Professional Documents

Culture Documents

AIIA Format

AIIA Format

Uploaded by

bhaskarsCopyright:

Available Formats

You might also like

- Planning of Product Realization ExampleDocument9 pagesPlanning of Product Realization Examplemdjeckel100% (1)

- Final Code of Safety Practice For An LPG Refilling Plant Completed (Final) With HLDocument57 pagesFinal Code of Safety Practice For An LPG Refilling Plant Completed (Final) With HLYeyen M. Evora67% (3)

- Sea Fastening PDFDocument57 pagesSea Fastening PDFsantosh bharathyNo ratings yet

- Ac178 PDFDocument7 pagesAc178 PDFBhavik Dhami100% (1)

- Corrective Action Plan TemplateDocument1 pageCorrective Action Plan TemplateSamsung JosephNo ratings yet

- Operator Manual - ECB 16 - ECB 18Document116 pagesOperator Manual - ECB 16 - ECB 18Ern100% (1)

- ASTM C1077 (English) PDFDocument9 pagesASTM C1077 (English) PDFfabiomorales100% (1)

- Hse Officer - CVDocument4 pagesHse Officer - CVAzher AhmedNo ratings yet

- AIIA-HIRA FormatDocument1 pageAIIA-HIRA FormatbhaskarsNo ratings yet

- EPD-EA-F01 & F02 (Env. Impacts Assesmt & Aspects Evaluation) - SAMPLEDocument12 pagesEPD-EA-F01 & F02 (Env. Impacts Assesmt & Aspects Evaluation) - SAMPLENISRINNo ratings yet

- Gentry Erection HiracDocument2 pagesGentry Erection Hiracgopal.chaudry01No ratings yet

- Risk Assment (Version 1) .XLSBDocument4 pagesRisk Assment (Version 1) .XLSBDanie PretoriusNo ratings yet

- Social Aspect Impact RegisterDocument1 pageSocial Aspect Impact RegisterAbderrahmene SaciNo ratings yet

- Safety Indicator Quantity CommentsDocument2 pagesSafety Indicator Quantity CommentsQadir ShaikhNo ratings yet

- HIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018Document5 pagesHIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018ghieee100% (2)

- 6 Daily Performance Monitoring 101716Document2 pages6 Daily Performance Monitoring 101716Godfrey VelozNo ratings yet

- (Attachment - A) 2012 - Safety - Promotion - Activities - Action Plan TDC Julio 2012Document2 pages(Attachment - A) 2012 - Safety - Promotion - Activities - Action Plan TDC Julio 2012Jose EspinosaNo ratings yet

- Form - First Article InspectionDocument1 pageForm - First Article InspectionMaria PatchinNo ratings yet

- 8D ReportDocument1 page8D ReportqualityNo ratings yet

- Dubai HSE LAwDocument103 pagesDubai HSE LAwnoufalhse100% (2)

- MGU-DD-TX-0001 - Soil Investigation Report - AA PDFDocument52 pagesMGU-DD-TX-0001 - Soil Investigation Report - AA PDFcmu baliNo ratings yet

- 05-Fixture Calibration ReportDocument1 page05-Fixture Calibration ReportSuresh RathodNo ratings yet

- D, Environmental Aspects and Impacts RegisterDocument7 pagesD, Environmental Aspects and Impacts RegisterAnand SinghNo ratings yet

- MGRP-OTD-R-01 Training Request Form - Doc 2011Document2 pagesMGRP-OTD-R-01 Training Request Form - Doc 2011vinothNo ratings yet

- Health Technology ManagementDocument26 pagesHealth Technology Managementhaseeb JuttNo ratings yet

- Commisioning ProcedureDocument21 pagesCommisioning ProcedureDavid100% (3)

- 2021-10-13 Project Quality Plan Rev. ADocument1 page2021-10-13 Project Quality Plan Rev. AjaymarNo ratings yet

