Professional Documents

Culture Documents

ITP Detail

ITP Detail

Uploaded by

ambar patnaikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP Detail

ITP Detail

Uploaded by

ambar patnaikCopyright:

Available Formats

M+W Group

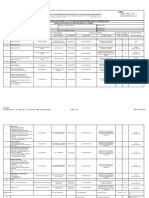

INSPECTION AND TEST PLAN FOR STRUCTURAL FABRICATION , ERECTION AND SHEETING ITP No :12

Rev: 00

Project No.018 Date

Project

DESCRIPTION:

Mechanical Systems

Reference Format of Inspection Requirement / Sign off

Op. Description of operation/Inspection or Type Type of Check Extent of check

Documents

Acceptance Criteria

Record Contractor CMO CLIENT

Remarks

No

Work Mobilization

1 Material

Confirmation of material incoming quality check BOQ,Approved

Project technical

Check material received confirm to specification make list &

visual,mechanical specifications,Approve notification of

Visual inspection for any physical damages 100% drawing and P/I/II W/A I/R

technical specifications d drawings,make list & inspection

Check consumables batch numbers & material test

BOQ

certificates certificates

2 Prefabrication

ASME SEC IX,check

Marking and cutting of Pipes and plates visual inspection 100% As per Drawing compliance with visual inspection I R R

speAcifications

WPS,PQR,WPQR.

ASME SEC IX,check

2.1 Welding procedure specification(WPS) Review Each process ASME SEC IX compliance with WPS P/I/IV W/R R/A

specifications

ASME SEC IX,check

visual ,mechanical &

2.2 Procedure qualification record(PQR) Each process ASME SEC IX compliance with PQR P/I/IV W/R R/A

DPT

specifications

Welder qualification test (WQT)submit list of

welders to be qualified with all particulars to

As per approved ASME SEC IX,check

client Approval before production welding Visual,mechanical &

2.3 Each process WPS ASME SEC compliance with WPQR P/I/II/IV W/R R/A

Qualification and witness by MWG/client submit DPT

IX/ NDT Reports specifications

test results for approval prepare welder

identification card

3 Welding Base plates and stiffners

Approved Visual welding

3.2 Check weld preparations visual Inspection Each batch ASME SEC IX I/P I/II/III S

WPS,PQR,WPQR inspection

Approved make IS 819/ Technical

3.3 Check welding consumables visual inspection 100% MRIR,MTC I/P I/II/III S

list specifications

Prepared By Reviewed BY Approved By

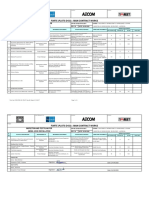

M+W Group

Reference Format of Inspection Requirement / Sign off

Op. Description of operation/Inspection or Type Type of Check Extent of check

Documents

Acceptance Criteria

Record Contractor CMO CLIENT

Remarks

No

Isometric

Approved drawing

Check fitup,configuration,dimension and drawings/IFC Visual welding

3.4 visual/dimensional 100% & as per approved I/P I/II/III S

orientation drawings&as per inspection

WPS

approved WPS

Isometric

Approved drawing

drawings/IFC

3.5 Material identification,cutting edge preparation visual/dimensional 100% & as per approved MRIR I/P I/II/III S

drawings&as per

WPS

approved WPS

Prepared By Reviewed BY Approved By

M+W Group

Reference Format of Inspection Requirement / Sign off

Op. Description of operation/Inspection or Type Type of Check Extent of check

Documents

Acceptance Criteria

Record Contractor CMO CLIENT

Remarks

No

Visual welding

3.6 All Fillet welding visual inspection 100% ASME SEC IX ASME SEC IX I R R

inspection

4 Coulumn , Rafter & Tie beams Erection

BOQ,Approved

Project technical

make list &

Check and con firmation of diamentin heights visual,technical specifications,Approve Notification of

4.1 100% drawing and P/I W R/W

and other spectification specifications d drawings,make list & inspection

material test

BOQ

certificates

IS 5290 and as per

As per approved approved

Check ground level and foundation bolts level IFC,isometric drawings ,standards Notification of

4.2 visual,dimentional 100% I/A/W/P II/S R/W

and heights. drawings,P&ID and contract inspection

and ASME B 31.3 specifications,isometric

&P&ID

Project technical

As per approved

specifications,Approve

4.3 Visual inspection for Erection level / water level visual 100% IFC,isometric visual inspection I R R

d drawings,make list &

drawings

BOQ

Project technical

As per technical

specifications,Approve

4.4 Check Bolt , nut and washer visual 100% specifications, visual inspection I/II/P M/W W/R

d drawings,make list &

drawings

BOQ

Project technical

As per technical

Check diagonal and spam for each sections , specifications,Approve

4.5 visual 100% specifications, visual inspection I/III/P W W

rafter and tie d drawings,make list &

drawings

BOQ

NFPA 14,Project

As per technical technical

4.6 Check Paint , micron and quality inspection visual,dimentional 100% specifications, specifications,Approve visual inspection I/P W S

drawings d drawings,make list &

BOQ

5 GI Purlin and Room sheeting installation

BOQ,Approved

Project technical

make list &

Check the confirmation of material of Purlin / visual ,technical specifications,Approve Notification of

