Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

5 viewsFiber Ratio Testing Procedure

Fiber Ratio Testing Procedure

Uploaded by

Nadeem AhmedCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Womenswear Forecast S S 24 SenseScapes enDocument18 pagesWomenswear Forecast S S 24 SenseScapes enRishab Manocha100% (1)

- Stress Cracking in PET BottlesDocument93 pagesStress Cracking in PET BottlesEliezer Gonzalez100% (3)

- Bamboo Tribe - Business Plan 2 - Lorejo Nicole Muffee C.Document30 pagesBamboo Tribe - Business Plan 2 - Lorejo Nicole Muffee C.Liza Cabalquinto Lorejo100% (3)

- Knit Garment STD Reqmnt CJB PDFDocument1 pageKnit Garment STD Reqmnt CJB PDFmishraajitNo ratings yet

- Prepared by : Muhammad Usman (IC-301) Rafia Himayel (IC-024) Ramsha Shamim (IC-012) Tehreem Sadaqat (IC-022)Document22 pagesPrepared by : Muhammad Usman (IC-301) Rafia Himayel (IC-024) Ramsha Shamim (IC-012) Tehreem Sadaqat (IC-022)RAMSHA RAMSHANo ratings yet

- Direct Esthetic Restorative MaterialsDocument31 pagesDirect Esthetic Restorative MaterialsNamrata Dalal LakraNo ratings yet

- Plastic Vial ProductsDocument2 pagesPlastic Vial ProductsaasdcdcNo ratings yet

- BQC kb03004 - Lowry Protein Assay Kit - ManualDocument16 pagesBQC kb03004 - Lowry Protein Assay Kit - ManualFaza FathiNo ratings yet

- Tanningg ProcessDocument8 pagesTanningg ProcessGaurav MalNo ratings yet

- Reverse OsmosisDocument131 pagesReverse OsmosisTaufiqTaufiq100% (6)

- SPS 370S - 2024 - Chapter 3.2Document52 pagesSPS 370S - 2024 - Chapter 3.2ziziphomkosana2003No ratings yet

- Training Material of UNA-620A System (Asahi Kasei) 170725Document33 pagesTraining Material of UNA-620A System (Asahi Kasei) 170725Vensy PutraNo ratings yet

- COA of Riboflavin 5 - Sodium Phosphate 23120803Document2 pagesCOA of Riboflavin 5 - Sodium Phosphate 23120803Dwi Satria PutraNo ratings yet

- Ceramic Brush On: Technical Reference InformationDocument2 pagesCeramic Brush On: Technical Reference InformationAbdul RafiiNo ratings yet

- Online Quiz 1 (To Be Completed by 15th March)Document3 pagesOnline Quiz 1 (To Be Completed by 15th March)Paartiban PaneerselvamNo ratings yet

- Synthetic Rubber Putty Ultra: Technical Reference InformationDocument2 pagesSynthetic Rubber Putty Ultra: Technical Reference InformationAbdul RafiiNo ratings yet

- Optimization of Finishing Parameters To Impart Various Finishes On Different FibresDocument41 pagesOptimization of Finishing Parameters To Impart Various Finishes On Different Fibresnagpal_aakashNo ratings yet

- 15 COA-Resveratrol 98%Document1 page15 COA-Resveratrol 98%Beatrice DragomirNo ratings yet

- Certificate of AnalysisDocument1 pageCertificate of AnalysisbluemyNo ratings yet

- Rivastigmine DevelopmentDocument1 pageRivastigmine DevelopmentRaju GangadhariNo ratings yet

- Styrene Butadiene RubberDocument27 pagesStyrene Butadiene RubberabdulqadirNo ratings yet

- Puralcal PDS PDFDocument2 pagesPuralcal PDS PDFJoseph MontoyaNo ratings yet

- Reaction Setup: Find Out More atDocument1 pageReaction Setup: Find Out More atElysiaNo ratings yet

- LyocellDocument65 pagesLyocellImran Anwar100% (1)

- A01027 - 60mg Lemon 30mL COADocument7 pagesA01027 - 60mg Lemon 30mL COAalikiyaei.aiNo ratings yet