- AF3000 BlankDocument2 pagesAF3000 Blankdebby3284No ratings yet

- Result TO CFSODocument5 pagesResult TO CFSOBhavana avhadNo ratings yet

- HSE-Incident TrackerDocument3 pagesHSE-Incident TrackerJIJESH GOKULDASNo ratings yet

- Per-Qf-33 Plantilla of Step IncrementDocument1 pagePer-Qf-33 Plantilla of Step IncrementMichelle O. MatiasNo ratings yet

- 2016-11-17 RRAA MS Construction of Pre-Cast Fence - Rev C (Arup)Document1 page2016-11-17 RRAA MS Construction of Pre-Cast Fence - Rev C (Arup)gregNo ratings yet

- 19-F02 Lifting Machinery RegisterDocument1 page19-F02 Lifting Machinery RegisterSn AhsanNo ratings yet

- 18014gçégengçéplgçérfqgçé8004 Rev A - RFQ For Induction BendsDocument28 pages18014gçégengçéplgçérfqgçé8004 Rev A - RFQ For Induction BendsAJAY PatilNo ratings yet

- Attachment #2. ESR - Meghnaghat - Jan 22 - JB Touch - 02.02.2021Document2 pagesAttachment #2. ESR - Meghnaghat - Jan 22 - JB Touch - 02.02.2021kishoreNo ratings yet

- Physical Inventory Count Data Collecting SheetDocument1 pagePhysical Inventory Count Data Collecting SheetamnuelNo ratings yet

- 01 Purchase Requisition FormDocument1 page01 Purchase Requisition FormAfrolyn BaredonNo ratings yet

- 2024-03-01 RRAA Botolan Weekly Report 01 - Phase 01Document4 pages2024-03-01 RRAA Botolan Weekly Report 01 - Phase 01stacruzsolarenergy.taccNo ratings yet

- PIR Workshop TemplatesDocument5 pagesPIR Workshop TemplatesnurNo ratings yet

- CLR FM 002 Calibration PlanDocument1 pageCLR FM 002 Calibration Planchemist_tmaNo ratings yet

- Manual Handling and People Handling Policy 2018Document35 pagesManual Handling and People Handling Policy 2018QNo ratings yet

- GG Inspector Auditor CL V5-6.1 enDocument8 pagesGG Inspector Auditor CL V5-6.1 enFCB100% (1)

- 08.05 Injury Record RegisterDocument1 page08.05 Injury Record RegisterdalNo ratings yet

- 08.05 Injury Record RegisterDocument1 page08.05 Injury Record RegisterdalNo ratings yet

- Date Name Nature of Injury Cause of Injury DR Referred To / Days OffDocument1 pageDate Name Nature of Injury Cause of Injury DR Referred To / Days OffdalNo ratings yet

- Daily Packing Production ReportDocument1 pageDaily Packing Production ReportRajkumar PrajapatiNo ratings yet

- Concrete Paving Airfield PosterDocument1 pageConcrete Paving Airfield PosterdavidhmoloneyNo ratings yet

- SE PDC-CENTRAL HSE Weekly Summary Report: (Overall)Document5 pagesSE PDC-CENTRAL HSE Weekly Summary Report: (Overall)ابو محمد عليNo ratings yet

- Form P-6 Manufacturer'S Data Report Suplementary Sheet As Required by The Provisions of The ASME Boiler and Pressure Vessel Code RulesDocument2 pagesForm P-6 Manufacturer'S Data Report Suplementary Sheet As Required by The Provisions of The ASME Boiler and Pressure Vessel Code Rulesmsb_75No ratings yet

- Indonesia ERT TrainingnExercise Matrix-Rev 04 - March 2017Document2 pagesIndonesia ERT TrainingnExercise Matrix-Rev 04 - March 2017sepri manerson sinagaNo ratings yet

- List of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)Document63 pagesList of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)rohitNo ratings yet

- Process Effectiveness & Reliability (FMEA) EvaluationDocument1 pageProcess Effectiveness & Reliability (FMEA) EvaluationEdwin Otniel LumbantoruanNo ratings yet

