Professional Documents

Culture Documents

JSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 Dhahran

JSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 Dhahran

Uploaded by

Altaf HassainCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 Dhahran

JSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 Dhahran

Uploaded by

Altaf HassainCopyright:

Available Formats

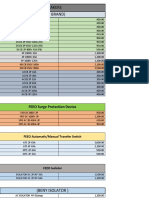

Job Safety Analysis

JOB SAFETY ANALYSIS RECORD SHEET

Project Name: Enhancement of Ladies Toilets Core Area

Work Order No:- 60537141 DATE PREPARED: DATE ISSUED:

16-February-23

Tower Bldg. 730 Dhahran

JSA NO.: 09

DESCRIPTION OF JOB/TASK: Electrical Work.

PREPARED BY: REVIEWED BY: APPROVED BY:

Muhamad Awais

Project Engineer

Altaf Hassain SA Safety Engineer

Safety Officer

REFERENCES:

Work Permit System GI-2.100

SA-CSM Hand Tools and Power Tools under Section 11.4 Requirements for Specific Types of Hand Tools

Lockout and Use of Hold tags process G.I 6.012

SAFETY EQUIPMENT REQUIRED: Safety Hat, Safety Shoes, Safety Gloves, Safety Glasses, Ear Plugs; pad lock & hold tag; caution/ warning tape

Note: Adequate and special PPE must also be considered for this task

JOB

STEP

NO. SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS REQUIRED HAZARD CONTROLS/SAFE WORK PROCEDURES

1 Activity planning and work start- Improper planning/coordination Coordinate with authorized Facility user/Proponent

up Failure to obtain Required Work Department.

Permit Strictly comply with Saudi Aramco’s Work Permit System

under G.I 2.100 and CSM II-14 Demolition.

Obtain a required Work Permit from the Area Supervisor

before starting the job and closing the Work Permit once

task is done. See SA-G.I. 2.100.

Get the permit validated for the specific day.

Document: - Job Safety Analysis. Page 1 of 9

If required, arrange for the disconnection of all affected

service lines in accordance with Isolation, Lockout and Use

of Hold tags process G.I 6.012.

Only Authorized/certified electrical technicians shall directly

engaged with energized facilities.

Assignment/selection of workers Lack of competence

Full supervision.

Training for electrical technicians.

Installation of electrical equipment and circuits shall

conform to NFPA 70.

Personnel shall not wear rings, wristwatches, jewelry or

other similar metallic objects.

Working on energized panels Ground-Fault Circuit Interrupter installed (GFCI).

2 Contact with energized parts Protective equipment.

and/or services

Isolation Confirmation Certificate (ICC) and PTW.

LOTO procedure implementation.

LOTO Training.

Power test before operation

Refer and comply with G.I. No.: 6.012 Isolation, Lockout

Improper isolation and Use of Hold Tags.

3

Isolation of Live Circuit Breaker Unfamiliar of lockout/tagout system Use SA approved lockout/tag out items.

Defective power tools / Battery-driven hand tools should be used as much as

Use of Electrical Tools possible to minimize the need for 220V tools.

equipment

Ensure portable electrical tools are double insulated

Untagged power tools Do not use handheld breakers within 500 mm from

Improper routing of electrical underground cables.

Ensure all portable electrical equipment has correct

cable.

safety guarding and protective devices are in place.

Slip, Trip and Fall Provision of socket outlets for distribution cables are

located as close to the working point as possible to prevent

the need for long trailing wires.

Document: - Job Safety Analysis. Page 2 of 9

Cables should be hanged up at workstations whenever

practicable to reduce trip hazards and damage to cables.

Use PVC insulated hooks/stands for cable routing.

Provide properly constructed and insulated electrode

holders (IP67, male female socket).

Ensure cables are sufficiently insulated, covered, or

armored, have protection from chemical damage and

where necessary additional protection,e.g. guarding, to

prevent mechanical damage.

Ensure all welding machines are installed with voltage

reducing devices.

Portable electric tools and extension cables should be

inspected and tagged every three months by a competent

person in compliance with color coding requirements.

Faulty electrical equipment or equipment without a tag

must be taken out of service and labeled with an ‘out of

service’ tag and should be reported to a supervisor.

Engagement of trained and competent person for power

tool operation.

Job specific PPE’s should be used for the activity.

Authorization card to be provided for operator.

