pagesMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNo ratings yet

- Icf MD Spec 252 Cast Steel Side Buffer ArrgtDocument17 pagesIcf MD Spec 252 Cast Steel Side Buffer ArrgtDipak Kumar ChatterjeeNo ratings yet

- 414 Column procedureDocument3 pages414 Column procedureMohammad MushtaqNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- Procedure For Srtuctural Fabrication & ErectionDocument5 pagesProcedure For Srtuctural Fabrication & ErectiondiptiNo ratings yet

- Repair ProceduresDocument5 pagesRepair Proceduresmohd as shahiddin jafriNo ratings yet

- PP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0Document14 pagesPP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0ibrahimNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument15 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Document6 pagesRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Method Statement For Erection of Tank t147 UpdatedDocument22 pagesMethod Statement For Erection of Tank t147 UpdatedAshutosh29% (7)

- 16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)Document7 pages16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)SANDEEPNo ratings yet

- Attachment 12.5 - QA - QC Checklist - SMDBDocument6 pagesAttachment 12.5 - QA - QC Checklist - SMDBehteshamNo ratings yet

- MS - Bored Piling Work PT Chosuk Development Indonesia Rev.03 Nov 2020Document23 pagesMS - Bored Piling Work PT Chosuk Development Indonesia Rev.03 Nov 2020Captain ChickenNo ratings yet

- Inspection and Test Plan For Anode MD5Document7 pagesInspection and Test Plan For Anode MD5congvt93No ratings yet

- Tank Fabrication ProcedureDocument11 pagesTank Fabrication ProcedureNurul100% (2)

- Specific Requirements & Scope of Work For RCC PilingDocument38 pagesSpecific Requirements & Scope of Work For RCC PilingTauqueerAhmadNo ratings yet

- Bolted Flange and Gasket Joints Assembly ProcedureDocument9 pagesBolted Flange and Gasket Joints Assembly ProceduremohdNo ratings yet

- TH THDocument9 pagesTH THP.MannaNo ratings yet

- Itp For Sampling Line (GFT Tank-48360)Document46 pagesItp For Sampling Line (GFT Tank-48360)Nithin GNo ratings yet

- SAIC-P-3004 Rev 7 FinalDocument3 pagesSAIC-P-3004 Rev 7 Finalmustafa abdelshafiNo ratings yet

- Welding Inspection Ass 1Document7 pagesWelding Inspection Ass 1mohd as shahiddin jafriNo ratings yet

- STS QAC SOP 007 Repair Procedure For Carbon SteelDocument6 pagesSTS QAC SOP 007 Repair Procedure For Carbon Steelmohd as shahiddin jafriNo ratings yet

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument4 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- Method Statement - Girth GearDocument15 pagesMethod Statement - Girth GearProjects DepartmentNo ratings yet

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDocument6 pagesQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNo ratings yet

- Qic-Qsp-Uni-Tdr-Cl-0418 (3) Rev001Document3 pagesQic-Qsp-Uni-Tdr-Cl-0418 (3) Rev001Ragab EisaNo ratings yet

- API 510 PC 20 31 Aug05 Bench MarkDocument5 pagesAPI 510 PC 20 31 Aug05 Bench MarkCss SfaxienNo ratings yet

- Bridge Crane & Hoist InstallationDocument7 pagesBridge Crane & Hoist Installationnike_y2kNo ratings yet

- Barracuda and Caratinga Crude Oil Fields Production Facilities ProjectDocument87 pagesBarracuda and Caratinga Crude Oil Fields Production Facilities ProjectneivaprojetosNo ratings yet

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Document17 pagesIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedNo ratings yet

- Drilling and Setting Procedure of Conductor PipesDocument7 pagesDrilling and Setting Procedure of Conductor PipesemadabdelsattarNo ratings yet

- Shic A 0008Document3 pagesShic A 000801095902062ahmedNo ratings yet

- Method Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDocument15 pagesMethod Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDonny Subarja100% (2)

- Cable Connection & Sealing of Sacrificial AnodesDocument5 pagesCable Connection & Sealing of Sacrificial AnodesmandiNo ratings yet

- Installation of T1501 PIPE ProcedureDocument6 pagesInstallation of T1501 PIPE Procedure1339979No ratings yet

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument5 pages5 - Tank Itp - Inspection & Test Plan For TanksmandiNo ratings yet

- NCR Disposition ProposalDocument2 pagesNCR Disposition ProposalKarthik DhayalanNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- 414 Column procedure - Rev 2Document5 pages414 Column procedure - Rev 2Mohammad MushtaqNo ratings yet

- 402-02 FdiDocument5 pages402-02 FdiMohammad MushtaqNo ratings yet

- 402-04 FdiDocument5 pages402-04 FdiMohammad MushtaqNo ratings yet

- 402-01 HydroDocument5 pages402-01 HydroMohammad MushtaqNo ratings yet

- AramcoDocument2 pagesAramcoMohammad MushtaqNo ratings yet

- 402-01 FdiDocument5 pages402-01 FdiMohammad MushtaqNo ratings yet

- Construction Cost in Bangalore A4D - Calculate Cost of Construction in Bangalore 2019 - 18 Residential Construction Cost CalculatorDocument97 pagesConstruction Cost in Bangalore A4D - Calculate Cost of Construction in Bangalore 2019 - 18 Residential Construction Cost CalculatorMohammad MushtaqNo ratings yet

- 488-01 WMDocument1 page488-01 WMMohammad MushtaqNo ratings yet

- About BlankDocument4 pagesAbout BlankMohammad MushtaqNo ratings yet

- CCA - Circular 2023Document2 pagesCCA - Circular 2023Mohammad MushtaqNo ratings yet

- Certification Program For The Year - 2019 Certification Program For The Year - 2019 Certification Program For The Year - 2019Document4 pagesCertification Program For The Year - 2019 Certification Program For The Year - 2019 Certification Program For The Year - 2019Mohammad MushtaqNo ratings yet

- CRM # 4044662347 (Zpec # 5)Document1 pageCRM # 4044662347 (Zpec # 5)Mohammad MushtaqNo ratings yet

- Temper Bead Welding MethodDocument3 pagesTemper Bead Welding MethodMohammad MushtaqNo ratings yet

- House and Bungalow Construction Cost Standard Packages - HapphoDocument9 pagesHouse and Bungalow Construction Cost Standard Packages - HapphoMohammad Mushtaq100% (1)

- Certification Program For The Year - 2019 Certification Program For The Year - 2019Document4 pagesCertification Program For The Year - 2019 Certification Program For The Year - 2019Mohammad MushtaqNo ratings yet

- Welding Engineer Interview Questions and Answers: Free EbookDocument38 pagesWelding Engineer Interview Questions and Answers: Free EbookMohammad MushtaqNo ratings yet

- Api-1169 Pipeline Construction Inspector: Body of KnowledgeDocument9 pagesApi-1169 Pipeline Construction Inspector: Body of KnowledgeMohammad MushtaqNo ratings yet