5.1 100% drawing and P/I W R/W

sheeting and connectors specifications d drawings,make list & inspection

material test

BOQ

certificates

Prepared By Reviewed BY Approved By

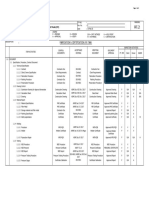

M+W Group

Reference Format of Inspection Requirement / Sign off

Op. Description of operation/Inspection or Type Type of Check Extent of check

Documents

Acceptance Criteria

Record Contractor CMO CLIENT

Remarks

No

IS 5290 and as per

As per approved approved

Notification of

Inspection of holes, screws, guage of sheets and IFC,isometric drawings ,standards

5.2 visual ,dimentional 100% inspection/visual I/A/W/P II/S R/W

purlin drawings ,P&ID and contract

inspection

and ASME B 31.3 specifications,isometric

&P&ID

Prepared By Reviewed BY Approved By

M+W Group

Reference Format of Inspection Requirement / Sign off

Op. Description of operation/Inspection or Type Type of Check Extent of check

Documents

Acceptance Criteria

Record Contractor CMO CLIENT

Remarks

No

6 Painting

Check color code of painting

Surface cleaning of Pipes,degreasing,remove

dust,dirt Project

Project

Inspection of surface preparation. specifications,pain painting

specifications,paint

6.1 Application of primer coat, visual/DFT checking random t cataloges and completion I/III/P/A S/A S

cataloges and method

Application of intermediate coats, method of report

of statement

Application of top coat, statement

Verification of DFT,

7 Punch listing

Generate internal punch list, As per approved

Each

Closing of internal punch list, IFC, isometric Punch list procedre as System closure

visual systems/equipment I/P W/A W/A

Conducting client walk down and punch listing, P&ID drawings bulit drawings checklist

100%

Closing of client punch list and ASME B 31.3

8 Documentation

Preparation of test packs , Each As per approved As per approved

Preparation,review and

Compiling of quality control dossiers(QCD) systems/equipment ITP ,quality plan ITP ,quality plan MDR P/A R/A H

certification

completeness specifications specifications

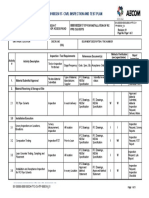

ITP Revision Status Legend

Rev Description contractor CMO Approval Authority Approval A Approve Hold Point

Third Sign :

2 Date : R Review Documentation Monitor

submission

Print Name :

I Inspection by Visual Prepare Documentations

II Inspection by Survey Spot Witness

Inspection by

III Witness

Measurement

IV Inspection by Testing Not Applicable

Prepared By Reviewed BY Approved By

You might also like

- Construction Logbook Sheet - Residential BuildingDocument30 pagesConstruction Logbook Sheet - Residential BuildingJet Espejon Javier100% (6)

- ITP Electrical Rev. GenDocument8 pagesITP Electrical Rev. GenAgiesta PradiosNo ratings yet

- Presentation - Tunel de ClaytonDocument7 pagesPresentation - Tunel de ClaytonMichael HurtadoNo ratings yet

- Inspection and Test Plan Piping Work ActivitiesDocument2 pagesInspection and Test Plan Piping Work ActivitiesAbram Berkat100% (2)

- ITP For Boiler ErectionDocument6 pagesITP For Boiler ErectionUmair Awan100% (2)

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Inspection and Test PlanDocument58 pagesInspection and Test PlanTouil Houssem100% (1)

- Inspection-Test-plan For Block WorkDocument3 pagesInspection-Test-plan For Block WorkAbdulrahman Alkilani100% (2)

- ITP - 031 (Earthing)Document2 pagesITP - 031 (Earthing)mohamed wahebNo ratings yet

- Qap - NRLDocument1 pageQap - NRLStructures ProductionNo ratings yet

- M Storm Drainage System IC M SDS 00Document2 pagesM Storm Drainage System IC M SDS 00achusanachuNo ratings yet

- SM Naga ItpDocument2 pagesSM Naga Itpjiao longNo ratings yet

- 1.SRO-QPITP - Mechanical WorksDocument2 pages1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- Inspection & Test Plan (ITP) For Simple Package EquipmentDocument2 pagesInspection & Test Plan (ITP) For Simple Package Equipmentxajo50% (2)