Ensure rubber mat is placed at all DB’s

Electrical Shock Turn off power to the installation area before beginning

Installation of Strip Lights any work.

Use insulated tools and wear appropriate personal

protective equipment (PPE) such as insulated gloves and

safety goggles.

Avoid working in wet or damp conditions and ensure the

work area is dry.

Use Ground Fault Circuit Interrupters (GFCIs) to quickly

cut off power in case of a ground fault.

Inspect wiring for damage or wear before connecting to

power.

Document: - Job Safety Analysis. Page 3 of 9

Ensure all electrical connections are securely made and

properly insulated.

Fire Hazard Use quality, reputable products from trusted manufacturers.

Avoid overloading circuits by adhering to recommended voltage

requirements and load capacities.

Ensure proper ventilation around the strip lights to prevent

overheating.

Keep strip lights away from heat sources and flammable

materials.

Use waterproof or water-resistant lights and connectors in

moisture-prone areas.

Regularly inspect the installation for signs of overheating or

damage.

Overloading Circuits Securely mount strip lights using appropriate mounting

hardware or adhesive tape.

Route wires and cables away from walkways and areas with

foot traffic.

Use cable management solutions to conceal and organize wires.

Ensure all connections are flush with surfaces to minimize

tripping risks.

Improper Installation Plan the installation carefully, considering factors such as

layout, load requirements, and mounting options.

Follow manufacturer instructions and guidelines for installation.

Test the strip lights before final installation to ensure they

function properly.

Seek assistance from a qualified electrician if unsure about any

aspect of the installation process.

Water Damage

Sharp Objects se caution when cutting strip lights to size, and use appropriate

tools.

Handle cut strips carefully to avoid cuts or punctures.

Dispose of any sharp or jagged edges safely.

By implementing these control measures, you can significantly

reduce the risks associated with strip lights installation and

create a safer environment for yourself and others. Always

Document: - Job Safety Analysis. Page 4 of 9

prioritize safety and take necessary precautions to prevent

accidents and hazards.

Inadequate Ventilation Ensure all connections between strip lights, connectors, and power

sources are adequately sealed to prevent water intrusion. Use

waterproof connectors, silicone sealant, or heat shrink tubing to

protect connections from moisture.

Adhere to the manufacturer's recommendations and guidelines for

installing and maintaining strip lights in wet or damp

environments. Follow their instructions for sealing connections

and choosing suitable mounting locations.

Adhere to the manufacturer's recommendations and guidelines for

installing and maintaining strip lights in wet or damp

environments. Follow their instructions for sealing connections

and choosing suitable mounting locations.

Use approved leather or rubber gloves

Cable, EMT and instrumentation Store and secure properly loose sharp edges items

tubes pulling and installation Inspection of issued tools prior to use.

pulling activity Any defective tools must be disposed of from the site.

One person designated to control the pull to ensure all

cable pullers are working as a team

Sharp edges Damaged/Faulty Tools Suitably maintained drum roller frames, jacks, rollers

Cable kicking during the pulling and operatives controlled to ensure hands are clear when

activity cable is moving.

Awareness of maximum permitted cable pulling tensions

and minimum bending radii.

Inspection of a cable prior to pulling for damage.

Cable drums stored on level stable surfaces.

Contact with energized parts Installation of electrical equipment and circuits shall

Termination of cables from conform to NFPA 70.

power source Personnel shall not wear rings, wristwatches, jewelry or

Document: - Job Safety Analysis. Page 5 of 9

other similar metallic objects.

Ground-Fault Circuit Interrupter installed (GFCI).

Protective equipment.

Isolation Confirmation Certificate (ICC) and PTW.

LOTO procedure implementation.

LOTO Training.

Power test before operation

Installation / fixing of disconnect Electrical personnel must undergo the energy isolation &

switches, DDC panel permit to work orientation and LOTO training.

programming Adhere with current applicable project procedure (LOTO,

Commissioning, etc.) and associated PTW system.

Follow the electrical testing/ programming project method

of statement and risk assessment.

Only trained and experienced technician / electrician must

carry out the electrical test/ programming.

Electrical test/ programming activity must be supervised

closely by the designated electrical engineer/ supervisor.

Electrical Shock Applicable PTW to be completed and discussed with the

• Fire workforce in line with the toolbox talks before the task

• Personnel injury begins.

