Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 views1 ANAESTHETIC SPECS WORD

1 ANAESTHETIC SPECS WORD

Uploaded by

Dumisani Tawanda Dube1 ANAESTHETIC SPECS WORD

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Beginners Guide To Blackwork by Lesley Wilkins2 PDFDocument63 pagesBeginners Guide To Blackwork by Lesley Wilkins2 PDFSCP100% (4)

- Genesis - Anaesthesia Workstation - enDocument8 pagesGenesis - Anaesthesia Workstation - enThiết bị Điện Tử Y SinhNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- 2016 Book StochasticAndInfiniteDimension PDFDocument304 pages2016 Book StochasticAndInfiniteDimension PDFJhoan Sebastian Tenjo Garcia100% (1)

- Anesthesia MachinesDocument4 pagesAnesthesia MachinesEmilio CánepaNo ratings yet

- 19 Anesthesia Machine With WorkstationDocument8 pages19 Anesthesia Machine With Workstationfarouktaher592No ratings yet

- Techspecs5 Anesthesia MachineDocument5 pagesTechspecs5 Anesthesia MachineChristian Joie MasiglatNo ratings yet

- 20 Mechanical VentillatorDocument12 pages20 Mechanical VentillatorHamzah AlbrakaniNo ratings yet

- Department of Pediatrics: Specifications of Nasal Cpap MachineDocument4 pagesDepartment of Pediatrics: Specifications of Nasal Cpap MachinenaveenNo ratings yet

- Ane 7paraDocument7 pagesAne 7paraRanjan ShahNo ratings yet

- AnesthesiaWortation (Low End) ABCDocument15 pagesAnesthesiaWortation (Low End) ABCMoosa QamarNo ratings yet

- PSA Oxygen Generator SystemDocument8 pagesPSA Oxygen Generator SystemSudhakar ShresthaNo ratings yet

- Scan 20-Dec-2023Document4 pagesScan 20-Dec-2023Swaroop PozhaylNo ratings yet

- Anesthesia MachineDocument13 pagesAnesthesia MachineCr médicaNo ratings yet

- Ventilator PintaDocument43 pagesVentilator PintaDikka AzizNo ratings yet

- Machine CheckDocument8 pagesMachine Checklittle mushroomNo ratings yet

- Prima 465 Sales en 0822Document6 pagesPrima 465 Sales en 0822Didier Andrey Sanchez JimenezNo ratings yet

- Medical Gas SytemDocument22 pagesMedical Gas SytemMamdouh AwadNo ratings yet

- O o o o o o o o 9.: VentilatorDocument2 pagesO o o o o o o o 9.: VentilatorLokesh KuppiliNo ratings yet

- Anaesthesia Machine With Integrated VentilatorDocument3 pagesAnaesthesia Machine With Integrated VentilatorRanjan ShahNo ratings yet

- Prima 460 Sales en 1022Document6 pagesPrima 460 Sales en 1022antonios.medilonNo ratings yet

- Advanced RSSDocument5 pagesAdvanced RSSTECNIMED SYSTEMNo ratings yet

- Aerosept 500-1cf5f-2894 170 PDFDocument2 pagesAerosept 500-1cf5f-2894 170 PDFsentekorNo ratings yet

- S1100 Ventilator Machine: Adult PediatricDocument4 pagesS1100 Ventilator Machine: Adult PediatricRay FNNo ratings yet

- Tender for Oxgyen Plant 200محطة توليد اوكسجينDocument8 pagesTender for Oxgyen Plant 200محطة توليد اوكسجينtinep0493No ratings yet

- Ventilator ICUDocument4 pagesVentilator ICUMohamed YounessNo ratings yet

- B 5Document8 pagesB 5Edson Lima CharlesNo ratings yet

- CCV-PA500 Ventilator: User'S ManualDocument24 pagesCCV-PA500 Ventilator: User'S ManualDewangga DiraNo ratings yet

- Ventilator Guidance UkDocument9 pagesVentilator Guidance UkJhonny Alexander Valdés CorreaNo ratings yet

- A9800 Anes. MachineDocument2 pagesA9800 Anes. MachinejoaksadaNo ratings yet

- Life Support Test Facility LSTF100Document3 pagesLife Support Test Facility LSTF100Bojana MarinkovicNo ratings yet