- Synthetic RubbersDocument59 pagesSynthetic RubbersshikaNo ratings yet

- Nan Ya Recicled PDFDocument20 pagesNan Ya Recicled PDFJUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- Ceramic Brush On - 95010K-1Document2 pagesCeramic Brush On - 95010K-1NazmiNo ratings yet

- Economical & Reliable Column: Tesa-PakDocument9 pagesEconomical & Reliable Column: Tesa-Pak김동완No ratings yet

- Certificate of Analysis - GlucosaminedocxDocument1 pageCertificate of Analysis - Glucosaminedocxiyas salihNo ratings yet

- Datasheet HFW1000Document3 pagesDatasheet HFW1000nikos.a.kyriakouNo ratings yet

- Reactores No ConvencionalesDocument28 pagesReactores No Convencionalesbruce callNo ratings yet

- Scheda Tecnica Passata 7% 12x500g - UKDocument1 pageScheda Tecnica Passata 7% 12x500g - UKhermrzNo ratings yet

- Session 3 B - TestingDocument98 pagesSession 3 B - TestingYogesh SharmaNo ratings yet

- Trickling Filter: by Akhmal and AimanDocument14 pagesTrickling Filter: by Akhmal and AimanAiman IsmailNo ratings yet

- TDS ELECTROLUBE UR5528 Black EngDocument4 pagesTDS ELECTROLUBE UR5528 Black EngscorpionbadshahNo ratings yet

- Waste MGMT & Env ControlDocument45 pagesWaste MGMT & Env ControlMasrawana Mohd Masran100% (1)

- CSM Technical SpecDocument1 pageCSM Technical SpecabasakNo ratings yet

- Name of Student: Sudipto BeheraDocument6 pagesName of Student: Sudipto BeheraSudipto BeheraNo ratings yet

- Insulation Jacket PropertiesDocument1 pageInsulation Jacket PropertiesEasy Energy SACNo ratings yet

- Blackberry Powder COA-WellgreenDocument1 pageBlackberry Powder COA-WellgreenRobiNo ratings yet

- OB 4 - Ultrasonic Irradiation Effect On The Activity of Platinum and Palladium Catalysts For Hydrogenation of Palm OleinDocument13 pagesOB 4 - Ultrasonic Irradiation Effect On The Activity of Platinum and Palladium Catalysts For Hydrogenation of Palm OleinzakwanmustafaNo ratings yet

- Tea Petronas SpecDocument1 pageTea Petronas SpecNhu TranNo ratings yet

- Chemdur - 54 Ceramic: Emulsified, Epoxy Mortar Tile GroutDocument3 pagesChemdur - 54 Ceramic: Emulsified, Epoxy Mortar Tile GroutghazanfarNo ratings yet

- Experiment No: 01 Experiment Name: Estimation of ScouringDocument7 pagesExperiment No: 01 Experiment Name: Estimation of ScouringMd. Sazzadul Islam100% (2)

- TDS Enus 0PDocument2 pagesTDS Enus 0Ptchaney84No ratings yet

- Untitled DiagramDocument1 pageUntitled DiagramMohd Izzat Abd GhaniNo ratings yet

- Spesifikasi Resin Kation Dan Anion Plant Demin-Blast Furnace Project Krakatau SteelDocument4 pagesSpesifikasi Resin Kation Dan Anion Plant Demin-Blast Furnace Project Krakatau SteelAllif RahmanNo ratings yet

- Light Fastness PDFDocument7 pagesLight Fastness PDFAmit SinghNo ratings yet

- Hoodia Gordonii Extract COADocument1 pageHoodia Gordonii Extract COAStefani StefaniNo ratings yet

- 06-77 Lab 05 Quality and TestingDocument5 pages06-77 Lab 05 Quality and TestingAsad Jamil RanaNo ratings yet

- weber_jointseal_PU_01Document3 pagesweber_jointseal_PU_01seylantechgroupNo ratings yet

- Rasberry Powder COA-WellgreenDocument1 pageRasberry Powder COA-WellgreenRobiNo ratings yet

- A Path To A Glove: 16-Curing Oven Section 1 (720 Sec. 120ºC)Document2 pagesA Path To A Glove: 16-Curing Oven Section 1 (720 Sec. 120ºC)Thaís SouzaNo ratings yet