A readily useable CO2 portable fire extinguisher (20 kg.)

capacity shall be deployed in the area.

Signs and barricades shall be erected in the test area to

avoid unauthorized entry.

Comply as per Section Electrical Hand Tools Safety & Hot

Work. Ensure that the tools to be use is properly inspected

and tagged prior to use. Tools with damage or frayed wiring

must not be allowed to use and must be removed from the

worksite. Repair can only be done by an authorized person

with expertise to electrical works.

Loading, Transporting& Off- (Moving parts) Struck by Lashings to be applied to load. (Sufficient lashing)

loading /Trapped or in between All operatives to be versed in manual handling regulation.

All operators to be trained in use of equipment

Maneuvering Boom truck, Banks man shall control the heavy vehicles and equipment

trailer etc. with reflecting jacket.

Document: - Job Safety Analysis. Page 6 of 9

Area to be barricaded & warning display sign

Transformers Installation Hold task briefing prior to work commencement

Installation check list shall be maintained.

Only competent personnel handle the job.

Proper coordination & follow supervisor instructions

Emphasis appropriate tools for each job during task briefing

meetings.

Right tools for the job; any damaged tools must not be

Improper handling used, only standard tools for job. Do not use modified tools.

Use of Hand tools Replace defective & damaged tools; allocate trained

Use of electrical hand tools persons applicable to the tools in use.

Emphasis appropriate tools for each job during task briefing

meetings.

Use tools suitable for the job.

Connect the tools to correctly equipped cabinets (electrical

protection, adapted voltages, standard sockets)

Use certified tools with sticker.

Make sure that activities are properly coordinated to the

Tie in from the existing circuit concern department.

breakers Shutdown power breakers.

Disruption of power

Refer and comply with G.I. No.: 6.012 Isolation, Lockout

and Use of Hold Tags.

Use SA approved lockout/tagout items

Incompetent / Uncertified

Installation of Conduit pipes and Electricians.

Only properly trained and certified electricians shall

pulling of power cables Electrocution

perform the job.

Power interruption

Turn off the Panel main circuit breaker.

Termination

/installation failure

5 Cable pulling and EMT Cable kicking during the pulling

installation activity One person designated to control the pull to ensure all cable

Working on Stepladder pullers are working as a team

Suitably maintained drum roller frames, jacks, rollers and

Document: - Job Safety Analysis. Page 7 of 9

operatives controlled to ensure hands are clear when cable is

moving.

Awareness of maximum permitted cable pulling tensions and

minimum bending radii.

Inspection of a cable prior to pulling for damage.

Cable drums stored on level stable surfaces.

Wear proper gloves.

Personnel shall not stand on a step ladders top, platform.

Make sure somebody’s holding the ladder while a worker is

working on it.

Closing out of work

Trash can shall be provided for garbage, trash and unwanted

materials. Trash shall remove from waste bin on a daily basis.

Discarded unnecessary things.

7 Poor Housekeeping

Keep tidy and clean area daily.

Use dump truck to transport debris material to Saudi Aramco

designated dumpsite...

Activity: _____________

Date: ______________

ATTENDANCE SHEET

I DO HEREBY DECLARE THAT THE JOB SAFETY ANALYSIS WAS EXPLAINED TO ME AND I FULLY UNDERSTAND.

Document: - Job Safety Analysis. Page 8 of 9

SN. NAME BADGE NO. POSITION SIGNATURE

1

10

11

12

13

14

15

Document: - Job Safety Analysis. Page 9 of 9

You might also like

- Saudi Aramco LOTO GuideDocument8 pagesSaudi Aramco LOTO GuideMusharaf Shah100% (3)

- Bayer Clinitek - Service ManualDocument172 pagesBayer Clinitek - Service ManualAngeles Lagunes100% (2)

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Job Safety Analysis Sheet: Electrical IsolationDocument1 pageJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj67% (3)

- VV016036E User Manual CataRhex Easy VC820100CEDocument20 pagesVV016036E User Manual CataRhex Easy VC820100CEMuhammad Khizar100% (2)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (2)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- GX2-RX200BX2 Install PDFDocument35 pagesGX2-RX200BX2 Install PDFauancasa100% (1)

- JSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 DhahranDocument9 pagesJSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 DhahranAltaf HassainNo ratings yet

- JSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 DhahranDocument9 pagesJSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 DhahranAltaf HassainNo ratings yet

