Professional Documents

Culture Documents

AIIA-HIRA Format

AIIA-HIRA Format

Uploaded by

bhaskarsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AIIA-HIRA Format

AIIA-HIRA Format

Uploaded by

bhaskarsCopyright:

Available Formats

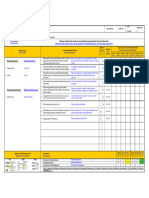

Format No.

GPSRPL/IMS/EAI-01

Hazard Identification and Risk Assessment Format Rev, Date Rev 1 Dt 02/04/2024

Document No. GPSRPL/BU/HIRA/QC/01

Document Rev.-(Date) 10.04.2024

Page No. 1

Department: Quality Control Prepared By Hemanth Kumar Checked By: S Bhaskar Approved By: Rakesh

R=> routine NR=> Non-routine Condition: N=> Normal AB=> Abnormal E=> Emergency LR=> :Legal Requirement IPC=> : Interested Party Concern BC=> : Business Concern Control:D=> :Direct Control ID=>Indirect Control

Legends: Rating: Scale=> Extent of Spread (M/c, dept, Factory, outside), Severity=> Magnitude POC=> Probability of Occurence PC=> Present control effectiveness RPN=> Risk priority no. (Scale x Sev x POC x PC)

Control Method Level (Heirarchy Order): 1=> Elimination, 2=> Substitution, 3=> Engg.Control, 4=> Administrative control, 5=> Use of PPE Action taken Reference: 1-Environmental Management (EMP), 2-Operation control procedure (OCP), 3-Emergency response procedure (ERP), 4-Monitoring & Measurement Plan (MMP), 5-Training Plan(TP), 6-PPE plan

Description of Controls Currently in Place (consider, in sequence: Elimination, Substitution, Use of

Behavioural Based Condition Control Rating Barriers, Use of Procedures, Use of Warning Systems/Signs, Use of PPE) Note: Also consider

Safety (BBS) I

L B Criteria for Training

Sl.No. Activity SubActivity R/NR Hazard Risk P Existing Control Method Responsibility Action Monitoring Reference

R C Significance

C C-Engineering D-Administration

Y/N N AB E D/ID Scale Severity POC PC RPN A-Elimination B-Substitution

control control

E-Use of PPE

Incoming material slippery floor can creat cut injury

1 Cutter Pump Testing NR slippery floor ( water) N N X D Use of barrication / Use of PPE 1 1 2 1 2 X X Quality Engineer

Inspection or fracture

slippery floor can creat cut injury

Gear Box with Motor Testing NR slippery floor ( oil) N N X D Use of barrication 1 3 2 1 6 X Quality Engineer

or fracture

it will affect the respiratory

2 In Process Inspection Penetrant testing NR Inhalation of Fumes and Chemical N N X D Use of PPE 1 3 3 1 9 X Quality Engineer

system

Pneumatic Testing NR Expolosion N leading serious injuries AB X D Use of barrication / Use of PPE 2 2 4 1 16 X Quality Engineer

Hydro testing NR Expolosion N leading serious injuries AB X D Use of barrication / Use of PPE 2 2 4 1 16 X Quality Engineer

3 Final Inspection lead into serious injuries or

Measuring at Height NR Man falling Y AB X D Use of PPE 2 1 4 1 8 X Quality Engineer

fractures

Inhalation of Chemical

4 Painting Painting Visual check NR N It can cause Breathing Difficulty N X D Use of PPE 1 3 4 1 12 X Quality Engineer

Preparation of Inspection Reports ,

5 Documenentation NR Ergonomic Hazards N Back Pain N X D Regular Breaks 1 1 5 2 10 X Quality Engineer

Procedures, formats

6 Documenentation Preparation of Inspection Reports ,

R Ergonomic Hazards Y Back Pain N N N N D Regular Breaks 1 3 4 1 12 X Quality Engineer

Procedures, formats

Page 1 of 1

You might also like

- HYD 20 - HIRA Cable Laying and TerminationDocument8 pagesHYD 20 - HIRA Cable Laying and TerminationPRIYESH . K. PRIYANNo ratings yet

- Corrective Action Plan TemplateDocument1 pageCorrective Action Plan TemplateSamsung JosephNo ratings yet

- Holistic Self Health CareDocument80 pagesHolistic Self Health Careadkittipong100% (1)