- Oxygen Plant: B Air CompressorDocument3 pagesOxygen Plant: B Air Compressorsumit11235No ratings yet

- Centralize Manifold Room and Medical Gases PipelineDocument12 pagesCentralize Manifold Room and Medical Gases PipelineRanjan ShahNo ratings yet

- Newhart TechnologyDocument37 pagesNewhart Technologypatel_vicky87No ratings yet

- Technical Specifications Package No:-COVID (GR) - 2018 Procurement of "Respiratory Equipment" (Lot-1 & Lot-2)Document4 pagesTechnical Specifications Package No:-COVID (GR) - 2018 Procurement of "Respiratory Equipment" (Lot-1 & Lot-2)Md Shariful IslamNo ratings yet

- Broschuere GB APUS 2020 10Document12 pagesBroschuere GB APUS 2020 10Farahat KhanNo ratings yet

- Featuri de Siguranță A Machinelor AnesteziceDocument3 pagesFeaturi de Siguranță A Machinelor AnesteziceAurelia AlexandraNo ratings yet

- PDF Specificaiton2!22!02 12Document34 pagesPDF Specificaiton2!22!02 12Teguh SetionoNo ratings yet

- Masina Anestezie - Service ManualDocument48 pagesMasina Anestezie - Service ManualAlia Popa0% (1)

- In-Situ Fermentors CatalogueDocument4 pagesIn-Situ Fermentors CatalogueVineet GuptaNo ratings yet

- Professional Anesthesia Handbook - Sharn PDFDocument78 pagesProfessional Anesthesia Handbook - Sharn PDFvicmanNo ratings yet

- FALCO 202 Evo: Intensive Care and Transport VentilatorDocument8 pagesFALCO 202 Evo: Intensive Care and Transport VentilatorLâm PhạmNo ratings yet

- ECOM Gradient HPLC SystemDocument3 pagesECOM Gradient HPLC Systemshahoshahwar85No ratings yet

- Co-Ordinated By: DR Parul Presented By: DR GurneetDocument45 pagesCo-Ordinated By: DR Parul Presented By: DR Gurneetreenujohney100% (2)

- PiFLOW OS PreppedDocument4 pagesPiFLOW OS PreppedPauline HölblingNo ratings yet

- Thermal Vacuum System ManualDocument19 pagesThermal Vacuum System ManualCCESARPLNo ratings yet

- ASHRAE 15 Mechanical Room SpecDocument6 pagesASHRAE 15 Mechanical Room SpecwillchamNo ratings yet

- Catalogo AnestesiaDocument6 pagesCatalogo AnestesiaMaurice GasanaNo ratings yet

- RMVS001 Rapidly Manufactured Ventilator Specification PDFDocument9 pagesRMVS001 Rapidly Manufactured Ventilator Specification PDFjalmeida88No ratings yet

- Superstar S1100: ICU VentilatorDocument8 pagesSuperstar S1100: ICU VentilatorRay FNNo ratings yet

- 20 OT-1 Anesthesia Machine With Ventilator& MonitorDocument12 pages20 OT-1 Anesthesia Machine With Ventilator& MonitorHamzah AlbrakaniNo ratings yet

- 8800A Production Training-2020Document25 pages8800A Production Training-2020africasemiconductorNo ratings yet

- Brosure FalconSEDocument12 pagesBrosure FalconSEBambang ApryantoNo ratings yet

- 1.1.1. Bellows Assembly Ports: Item Diagram DescriptionDocument22 pages1.1.1. Bellows Assembly Ports: Item Diagram DescriptionMitricof BiancaNo ratings yet

- Oxygen Plant Features and SpecsDocument4 pagesOxygen Plant Features and SpecsKyaw Win ZanNo ratings yet

- Carestation 600 SeriesDocument3 pagesCarestation 600 SeriesABHINANDAN SHARMANo ratings yet

- Technical Specifications For Pressure Swing Adsorption (PSA) Oxygen PlantsDocument5 pagesTechnical Specifications For Pressure Swing Adsorption (PSA) Oxygen Plantszee khanNo ratings yet

- Prima 320 Advance Sales en 0522Document6 pagesPrima 320 Advance Sales en 0522Didier Andrey Sanchez JimenezNo ratings yet