- JSA-Electrical work 3060 Bldng.Document7 pagesJSA-Electrical work 3060 Bldng.Altaf HassainNo ratings yet

- JSA -Electrical Work (Termination of Cable, Installation of Conduits, use of A Type ladder) Khaleej Abqaiq.Document6 pagesJSA -Electrical Work (Termination of Cable, Installation of Conduits, use of A Type ladder) Khaleej Abqaiq.Altaf HassainNo ratings yet

- 04_jsa_installation_cpvc Nonmetalic Pipe_modification Works at Al Khaleej House @Abqaiq.Document8 pages04_jsa_installation_cpvc Nonmetalic Pipe_modification Works at Al Khaleej House @Abqaiq.Altaf HassainNo ratings yet

- JSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)Document6 pagesJSA No - 08 - Grounding System Installation and Testing - Biju - (Revised - 17 July 2016)babjihanumanthuNo ratings yet

- JSA CABLE TaggingDocument5 pagesJSA CABLE TaggingthennarasuNo ratings yet

- Jsa_installation Fire Water Pump_upgrade Existing Fire Pumps North Parking Ac Plant1,2,3 Building-330 DhahranDocument7 pagesJsa_installation Fire Water Pump_upgrade Existing Fire Pumps North Parking Ac Plant1,2,3 Building-330 DhahranAltaf HassainNo ratings yet

- JSA For Cable Joint & Termination WorkDocument2 pagesJSA For Cable Joint & Termination WorkVivek Verma100% (1)

- Lock Out Tag OutDocument2 pagesLock Out Tag OutPablo Arreola RomeroNo ratings yet

- 5-Thrust Boring 56 Inch PipeDocument8 pages5-Thrust Boring 56 Inch PipeAmeerHamzaWarraichNo ratings yet

- E30-E01-02 - 1 Elect Lockout-Tagout RequirementDocument5 pagesE30-E01-02 - 1 Elect Lockout-Tagout RequirementMuhammad IrfanNo ratings yet

- JSA - Electrical IsolationDocument1 pageJSA - Electrical IsolationRaju KhalifaNo ratings yet

- Jsa 06 Electrical IsolationDocument1 pageJsa 06 Electrical Isolationdafrizal974No ratings yet

- Job Safety Analysis: Abqaiq Plants OperationDocument5 pagesJob Safety Analysis: Abqaiq Plants OperationZia ur RehmanNo ratings yet

- JSA_Installation of SPRINKLER_MODIFICATION WORKS AT AL KHALEEJ HOUSE BLDG #9-999 @ABQAIQ.Document4 pagesJSA_Installation of SPRINKLER_MODIFICATION WORKS AT AL KHALEEJ HOUSE BLDG #9-999 @ABQAIQ.Altaf HassainNo ratings yet

- SP0509 Circuit Breaker Testing SWPDocument6 pagesSP0509 Circuit Breaker Testing SWPEnthusiastNo ratings yet

- Steel Cutting, Bending, Welding and Grinding Work JsaDocument2 pagesSteel Cutting, Bending, Welding and Grinding Work JsaAKBAR ALINo ratings yet

- JSA- Water proofing Work3060 bldgDocument4 pagesJSA- Water proofing Work3060 bldgAltaf HassainNo ratings yet

- Energy IsolationDocument17 pagesEnergy IsolationAnggara BudiantoNo ratings yet

- 1 U Quick Installation Guide (IEC 19-Inch & ETSI 21-Inch Cabinet)Document1 page1 U Quick Installation Guide (IEC 19-Inch & ETSI 21-Inch Cabinet)ClaireNo ratings yet

- JSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00Document7 pagesJSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00DLPS HSENo ratings yet

- Ongoing / Upcoming Activities at Manifa CHF Project: HSE HSEDocument12 pagesOngoing / Upcoming Activities at Manifa CHF Project: HSE HSERahil TasawarNo ratings yet

- Electrical Safety: Casimiro L. Flores JRDocument23 pagesElectrical Safety: Casimiro L. Flores JRJoseph CeaNo ratings yet

- QESH-SP-ESH-26F1 Work Safety Permit FormDocument6 pagesQESH-SP-ESH-26F1 Work Safety Permit FormJohn Ervin AgenaNo ratings yet

