Professional Documents

Culture Documents

tubo 160

tubo 160

Uploaded by

deybi resarteCopyright:

Available Formats

You might also like

- MTCDocument1 pageMTCali hassanNo ratings yet

- Test Report - TubeDocument26 pagesTest Report - TubeVictor PerezNo ratings yet

- P38-Mill CertDocument1 pageP38-Mill CertKennyNo ratings yet

- Test Report - TubeDocument40 pagesTest Report - TubeVictor PerezNo ratings yet

- A283 Grade C MTC - Hangang.Document1 pageA283 Grade C MTC - Hangang.fvssc05No ratings yet

- Product Quality Certificate of Pressure VesselsDocument18 pagesProduct Quality Certificate of Pressure VesselsbabarNo ratings yet

- Test Report - TubeDocument5 pagesTest Report - TubeVictor PerezNo ratings yet

- 180023285-MTC Jerusalem Certificado.Document1 page180023285-MTC Jerusalem Certificado.Maximiliano MonzónNo ratings yet

- 73 89 MTC PSL2Document12 pages73 89 MTC PSL2Agung Eko PurnomoNo ratings yet

- Aço Cearense - 2023-11 - 2002425977Document1 pageAço Cearense - 2023-11 - 2002425977ENGENHARIA PADRÃO ENERGIANo ratings yet

- 26.HAIYUN-Voice Coil-Bobbin-Kapton (KSV) - A10C8 HAlogen SB PFOS PFOA-20220514Document10 pages26.HAIYUN-Voice Coil-Bobbin-Kapton (KSV) - A10C8 HAlogen SB PFOS PFOA-20220514anisa novita sariNo ratings yet

- Aba026 Mtc-IiDocument6 pagesAba026 Mtc-Iiarribasplata007No ratings yet

- Formel q 过程审核佛吉亚Document26 pagesFormel q 过程审核佛吉亚cong daNo ratings yet

- BJ013 2Document2 pagesBJ013 2Saul Omar Fernandez RojasNo ratings yet

- Certif. Calidad LaminaDocument1 pageCertif. Calidad LaminaLuis GarciaNo ratings yet

- MTC Hl-Ed-P21001 3 1-2Document10 pagesMTC Hl-Ed-P21001 3 1-2Ricardo PeñafielNo ratings yet

- 1 GBM Catalog1Document13 pages1 GBM Catalog1Nugroho SetioajiNo ratings yet

- Aba026 Mtc-IDocument14 pagesAba026 Mtc-Iarribasplata007No ratings yet

- PoscoDocument1 pagePoscoVinoth MechNo ratings yet

- 品质证明214030990002Document1 page品质证明214030990002Choi Lai LonNo ratings yet

- A36 MTCDocument1 pageA36 MTCfvssc05No ratings yet

- SDT-281-test ReportDocument4 pagesSDT-281-test Reportsd0268No ratings yet

- ABA026-SERMEFITDocument1 pageABA026-SERMEFITjofer1985.jfNo ratings yet

- LAMINA 3-8 - PisoDocument1 pageLAMINA 3-8 - PisoHugo F Barrera AlvaradoNo ratings yet

- Certificado de Calidad Tubo Acero SCH-80 12MMDocument1 pageCertificado de Calidad Tubo Acero SCH-80 12MMAlexis SanjinesNo ratings yet

- MTC of GH5188Document1 pageMTC of GH5188yuwenalfredNo ratings yet

- TuboDocument1 pageTubojhulyNo ratings yet

- Meca-Inox Brochure - Industrial Gas - GB - CN - V16Document2 pagesMeca-Inox Brochure - Industrial Gas - GB - CN - V16Willie Cheong Han YangNo ratings yet

- Master Xiao - Material Report For The SS304 Vent ProtectorDocument1 pageMaster Xiao - Material Report For The SS304 Vent ProtectorMallesh QCNo ratings yet

- Aluminium Bronze Wire Product Quality GuaranteeDocument3 pagesAluminium Bronze Wire Product Quality GuaranteeroalhidraulicpumpscolNo ratings yet

- 5454 o MTCDocument1 page5454 o MTCMafer GonzálezNo ratings yet

- Eholding Productcatalogue CN 1014Document16 pagesEholding Productcatalogue CN 1014words2zhigang_612545No ratings yet