- Agilent GC MS SpecificationDocument5 pagesAgilent GC MS Specificationashif28No ratings yet

- WATO EX-55 BrochureDocument4 pagesWATO EX-55 BrochurekentrunqNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- SPN for EHS Procurement FinalDocument2 pagesSPN for EHS Procurement FinalDumisani Tawanda DubeNo ratings yet

- 4 OPERATING THEATRE TABLEDocument3 pages4 OPERATING THEATRE TABLEDumisani Tawanda DubeNo ratings yet

- 5 DOUBLE BOTTLE SUCTION MACHINEDocument2 pages5 DOUBLE BOTTLE SUCTION MACHINEDumisani Tawanda DubeNo ratings yet

- Dumisani Maths Prac AssignmentDocument6 pagesDumisani Maths Prac AssignmentDumisani Tawanda DubeNo ratings yet

- 3 OPERATING THEATRE LIGHTDocument3 pages3 OPERATING THEATRE LIGHTDumisani Tawanda DubeNo ratings yet

- Engineering Management Practical 2Document4 pagesEngineering Management Practical 2Dumisani Tawanda DubeNo ratings yet

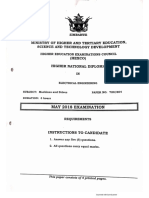

- Machines & Drives May 2018Document4 pagesMachines & Drives May 2018Dumisani Tawanda DubeNo ratings yet

- Management Theory Assignment 2Document9 pagesManagement Theory Assignment 2Dumisani Tawanda DubeNo ratings yet

- Prevent ProposalDocument10 pagesPrevent ProposalDumisani Tawanda DubeNo ratings yet

- 300 SeriesDocument86 pages300 SeriesDumisani Tawanda DubeNo ratings yet

- MicrocomputerDocument9 pagesMicrocomputerDumisani Tawanda DubeNo ratings yet

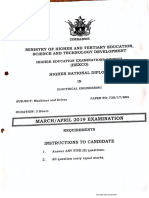

- Machines and Drives March 2019Document4 pagesMachines and Drives March 2019Dumisani Tawanda DubeNo ratings yet

- CamScanner 08-30-2022 21.38Document9 pagesCamScanner 08-30-2022 21.38Dumisani Tawanda DubeNo ratings yet

- 2022 Microcomputer Theory Assignmnt 1Document1 page2022 Microcomputer Theory Assignmnt 1Dumisani Tawanda DubeNo ratings yet

- LCM105 LCM115 PDFDocument3 pagesLCM105 LCM115 PDFCABean1No ratings yet

- Week 5Document7 pagesWeek 5mylene neviarNo ratings yet

- DIGITAL MARKETING (Unit 4)Document9 pagesDIGITAL MARKETING (Unit 4)sharmapranav780No ratings yet

- Acts 13 New 2Document8 pagesActs 13 New 2fitsum tesfayeNo ratings yet

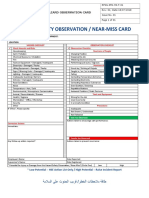

- RPSG-IMS-HS-F - 01 - Hazard Observation CardDocument2 pagesRPSG-IMS-HS-F - 01 - Hazard Observation CardRocky BisNo ratings yet

- Product Research SpreadsheetDocument7 pagesProduct Research SpreadsheetCharlie ElmesNo ratings yet

- Jadual Waktu Kelas PKPP PDFDocument18 pagesJadual Waktu Kelas PKPP PDFAidda SuriNo ratings yet

- Sublimatex Company ProfileDocument17 pagesSublimatex Company ProfileMohamed MahmoudNo ratings yet

- Mutiple Choice Question For Satellite CommunicationDocument4 pagesMutiple Choice Question For Satellite CommunicationRaja Pirian67% (3)

- Indian Income Tax Return Acknowledgement: Name of Premises/Building/VillageDocument1 pageIndian Income Tax Return Acknowledgement: Name of Premises/Building/Villagehealth with wealthNo ratings yet

- D Claves - Examen A2Document1 pageD Claves - Examen A2Anyelin JaimesNo ratings yet

- Princess Maker 2 EndingsDocument11 pagesPrincess Maker 2 EndingspsnapplebeeNo ratings yet