- Electrical Safety Management Procedure May 2013Document35 pagesElectrical Safety Management Procedure May 2013Roni Enjelani100% (2)

- Project: Install Generator For Back Up Power Supply For Building 3056 For ShedgumDocument11 pagesProject: Install Generator For Back Up Power Supply For Building 3056 For ShedgumAnonymous voA5Tb0No ratings yet

- Bar Bending and Cutting WorkDocument1 pageBar Bending and Cutting WorkAKBAR ALINo ratings yet

- SB-ADM-W26 Lock Out, Tag Out & Try Out Operation Management Procedure Ed 02Document7 pagesSB-ADM-W26 Lock Out, Tag Out & Try Out Operation Management Procedure Ed 02simatelexrecruitsmbNo ratings yet

- 10.26.2020 20-029 Drilling Activity Using Drill MachineDocument4 pages10.26.2020 20-029 Drilling Activity Using Drill MachinePangky AbasoloNo ratings yet

- Up Dated Job Safety Analysis Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis Gypsum Plastering WorksshahbazchafekarNo ratings yet

- Manual Excavation For Identified Depth and Elevation of Existing PipelineDocument15 pagesManual Excavation For Identified Depth and Elevation of Existing PipelineshahbazchafekarNo ratings yet

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- LOTO - PSM Week 2019Document24 pagesLOTO - PSM Week 2019rizwanNo ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- 9.1.1 Foreword: 9.1 Electric SystemDocument4 pages9.1.1 Foreword: 9.1 Electric SystemEdwin Alfonso Hernandez MontesNo ratings yet

- Ocef Relay TestingDocument6 pagesOcef Relay TestingPandrayar MaruthuNo ratings yet

- Element 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetDocument14 pagesElement 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetGurumoorthy Rajavijayan100% (2)

- EPS Startup Test Procedure - SECDocument45 pagesEPS Startup Test Procedure - SECEng Zaid NawaysehNo ratings yet

- JSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00Document9 pagesJSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00DLPS HSENo ratings yet

- ARK-JSA-08 Manual Tie-In Welding Rev-3Document9 pagesARK-JSA-08 Manual Tie-In Welding Rev-3REMYANo ratings yet

- 2.2 Lock Out, Tag Out and Try OutDocument11 pages2.2 Lock Out, Tag Out and Try OutSuad BushiNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- Electrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceFrom EverandElectrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceNo ratings yet

- Jsa_installation Fire Water Pump_upgrade Existing Fire Pumps North Parking Ac Plant1,2,3 Building-330 DhahranDocument7 pagesJsa_installation Fire Water Pump_upgrade Existing Fire Pumps North Parking Ac Plant1,2,3 Building-330 DhahranAltaf HassainNo ratings yet

- JSA DISMANTLING OF CRANE_DISMATLING MECHNICAL AND FABRICATION WORKSHOP STEEL STRUCTUREDocument3 pagesJSA DISMANTLING OF CRANE_DISMATLING MECHNICAL AND FABRICATION WORKSHOP STEEL STRUCTUREAltaf HassainNo ratings yet

- JSA_Installation of SPRINKLER_MODIFICATION WORKS AT AL KHALEEJ HOUSE BLDG #9-999 @ABQAIQ.Document4 pagesJSA_Installation of SPRINKLER_MODIFICATION WORKS AT AL KHALEEJ HOUSE BLDG #9-999 @ABQAIQ.Altaf HassainNo ratings yet

- 04_jsa_installation_cpvc Nonmetalic Pipe_modification Works at Al Khaleej House @Abqaiq.Document8 pages04_jsa_installation_cpvc Nonmetalic Pipe_modification Works at Al Khaleej House @Abqaiq.Altaf HassainNo ratings yet

- JSA -Electrical Work (Termination of Cable, Installation of Conduits, use of A Type ladder) Khaleej Abqaiq.Document6 pagesJSA -Electrical Work (Termination of Cable, Installation of Conduits, use of A Type ladder) Khaleej Abqaiq.Altaf HassainNo ratings yet

- JSA- Water proofing Work3060 bldgDocument4 pagesJSA- Water proofing Work3060 bldgAltaf HassainNo ratings yet

- Sample Road Closure Plan_240611_114757-convertedDocument1 pageSample Road Closure Plan_240611_114757-convertedAltaf HassainNo ratings yet