- Certificate Of Inspection: 湖南申德钢铁有限公司 Hunan Standard Steel Co.,LtdDocument1 pageCertificate Of Inspection: 湖南申德钢铁有限公司 Hunan Standard Steel Co.,LtdPrasanthNo ratings yet

- Plate Coil1-UnlockedDocument1 pagePlate Coil1-Unlockedchandrashekhar chaurasiyaNo ratings yet

- 厂检报告EI-060+WPE00-21-KCQP172+(1802支)Document49 pages厂检报告EI-060+WPE00-21-KCQP172+(1802支)Pastor Chavez TitoNo ratings yet

- Aceros Arequipa - T092-0045767-PiscoDocument3 pagesAceros Arequipa - T092-0045767-PiscoOscarNo ratings yet

- MTC Rebar A615 GR.60 MJZZL - 20221128Document1 pageMTC Rebar A615 GR.60 MJZZL - 20221128juan sobalvarroNo ratings yet

- Kinlong Cover Plate Test ReportDocument3 pagesKinlong Cover Plate Test ReportPaulo Jerico ColomaNo ratings yet

- Series 5 Aluminum PlateDocument1 pageSeries 5 Aluminum PlatevolarclothNo ratings yet

- PGCA EF H02 001 - C1 - 1 - PublicationDocument12 pagesPGCA EF H02 001 - C1 - 1 - PublicationMOHD FHAIRUZ BIN WAHID STUDENTNo ratings yet

- 焊接材料 山东聚力质量证明书Document1 page焊接材料 山东聚力质量证明书yangshileiNo ratings yet

- CCIC检测报告3Document6 pagesCCIC检测报告3AlbertNo ratings yet

- Inconel 718 MTCDocument1 pageInconel 718 MTCyuwenalfredNo ratings yet

- Ma CoaDocument1 pageMa CoaDongliang LiuNo ratings yet

- Cert. Tubería en Tramos Menores de 6-12mDocument3 pagesCert. Tubería en Tramos Menores de 6-12mrosa aurora montesano somarribaNo ratings yet

- MTC ERW 4500473545 Tubos sch-3 - 20044008Document1 pageMTC ERW 4500473545 Tubos sch-3 - 20044008Saul Omar Fernandez RojasNo ratings yet

- 2020 台橡高雄廠溫室氣體盤查報告書Document38 pages2020 台橡高雄廠溫室氣體盤查報告書林冠年No ratings yet

- DB11 238-2012 京标V车用汽油 PDFDocument9 pagesDB11 238-2012 京标V车用汽油 PDF尤弋No ratings yet

- Test ReportDocument4 pagesTest Reportdeportesaldia2014No ratings yet

- Mill Certificate For S275JR-1Document2 pagesMill Certificate For S275JR-1Sreetharan SNo ratings yet

- 50X3H93M 5AMD 01 (DW AS 6609) A版 - 新表格 - 凝结温度 - 2021Document17 pages50X3H93M 5AMD 01 (DW AS 6609) A版 - 新表格 - 凝结温度 - 2021pant.vk8514No ratings yet

- Certificado de CobreDocument1 pageCertificado de CobreEMMRNo ratings yet

- Sae 1010 MTCDocument1 pageSae 1010 MTCgwenaelNo ratings yet

- Silicone Fluid COADocument3 pagesSilicone Fluid COASACHIN BORADENo ratings yet

- Bicarbonate PotassiumDocument1 pageBicarbonate Potassiumiyas salihNo ratings yet

- Sulzer Pumps - Eomr100188253 PDFDocument336 pagesSulzer Pumps - Eomr100188253 PDFKhawaja Ameer Moavia100% (2)

- PROD Tech PDMFAT22148D 202MLB 6P - C3011552Document10 pagesPROD Tech PDMFAT22148D 202MLB 6P - C3011552junior.moschen168No ratings yet

- ASME质保体系的建立及ASME U授权证书和钢印的获取 薛显坤Document3 pagesASME质保体系的建立及ASME U授权证书和钢印的获取 薛显坤Jinliang LiuNo ratings yet

- MTC Billet Partai HJ - MV DS Proper 3000mtDocument31 pagesMTC Billet Partai HJ - MV DS Proper 3000mtjoko purwantoNo ratings yet

tubo 160

tubo 160

Uploaded by

deybi resarteCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

tubo 160

tubo 160

Uploaded by

deybi resarteCopyright:

Available Formats

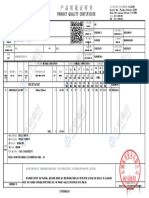

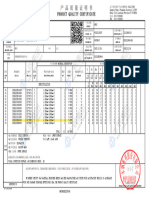

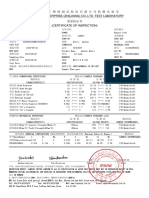

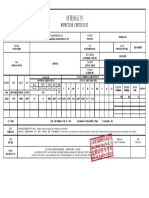

Documento: FAV - 233822

07/05/2024 9:06:50 - FernandoG

SHANDONG MOLONG PETROLEUM MACHINERY CO.LTD 本公司已通过ISO9001-2008

产品质量证明书 OUR COMPANY HAS PASSED THROUGH ISO9001-2008

PRODUCT QUALITY CERTIFICATE EN10204 3.1 国际质量体系认证

客户名称:CLIENT NAME:CODIFER S.A.S INTERNATIONAL QUALITY CERTIFICATE SYSTEM

产品名称:无缝钢管 兹为贵公司制造的钢管,业经本公司质检处依据产品标准,技术条件及合同规定,检验合格,特发此证 合同号: HJY20230724-CD

THIS TO CERTIFY THAT IN ACCORDANCE WITH THE RELEVANT PRODUCT SPECIFICATION, TECHNIQUE CONDITIONS AND CONTRACT STIPULATIONS, THE STEEL PIPES MANUFACTURED FOR YOUR UNIT,

NAME OF GOODS: TUBERIA SMLS WERE TESTED QUALIFIED BY OUR QUALITY CONTROL DEPARTMENT. CONTRACT NO.: HJY20230724-CD

证书号:LICENSE NO.: BS20230724-2023S BRAND: MOLONG

执行标准:ADMINISTER STANDARD: ASTM A106 A53 Gr.B PSL1 总重:TOTAL WEIGHT: 2.027 MT 钢级GRADE *5 B BRAND: MOLONG 检验结果:INSPECTION RESULT: OK IMP: 3426

碳当量

化学成分CHEMICAL VALUES (%) Carbono

equivalente

重量检测WEIGHT

Type Nb+V+ Cr+Mo+ 外观检测 FLATTENING 残余磁性

C Si Mn P S Cr Cu Mo Ni Nb V B Ti Al Nb+V Ca O N Al/N As Pb Sb Sn Bi CEIIW CEPcm 交货状态 INSPECTION

炉号 批号 取样*3 Ti Ni+Cu DELIVERY

VISUAL&DIMENSI

壁厚检测

压扁/ RESIDUAL

HEAT NO.: BATH NO. ONAL BENDING MAGNETISM

CONDITION THICKNESS

INSPECTION 弯曲 ≤30GS

Max 0.28 - 1.06 0.03 0.03 0.40 0.40 0.15 0.40 0.001 0.04 0.06 0.06 0.15 0.006 0.004 0.012 0.8 0.02 0.005 0.01 0.015 0.005 INSPECTION

Min - 0.10 0.29 - - - - - - 2

H 0.21 0.31 0.82 0.012 0.012 0.24 0.15 0.11 0.18 0.0027 0.006 0.001 0.006 0.0168 0.0087 0.0147 0.005 0.002 0.007 2.40 0.68 0.005 0.004 0.001 0.002 0.0002 - - 27

HOT ROOLING

E22635259 T23644874 P 0.20 0.30 0.83 0.018 0.011 0.26 0.18 0.08 0.14 0.0028 0.009 0.001 0.006 0.0216 0.0118 0.0178 0.005 0.002 0.009 2.40 0.66 0.003 0.004 0.001 0.004 0.0002 - - /(NOT COLD QUALIFIED QUALIFIED QUALIFIED 23

EXPANDED)

P 0.19 0.27 0.84 0.017 0.010 0.20 0.17 0.09 0.12 0.0027 0.005 0.001 0.008 0.0147 0.0077 0.0157 0.005 0.002 0.007 2.10 0.58 0.006 0.002 0.002 0.004 0.0001 - - 24