- Attach-2 ITP For Building WaterDocument29 pagesAttach-2 ITP For Building WaterSukalyan BasuNo ratings yet

- ITP - 028 (Lighting Fixtures)Document2 pagesITP - 028 (Lighting Fixtures)mohamed wahebNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- Inspection Plan For Pipe LineDocument4 pagesInspection Plan For Pipe LineArfanAliNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument10 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Forte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationDocument2 pagesForte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationfrancisbautistaNo ratings yet

- Itp - 029 (CCTV)Document2 pagesItp - 029 (CCTV)mohamed wahebNo ratings yet

- ITP FOR HBE (1)Document3 pagesITP FOR HBE (1)Mohammed Abdul WaheedNo ratings yet

- Qa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Document3 pagesQa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Ali Haider100% (1)

- ITP Sample For Piping Assembly WorksDocument7 pagesITP Sample For Piping Assembly WorksTee Klong RungNo ratings yet

- ITP - 030 (Fire Alarm)Document4 pagesITP - 030 (Fire Alarm)mohamed wahebNo ratings yet

- CDP RDC Ar Mal Qac 0001Document5 pagesCDP RDC Ar Mal Qac 0001ElvinNo ratings yet

- S96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorkDocument2 pagesS96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorktinzarmoeNo ratings yet

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Document4 pagesTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuNo ratings yet

- SA04C2-00-WG-I-00111-A - ITP Steel Structure - ErectionDocument4 pagesSA04C2-00-WG-I-00111-A - ITP Steel Structure - ErectionABAID ULLAHNo ratings yet

- Inspection & Test Plan Advance Valves Butterfly ValvesDocument2 pagesInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- PROJECT Site Record Acceptance Norms RefDocument6 pagesPROJECT Site Record Acceptance Norms Refvanchai sapaNo ratings yet

- Itp For Piping QPDocument4 pagesItp For Piping QPRejoy baby100% (2)

- 7) ITP For Wiring Accessories InstallationDocument1 page7) ITP For Wiring Accessories Installationislam mohamedNo ratings yet

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- Ajts QCP Fab Format Rev 01Document4 pagesAjts QCP Fab Format Rev 01Pradip DabhiNo ratings yet

- S-000-1676-0001V - 11 - ITP For Piping WorkDocument47 pagesS-000-1676-0001V - 11 - ITP For Piping WorkVO DINH TRI100% (2)

- Boc India Limited: Cryogenic Nitrogen Plant Bharat Oman Refineries Ltd. Engineers India Ltd. BOC India Ltd. Bina (M.P.)Document6 pagesBoc India Limited: Cryogenic Nitrogen Plant Bharat Oman Refineries Ltd. Engineers India Ltd. BOC India Ltd. Bina (M.P.)aceengineering08No ratings yet

- ITP-MEP-003 Water Supply Connection To Landlord NetworkDocument1 pageITP-MEP-003 Water Supply Connection To Landlord Networkjagathmukundhan00No ratings yet

- Inspection and Test Plan: Tile WorksDocument2 pagesInspection and Test Plan: Tile WorksAlvene Tagoc100% (2)

- 22 - ITP For BMSDocument2 pages22 - ITP For BMShassanabunafeesahNo ratings yet

- Rock Dowels & Rock Nails ITPDocument7 pagesRock Dowels & Rock Nails ITPVishnudas MgNo ratings yet

- Itp For Re-Slurry Tank - R-1Document8 pagesItp For Re-Slurry Tank - R-1Rejoy babyNo ratings yet

- Inspection and Test Plan 2Document3 pagesInspection and Test Plan 2EdNo ratings yet

- Itp Jib Crane Rev.1Document1 pageItp Jib Crane Rev.1Roger MahilumNo ratings yet

- Field Quality Plan: KSK Power Company LimitedDocument6 pagesField Quality Plan: KSK Power Company LimitedGayatree RathoreNo ratings yet

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocument7 pagesITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (4)

- QAP FinalDocument6 pagesQAP FinalANSHUMAN KUMARNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanReduddboy100% (1)

- Shic A 0009Document1 pageShic A 000901095902062ahmedNo ratings yet

- MDR C40 Pt. DmiDocument14 pagesMDR C40 Pt. DmiwidiNo ratings yet

- Manufacturing of Centrifugal and Reciprocating PumpDocument100 pagesManufacturing of Centrifugal and Reciprocating PumpDavidNo ratings yet

- Fabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Document3 pagesFabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Rifki HasyaNo ratings yet

- 2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02Document7 pages2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02teethai2524No ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- 2021.12.13 ITP - Concreting (5244.009) V.0Document4 pages2021.12.13 ITP - Concreting (5244.009) V.0huot phirunNo ratings yet