- Amberlyst 15 (DOW)Document4 pagesAmberlyst 15 (DOW)RASHVEENA KAUR RANJIT SINGHNo ratings yet

- Характеристики покрытийDocument13 pagesХарактеристики покрытийgrandtechNo ratings yet

- Procurement & Preparation of Materials Batching of Concrete MixtureDocument4 pagesProcurement & Preparation of Materials Batching of Concrete MixtureQueen OndeNo ratings yet

- FT (SB) - PretreatmentDocument46 pagesFT (SB) - PretreatmentSubhenduNo ratings yet

- Operations System: Petrochemical Plant As AnDocument5 pagesOperations System: Petrochemical Plant As AnVikrant VishalNo ratings yet

- Membranes International CationDocument1 pageMembranes International CationjfdezmtnezNo ratings yet

- Business Plan 3Document9 pagesBusiness Plan 3Augustine Stanley Gomes (231011095)No ratings yet

- SM - Case Study - Reviving Khadi in India - V2Document4 pagesSM - Case Study - Reviving Khadi in India - V2praful s.gNo ratings yet

- Textile-Enhancers - PDF MomentiveDocument17 pagesTextile-Enhancers - PDF MomentiveGokhan RamiNo ratings yet

- Biodegradable Textiles, Recycling, and Sustainability AchievementDocument38 pagesBiodegradable Textiles, Recycling, and Sustainability AchievementSherin ShakerNo ratings yet

- Lyocell Fibre DocumentDocument4 pagesLyocell Fibre DocumentHossain RsfaNo ratings yet

- Fabric Study - (Textbook + Practical Manual) XIIDocument90 pagesFabric Study - (Textbook + Practical Manual) XIIAn Bn50% (2)

- STDS'M&SDocument8 pagesSTDS'M&SSazid Rahman100% (1)

- Textile SyllabusDocument203 pagesTextile SyllabusJagdish RudaniNo ratings yet

- History of CottonDocument17 pagesHistory of CottonRebeccaMastertonNo ratings yet

- ) .Mechanical, Chemical, Biological - Moving Towards Closed-Loop Bio-Based - Recycling in A Circular Economy of Sustainable TextilesDocument13 pages) .Mechanical, Chemical, Biological - Moving Towards Closed-Loop Bio-Based - Recycling in A Circular Economy of Sustainable TextilesAydee ChoqueNo ratings yet

- Study On Recycled Textiles and Textile Recyclability CHDocument45 pagesStudy On Recycled Textiles and Textile Recyclability CHMustafa Colkesen100% (1)

- Momenti Per Me CatalogDocument126 pagesMomenti Per Me Catalogdustofangel1No ratings yet

- Nonwovens enDocument36 pagesNonwovens enEn10139No ratings yet

- Nagpur Paper Final-1Document8 pagesNagpur Paper Final-1Prajwal NikharNo ratings yet

- Rayon DyeingDocument26 pagesRayon Dyeingtkr163100% (1)

- Beximco Fashions LimitedDocument16 pagesBeximco Fashions LimitedSarwar ShakilNo ratings yet

- The Environmental Aspects of SolventDocument5 pagesThe Environmental Aspects of SolventAditya ShrivastavaNo ratings yet

- (23000929 - Autex Research Journal) Comparison of Mechanical and Thermal Comfort Properties of Tencel Blended With Regenerated Fibers and Cotton Woven FabricsDocument6 pages(23000929 - Autex Research Journal) Comparison of Mechanical and Thermal Comfort Properties of Tencel Blended With Regenerated Fibers and Cotton Woven FabricsAmina BenrbehNo ratings yet

- Tencel Yarn PropertiesDocument1 pageTencel Yarn Propertiesnil006No ratings yet

- Kohinoor Textile MILLS, LTDDocument16 pagesKohinoor Textile MILLS, LTDBilal NaseerNo ratings yet

- Design To Reduce Chemical Impacts PDFDocument29 pagesDesign To Reduce Chemical Impacts PDFRayeddNo ratings yet

- It'S About FinishingDocument8 pagesIt'S About FinishingLievenVerraestNo ratings yet