- AIIA FormatDocument3 pagesAIIA FormatbhaskarsNo ratings yet

- Gentry Erection HiracDocument2 pagesGentry Erection Hiracgopal.chaudry01No ratings yet

- HIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018Document5 pagesHIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018ghieee100% (2)

- EPD-EA-F01 & F02 (Env. Impacts Assesmt & Aspects Evaluation) - SAMPLEDocument12 pagesEPD-EA-F01 & F02 (Env. Impacts Assesmt & Aspects Evaluation) - SAMPLENISRINNo ratings yet

- Health Technology ManagementDocument26 pagesHealth Technology Managementhaseeb JuttNo ratings yet

- Nas - A-6.0 - 04-02-2022-Hira-NasDocument8 pagesNas - A-6.0 - 04-02-2022-Hira-NasRahul OjhaNo ratings yet

- Intergraged Management System: Without Controls With ControlsDocument5 pagesIntergraged Management System: Without Controls With ControlsMohammed JavidNo ratings yet

- Dubai HSE LAwDocument103 pagesDubai HSE LAwnoufalhse100% (2)

- (Attachment - A) 2012 - Safety - Promotion - Activities - Action Plan TDC Julio 2012Document2 pages(Attachment - A) 2012 - Safety - Promotion - Activities - Action Plan TDC Julio 2012Jose EspinosaNo ratings yet

- Risk AssessmentDocument7 pagesRisk AssessmentHeltonNo ratings yet

- Risk Assment (Version 1) .XLSBDocument4 pagesRisk Assment (Version 1) .XLSBDanie PretoriusNo ratings yet

- Safety Indicator Quantity CommentsDocument2 pagesSafety Indicator Quantity CommentsQadir ShaikhNo ratings yet

- RA For SPT Test (Reviewed)Document5 pagesRA For SPT Test (Reviewed)shamshad ahamedNo ratings yet

- 6 Daily Performance Monitoring 101716Document2 pages6 Daily Performance Monitoring 101716Godfrey VelozNo ratings yet

- Manual Handling and People Handling Policy 2018Document35 pagesManual Handling and People Handling Policy 2018QNo ratings yet

- MGU-DD-TX-0001 - Soil Investigation Report - AA PDFDocument52 pagesMGU-DD-TX-0001 - Soil Investigation Report - AA PDFcmu baliNo ratings yet

- S-JRA-104 Working Inside Seatruck Cabin DuringDocument1 pageS-JRA-104 Working Inside Seatruck Cabin DuringHendri SsputroNo ratings yet

- Social Aspect Impact RegisterDocument1 pageSocial Aspect Impact RegisterAbderrahmene SaciNo ratings yet

- 8D ReportDocument1 page8D ReportqualityNo ratings yet

- Ra For Concreate Floor BreakingDocument5 pagesRa For Concreate Floor Breakingshamshad ahamedNo ratings yet

- Hse Risk Register OffshoreDocument1 pageHse Risk Register OffshoreSubbu AbuNo ratings yet

- DAU - Wall Chart BackDocument1 pageDAU - Wall Chart BackrjostNo ratings yet

- Implementing Quality Management System Under ISO 9001:2015 in The Central Environmental AuthorityDocument16 pagesImplementing Quality Management System Under ISO 9001:2015 in The Central Environmental AuthorityChathura WickramaNo ratings yet

- HSE-Incident TrackerDocument3 pagesHSE-Incident TrackerJIJESH GOKULDASNo ratings yet

- Sample Risk-Opportunity Assessment ReportDocument3 pagesSample Risk-Opportunity Assessment ReportCatherine Ferreol100% (1)

- Fixing Fly Traps RADocument1 pageFixing Fly Traps RAmohamed atefNo ratings yet

- Concrete Paving Airfield PosterDocument1 pageConcrete Paving Airfield PosterdavidhmoloneyNo ratings yet

- Risk Assessment For Drainage uPVC PipesDocument1 pageRisk Assessment For Drainage uPVC PipesZameer Basha Navzath AliNo ratings yet

- 19-F02 Lifting Machinery RegisterDocument1 page19-F02 Lifting Machinery RegisterSn AhsanNo ratings yet

- 特殊 Goods PrincipleDocument1 page特殊 Goods Principle3213349886No ratings yet

- Attachment #2. ESR - Meghnaghat - Jan 22 - JB Touch - 02.02.2021Document2 pagesAttachment #2. ESR - Meghnaghat - Jan 22 - JB Touch - 02.02.2021kishoreNo ratings yet