- 0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxDocument1 page0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxMeshaal ALBalharithNo ratings yet

- Pressure Vessel ITP Rev 0Document10 pagesPressure Vessel ITP Rev 0SLC HosurNo ratings yet

- Inspection and Test Planrev01Document16 pagesInspection and Test Planrev01Nguyễn MinhNo ratings yet

- Wiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsNo ratings yet

- Wiley Practitioner's Guide to GAAS 2017: Covering all SASs, SSAEs, SSARSs, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2017: Covering all SASs, SSAEs, SSARSs, and InterpretationsNo ratings yet

- AssamDocument6 pagesAssamSarang MohideNo ratings yet

- How Do I Calculate Shuttering Quantity For Beams & Columns?Document8 pagesHow Do I Calculate Shuttering Quantity For Beams & Columns?Charles KingNo ratings yet

- Ms DrainagesDocument3 pagesMs DrainagesdeanicoNo ratings yet

- ST 02Document1 pageST 02Anas Hasan KhanNo ratings yet

- TRANSFORMER YARD METHOD STATEMENT MCC Draft 1Document8 pagesTRANSFORMER YARD METHOD STATEMENT MCC Draft 1lucasNo ratings yet

- Career Research PaperDocument4 pagesCareer Research Paperapi-397814738No ratings yet

- Civil Engineering Hydraulics BOOKDocument409 pagesCivil Engineering Hydraulics BOOKsawmag123100% (3)

- Major Projects Work Executed by Trade Vision India PVT LTDDocument2 pagesMajor Projects Work Executed by Trade Vision India PVT LTDisathumagalbailiNo ratings yet

- Scaffold Inspection ChecklistDocument4 pagesScaffold Inspection ChecklistdabambuleloNo ratings yet

- Md. Safiqul Islam,: Career SummaryDocument5 pagesMd. Safiqul Islam,: Career SummaryI K BabuNo ratings yet

- BC PPT II 3 MasonryDocument54 pagesBC PPT II 3 MasonryAJAY J BIT100% (1)

- P&P Km8 Km20-Dudnai DaluDocument26 pagesP&P Km8 Km20-Dudnai Dalusujeet100% (1)

- Brick CourseworkDocument6 pagesBrick Courseworkfrebulnfg100% (2)

- Concept of Soil Confinement and Applicable MeasuresDocument16 pagesConcept of Soil Confinement and Applicable MeasuresHimanshu RanaNo ratings yet

- Karyawan Tambang Pt. Abg: No Nama Jabatan/posisi HP Office Project/Site Pendid IkanDocument9 pagesKaryawan Tambang Pt. Abg: No Nama Jabatan/posisi HP Office Project/Site Pendid IkanWinatha KusumaNo ratings yet

- CHK ListDocument38 pagesCHK Listsanjaya tamangNo ratings yet

- Foysal Hossain CV.Document2 pagesFoysal Hossain CV.Nurun NabiNo ratings yet

- List Nama CA CPS - Batch 2Document1 pageList Nama CA CPS - Batch 2rizal falamiNo ratings yet

- Section: Club House, JodhpurDocument1 pageSection: Club House, JodhpurHarshita BhanawatNo ratings yet

- Concrete Bridge Design and Construction SeriesDocument5 pagesConcrete Bridge Design and Construction SeriesJianhua WuNo ratings yet

- EPN2601 Assignment 1 REV1Document3 pagesEPN2601 Assignment 1 REV1Masithembe Tera DumezweniNo ratings yet

- Civil Engineering Materials UOL Lahore: ConcreteDocument119 pagesCivil Engineering Materials UOL Lahore: ConcreteNawab Zada ManekaNo ratings yet

- Hydraulic Hammers: Botswana GAUTENG & NORTH WEST ContinuedDocument2 pagesHydraulic Hammers: Botswana GAUTENG & NORTH WEST ContinuedtertuisNo ratings yet

- Plano Clave de Agua Potable: Tuberia PresionDocument1 pagePlano Clave de Agua Potable: Tuberia PresionHenrry GonzalesNo ratings yet

- Abdifatah Jama: Work ExperienceDocument5 pagesAbdifatah Jama: Work ExperienceMuthomi MunyuaNo ratings yet

- Perhitungan Pondasi Chimney Dengan Program AFES PDFDocument52 pagesPerhitungan Pondasi Chimney Dengan Program AFES PDFd'Hell CaesarNo ratings yet

- Plan For CID No. 21ID0029-2Document10 pagesPlan For CID No. 21ID0029-2Lara FloresNo ratings yet

- Concrete and Formwork CalculationDocument6 pagesConcrete and Formwork CalculationDeenNo ratings yet