Professional Documents

Culture Documents

FD Fan Balancing

FD Fan Balancing

Uploaded by

Firma .0 ratings0% found this document useful (0 votes)

2 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views5 pagesFD Fan Balancing

FD Fan Balancing

Uploaded by

Firma .Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

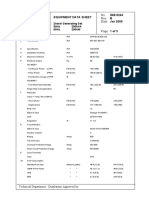

(MCS) Machinery Consultation And Services 11/06/2023

Machine Info. FD Fan - Outage 2023

Date 10.06.2023

Speed 750 RPM

No. of blades 10

Angle between Blades 36 Degree

Rotor Weight 450 Kg

Rotor Diameter 1920 mm

Device Used Commtest Vb7

Original Run (O) (1X) Amp mm/s Phase

FDEH 0.6 20⁰

FNDEH 2.1 241⁰

FDEV 0.4 37⁰

FNDEV 5.1 321⁰

Trail weight 140 gm 108⁰ Removed

Trail Run (O+T) (1X) Amp Phase Estimated Weights

FDEH 0.5 28⁰ gm ⁰

FNDEH 1.8 249⁰ 726 gm 146⁰

FDEV 0.3 46⁰ gm ⁰

FNDEV 3.9 334⁰ 455 gm 142⁰

Correction Weight 470 gm 144⁰

Correction Run (1X) Amp mm/s Phase Estimated Weights

FDEH 0.2 10⁰ gm ⁰

FNDEH 0.7 271⁰ gm ⁰

FDEV 0.2 35⁰ gm ⁰

FNDEV 1.7 358⁰ 749.2 gm 160⁰

Trim Weight 109 gm 160⁰ Correction Weight Not Removed

Trim Run (1X) Amp mm/s Phase

FDEH 0.1 11⁰

FNDEH 0.5 313⁰

FDEV 0.2 33⁰

FNDEV 1.1 12⁰

Final Readings (1X) Amp mm/s Overall Units

FDEH 0.1 0.8 mm/s RMS

FNDEH 0.5 2.3 mm/s RMS

FDEV 0.2 0.3 mm/s RMS

FNDEV 1.1 5.5 mm/s RMS

(MCS) Machinery Consultation And Services 1

(MCS) Machinery Consultation And Services 11/06/2023

Machine Layout

Fan

Motor

FNDE FDE

Trail Weight

Correction Weight

(MCS) Machinery Consultation And Services 2

(MCS) Machinery Consultation And Services 11/06/2023

Vibration Levels Before Balancing

3X

Vibration Levels After Balancing 1X Running

Speed Vibration

- Unbalance -

Shows signfcant

dropp in the

vibration levels.

3X Component still high - with

no change in vibration levels

(MCS) Machinery Consultation And Services 3

(MCS) Machinery Consultation And Services 11/06/2023

Polar Plot

Polar Plot for

Horz. Direction

Polar Plot for Vert.

Direction

Influence Coefficient Original Vibration

0.01@359 deg mm/s/g Original Vib. + Trail Weight

Trail Weight effect

(MCS) Machinery Consultation And Services 4

(MCS) Machinery Consultation And Services 11/06/2023

Standards

Analysis & Recommendations:

1. The Fan Non-Drive End showed elevated vibration at the running speed components 1X

and 3X, levels were higher in the vertical direction compared to the horizontal direction,

and the Fan Drive End showed much lower vibration levels compared to FNDE.

2. Based on the data collected we concluded that unbalance was not the main cause of the

vibration, however, we performed balancing to reduce any amount of residual unbalance

so can we reduce the stress on the bearing and reduce the vibration levels as much as

possible.

3. Unbalance vibration value dropped from 5.1 mm/s rms to 1.1 mm/s rms. and overall

vibration dropped from 8.1 mm/s rms to 5.1 mm/s in the vertical direction.

4. It is recommended to check the FNDE bearing for fixation/assembly problems and to

check the Fan impeller assembly with the shaft.