- SE PDC-CENTRAL HSE Weekly Summary Report: (Overall)Document5 pagesSE PDC-CENTRAL HSE Weekly Summary Report: (Overall)ابو محمد عليNo ratings yet

- Environmental Aspects and Impacts Evaluation REV-003Document12 pagesEnvironmental Aspects and Impacts Evaluation REV-003sunthu100% (1)

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- Implementing Quality Management System Under ISO 9001:2015 in The Central Environmental AuthorityDocument16 pagesImplementing Quality Management System Under ISO 9001:2015 in The Central Environmental AuthorityChathura WickramaNo ratings yet

- 特殊 Goods PrincipleDocument1 page特殊 Goods Principle3213349886No ratings yet

- Score Card BNI April 2023Document1 pageScore Card BNI April 2023Al - AminNo ratings yet

- Risk AssessmentDocument7 pagesRisk AssessmentHeltonNo ratings yet

- Sample Risk-Opportunity Assessment ReportDocument3 pagesSample Risk-Opportunity Assessment ReportCatherine Ferreol100% (1)

- WK No 26, June 2022 Sepdc-Central - Weekly Kpi - (380kv Ohtl in Qiddyia, Bsp#9082 Dirryia Gatw) - Rev. 02 (Individual)Document5 pagesWK No 26, June 2022 Sepdc-Central - Weekly Kpi - (380kv Ohtl in Qiddyia, Bsp#9082 Dirryia Gatw) - Rev. 02 (Individual)ابو محمد عليNo ratings yet

- EP03Document5 pagesEP03Anonymous B7pghhNo ratings yet

- Intergraged Management System: Without Controls With ControlsDocument5 pagesIntergraged Management System: Without Controls With ControlsMohammed JavidNo ratings yet

- Nas - A-6.0 - 04-02-2022-Hira-NasDocument8 pagesNas - A-6.0 - 04-02-2022-Hira-NasRahul OjhaNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 4: Language ArtsRating: 5 out of 5 stars5/5 (1)

- Astm A227Document4 pagesAstm A227Adolfo Luis Avila MurciaNo ratings yet

- 03 Baty Vision SystemsDocument16 pages03 Baty Vision SystemsAMAL NADH JNo ratings yet

- SPM Choke Valves Operation Instruction and Service ManualDocument37 pagesSPM Choke Valves Operation Instruction and Service Manualbill100% (1)

- TCVN 5318-2001 Mobile Offshore Installation-Welding (EN) PDFDocument9 pagesTCVN 5318-2001 Mobile Offshore Installation-Welding (EN) PDFPushkar GopalNo ratings yet

- SPP Book 2 PDFDocument612 pagesSPP Book 2 PDFBagadi AvinashNo ratings yet

- Inspection & Assessment of Damaged Subsea Pipelines: A Case StudyDocument8 pagesInspection & Assessment of Damaged Subsea Pipelines: A Case StudyDanny BoysieNo ratings yet

- Welding II Curriculum MapDocument9 pagesWelding II Curriculum Mapapi-525855204No ratings yet

- SAEP-22 - Tank Calibration Requirements PDFDocument14 pagesSAEP-22 - Tank Calibration Requirements PDFMuhammad Farukh Manzoor100% (1)

- Structural Integrity Inspection and Nondestructive Testing FOR Ilf Engineers Nigeria LimitedDocument3 pagesStructural Integrity Inspection and Nondestructive Testing FOR Ilf Engineers Nigeria LimitedChukwuma Emmanuel OnwufujuNo ratings yet

- Bachelor of Computer Application (BCA) (Indian & Angolan Embassy Attested)Document3 pagesBachelor of Computer Application (BCA) (Indian & Angolan Embassy Attested)Ali Ben AmorNo ratings yet

- TEC-042200 - MET-DoR-005 (Method Statement For Rectification For MEP Chasing at Block Walls)Document8 pagesTEC-042200 - MET-DoR-005 (Method Statement For Rectification For MEP Chasing at Block Walls)Alvene TagocNo ratings yet