- "©HAND Rapids" Grinders .: & Livomsstron CODocument42 pages"©HAND Rapids" Grinders .: & Livomsstron CONew100% (1)

- Landslides Causes EffectsDocument9 pagesLandslides Causes EffectsDaljeet SidhuNo ratings yet

- Syllabus Class 4 - 2019-20Document11 pagesSyllabus Class 4 - 2019-20Dominic SavioNo ratings yet

- Daksh Booklet - 26 PDF by Ankush LambaDocument35 pagesDaksh Booklet - 26 PDF by Ankush LambaSoham ChaudhuriNo ratings yet

- PeriodontitisDocument14 pagesPeriodontitisDanni MontielNo ratings yet

- Warhammer Skaven Paint GuideDocument2 pagesWarhammer Skaven Paint Guiderandom-userNo ratings yet

- Schools in Ghaz. & NoidaDocument58 pagesSchools in Ghaz. & Noidanitinthukral10No ratings yet

- Statements of Financial Position As at 31 December 2009 and 2010Document3 pagesStatements of Financial Position As at 31 December 2009 and 2010mohitgaba19No ratings yet

- GPS World - January 2017Document77 pagesGPS World - January 2017Diego Franco100% (2)

- Edith Stein: Women, Social-Political Philosophy, Theology, Metaphysics and Public HistoryDocument281 pagesEdith Stein: Women, Social-Political Philosophy, Theology, Metaphysics and Public HistorySantiago GarciaNo ratings yet

- Carter Procession Closure MapDocument1 pageCarter Procession Closure Mapcookiespiffey21No ratings yet

- Discourse Vs - TextDocument11 pagesDiscourse Vs - TextImmo Eagle JuniØrNo ratings yet

- British Mathematical Olympiad 2004 British Mathematical Olympiad Round 2Document1 pageBritish Mathematical Olympiad 2004 British Mathematical Olympiad Round 2Ajay NegiNo ratings yet

- Basic Accounting Principles ModuleDocument23 pagesBasic Accounting Principles ModulezendeexNo ratings yet

- Isu Moa OjtDocument5 pagesIsu Moa OjtJan Dominic D. CorpuzNo ratings yet

- Penarth Classified 120516Document2 pagesPenarth Classified 120516Digital MediaNo ratings yet

1 ANAESTHETIC SPECS WORD

1 ANAESTHETIC SPECS WORD

Uploaded by

Dumisani Tawanda Dube0 ratings0% found this document useful (0 votes)

1 views3 pages1 ANAESTHETIC SPECS WORD

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1 ANAESTHETIC SPECS WORD

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views3 pages1 ANAESTHETIC SPECS WORD

1 ANAESTHETIC SPECS WORD

Uploaded by

Dumisani Tawanda Dube1 ANAESTHETIC SPECS WORD

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

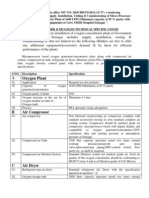

Item Item description and full technical Specification Compliance Order Quantity

required (including applicable standards)

1.Anaesthetic ANAESTHESIA WORKSTATION COMPLETE

Machine (Anaesthetic machine and Multiparameter monitor) 25

Item description

Complete anaesthesia Workstation comprises of

· Anaesthetic machine (small)

· Multiparameter monitor

The Anaesthetic Machine, Ventilator and the

Multiparameter Monitor should be from the same

manufacturer.

Year of Manufacturer- The Technology must be not

more than 5 years. Written confirmation from the

manufacturer is required.

Technical specifications for the anaesthetic machine

Should be compact, ergonomic & easy to use with

automatic pre-use check for electronic parts.

Should have complete integrated anesthesia gas

delivery system.

It should be electronically controlled with a master

switch, pneumatically operated with prioritized alarm

system.

Should provide both adult and pediatric reusable and

auto-clavable lightweight tubing breathing circuit.

Should be able to deliver a tidal volume from 50ml to

1500ml.

Should have a battery backup for at least 4hours with

low battery alarm and over charge protection.

Should have a built-in anaesthesia ventilator with

Pressure, volume-controlled modes with PEEP.