- Without Controls With Controls: High LOWDocument5 pagesWithout Controls With Controls: High LOWZameer Basha Navzath AliNo ratings yet

- Form - First Article InspectionDocument1 pageForm - First Article InspectionMaria PatchinNo ratings yet

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- 2021-10-13 Project Quality Plan Rev. ADocument1 page2021-10-13 Project Quality Plan Rev. AjaymarNo ratings yet

- Commisioning ProcedureDocument21 pagesCommisioning ProcedureDavid100% (3)

- GG Inspector Auditor CL V5-6.1 enDocument8 pagesGG Inspector Auditor CL V5-6.1 enFCB100% (1)

- 05-Fixture Calibration ReportDocument1 page05-Fixture Calibration ReportSuresh RathodNo ratings yet

- Ccte Counseling Closing-The-Gap Results ReportDocument2 pagesCcte Counseling Closing-The-Gap Results ReportCheryl McfaddenNo ratings yet

- Msds-Urée 46%Document9 pagesMsds-Urée 46%Remy YamyNo ratings yet

- 01 Purchase Requisition FormDocument1 page01 Purchase Requisition FormAfrolyn BaredonNo ratings yet

- Process Effectiveness & Reliability (FMEA) EvaluationDocument1 pageProcess Effectiveness & Reliability (FMEA) EvaluationEdwin Otniel LumbantoruanNo ratings yet

- 1 20RiskRegisterexampleDocument3 pages1 20RiskRegisterexampleChristian Alfred SorianoNo ratings yet

- 08.05 Injury Record RegisterDocument1 page08.05 Injury Record RegisterdalNo ratings yet

- Investigative ProcessDocument20 pagesInvestigative ProcessJaneth LwenaNo ratings yet

- Date Name Nature of Injury Cause of Injury DR Referred To / Days OffDocument1 pageDate Name Nature of Injury Cause of Injury DR Referred To / Days OffdalNo ratings yet

- 08.05 Injury Record RegisterDocument1 page08.05 Injury Record RegisterdalNo ratings yet

- Chemical Spill KitDocument1 pageChemical Spill KitVirna Estela BunanNo ratings yet

- Score Card BNI April 2023Document1 pageScore Card BNI April 2023Al - AminNo ratings yet

- rs2011 Ig04 PDFDocument67 pagesrs2011 Ig04 PDFNELLY VAZQUEZ FLORESNo ratings yet

- Storage of Chemical - Risk AssessmentsDocument1 pageStorage of Chemical - Risk AssessmentsMohammed Amer PashaNo ratings yet

- Safe Plan of Action (Spa) : Project Number/Project Name Location Work Order Number Describe The Job or Task DateDocument2 pagesSafe Plan of Action (Spa) : Project Number/Project Name Location Work Order Number Describe The Job or Task DateYi MaNo ratings yet

- CLR FM 002 Calibration PlanDocument1 pageCLR FM 002 Calibration Planchemist_tmaNo ratings yet

- Date: Pt. Grid Solutions Indonesia: Hazard Identification, Risk Assessment & Determining Control (Hiradc) TabelDocument3 pagesDate: Pt. Grid Solutions Indonesia: Hazard Identification, Risk Assessment & Determining Control (Hiradc) TabelAshadi Amir100% (1)

- Risk Assesment For Shifting of MEP Services and Re-Installations 26-03-2022Document5 pagesRisk Assesment For Shifting of MEP Services and Re-Installations 26-03-2022Zameer Basha Navzath AliNo ratings yet

- Result TO CFSODocument5 pagesResult TO CFSOBhavana avhadNo ratings yet

- Storage of Chemical Risk AssessmentsDocument1 pageStorage of Chemical Risk AssessmentsMohammed Amer PashaNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 4: Language ArtsRating: 5 out of 5 stars5/5 (1)

- Physics Answers Electric and MagnetismDocument8 pagesPhysics Answers Electric and MagnetismGeethanjali SivakumarNo ratings yet

- MPT ProjectDocument10 pagesMPT ProjectTina SanghaviNo ratings yet

- CHINT Installation Operation Manual For Inverter of 50-60KTLDocument98 pagesCHINT Installation Operation Manual For Inverter of 50-60KTLr.pimentel.souzaNo ratings yet