- Method Statement (Beach Access)Document9 pagesMethod Statement (Beach Access)arnel sungkipNo ratings yet

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- Saudi Aramco Form 175Document22 pagesSaudi Aramco Form 175dissanayake90kanishkaNo ratings yet

- f2 Fou Con Sai PL Qa 00002 Project Quality Plan Rev 00Document52 pagesf2 Fou Con Sai PL Qa 00002 Project Quality Plan Rev 00Firman Indra JayaNo ratings yet

- Thiyagarajan.B.E Civil Engineer. CV Updated Novemeber 2018Document4 pagesThiyagarajan.B.E Civil Engineer. CV Updated Novemeber 2018Thiyagarajan TiguNo ratings yet

- Certificate of Eot Tmi-22Document3 pagesCertificate of Eot Tmi-22engr.haseebbalochNo ratings yet

- 4.production Planning & ControlDocument22 pages4.production Planning & ControlSaFdaR QaZiNo ratings yet

- Jis G4308Document13 pagesJis G4308ATULNo ratings yet

- HT Panel QapDocument2 pagesHT Panel QapAlla Naveen KumarNo ratings yet

- Project Quality Plan: Document Title Project Quality Plan Document Ref. No. NRR/PMF - QAC-PQP-01-R00 Date 31-August-2019Document50 pagesProject Quality Plan: Document Title Project Quality Plan Document Ref. No. NRR/PMF - QAC-PQP-01-R00 Date 31-August-2019FahadNo ratings yet

- MS-02 Bridge Demolition - Rev.1Document17 pagesMS-02 Bridge Demolition - Rev.1Leo TorresNo ratings yet

- FIR 001 - Rev.06 12Document12 pagesFIR 001 - Rev.06 12SteveYobsNo ratings yet

- Spacecraft 8 Attitude Control Anomaly ReportDocument70 pagesSpacecraft 8 Attitude Control Anomaly ReportBob AndrepontNo ratings yet

AIIA Format

AIIA Format

Uploaded by

bhaskarsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AIIA Format

AIIA Format

Uploaded by

bhaskarsCopyright:

Available Formats

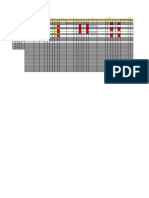

Format No.

GPSRPL/IMS/EAI-01

Aspect Identification and Impact Assessment Format Rev, Date Rev 1 Dt 02/04/2024

Document No. GPSRPL/BU/AIA/QC/01

Document Rev.-(Date) 10-04-2024

Page No. 1

Department: Quality Control Prepared By Hemanth Kumar Checked By: S Bhaskar Approved By: Rakesh

R=> routine NR=> Non-routine Condition: N=> Normal AB=> Abnormal E=> Emergency LR=> :Legal Requirement IPC=> : Interested Party Concern BC=> : Business Concern Control:D=> :Direct Control ID=>Indirect Control

Legends: Rating: Scale=> Extent of Spread (M/c, dept, Factory, outside), Severity=> Magnitude POC=> Probability of Occurence PC=> Present control effectiveness RPN=> Risk priority no. (Scale x Sev x POC x PC)

Control Method Level (Heirarchy Order): 1=> Elimination, 2=> Substitution, 3=> Engg.Control, 4=> Administrative control, 5=> Use of PPE Action taken Reference: 1-Environmental Management (EMP), 2-Operation control procedure (OCP), 3-Emergency response procedure (ERP), 4-Monitoring & Measurement Plan (MMP), 5-Training Plan(TP), 6-PPE plan

Behavioural Description of Controls Currently in Place (consider, in sequence: Elimination, Substitution, Use of

Based Safety Condition Control Rating Barriers, Use of Procedures, Use of Warning Systems/Signs, Use of PPE) Note: Also consider

I

(BBS) L B Criteria for Training

Sl.No. Activity SubActivity R/NR Aspect Impact P Existing Control Method Responsibility Action Monitoring Reference