- A Practical Guide To Fibre Science (PDFDrive)Document311 pagesA Practical Guide To Fibre Science (PDFDrive)Ola SeragNo ratings yet

- Post-Coronavirus - Defensive TextilesDocument19 pagesPost-Coronavirus - Defensive TextilesNataliaMaceiraNo ratings yet

- Revolution of Biotechnology in Finishing Sector of Textile: AbstractDocument12 pagesRevolution of Biotechnology in Finishing Sector of Textile: AbstractS BiswasNo ratings yet

- 3723 20789 1 PB PDFDocument7 pages3723 20789 1 PB PDFbayu priyatnaNo ratings yet

- Factors Influencing Comfort Properties of TextilesDocument6 pagesFactors Influencing Comfort Properties of TextilesMohammed Atiqul Hoque Chowdhury100% (1)

- New Fibres For Home Textile Lyocell FibreDocument5 pagesNew Fibres For Home Textile Lyocell FibreVasant KothariNo ratings yet

Fiber Ratio Testing Procedure

Fiber Ratio Testing Procedure

Uploaded by

Nadeem Ahmed0 ratings0% found this document useful (0 votes)

5 views4 pagesCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

5 views4 pagesFiber Ratio Testing Procedure

Fiber Ratio Testing Procedure

Uploaded by

Nadeem AhmedCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 4

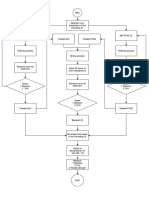

Fiber Blend Ratio Testing Procedure

Fiber Disolving Method (Step By Step)

If Fiber Blend is Protex+Tencel+Para Aramid+Antistatic

Dissolving Steps & Chemical Slection

Steps Chemical Dip Temprature Dip Time Disolved Fiber

Step-1 Di-Methyle 90~100 Co 10 Min Protex

Step-2 Formic Acid Normal Temp 06 Min Antistatic

Step-3 60%Sulfuric Acid+40%Water Normal Temp 20 Min Tencel

Survival Fiber Para Aramid

Fiber Blend Ratio Testing Procedure

Fiber Disolving Method (Step By Step)

If Fiber Blend is Protex+Cotton+Lenzing FR (Viscose)+Antistatic

Dissolving Steps & Chemical Slection

Steps Chemical Dip Temprature Dip Time Disolved Fiber

Step-1 Di-Methyle 90~100 Co 10 Min Protex

Step-2 Formic Acid Normal Temp 06 Min Antistatic

Step-3 80%Sulfuric Acid+20%Zinc Chloride 43 Co 160 Min L-FR

Survival Fiber Cotton

Fiber Blend Ratio Testing Procedure

Fiber Disolving Method (Step By Step)

If Fiber Blend is Polyester+Cotton

Dissolving Steps & Chemical Slection

Steps Chemical Dip Temprature Dip Time Disolved Fiber

Step-1 (For Polyester Dissolve) 70%Sulfuric Acid+30%Water Normal Temp 30 Min Polyester

Step-1 (For Cotton Dissolve) Formic Acid Normal Temp 06 Min Cotton

Survival Fiber (Polyester) / (Cotton)

Fiber Blend Ratio Testing Procedure

Fiber Disolving Method (Step By Step)

If Fiber Blend is Nylon+Cotton

Dissolving Steps & Chemical Slection

Steps Chemical Dip Temprature Dip Time Disolved Fiber

Step-1 Formic Acid Normal Temp 06 Min Nylon

Survival Fiber Cotton

You might also like

- Womenswear Forecast S S 24 SenseScapes enDocument18 pagesWomenswear Forecast S S 24 SenseScapes enRishab Manocha100% (1)

- Stress Cracking in PET BottlesDocument93 pagesStress Cracking in PET BottlesEliezer Gonzalez100% (3)

- Bamboo Tribe - Business Plan 2 - Lorejo Nicole Muffee C.Document30 pagesBamboo Tribe - Business Plan 2 - Lorejo Nicole Muffee C.Liza Cabalquinto Lorejo100% (3)

- Knit Garment STD Reqmnt CJB PDFDocument1 pageKnit Garment STD Reqmnt CJB PDFmishraajitNo ratings yet