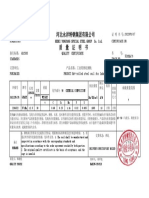

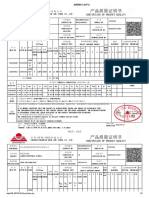

Descriptions of Delivery 冲击实验IMPACT TEST

拉伸实验 水压 无损测试

TENSILE TEST HYDROSTATIC TEST NONDESTRUCTIVE TESTING

横向TRANSVERSE 纵向LONGITUDINAL

硬度测试HARDNESS TEST 金相试验

(≤240 HV10) METALLOGRAPHIC

30J≤单个最小值<40J 30J≤单个最小值<40J

屈服强度 NDT 30J≤Single minimum<40J 30J≤Single minimum<40J

抗拉强度 伸长率 TEMPER 平均值≥40J Average value≥40J 平均值≥40J Average value≥40J

YIELD SPECIM

壁厚 重量 TENSILE ELONGATI

外径 外径 支数 STRENGTH ATURE

炉号 批号BATH THICKNES 长度 TOTAL STRENGTH ON EN TYPE

OD OD QUANTITY 试验类型 方向 Rt0.5 Rm 压力值 温度

HEAT NO.: NO. S LENGTH WEIGHT 位置 MPA (%) 稳压时 试样尺寸

KCV AVERAG AVERAG

(INCH) (MM) (PCS) TEST ORIENTAT 尺寸 MPA PRESS 结果 *2 UNIT SHEAR. UNIT SHEAR.

(MM) (MT) LOCATION 间 (℃) E E

TYPE ION SIZE VALUE RESULT VALUE AREA. VALUE AREA.

*1 TIME VALUE VALUE

*1 *1 Mpa 显微组织 晶粒度

方法 结果

GRADE INSIDE 内 MIDDLE 中 OUTSIDE 外 MICROSTRUC- GRAIN

Max - - - METHOD RESULT

TURE SIZE

单个值 平均值 剪切面积% 单个值 平均值 剪切面积%

Min 415 245 24.5

P B L B:38.1MM, L:50MM / 523 293 33 - - - - - - - - - - - - -

QUALIF QUALIF

E22635259 T23644874 6" 168.3 18.26 6 2.027 5 P B L B:38.1MM, L:50MM / 465 266 32 19 5s ET+UT E3+U3 - - - - - - - - - - - - -

IED IED

P B L B:38.1MM, L:50MM / 470 274 30 - - - - - - - - - - - - -

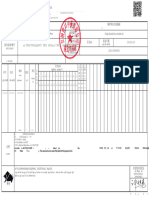

说明ELUCIDATION::

1: *1:试验类型(P 产品试验, S: 样品试验)TEST TYPE(P: PRODUCT TEST S: SAMPLE TEST)

取样位置(B:管体, E :墩粗端)LOCATION(B: PIPE BODY, U: UPSETTING END) 7.本产品只保证在标准(合同)规定条件下使用。

实验方向L — 纵向试块 T — 横向试块ORIENTATION(L—LONGITUDINAL SAMPLE T—TRANSVERSE SAMPLE) THIS PRODUCTS ARE ONLY GUARANTEED FOR USING UNDER STANDARD (CONTRACT) STIPULATION CONDITIONS.

2:*2:Impact Specimen(冲击试样):C1 -10x5x55,C2 -10x6.7x55,C3-10x7.5x55,C4-10x10x55,C5- Sample of specified size(特定尺寸试样):(--) ; 8.本证明书复印无防伪标记和未加产品质量专用章无效。

3:*3:H: 熔炼分析 H-HEAT ANALYSIS. P: 成品分析 P- PRODUCT ANALYSIS. THIS CERTIFICATE IS INVALID WHEN PHOTOCOPIED WITHOUT FAKE PREVENTING MARKS AND SPECIAL QUALITY STAMP.

4:*4:In the applicable inspection method box“√”(在适用的检验方法框内打“√”) 9. 运输和卸货造成的产品缺陷不予保证。THE PIPES DAMD DURING TRANSPORTATION AND UNLOADING ARE NOT GUARANTEED.

5:*5:Steel Marking(炼 钢) 10. 如对产品有异议, 请予十五日内以书面形式提出,逾期本公司不予受理。

6: NAME AND LOCATION OF FACILITIES USED FOR PIPE MANUFACTURING:地址和名称: IF YOU HAVE DIFFERENT OPINION FOR OUR PRODUCTS, PLEASE PROVIDE US IN WRITTEN FORM IN FIFTEEN.