R C Significance

C

C-Engineering D-Administration

Y/N N AB E D/ID Scale Severity POC PC RPN A-Elimination B-Substitution

control control

E-Use of PPE

1

Incoming material Receiving Small Items can be

N N N Y N D 1 1 4 1 4 use of sinage Quality Engineer

Inspection lifted / Transfered manually

Receiving of material R cosumption of Power Depletion of Natural resources

During sample selection material

Y N N N N D will be moving smoothly to avoid 1 1 4 1 4 use of sinage Quality Engineer

Heat Generation

sample selection R Generation of Heat land Pollution

welding will be done at open place

2 In Process Inspection Y N N N N D smoke not accumulating hence 1 1 5 1 5 open Air Control Quality Engineer

controlled by open air

welding /welding Inspection R Emission of smoke Air Pollution

Air leak Testing NR generation of Pressure Y Land Pollution AB N N N D Barricating the testing Area 1 2 3 2 12 Use of Barriers Quality Engineer

Hydro testing NR generation of Pressure Y Land Pollution AB N N N D Barricating the testing Area 1 2 3 2 12 Use of Barriers Quality Engineer

testing will be done at Open

NR N Air pollution N N N N D Ventillated area and controlled by 1 2 4 1 8 use of Procedure Quality Engineer

Penetrant testing Emission of Chemical Open Air

3 NR Y Air pollution N N N N D Using the Exhaust System 1 2 4 1 8 use of Procedure Quality Engineer

Painting Painting / Visual check Emission of Chemical

based on the Job type using

4 Land Pollution N the wooden pallet packing so

NR consumption plastic sheet Y N N N D 1 3 3 2 12 use of Procedure Quality Engineer

Minimize the use of Plastic

packing Packing/ visual check sheet

Documenentation

Some of the Reports are

5 R Consumption of Paper N Land Pollution N N N N D Maintaining soft Copy to reduce 1 2 4 2 16 use of signage Quality Engineer

Preparation of Inspection Reports , Procedures, the Paper Consumption

formats

You might also like

- Planning of Product Realization ExampleDocument9 pagesPlanning of Product Realization Examplemdjeckel100% (1)

- Final Code of Safety Practice For An LPG Refilling Plant Completed (Final) With HLDocument57 pagesFinal Code of Safety Practice For An LPG Refilling Plant Completed (Final) With HLYeyen M. Evora67% (3)

- Sea Fastening PDFDocument57 pagesSea Fastening PDFsantosh bharathyNo ratings yet

- Ac178 PDFDocument7 pagesAc178 PDFBhavik Dhami100% (1)

- Corrective Action Plan TemplateDocument1 pageCorrective Action Plan TemplateSamsung JosephNo ratings yet

- Operator Manual - ECB 16 - ECB 18Document116 pagesOperator Manual - ECB 16 - ECB 18Ern100% (1)

- ASTM C1077 (English) PDFDocument9 pagesASTM C1077 (English) PDFfabiomorales100% (1)

- Hse Officer - CVDocument4 pagesHse Officer - CVAzher AhmedNo ratings yet

- AIIA-HIRA FormatDocument1 pageAIIA-HIRA FormatbhaskarsNo ratings yet

- EPD-EA-F01 & F02 (Env. Impacts Assesmt & Aspects Evaluation) - SAMPLEDocument12 pagesEPD-EA-F01 & F02 (Env. Impacts Assesmt & Aspects Evaluation) - SAMPLENISRINNo ratings yet

- Gentry Erection HiracDocument2 pagesGentry Erection Hiracgopal.chaudry01No ratings yet

- Risk Assment (Version 1) .XLSBDocument4 pagesRisk Assment (Version 1) .XLSBDanie PretoriusNo ratings yet

- Social Aspect Impact RegisterDocument1 pageSocial Aspect Impact RegisterAbderrahmene SaciNo ratings yet

- Safety Indicator Quantity CommentsDocument2 pagesSafety Indicator Quantity CommentsQadir ShaikhNo ratings yet

- HIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018Document5 pagesHIRADC - Pekerjaan 20 KV - PLTGU - Update 5 March 2018ghieee100% (2)

- 6 Daily Performance Monitoring 101716Document2 pages6 Daily Performance Monitoring 101716Godfrey VelozNo ratings yet

- (Attachment - A) 2012 - Safety - Promotion - Activities - Action Plan TDC Julio 2012Document2 pages(Attachment - A) 2012 - Safety - Promotion - Activities - Action Plan TDC Julio 2012Jose EspinosaNo ratings yet

- Form - First Article InspectionDocument1 pageForm - First Article InspectionMaria PatchinNo ratings yet

- 8D ReportDocument1 page8D ReportqualityNo ratings yet

- Dubai HSE LAwDocument103 pagesDubai HSE LAwnoufalhse100% (2)

- MGU-DD-TX-0001 - Soil Investigation Report - AA PDFDocument52 pagesMGU-DD-TX-0001 - Soil Investigation Report - AA PDFcmu baliNo ratings yet

- 05-Fixture Calibration ReportDocument1 page05-Fixture Calibration ReportSuresh RathodNo ratings yet

- D, Environmental Aspects and Impacts RegisterDocument7 pagesD, Environmental Aspects and Impacts RegisterAnand SinghNo ratings yet

- MGRP-OTD-R-01 Training Request Form - Doc 2011Document2 pagesMGRP-OTD-R-01 Training Request Form - Doc 2011vinothNo ratings yet

- Health Technology ManagementDocument26 pagesHealth Technology Managementhaseeb JuttNo ratings yet

- Commisioning ProcedureDocument21 pagesCommisioning ProcedureDavid100% (3)

- 2021-10-13 Project Quality Plan Rev. ADocument1 page2021-10-13 Project Quality Plan Rev. AjaymarNo ratings yet

- AF3000 BlankDocument2 pagesAF3000 Blankdebby3284No ratings yet

- Result TO CFSODocument5 pagesResult TO CFSOBhavana avhadNo ratings yet

- HSE-Incident TrackerDocument3 pagesHSE-Incident TrackerJIJESH GOKULDASNo ratings yet

- Per-Qf-33 Plantilla of Step IncrementDocument1 pagePer-Qf-33 Plantilla of Step IncrementMichelle O. MatiasNo ratings yet

- 2016-11-17 RRAA MS Construction of Pre-Cast Fence - Rev C (Arup)Document1 page2016-11-17 RRAA MS Construction of Pre-Cast Fence - Rev C (Arup)gregNo ratings yet

- 19-F02 Lifting Machinery RegisterDocument1 page19-F02 Lifting Machinery RegisterSn AhsanNo ratings yet

- 18014gçégengçéplgçérfqgçé8004 Rev A - RFQ For Induction BendsDocument28 pages18014gçégengçéplgçérfqgçé8004 Rev A - RFQ For Induction BendsAJAY PatilNo ratings yet

- Attachment #2. ESR - Meghnaghat - Jan 22 - JB Touch - 02.02.2021Document2 pagesAttachment #2. ESR - Meghnaghat - Jan 22 - JB Touch - 02.02.2021kishoreNo ratings yet

- Physical Inventory Count Data Collecting SheetDocument1 pagePhysical Inventory Count Data Collecting SheetamnuelNo ratings yet

- 01 Purchase Requisition FormDocument1 page01 Purchase Requisition FormAfrolyn BaredonNo ratings yet

- 2024-03-01 RRAA Botolan Weekly Report 01 - Phase 01Document4 pages2024-03-01 RRAA Botolan Weekly Report 01 - Phase 01stacruzsolarenergy.taccNo ratings yet

- PIR Workshop TemplatesDocument5 pagesPIR Workshop TemplatesnurNo ratings yet

- CLR FM 002 Calibration PlanDocument1 pageCLR FM 002 Calibration Planchemist_tmaNo ratings yet

- Manual Handling and People Handling Policy 2018Document35 pagesManual Handling and People Handling Policy 2018QNo ratings yet