Thanks,

Salah Attia

Technical Consultant

VCAT4, TCAT2, LCAT2,CMRP, ARPA

Machinery Consultation and services

Australia |QLD

T: +61499881294 | WhatsApp: +61499881294

Email: Salah.attia@mcsturbo.com

Website: https://mcsturbo.com/

(MCS) Machinery Consultation And Services 5

You might also like

- Introduction To Social Work 12th Edition Farley Test BankDocument28 pagesIntroduction To Social Work 12th Edition Farley Test Bankjojyhys50% (2)

- Global Trend Alert. Stan WeinsteinDocument30 pagesGlobal Trend Alert. Stan WeinsteinMARIANO7363100% (3)

- Magnapunch Parts PunchDocument18 pagesMagnapunch Parts PunchAlex GonzalezNo ratings yet

- Parts Manual Serial No 23124Document200 pagesParts Manual Serial No 23124Cesar Augusto Aquino100% (1)

- Antenna Scenario 20-AQU4518R23v06-1963 DatasheetDocument2 pagesAntenna Scenario 20-AQU4518R23v06-1963 DatasheetvictorNo ratings yet

- Ready IMU ModulesDocument6 pagesReady IMU ModulesYonas GhiwotNo ratings yet

- Blood Bank Management SystemDocument25 pagesBlood Bank Management Systemshijinbgopal56% (9)

- Formwork and ScaffoldingDocument43 pagesFormwork and ScaffoldingAarti Vij50% (2)

- Vibration Analysis Report OnDocument7 pagesVibration Analysis Report OnCesar SampaioNo ratings yet

- Specification PagesDocument44 pagesSpecification PagesGerardo Daniel Arroyo GarciaNo ratings yet

- FDZ-529022 YD-702J-6637J Super Slim 3.5 FloppyDocument14 pagesFDZ-529022 YD-702J-6637J Super Slim 3.5 FloppyLpicNo ratings yet

- Smzen 114 003 - MZ01 01 CFDDocument20 pagesSmzen 114 003 - MZ01 01 CFDmfsNo ratings yet

- GPA-017S FurunoDocument4 pagesGPA-017S FurunoVishalNo ratings yet

- AWSD01906PRDocument1 pageAWSD01906PRUtpalNo ratings yet

- VS-6556 and VS 6577 Technical Data SheetDocument3 pagesVS-6556 and VS 6577 Technical Data SheetKien Nguyen TrungNo ratings yet

- Prose G6w22he-21 - 0.1Document3 pagesProse G6w22he-21 - 0.1dwiki.marchiano86No ratings yet

- Tip Speed Calculation: RPM CalculationDocument13 pagesTip Speed Calculation: RPM CalculationNishant InamdarNo ratings yet

- Team Name: - Team ID - College/University Name:: IndrajitDocument13 pagesTeam Name: - Team ID - College/University Name:: IndrajitINDRAJIT SVCENo ratings yet

- Acceleration &velocityDocument125 pagesAcceleration &velocityRodolfo HernandezNo ratings yet

- Installation, Operating and Maintenance Instructions For Bibby TransmissionsDocument13 pagesInstallation, Operating and Maintenance Instructions For Bibby Transmissionsing_julio_siviraNo ratings yet

- 19-75-9m-Safety AchievedDocument16 pages19-75-9m-Safety Achievedanush_swaminathanNo ratings yet

- F0118-i1STF (1HL) (29.05.23) (P-112) SoftnerDocument1 pageF0118-i1STF (1HL) (29.05.23) (P-112) SoftnerBeximco Denim LabNo ratings yet

- Trendline Gyro While Drilling Service PDFDocument2 pagesTrendline Gyro While Drilling Service PDFJorge FernandoNo ratings yet

- VM 6083 - 60B1 Data SheetDocument3 pagesVM 6083 - 60B1 Data SheetMinh HoàngNo ratings yet

- Jaybeam 5920200 LVDocument4 pagesJaybeam 5920200 LVcosconorNo ratings yet

- G4WC 21Document2 pagesG4WC 21НиколайИгоревичНасыбуллинNo ratings yet

- Balancing ENG LatestDocument4 pagesBalancing ENG LatestPaul GálvezNo ratings yet

- Specification DNA-31734 Tracking Resistant ADSS CableDocument5 pagesSpecification DNA-31734 Tracking Resistant ADSS CableDerrick Kojo SenyoNo ratings yet

- ANT-ATR4517R10v06-2579 DatasheetDocument2 pagesANT-ATR4517R10v06-2579 DatasheetSilviuSNo ratings yet

- Service Manual: XR-CA370/CA370XDocument32 pagesService Manual: XR-CA370/CA370Xpaco37No ratings yet

- Oil Sample report-31.5MVA, Indotech PTR at Turkayamjal SSDocument2 pagesOil Sample report-31.5MVA, Indotech PTR at Turkayamjal SSMUSHAM217No ratings yet