Should have monitoring facility of continuous airway

pressure, tidal volume, frequency , oxygen

concentration and oxygen supply pressure

Ventilator display should be at least at least 7 inches

for set parameters

Should have pressure gauge for all gas inlets including

central lines mounted on the front panel for easy

visibility

Should have audible alarm for O2 failure

Should be supplied with driver gas hoses with

necessary attachments (colour coded)

Should have power on self test and automated system

checks

Anaesthesia machine should have a minimum of with 2

gas supply system (O2 and Air) with pipeline

connections and reserve cylinder yokes.

Gas cylinder (pin indexed) yokes with sturdy clamping

bars for easy handling.

Regulator one each for each iof the gases.

If machine is supplied with N2O supply, it should cut

off if O2 supply fails. (hypoxic guard).

Anaesthetic Gas Module capable of measuring End

Tidal Carbon Dioxide and Anaesthetic Gases (NB, this

can be on the monitor or anaesthetic machine)

The anaesthesia machine should have a master control

ON/OFF switch.

Provision to mount two vaporizers with interlocking

facility to allow use of only one vaporizer at a time.

Should be supplied with two vaporiser, namely

Isoflurane & Sevoflurane. These should be key filled

vaporizers of newer generation having specifications

equivalent to tech 7 type to be provided together with

minimum of 2 keys.

Should be supplied with necessary attachments to use

the breathing circuits viz namely Circle System with

CO2 Absorber, Bains, Jackson-Rees

Should have auxiliary common gas outlet for open

circuit.

Should provide with oxygen flush switch

Circle absorber with corrugated reusable (silicone)

breathing circuit for closed circuit system with each

unit. It should be autoclavable. It should be with

ventilator selector switch and circle on/off switch.

Should have low flow anaesthesia technique

should have a facility to connect to the passive

scavenging system and the required tubing to be

provided.

Should have at least two universal electrical outlets

should have at least two drawers

Should have antistatic non staining wheels and

Footbrakes.

Standard Accessories for the anaesthetic machine Quantity

Standard Bains circuit : 1 no. with each unit. 2

Reservoir bag (2liters) 2

Connectors for Bains circuit 2

reusable silicone circle system breathing circuits 5

Should supply with Soda Lime along with machine. 5kg

AMBU Resuscitator Bag 1

power: 220-240Vac 50 Hz input supply.

Should come with a medical grade 13 amp three pin

plug

Documentation

Colour brochure with technical specifications for

the machine should be included with the bid.

A signed letter of authorization from the

manufacturer and not third part dealers is

mandatory.

Factory training for at least two technicians prior to

installation

The equipment should be European CE / US FDA/ISO

certified

You might also like

- Beginners Guide To Blackwork by Lesley Wilkins2 PDFDocument63 pagesBeginners Guide To Blackwork by Lesley Wilkins2 PDFSCP100% (4)

- Genesis - Anaesthesia Workstation - enDocument8 pagesGenesis - Anaesthesia Workstation - enThiết bị Điện Tử Y SinhNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- 2016 Book StochasticAndInfiniteDimension PDFDocument304 pages2016 Book StochasticAndInfiniteDimension PDFJhoan Sebastian Tenjo Garcia100% (1)

- Anesthesia MachinesDocument4 pagesAnesthesia MachinesEmilio CánepaNo ratings yet

- 19 Anesthesia Machine With WorkstationDocument8 pages19 Anesthesia Machine With Workstationfarouktaher592No ratings yet

- Techspecs5 Anesthesia MachineDocument5 pagesTechspecs5 Anesthesia MachineChristian Joie MasiglatNo ratings yet

- 20 Mechanical VentillatorDocument12 pages20 Mechanical VentillatorHamzah AlbrakaniNo ratings yet

- Department of Pediatrics: Specifications of Nasal Cpap MachineDocument4 pagesDepartment of Pediatrics: Specifications of Nasal Cpap MachinenaveenNo ratings yet

- Ane 7paraDocument7 pagesAne 7paraRanjan ShahNo ratings yet

- AnesthesiaWortation (Low End) ABCDocument15 pagesAnesthesiaWortation (Low End) ABCMoosa QamarNo ratings yet

- PSA Oxygen Generator SystemDocument8 pagesPSA Oxygen Generator SystemSudhakar ShresthaNo ratings yet