- GG Inspector Auditor CL V5-6.1 enDocument8 pagesGG Inspector Auditor CL V5-6.1 enFCB100% (1)

- 08.05 Injury Record RegisterDocument1 page08.05 Injury Record RegisterdalNo ratings yet

- 08.05 Injury Record RegisterDocument1 page08.05 Injury Record RegisterdalNo ratings yet

- Date Name Nature of Injury Cause of Injury DR Referred To / Days OffDocument1 pageDate Name Nature of Injury Cause of Injury DR Referred To / Days OffdalNo ratings yet

- Daily Packing Production ReportDocument1 pageDaily Packing Production ReportRajkumar PrajapatiNo ratings yet

- Concrete Paving Airfield PosterDocument1 pageConcrete Paving Airfield PosterdavidhmoloneyNo ratings yet

- SE PDC-CENTRAL HSE Weekly Summary Report: (Overall)Document5 pagesSE PDC-CENTRAL HSE Weekly Summary Report: (Overall)ابو محمد عليNo ratings yet

- Form P-6 Manufacturer'S Data Report Suplementary Sheet As Required by The Provisions of The ASME Boiler and Pressure Vessel Code RulesDocument2 pagesForm P-6 Manufacturer'S Data Report Suplementary Sheet As Required by The Provisions of The ASME Boiler and Pressure Vessel Code Rulesmsb_75No ratings yet

- Indonesia ERT TrainingnExercise Matrix-Rev 04 - March 2017Document2 pagesIndonesia ERT TrainingnExercise Matrix-Rev 04 - March 2017sepri manerson sinagaNo ratings yet

- List of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)Document63 pagesList of C.P.D Programs Attended 2016 - 21 Category: Professional Engineer (P.e)rohitNo ratings yet

- Process Effectiveness & Reliability (FMEA) EvaluationDocument1 pageProcess Effectiveness & Reliability (FMEA) EvaluationEdwin Otniel LumbantoruanNo ratings yet

- SE PDC-CENTRAL HSE Weekly Summary Report: (Overall)Document5 pagesSE PDC-CENTRAL HSE Weekly Summary Report: (Overall)ابو محمد عليNo ratings yet

- Environmental Aspects and Impacts Evaluation REV-003Document12 pagesEnvironmental Aspects and Impacts Evaluation REV-003sunthu100% (1)

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- Implementing Quality Management System Under ISO 9001:2015 in The Central Environmental AuthorityDocument16 pagesImplementing Quality Management System Under ISO 9001:2015 in The Central Environmental AuthorityChathura WickramaNo ratings yet

- 特殊 Goods PrincipleDocument1 page特殊 Goods Principle3213349886No ratings yet

- Score Card BNI April 2023Document1 pageScore Card BNI April 2023Al - AminNo ratings yet

- Risk AssessmentDocument7 pagesRisk AssessmentHeltonNo ratings yet

- Sample Risk-Opportunity Assessment ReportDocument3 pagesSample Risk-Opportunity Assessment ReportCatherine Ferreol100% (1)

- WK No 26, June 2022 Sepdc-Central - Weekly Kpi - (380kv Ohtl in Qiddyia, Bsp#9082 Dirryia Gatw) - Rev. 02 (Individual)Document5 pagesWK No 26, June 2022 Sepdc-Central - Weekly Kpi - (380kv Ohtl in Qiddyia, Bsp#9082 Dirryia Gatw) - Rev. 02 (Individual)ابو محمد عليNo ratings yet

- EP03Document5 pagesEP03Anonymous B7pghhNo ratings yet

- Intergraged Management System: Without Controls With ControlsDocument5 pagesIntergraged Management System: Without Controls With ControlsMohammed JavidNo ratings yet

- Nas - A-6.0 - 04-02-2022-Hira-NasDocument8 pagesNas - A-6.0 - 04-02-2022-Hira-NasRahul OjhaNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 4: Language ArtsRating: 5 out of 5 stars5/5 (1)