- ADU451720Document2 pagesADU451720Raluca Roxana SzaszNo ratings yet

- MTS103# 2GDP-21Document2 pagesMTS103# 2GDP-21NataliaNo ratings yet

- GTP-GPIL-ENERFRA-ACSR DOG With Current RatingDocument2 pagesGTP-GPIL-ENERFRA-ACSR DOG With Current RatingShashikumar SNo ratings yet

- ANT-ADU4516R2-1702-001 Datasheet - LTE ANCHADocument3 pagesANT-ADU4516R2-1702-001 Datasheet - LTE ANCHAAnny Yohana Reyes SilvaNo ratings yet

- Amtir-1 Datasheet CesDocument5 pagesAmtir-1 Datasheet Ces'Sebastian OrtizNo ratings yet

- Saba2 JVC qlf6Document28 pagesSaba2 JVC qlf6SparkyNo ratings yet

- D Agent - 1 - Work 331 S Upload 141638AA1Document11 pagesD Agent - 1 - Work 331 S Upload 141638AA1Bruno PereiraNo ratings yet

- Htxcw331821 000: Xx-Pol - Dual Band Vet Panel - 33° / 33° - 17.5 / 19.5 DbiDocument4 pagesHtxcw331821 000: Xx-Pol - Dual Band Vet Panel - 33° / 33° - 17.5 / 19.5 Dbijhon mirandaNo ratings yet

- IP812-ME2107-M3_005 (Inverter)Document6 pagesIP812-ME2107-M3_005 (Inverter)Dimas BambangNo ratings yet

- Parameter Old Design New Design Acceleration (m/s2) 4.33 5.04Document8 pagesParameter Old Design New Design Acceleration (m/s2) 4.33 5.04SagarNo ratings yet

- 200 KVA DC9 Spec SheetsDocument3 pages200 KVA DC9 Spec SheetsMateen YounasNo ratings yet

- LS-325 (激光整平机)English Operating Manual A4Document40 pagesLS-325 (激光整平机)English Operating Manual A42post.mariyaNo ratings yet

- Dxxx-790-960/1710-2690/1710-2690-65/65/65-17I/18I/18I-M/M/M-R Easyret 6-Port Antenna With 3 Integrated Rcus - 2.6M Model: Atr4518R7V06Document2 pagesDxxx-790-960/1710-2690/1710-2690-65/65/65-17I/18I/18I-M/M/M-R Easyret 6-Port Antenna With 3 Integrated Rcus - 2.6M Model: Atr4518R7V06НиколайИгоревичНасыбуллинNo ratings yet

- Dxxx-790-960/1710-2690/1710-2690-65/65/65-17I/18I/18I-M/M/M-R Easyret 6-Port Antenna With 3 Integrated Rcus - 2.6M Model: Atr4518R7V06Document2 pagesDxxx-790-960/1710-2690/1710-2690-65/65/65-17I/18I/18I-M/M/M-R Easyret 6-Port Antenna With 3 Integrated Rcus - 2.6M Model: Atr4518R7V06Roman HavrylenkoNo ratings yet

- ADU451503Document2 pagesADU451503Raluca Roxana SzaszNo ratings yet

- 10 GMFL Short Tool Performance Specification (D2078 Rev A)Document1 page10 GMFL Short Tool Performance Specification (D2078 Rev A)abidahad311No ratings yet

- 1LE7503-3AB23-4AA4-Z L53 Datasheet enDocument2 pages1LE7503-3AB23-4AA4-Z L53 Datasheet enjoy baruaNo ratings yet

- Opgw Fiber Spec Dno 91391Document5 pagesOpgw Fiber Spec Dno 91391carlos diazNo ratings yet

- Team Super Ignite: Guru Nanak Institute of TechnologyDocument15 pagesTeam Super Ignite: Guru Nanak Institute of TechnologyShaik Himam SahebNo ratings yet

- Selection and Ordering Data: Motion ControlDocument46 pagesSelection and Ordering Data: Motion ControlMiguel RomeroNo ratings yet

- ANT APE4518R19v06 2333 DatasheetDocument2 pagesANT APE4518R19v06 2333 Datasheetluciano100% (1)

- Prose Mb-G64o9x65v-00Document3 pagesProse Mb-G64o9x65v-00hasib_muhammedNo ratings yet