- Prepared by : Muhammad Usman (IC-301) Rafia Himayel (IC-024) Ramsha Shamim (IC-012) Tehreem Sadaqat (IC-022)Document22 pagesPrepared by : Muhammad Usman (IC-301) Rafia Himayel (IC-024) Ramsha Shamim (IC-012) Tehreem Sadaqat (IC-022)RAMSHA RAMSHANo ratings yet

- Direct Esthetic Restorative MaterialsDocument31 pagesDirect Esthetic Restorative MaterialsNamrata Dalal LakraNo ratings yet

- Plastic Vial ProductsDocument2 pagesPlastic Vial ProductsaasdcdcNo ratings yet

- BQC kb03004 - Lowry Protein Assay Kit - ManualDocument16 pagesBQC kb03004 - Lowry Protein Assay Kit - ManualFaza FathiNo ratings yet

- Tanningg ProcessDocument8 pagesTanningg ProcessGaurav MalNo ratings yet

- Reverse OsmosisDocument131 pagesReverse OsmosisTaufiqTaufiq100% (6)

- SPS 370S - 2024 - Chapter 3.2Document52 pagesSPS 370S - 2024 - Chapter 3.2ziziphomkosana2003No ratings yet

- Training Material of UNA-620A System (Asahi Kasei) 170725Document33 pagesTraining Material of UNA-620A System (Asahi Kasei) 170725Vensy PutraNo ratings yet

- COA of Riboflavin 5 - Sodium Phosphate 23120803Document2 pagesCOA of Riboflavin 5 - Sodium Phosphate 23120803Dwi Satria PutraNo ratings yet

- Ceramic Brush On: Technical Reference InformationDocument2 pagesCeramic Brush On: Technical Reference InformationAbdul RafiiNo ratings yet

- Online Quiz 1 (To Be Completed by 15th March)Document3 pagesOnline Quiz 1 (To Be Completed by 15th March)Paartiban PaneerselvamNo ratings yet

- Synthetic Rubber Putty Ultra: Technical Reference InformationDocument2 pagesSynthetic Rubber Putty Ultra: Technical Reference InformationAbdul RafiiNo ratings yet

- Optimization of Finishing Parameters To Impart Various Finishes On Different FibresDocument41 pagesOptimization of Finishing Parameters To Impart Various Finishes On Different Fibresnagpal_aakashNo ratings yet

- 15 COA-Resveratrol 98%Document1 page15 COA-Resveratrol 98%Beatrice DragomirNo ratings yet

- Certificate of AnalysisDocument1 pageCertificate of AnalysisbluemyNo ratings yet

- Rivastigmine DevelopmentDocument1 pageRivastigmine DevelopmentRaju GangadhariNo ratings yet

- Styrene Butadiene RubberDocument27 pagesStyrene Butadiene RubberabdulqadirNo ratings yet

- Puralcal PDS PDFDocument2 pagesPuralcal PDS PDFJoseph MontoyaNo ratings yet

- Reaction Setup: Find Out More atDocument1 pageReaction Setup: Find Out More atElysiaNo ratings yet

- LyocellDocument65 pagesLyocellImran Anwar100% (1)

- A01027 - 60mg Lemon 30mL COADocument7 pagesA01027 - 60mg Lemon 30mL COAalikiyaei.aiNo ratings yet

- Synthetic RubbersDocument59 pagesSynthetic RubbersshikaNo ratings yet

- Nan Ya Recicled PDFDocument20 pagesNan Ya Recicled PDFJUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- Ceramic Brush On - 95010K-1Document2 pagesCeramic Brush On - 95010K-1NazmiNo ratings yet

- Economical & Reliable Column: Tesa-PakDocument9 pagesEconomical & Reliable Column: Tesa-Pak김동완No ratings yet

- Certificate of Analysis - GlucosaminedocxDocument1 pageCertificate of Analysis - Glucosaminedocxiyas salihNo ratings yet

- Datasheet HFW1000Document3 pagesDatasheet HFW1000nikos.a.kyriakouNo ratings yet

- Reactores No ConvencionalesDocument28 pagesReactores No Convencionalesbruce callNo ratings yet

- Scheda Tecnica Passata 7% 12x500g - UKDocument1 pageScheda Tecnica Passata 7% 12x500g - UKhermrzNo ratings yet