SHANDONG MOLONG PETROLEUM MACHINERY CO.LTD山东墨龙石油机械股份有限公司

NO. 999 WENSHENG STREET SHOUGUANG CITY, SHANDONG PROVINCE PEOPLE'S REPUBLIC OF CHINA 生产地址1:山东省寿光市文圣街999号

检验员 INSPECTOR: 李玉彬 审核: VERIFIER: 武立海 制表: TAB: 陈 燕 签发日期:DATE OF ISSUE: 2023年08月20日 30 / 30

You might also like

- MTCDocument1 pageMTCali hassanNo ratings yet

- Test Report - TubeDocument26 pagesTest Report - TubeVictor PerezNo ratings yet

- P38-Mill CertDocument1 pageP38-Mill CertKennyNo ratings yet

- Test Report - TubeDocument40 pagesTest Report - TubeVictor PerezNo ratings yet

- A283 Grade C MTC - Hangang.Document1 pageA283 Grade C MTC - Hangang.fvssc05No ratings yet

- Product Quality Certificate of Pressure VesselsDocument18 pagesProduct Quality Certificate of Pressure VesselsbabarNo ratings yet

- Test Report - TubeDocument5 pagesTest Report - TubeVictor PerezNo ratings yet

- 180023285-MTC Jerusalem Certificado.Document1 page180023285-MTC Jerusalem Certificado.Maximiliano MonzónNo ratings yet

- 73 89 MTC PSL2Document12 pages73 89 MTC PSL2Agung Eko PurnomoNo ratings yet

- Aço Cearense - 2023-11 - 2002425977Document1 pageAço Cearense - 2023-11 - 2002425977ENGENHARIA PADRÃO ENERGIANo ratings yet

- 26.HAIYUN-Voice Coil-Bobbin-Kapton (KSV) - A10C8 HAlogen SB PFOS PFOA-20220514Document10 pages26.HAIYUN-Voice Coil-Bobbin-Kapton (KSV) - A10C8 HAlogen SB PFOS PFOA-20220514anisa novita sariNo ratings yet

- Aba026 Mtc-IiDocument6 pagesAba026 Mtc-Iiarribasplata007No ratings yet

- Formel q 过程审核佛吉亚Document26 pagesFormel q 过程审核佛吉亚cong daNo ratings yet

- BJ013 2Document2 pagesBJ013 2Saul Omar Fernandez RojasNo ratings yet

- Certif. Calidad LaminaDocument1 pageCertif. Calidad LaminaLuis GarciaNo ratings yet

- MTC Hl-Ed-P21001 3 1-2Document10 pagesMTC Hl-Ed-P21001 3 1-2Ricardo PeñafielNo ratings yet

- 1 GBM Catalog1Document13 pages1 GBM Catalog1Nugroho SetioajiNo ratings yet

- Aba026 Mtc-IDocument14 pagesAba026 Mtc-Iarribasplata007No ratings yet

- PoscoDocument1 pagePoscoVinoth MechNo ratings yet

- 品质证明214030990002Document1 page品质证明214030990002Choi Lai LonNo ratings yet

- A36 MTCDocument1 pageA36 MTCfvssc05No ratings yet

- SDT-281-test ReportDocument4 pagesSDT-281-test Reportsd0268No ratings yet

- ABA026-SERMEFITDocument1 pageABA026-SERMEFITjofer1985.jfNo ratings yet

- LAMINA 3-8 - PisoDocument1 pageLAMINA 3-8 - PisoHugo F Barrera AlvaradoNo ratings yet

- Certificado de Calidad Tubo Acero SCH-80 12MMDocument1 pageCertificado de Calidad Tubo Acero SCH-80 12MMAlexis SanjinesNo ratings yet

- MTC of GH5188Document1 pageMTC of GH5188yuwenalfredNo ratings yet

- TuboDocument1 pageTubojhulyNo ratings yet

- Meca-Inox Brochure - Industrial Gas - GB - CN - V16Document2 pagesMeca-Inox Brochure - Industrial Gas - GB - CN - V16Willie Cheong Han YangNo ratings yet

- Master Xiao - Material Report For The SS304 Vent ProtectorDocument1 pageMaster Xiao - Material Report For The SS304 Vent ProtectorMallesh QCNo ratings yet

- Aluminium Bronze Wire Product Quality GuaranteeDocument3 pagesAluminium Bronze Wire Product Quality GuaranteeroalhidraulicpumpscolNo ratings yet