- Astm A227Document4 pagesAstm A227Adolfo Luis Avila MurciaNo ratings yet

- 03 Baty Vision SystemsDocument16 pages03 Baty Vision SystemsAMAL NADH JNo ratings yet

- SPM Choke Valves Operation Instruction and Service ManualDocument37 pagesSPM Choke Valves Operation Instruction and Service Manualbill100% (1)

- TCVN 5318-2001 Mobile Offshore Installation-Welding (EN) PDFDocument9 pagesTCVN 5318-2001 Mobile Offshore Installation-Welding (EN) PDFPushkar GopalNo ratings yet

- SPP Book 2 PDFDocument612 pagesSPP Book 2 PDFBagadi AvinashNo ratings yet

- Inspection & Assessment of Damaged Subsea Pipelines: A Case StudyDocument8 pagesInspection & Assessment of Damaged Subsea Pipelines: A Case StudyDanny BoysieNo ratings yet

- Welding II Curriculum MapDocument9 pagesWelding II Curriculum Mapapi-525855204No ratings yet

- SAEP-22 - Tank Calibration Requirements PDFDocument14 pagesSAEP-22 - Tank Calibration Requirements PDFMuhammad Farukh Manzoor100% (1)

- Structural Integrity Inspection and Nondestructive Testing FOR Ilf Engineers Nigeria LimitedDocument3 pagesStructural Integrity Inspection and Nondestructive Testing FOR Ilf Engineers Nigeria LimitedChukwuma Emmanuel OnwufujuNo ratings yet

- Bachelor of Computer Application (BCA) (Indian & Angolan Embassy Attested)Document3 pagesBachelor of Computer Application (BCA) (Indian & Angolan Embassy Attested)Ali Ben AmorNo ratings yet

- TEC-042200 - MET-DoR-005 (Method Statement For Rectification For MEP Chasing at Block Walls)Document8 pagesTEC-042200 - MET-DoR-005 (Method Statement For Rectification For MEP Chasing at Block Walls)Alvene TagocNo ratings yet

- Method Statement (Beach Access)Document9 pagesMethod Statement (Beach Access)arnel sungkipNo ratings yet

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- Saudi Aramco Form 175Document22 pagesSaudi Aramco Form 175dissanayake90kanishkaNo ratings yet

- f2 Fou Con Sai PL Qa 00002 Project Quality Plan Rev 00Document52 pagesf2 Fou Con Sai PL Qa 00002 Project Quality Plan Rev 00Firman Indra JayaNo ratings yet

- Thiyagarajan.B.E Civil Engineer. CV Updated Novemeber 2018Document4 pagesThiyagarajan.B.E Civil Engineer. CV Updated Novemeber 2018Thiyagarajan TiguNo ratings yet

- Certificate of Eot Tmi-22Document3 pagesCertificate of Eot Tmi-22engr.haseebbalochNo ratings yet

- 4.production Planning & ControlDocument22 pages4.production Planning & ControlSaFdaR QaZiNo ratings yet

- Jis G4308Document13 pagesJis G4308ATULNo ratings yet

- HT Panel QapDocument2 pagesHT Panel QapAlla Naveen KumarNo ratings yet

- Project Quality Plan: Document Title Project Quality Plan Document Ref. No. NRR/PMF - QAC-PQP-01-R00 Date 31-August-2019Document50 pagesProject Quality Plan: Document Title Project Quality Plan Document Ref. No. NRR/PMF - QAC-PQP-01-R00 Date 31-August-2019FahadNo ratings yet

- MS-02 Bridge Demolition - Rev.1Document17 pagesMS-02 Bridge Demolition - Rev.1Leo TorresNo ratings yet

- FIR 001 - Rev.06 12Document12 pagesFIR 001 - Rev.06 12SteveYobsNo ratings yet

- Spacecraft 8 Attitude Control Anomaly ReportDocument70 pagesSpacecraft 8 Attitude Control Anomaly ReportBob AndrepontNo ratings yet