- Session 3 B - TestingDocument98 pagesSession 3 B - TestingYogesh SharmaNo ratings yet

- Trickling Filter: by Akhmal and AimanDocument14 pagesTrickling Filter: by Akhmal and AimanAiman IsmailNo ratings yet

- TDS ELECTROLUBE UR5528 Black EngDocument4 pagesTDS ELECTROLUBE UR5528 Black EngscorpionbadshahNo ratings yet

- Waste MGMT & Env ControlDocument45 pagesWaste MGMT & Env ControlMasrawana Mohd Masran100% (1)

- CSM Technical SpecDocument1 pageCSM Technical SpecabasakNo ratings yet

- Name of Student: Sudipto BeheraDocument6 pagesName of Student: Sudipto BeheraSudipto BeheraNo ratings yet

- Insulation Jacket PropertiesDocument1 pageInsulation Jacket PropertiesEasy Energy SACNo ratings yet

- Blackberry Powder COA-WellgreenDocument1 pageBlackberry Powder COA-WellgreenRobiNo ratings yet

- OB 4 - Ultrasonic Irradiation Effect On The Activity of Platinum and Palladium Catalysts For Hydrogenation of Palm OleinDocument13 pagesOB 4 - Ultrasonic Irradiation Effect On The Activity of Platinum and Palladium Catalysts For Hydrogenation of Palm OleinzakwanmustafaNo ratings yet

- Tea Petronas SpecDocument1 pageTea Petronas SpecNhu TranNo ratings yet

- Chemdur - 54 Ceramic: Emulsified, Epoxy Mortar Tile GroutDocument3 pagesChemdur - 54 Ceramic: Emulsified, Epoxy Mortar Tile GroutghazanfarNo ratings yet

- Experiment No: 01 Experiment Name: Estimation of ScouringDocument7 pagesExperiment No: 01 Experiment Name: Estimation of ScouringMd. Sazzadul Islam100% (2)

- TDS Enus 0PDocument2 pagesTDS Enus 0Ptchaney84No ratings yet

- Untitled DiagramDocument1 pageUntitled DiagramMohd Izzat Abd GhaniNo ratings yet

- Spesifikasi Resin Kation Dan Anion Plant Demin-Blast Furnace Project Krakatau SteelDocument4 pagesSpesifikasi Resin Kation Dan Anion Plant Demin-Blast Furnace Project Krakatau SteelAllif RahmanNo ratings yet

- Light Fastness PDFDocument7 pagesLight Fastness PDFAmit SinghNo ratings yet

- Hoodia Gordonii Extract COADocument1 pageHoodia Gordonii Extract COAStefani StefaniNo ratings yet

- 06-77 Lab 05 Quality and TestingDocument5 pages06-77 Lab 05 Quality and TestingAsad Jamil RanaNo ratings yet

- weber_jointseal_PU_01Document3 pagesweber_jointseal_PU_01seylantechgroupNo ratings yet

- Rasberry Powder COA-WellgreenDocument1 pageRasberry Powder COA-WellgreenRobiNo ratings yet

- A Path To A Glove: 16-Curing Oven Section 1 (720 Sec. 120ºC)Document2 pagesA Path To A Glove: 16-Curing Oven Section 1 (720 Sec. 120ºC)Thaís SouzaNo ratings yet

- Amberlyst 15 (DOW)Document4 pagesAmberlyst 15 (DOW)RASHVEENA KAUR RANJIT SINGHNo ratings yet

- Характеристики покрытийDocument13 pagesХарактеристики покрытийgrandtechNo ratings yet

- Procurement & Preparation of Materials Batching of Concrete MixtureDocument4 pagesProcurement & Preparation of Materials Batching of Concrete MixtureQueen OndeNo ratings yet

- FT (SB) - PretreatmentDocument46 pagesFT (SB) - PretreatmentSubhenduNo ratings yet

- Operations System: Petrochemical Plant As AnDocument5 pagesOperations System: Petrochemical Plant As AnVikrant VishalNo ratings yet

- Membranes International CationDocument1 pageMembranes International CationjfdezmtnezNo ratings yet

- Business Plan 3Document9 pagesBusiness Plan 3Augustine Stanley Gomes (231011095)No ratings yet