- 5454 o MTCDocument1 page5454 o MTCMafer GonzálezNo ratings yet

- Eholding Productcatalogue CN 1014Document16 pagesEholding Productcatalogue CN 1014words2zhigang_612545No ratings yet

- Certificate Of Inspection: 湖南申德钢铁有限公司 Hunan Standard Steel Co.,LtdDocument1 pageCertificate Of Inspection: 湖南申德钢铁有限公司 Hunan Standard Steel Co.,LtdPrasanthNo ratings yet

- Plate Coil1-UnlockedDocument1 pagePlate Coil1-Unlockedchandrashekhar chaurasiyaNo ratings yet

- 厂检报告EI-060+WPE00-21-KCQP172+(1802支)Document49 pages厂检报告EI-060+WPE00-21-KCQP172+(1802支)Pastor Chavez TitoNo ratings yet

- Aceros Arequipa - T092-0045767-PiscoDocument3 pagesAceros Arequipa - T092-0045767-PiscoOscarNo ratings yet

- MTC Rebar A615 GR.60 MJZZL - 20221128Document1 pageMTC Rebar A615 GR.60 MJZZL - 20221128juan sobalvarroNo ratings yet

- Kinlong Cover Plate Test ReportDocument3 pagesKinlong Cover Plate Test ReportPaulo Jerico ColomaNo ratings yet

- Series 5 Aluminum PlateDocument1 pageSeries 5 Aluminum PlatevolarclothNo ratings yet

- PGCA EF H02 001 - C1 - 1 - PublicationDocument12 pagesPGCA EF H02 001 - C1 - 1 - PublicationMOHD FHAIRUZ BIN WAHID STUDENTNo ratings yet

- 焊接材料 山东聚力质量证明书Document1 page焊接材料 山东聚力质量证明书yangshileiNo ratings yet

- CCIC检测报告3Document6 pagesCCIC检测报告3AlbertNo ratings yet

- Inconel 718 MTCDocument1 pageInconel 718 MTCyuwenalfredNo ratings yet

- Ma CoaDocument1 pageMa CoaDongliang LiuNo ratings yet

- Cert. Tubería en Tramos Menores de 6-12mDocument3 pagesCert. Tubería en Tramos Menores de 6-12mrosa aurora montesano somarribaNo ratings yet

- MTC ERW 4500473545 Tubos sch-3 - 20044008Document1 pageMTC ERW 4500473545 Tubos sch-3 - 20044008Saul Omar Fernandez RojasNo ratings yet

- 2020 台橡高雄廠溫室氣體盤查報告書Document38 pages2020 台橡高雄廠溫室氣體盤查報告書林冠年No ratings yet

- DB11 238-2012 京标V车用汽油 PDFDocument9 pagesDB11 238-2012 京标V车用汽油 PDF尤弋No ratings yet

- Test ReportDocument4 pagesTest Reportdeportesaldia2014No ratings yet

- Mill Certificate For S275JR-1Document2 pagesMill Certificate For S275JR-1Sreetharan SNo ratings yet

- 50X3H93M 5AMD 01 (DW AS 6609) A版 - 新表格 - 凝结温度 - 2021Document17 pages50X3H93M 5AMD 01 (DW AS 6609) A版 - 新表格 - 凝结温度 - 2021pant.vk8514No ratings yet

- Certificado de CobreDocument1 pageCertificado de CobreEMMRNo ratings yet

- Sae 1010 MTCDocument1 pageSae 1010 MTCgwenaelNo ratings yet

- Silicone Fluid COADocument3 pagesSilicone Fluid COASACHIN BORADENo ratings yet

- Bicarbonate PotassiumDocument1 pageBicarbonate Potassiumiyas salihNo ratings yet

- Sulzer Pumps - Eomr100188253 PDFDocument336 pagesSulzer Pumps - Eomr100188253 PDFKhawaja Ameer Moavia100% (2)

- PROD Tech PDMFAT22148D 202MLB 6P - C3011552Document10 pagesPROD Tech PDMFAT22148D 202MLB 6P - C3011552junior.moschen168No ratings yet

- ASME质保体系的建立及ASME U授权证书和钢印的获取 薛显坤Document3 pagesASME质保体系的建立及ASME U授权证书和钢印的获取 薛显坤Jinliang LiuNo ratings yet

- MTC Billet Partai HJ - MV DS Proper 3000mtDocument31 pagesMTC Billet Partai HJ - MV DS Proper 3000mtjoko purwantoNo ratings yet