- JSA-Electrical work 3060 Bldng.Document7 pagesJSA-Electrical work 3060 Bldng.Altaf HassainNo ratings yet

- Risk Register - TemplateDocument8 pagesRisk Register - TemplateAltaf HassainNo ratings yet

- JSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 DhahranDocument9 pagesJSA_Electrical Work_Enhancement of Ladies Toilets Core Area Tower Bldg. 730 DhahranAltaf HassainNo ratings yet

- Manual TIC ControllerDocument40 pagesManual TIC ControllerSölangs QüntellaNo ratings yet

- UT803 Eng ManualDocument58 pagesUT803 Eng ManualAnonymous j7toV6z7PNo ratings yet

- B80 enDocument6 pagesB80 enbharatdesh2011No ratings yet

- Manual OMC-118 PDFDocument49 pagesManual OMC-118 PDFEnrique Hernández VázquezNo ratings yet

- Te S Raychem Screened Elbow/Straight Separable Connectors Rses/RsssDocument2 pagesTe S Raychem Screened Elbow/Straight Separable Connectors Rses/RsssIrfan Pv50% (2)

- Welcome: Navico Training AcademyDocument24 pagesWelcome: Navico Training AcademyANDREASBOULNo ratings yet

- Lux EngineDocument21 pagesLux Engineompol dewoNo ratings yet

- United States Patent: (12) (10) Patent No.: US 8,294,044 B2Document13 pagesUnited States Patent: (12) (10) Patent No.: US 8,294,044 B2john ramseyNo ratings yet

- Semikron SKD - 51 - 07223281Document3 pagesSemikron SKD - 51 - 07223281shamkhairnarNo ratings yet

- Samurai TransmissionDocument37 pagesSamurai TransmissioninnovateiowaNo ratings yet

- 94 ManualDocument12 pages94 Manualmjkeyans10No ratings yet

- United Security CVD2020 User ManualDocument2 pagesUnited Security CVD2020 User ManualJMAC SupplyNo ratings yet

- Verifone: Ruby2 Register - Hardware GuideDocument24 pagesVerifone: Ruby2 Register - Hardware GuideT.L. CaldwellNo ratings yet

- GFC500 Part 23 AML STC Installation ManualDocument96 pagesGFC500 Part 23 AML STC Installation ManualDiovanni CamposNo ratings yet

- Abb Compression LugDocument39 pagesAbb Compression LugBenoit LefebvreNo ratings yet

- Skoda Scala Kamiq Body Repairs Exterior EngDocument213 pagesSkoda Scala Kamiq Body Repairs Exterior EngwprzyjemskiNo ratings yet

- MSZ-FH09-15NA Operation JG79A806H02 03-14Document44 pagesMSZ-FH09-15NA Operation JG79A806H02 03-14JordanNo ratings yet

- MDM2200 IP Satellite Modem: User Manual MDM2200 R3.2 v1.1Document66 pagesMDM2200 IP Satellite Modem: User Manual MDM2200 R3.2 v1.1axj42128No ratings yet

- Breakers (Feeo Brand) : FEEO Surge Protection DeviceDocument26 pagesBreakers (Feeo Brand) : FEEO Surge Protection DeviceMech T RonicsNo ratings yet

- siemens-DC Charger 50KWDocument8 pagessiemens-DC Charger 50KWAmr EidNo ratings yet

- Manual Book Genset Denyo DCA-70, - 125, & - 180ESEIDocument65 pagesManual Book Genset Denyo DCA-70, - 125, & - 180ESEIDadung PrakosoNo ratings yet

- Pixhawk2 PDFDocument28 pagesPixhawk2 PDFFazrulNo ratings yet

- Manual de Termometria Safegrain 4Document7 pagesManual de Termometria Safegrain 4danilocastillo05No ratings yet

- Thecus: User's ManualDocument185 pagesThecus: User's ManualemilelekNo ratings yet

- Instruction Manual: Model: AT7010S04 AC 220-240V 50/60Hz 2800WDocument22 pagesInstruction Manual: Model: AT7010S04 AC 220-240V 50/60Hz 2800WSonaina KhanNo ratings yet

- Cat 772G Ta-1Document25 pagesCat 772G Ta-1Soubhik BagchiNo ratings yet

- Replacing The Fan Box in The APM30HDocument2 pagesReplacing The Fan Box in The APM30Hm_valladaresmejiaNo ratings yet