- SM - Case Study - Reviving Khadi in India - V2Document4 pagesSM - Case Study - Reviving Khadi in India - V2praful s.gNo ratings yet

- Textile-Enhancers - PDF MomentiveDocument17 pagesTextile-Enhancers - PDF MomentiveGokhan RamiNo ratings yet

- Biodegradable Textiles, Recycling, and Sustainability AchievementDocument38 pagesBiodegradable Textiles, Recycling, and Sustainability AchievementSherin ShakerNo ratings yet

- Lyocell Fibre DocumentDocument4 pagesLyocell Fibre DocumentHossain RsfaNo ratings yet

- Fabric Study - (Textbook + Practical Manual) XIIDocument90 pagesFabric Study - (Textbook + Practical Manual) XIIAn Bn50% (2)

- STDS'M&SDocument8 pagesSTDS'M&SSazid Rahman100% (1)

- Textile SyllabusDocument203 pagesTextile SyllabusJagdish RudaniNo ratings yet

- History of CottonDocument17 pagesHistory of CottonRebeccaMastertonNo ratings yet

- ) .Mechanical, Chemical, Biological - Moving Towards Closed-Loop Bio-Based - Recycling in A Circular Economy of Sustainable TextilesDocument13 pages) .Mechanical, Chemical, Biological - Moving Towards Closed-Loop Bio-Based - Recycling in A Circular Economy of Sustainable TextilesAydee ChoqueNo ratings yet

- Study On Recycled Textiles and Textile Recyclability CHDocument45 pagesStudy On Recycled Textiles and Textile Recyclability CHMustafa Colkesen100% (1)

- Momenti Per Me CatalogDocument126 pagesMomenti Per Me Catalogdustofangel1No ratings yet

- Nonwovens enDocument36 pagesNonwovens enEn10139No ratings yet

- Nagpur Paper Final-1Document8 pagesNagpur Paper Final-1Prajwal NikharNo ratings yet

- Rayon DyeingDocument26 pagesRayon Dyeingtkr163100% (1)

- Beximco Fashions LimitedDocument16 pagesBeximco Fashions LimitedSarwar ShakilNo ratings yet

- The Environmental Aspects of SolventDocument5 pagesThe Environmental Aspects of SolventAditya ShrivastavaNo ratings yet

- (23000929 - Autex Research Journal) Comparison of Mechanical and Thermal Comfort Properties of Tencel Blended With Regenerated Fibers and Cotton Woven FabricsDocument6 pages(23000929 - Autex Research Journal) Comparison of Mechanical and Thermal Comfort Properties of Tencel Blended With Regenerated Fibers and Cotton Woven FabricsAmina BenrbehNo ratings yet

- Tencel Yarn PropertiesDocument1 pageTencel Yarn Propertiesnil006No ratings yet

- Kohinoor Textile MILLS, LTDDocument16 pagesKohinoor Textile MILLS, LTDBilal NaseerNo ratings yet

- Design To Reduce Chemical Impacts PDFDocument29 pagesDesign To Reduce Chemical Impacts PDFRayeddNo ratings yet

- It'S About FinishingDocument8 pagesIt'S About FinishingLievenVerraestNo ratings yet

- A Practical Guide To Fibre Science (PDFDrive)Document311 pagesA Practical Guide To Fibre Science (PDFDrive)Ola SeragNo ratings yet

- Post-Coronavirus - Defensive TextilesDocument19 pagesPost-Coronavirus - Defensive TextilesNataliaMaceiraNo ratings yet

- Revolution of Biotechnology in Finishing Sector of Textile: AbstractDocument12 pagesRevolution of Biotechnology in Finishing Sector of Textile: AbstractS BiswasNo ratings yet

- 3723 20789 1 PB PDFDocument7 pages3723 20789 1 PB PDFbayu priyatnaNo ratings yet

- Factors Influencing Comfort Properties of TextilesDocument6 pagesFactors Influencing Comfort Properties of TextilesMohammed Atiqul Hoque Chowdhury100% (1)

- New Fibres For Home Textile Lyocell FibreDocument5 pagesNew Fibres For Home Textile Lyocell FibreVasant KothariNo ratings yet