- File Balance Bullgear BSP 14-09-23Document3 pagesFile Balance Bullgear BSP 14-09-23Azka AzzaNo ratings yet

- Leaflet MTiDocument4 pagesLeaflet MTiAlexNo ratings yet

- G493 Series Servo MotorsDocument4 pagesG493 Series Servo MotorsIain JubbNo ratings yet

- 36847-CG14154 Damping Scheme EHS 5 - 16-20140718Document5 pages36847-CG14154 Damping Scheme EHS 5 - 16-20140718alanetnNo ratings yet

- ANT-A704515R0v06-1698-001 DatasheetDocument2 pagesANT-A704515R0v06-1698-001 DatasheetАнтонNo ratings yet

- Power Station Engine Generator Vibration Analysis ReportDocument5 pagesPower Station Engine Generator Vibration Analysis ReportDerrick AramNo ratings yet

- OPENMARK 4000 System SpecificationsDocument7 pagesOPENMARK 4000 System SpecificationsVixiMerahNo ratings yet

- FDAA-520037 B YD-702D-6238D 3.5in 2mbDocument13 pagesFDAA-520037 B YD-702D-6238D 3.5in 2mbLpicNo ratings yet

- Prose 6w22me-01 - 1.0Document3 pagesProse 6w22me-01 - 1.0dwiki.marchiano86No ratings yet

- F Opt Opgwdno 6417-1Document5 pagesF Opt Opgwdno 6417-1gercubNo ratings yet

- Airlift BioreactorDocument18 pagesAirlift BioreactorDark_Kiro100% (1)

- GEMPAC UserManual Appendix1 Ver 8 PDFDocument40 pagesGEMPAC UserManual Appendix1 Ver 8 PDFLuisPupialesNo ratings yet

- M316C MJIDE 2sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDocument3 pagesM316C MJIDE 2sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPchakrouneNo ratings yet

- Window Cleaning Safe ProfilesDocument6 pagesWindow Cleaning Safe ProfilesGraemeNichollsNo ratings yet

- PharaprasingDocument3 pagesPharaprasingAlfizan adibNo ratings yet

- Survey Management System-Revamped VersionDocument10 pagesSurvey Management System-Revamped VersionNeetika AgarwalNo ratings yet

- Role PlayingDocument4 pagesRole PlayingRicha RastogiNo ratings yet

- Practical Lab 1.2Document5 pagesPractical Lab 1.2Ustaz DurianNo ratings yet

- User Manual 2791503Document44 pagesUser Manual 2791503rodriNo ratings yet

- VS4820Document6 pagesVS4820Catalin CarpinisNo ratings yet

- Glassdoor - Resume - My PVT ResumeDocument3 pagesGlassdoor - Resume - My PVT ResumePrashant TodkarNo ratings yet

- Foxpro For O LevelDocument3 pagesFoxpro For O LevelShiv PathakNo ratings yet

- Sono ChemistryDocument4 pagesSono ChemistryShyamol BoseNo ratings yet

- Strain Hardening of Copper AlloyDocument5 pagesStrain Hardening of Copper AlloyThien Van TranNo ratings yet

- Iclass: R10 ReaderDocument2 pagesIclass: R10 ReaderTarek SleemNo ratings yet

- Part Interval Service CLG835 6BTAA5 9-C130 UpdateDocument1 pagePart Interval Service CLG835 6BTAA5 9-C130 UpdatePurnama Abhie100% (1)

- Yirga Hagos Research ProposalDocument16 pagesYirga Hagos Research ProposalTilahun Mikias100% (4)

- Fleximrbts Inst Fcoa QguideDocument15 pagesFleximrbts Inst Fcoa QguideasveNo ratings yet

- Cat WireSENSOR enDocument56 pagesCat WireSENSOR enAlessandroAleottiNo ratings yet

- BXUV.P204 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P204 Fire Resistance Ratings - ANSI/UL 263AlexNo ratings yet

- Continuity Test For UseDocument11 pagesContinuity Test For Usefadhlan hidayatNo ratings yet

- WINCHE FA5A-MR Ingersoll RandDocument65 pagesWINCHE FA5A-MR Ingersoll RandcabarbozavNo ratings yet

- Prime Web Brochure PDFDocument14 pagesPrime Web Brochure PDFDnyaneshwar ChincholikarNo ratings yet

- TTQC L-4Document3 pagesTTQC L-4api-3710756100% (2)