- Scan 20-Dec-2023Document4 pagesScan 20-Dec-2023Swaroop PozhaylNo ratings yet

- Anesthesia MachineDocument13 pagesAnesthesia MachineCr médicaNo ratings yet

- Ventilator PintaDocument43 pagesVentilator PintaDikka AzizNo ratings yet

- Machine CheckDocument8 pagesMachine Checklittle mushroomNo ratings yet

- Prima 465 Sales en 0822Document6 pagesPrima 465 Sales en 0822Didier Andrey Sanchez JimenezNo ratings yet

- Medical Gas SytemDocument22 pagesMedical Gas SytemMamdouh AwadNo ratings yet

- O o o o o o o o 9.: VentilatorDocument2 pagesO o o o o o o o 9.: VentilatorLokesh KuppiliNo ratings yet

- Anaesthesia Machine With Integrated VentilatorDocument3 pagesAnaesthesia Machine With Integrated VentilatorRanjan ShahNo ratings yet

- Prima 460 Sales en 1022Document6 pagesPrima 460 Sales en 1022antonios.medilonNo ratings yet

- Advanced RSSDocument5 pagesAdvanced RSSTECNIMED SYSTEMNo ratings yet

- Aerosept 500-1cf5f-2894 170 PDFDocument2 pagesAerosept 500-1cf5f-2894 170 PDFsentekorNo ratings yet

- S1100 Ventilator Machine: Adult PediatricDocument4 pagesS1100 Ventilator Machine: Adult PediatricRay FNNo ratings yet

- Tender for Oxgyen Plant 200محطة توليد اوكسجينDocument8 pagesTender for Oxgyen Plant 200محطة توليد اوكسجينtinep0493No ratings yet

- Ventilator ICUDocument4 pagesVentilator ICUMohamed YounessNo ratings yet

- B 5Document8 pagesB 5Edson Lima CharlesNo ratings yet

- CCV-PA500 Ventilator: User'S ManualDocument24 pagesCCV-PA500 Ventilator: User'S ManualDewangga DiraNo ratings yet

- Ventilator Guidance UkDocument9 pagesVentilator Guidance UkJhonny Alexander Valdés CorreaNo ratings yet

- A9800 Anes. MachineDocument2 pagesA9800 Anes. MachinejoaksadaNo ratings yet

- Life Support Test Facility LSTF100Document3 pagesLife Support Test Facility LSTF100Bojana MarinkovicNo ratings yet

- Oxygen Plant: B Air CompressorDocument3 pagesOxygen Plant: B Air Compressorsumit11235No ratings yet

- Centralize Manifold Room and Medical Gases PipelineDocument12 pagesCentralize Manifold Room and Medical Gases PipelineRanjan ShahNo ratings yet

- Newhart TechnologyDocument37 pagesNewhart Technologypatel_vicky87No ratings yet

- Technical Specifications Package No:-COVID (GR) - 2018 Procurement of "Respiratory Equipment" (Lot-1 & Lot-2)Document4 pagesTechnical Specifications Package No:-COVID (GR) - 2018 Procurement of "Respiratory Equipment" (Lot-1 & Lot-2)Md Shariful IslamNo ratings yet

- Broschuere GB APUS 2020 10Document12 pagesBroschuere GB APUS 2020 10Farahat KhanNo ratings yet

- Featuri de Siguranță A Machinelor AnesteziceDocument3 pagesFeaturi de Siguranță A Machinelor AnesteziceAurelia AlexandraNo ratings yet

- PDF Specificaiton2!22!02 12Document34 pagesPDF Specificaiton2!22!02 12Teguh SetionoNo ratings yet

- Masina Anestezie - Service ManualDocument48 pagesMasina Anestezie - Service ManualAlia Popa0% (1)

- In-Situ Fermentors CatalogueDocument4 pagesIn-Situ Fermentors CatalogueVineet GuptaNo ratings yet

- Professional Anesthesia Handbook - Sharn PDFDocument78 pagesProfessional Anesthesia Handbook - Sharn PDFvicmanNo ratings yet

- FALCO 202 Evo: Intensive Care and Transport VentilatorDocument8 pagesFALCO 202 Evo: Intensive Care and Transport VentilatorLâm PhạmNo ratings yet