- SRHR - FGD With Young PeopleDocument3 pagesSRHR - FGD With Young PeopleMandira PrakashNo ratings yet

- Exploded View & Parts Listing Air Operated Double Diaphragm PumpDocument3 pagesExploded View & Parts Listing Air Operated Double Diaphragm PumpEdgar NercarNo ratings yet

- Livebook ACBDocument420 pagesLivebook ACBShubhangi JagtapNo ratings yet

- Environmental Crisis Causes and ManifestationsDocument26 pagesEnvironmental Crisis Causes and Manifestationsबाजीराव सिंघम0% (1)

- John White Videos of Spooky2 InterfaceDocument24 pagesJohn White Videos of Spooky2 InterfaceTimothy M HallNo ratings yet

- Interactive Effect of Caste and Disability: An AnalysisDocument8 pagesInteractive Effect of Caste and Disability: An AnalysisIJELS Research JournalNo ratings yet

- Group3 Dilemmac pr6031Document8 pagesGroup3 Dilemmac pr6031api-576539858No ratings yet

- Economics 9732/01: Pioneer Junior College, Singapore Preliminary Examinations 2014 Higher 2Document8 pagesEconomics 9732/01: Pioneer Junior College, Singapore Preliminary Examinations 2014 Higher 2Yvette LimNo ratings yet

- VBIED Attack July 31, 2007Document1 pageVBIED Attack July 31, 2007Rhonda NoldeNo ratings yet

- Aisyah Fadiyah - SPEECH DRAFTDocument5 pagesAisyah Fadiyah - SPEECH DRAFTAisyah FawNo ratings yet

- PLKS321 Unit 8.9 PMDocument56 pagesPLKS321 Unit 8.9 PMmonagomolemo9No ratings yet

- PHAS0027 RevisionDocument21 pagesPHAS0027 Revisionunknown.unknown9901No ratings yet

- Final LIST OF IMPORTANT GRID ELEMENTS Updated On May 2020 PDFDocument74 pagesFinal LIST OF IMPORTANT GRID ELEMENTS Updated On May 2020 PDFbhargavNo ratings yet

- Problem Sets For Solutions AnalysisDocument2 pagesProblem Sets For Solutions AnalysisKamil Guillergan100% (1)

- Evaluating The Adjuvant Effect of Dexamethasone To Ropivacaine in Transversus Abdominis Plane Block For Inguinal Hernia Repair and Spermatocelectomy: A Randomized Controlled TrialDocument6 pagesEvaluating The Adjuvant Effect of Dexamethasone To Ropivacaine in Transversus Abdominis Plane Block For Inguinal Hernia Repair and Spermatocelectomy: A Randomized Controlled TrialGonzalo MendozaNo ratings yet

- An International Cohort Study of Cancer in Systemic Lupus ErythematosusDocument10 pagesAn International Cohort Study of Cancer in Systemic Lupus ErythematosusCristina TudorNo ratings yet

- Model ETR-9200 Automatic Tuning Smarter Logic ControllerDocument26 pagesModel ETR-9200 Automatic Tuning Smarter Logic ControllervhelectronicaNo ratings yet

- Lesson 3 Characteristics of Properly Designed PCBDocument11 pagesLesson 3 Characteristics of Properly Designed PCBJosephine QuinnNo ratings yet

- Sago Pudding - Recipes - Poh's KitchenDocument2 pagesSago Pudding - Recipes - Poh's KitchenXuxu TooNo ratings yet

- Grade 12 LM Physical Science 1 Module4Document21 pagesGrade 12 LM Physical Science 1 Module4ladyheart ۦۦNo ratings yet

- Frenkel's ExerciseDocument40 pagesFrenkel's ExerciseManiu EmeseNo ratings yet

- Chapter4 Questions WithoutSupersonicDocument5 pagesChapter4 Questions WithoutSupersonicsh1999No ratings yet

- SPE 13932 Wettability Part2 AndersonDocument17 pagesSPE 13932 Wettability Part2 AndersonSergio EduardoNo ratings yet

- 1 Case IDC PDFDocument7 pages1 Case IDC PDFPilar Dueñas Maldonado0% (1)

- To, The Medical Superintendent, Services Hospital LahoreDocument1 pageTo, The Medical Superintendent, Services Hospital LahoreAfraz AliNo ratings yet

- STOC03 (Emissions)Document20 pagesSTOC03 (Emissions)tungluongNo ratings yet