- ECOM Gradient HPLC SystemDocument3 pagesECOM Gradient HPLC Systemshahoshahwar85No ratings yet

- Co-Ordinated By: DR Parul Presented By: DR GurneetDocument45 pagesCo-Ordinated By: DR Parul Presented By: DR Gurneetreenujohney100% (2)

- PiFLOW OS PreppedDocument4 pagesPiFLOW OS PreppedPauline HölblingNo ratings yet

- Thermal Vacuum System ManualDocument19 pagesThermal Vacuum System ManualCCESARPLNo ratings yet

- ASHRAE 15 Mechanical Room SpecDocument6 pagesASHRAE 15 Mechanical Room SpecwillchamNo ratings yet

- Catalogo AnestesiaDocument6 pagesCatalogo AnestesiaMaurice GasanaNo ratings yet

- RMVS001 Rapidly Manufactured Ventilator Specification PDFDocument9 pagesRMVS001 Rapidly Manufactured Ventilator Specification PDFjalmeida88No ratings yet

- Superstar S1100: ICU VentilatorDocument8 pagesSuperstar S1100: ICU VentilatorRay FNNo ratings yet

- 20 OT-1 Anesthesia Machine With Ventilator& MonitorDocument12 pages20 OT-1 Anesthesia Machine With Ventilator& MonitorHamzah AlbrakaniNo ratings yet

- 8800A Production Training-2020Document25 pages8800A Production Training-2020africasemiconductorNo ratings yet

- Brosure FalconSEDocument12 pagesBrosure FalconSEBambang ApryantoNo ratings yet

- 1.1.1. Bellows Assembly Ports: Item Diagram DescriptionDocument22 pages1.1.1. Bellows Assembly Ports: Item Diagram DescriptionMitricof BiancaNo ratings yet

- Oxygen Plant Features and SpecsDocument4 pagesOxygen Plant Features and SpecsKyaw Win ZanNo ratings yet

- Carestation 600 SeriesDocument3 pagesCarestation 600 SeriesABHINANDAN SHARMANo ratings yet

- Technical Specifications For Pressure Swing Adsorption (PSA) Oxygen PlantsDocument5 pagesTechnical Specifications For Pressure Swing Adsorption (PSA) Oxygen Plantszee khanNo ratings yet

- Prima 320 Advance Sales en 0522Document6 pagesPrima 320 Advance Sales en 0522Didier Andrey Sanchez JimenezNo ratings yet

- Agilent GC MS SpecificationDocument5 pagesAgilent GC MS Specificationashif28No ratings yet

- WATO EX-55 BrochureDocument4 pagesWATO EX-55 BrochurekentrunqNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- SPN for EHS Procurement FinalDocument2 pagesSPN for EHS Procurement FinalDumisani Tawanda DubeNo ratings yet

- 4 OPERATING THEATRE TABLEDocument3 pages4 OPERATING THEATRE TABLEDumisani Tawanda DubeNo ratings yet

- 5 DOUBLE BOTTLE SUCTION MACHINEDocument2 pages5 DOUBLE BOTTLE SUCTION MACHINEDumisani Tawanda DubeNo ratings yet

- Dumisani Maths Prac AssignmentDocument6 pagesDumisani Maths Prac AssignmentDumisani Tawanda DubeNo ratings yet

- 3 OPERATING THEATRE LIGHTDocument3 pages3 OPERATING THEATRE LIGHTDumisani Tawanda DubeNo ratings yet

- Engineering Management Practical 2Document4 pagesEngineering Management Practical 2Dumisani Tawanda DubeNo ratings yet

- Machines & Drives May 2018Document4 pagesMachines & Drives May 2018Dumisani Tawanda DubeNo ratings yet

- Management Theory Assignment 2Document9 pagesManagement Theory Assignment 2Dumisani Tawanda DubeNo ratings yet

- Prevent ProposalDocument10 pagesPrevent ProposalDumisani Tawanda DubeNo ratings yet

- 300 SeriesDocument86 pages300 SeriesDumisani Tawanda DubeNo ratings yet

- MicrocomputerDocument9 pagesMicrocomputerDumisani Tawanda DubeNo ratings yet

- Machines and Drives March 2019Document4 pagesMachines and Drives March 2019Dumisani Tawanda DubeNo ratings yet

- CamScanner 08-30-2022 21.38Document9 pagesCamScanner 08-30-2022 21.38Dumisani Tawanda DubeNo ratings yet

- 2022 Microcomputer Theory Assignmnt 1Document1 page2022 Microcomputer Theory Assignmnt 1Dumisani Tawanda DubeNo ratings yet

- LCM105 LCM115 PDFDocument3 pagesLCM105 LCM115 PDFCABean1No ratings yet

- Week 5Document7 pagesWeek 5mylene neviarNo ratings yet

- DIGITAL MARKETING (Unit 4)Document9 pagesDIGITAL MARKETING (Unit 4)sharmapranav780No ratings yet

- Acts 13 New 2Document8 pagesActs 13 New 2fitsum tesfayeNo ratings yet

- RPSG-IMS-HS-F - 01 - Hazard Observation CardDocument2 pagesRPSG-IMS-HS-F - 01 - Hazard Observation CardRocky BisNo ratings yet

- Product Research SpreadsheetDocument7 pagesProduct Research SpreadsheetCharlie ElmesNo ratings yet

- Jadual Waktu Kelas PKPP PDFDocument18 pagesJadual Waktu Kelas PKPP PDFAidda SuriNo ratings yet

- Sublimatex Company ProfileDocument17 pagesSublimatex Company ProfileMohamed MahmoudNo ratings yet

- Mutiple Choice Question For Satellite CommunicationDocument4 pagesMutiple Choice Question For Satellite CommunicationRaja Pirian67% (3)

- Indian Income Tax Return Acknowledgement: Name of Premises/Building/VillageDocument1 pageIndian Income Tax Return Acknowledgement: Name of Premises/Building/Villagehealth with wealthNo ratings yet

- D Claves - Examen A2Document1 pageD Claves - Examen A2Anyelin JaimesNo ratings yet

- Princess Maker 2 EndingsDocument11 pagesPrincess Maker 2 EndingspsnapplebeeNo ratings yet

- "©HAND Rapids" Grinders .: & Livomsstron CODocument42 pages"©HAND Rapids" Grinders .: & Livomsstron CONew100% (1)

- Landslides Causes EffectsDocument9 pagesLandslides Causes EffectsDaljeet SidhuNo ratings yet

- Syllabus Class 4 - 2019-20Document11 pagesSyllabus Class 4 - 2019-20Dominic SavioNo ratings yet

- Daksh Booklet - 26 PDF by Ankush LambaDocument35 pagesDaksh Booklet - 26 PDF by Ankush LambaSoham ChaudhuriNo ratings yet

- PeriodontitisDocument14 pagesPeriodontitisDanni MontielNo ratings yet

- Warhammer Skaven Paint GuideDocument2 pagesWarhammer Skaven Paint Guiderandom-userNo ratings yet

- Schools in Ghaz. & NoidaDocument58 pagesSchools in Ghaz. & Noidanitinthukral10No ratings yet

- Statements of Financial Position As at 31 December 2009 and 2010Document3 pagesStatements of Financial Position As at 31 December 2009 and 2010mohitgaba19No ratings yet

- GPS World - January 2017Document77 pagesGPS World - January 2017Diego Franco100% (2)

- Edith Stein: Women, Social-Political Philosophy, Theology, Metaphysics and Public HistoryDocument281 pagesEdith Stein: Women, Social-Political Philosophy, Theology, Metaphysics and Public HistorySantiago GarciaNo ratings yet

- Carter Procession Closure MapDocument1 pageCarter Procession Closure Mapcookiespiffey21No ratings yet

- Discourse Vs - TextDocument11 pagesDiscourse Vs - TextImmo Eagle JuniØrNo ratings yet

- British Mathematical Olympiad 2004 British Mathematical Olympiad Round 2Document1 pageBritish Mathematical Olympiad 2004 British Mathematical Olympiad Round 2Ajay NegiNo ratings yet

- Basic Accounting Principles ModuleDocument23 pagesBasic Accounting Principles ModulezendeexNo ratings yet

- Isu Moa OjtDocument5 pagesIsu Moa OjtJan Dominic D. CorpuzNo ratings yet

- Penarth Classified 120516Document2 pagesPenarth Classified 120516Digital MediaNo ratings yet