Professional Documents

Culture Documents

G8400-90015_Schedule (1)

G8400-90015_Schedule (1)

Uploaded by

alpatsukruCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G8400-90015_Schedule (1)

G8400-90015_Schedule (1)

Uploaded by

alpatsukruCopyright:

Available Formats

3 Maintenance

Scheduling Maintenance

Scheduling Maintenance

Routine maintenance extends the operating life of the components, and lets the

Agilent 7800/7850/7900 ICP-MS perform at optimum level.

The following table shows the maintenance items/frequency for the ICP-MS.

Table 6. Maintenance Schedule

Frequency Component Task/Action Remarks

Daily Argon gas Check argon gas pressure

(As a matter of routine, check daily and volume

before starting work and over the

course of daily analysis) Drain vessel Check, empty if required Refer to note in Chapter 2,

“Precautions”

Sample uptake tubing Check for

damage/deterioration

Weekly Sampling cone, Skimmer cone Check orifice for foreign Clean when necessary

matter, deformation and

enlargement

Monthly Foreline Pump Check oil level and color.

Check the exhaust hose from

foreline pump is not

damaged, not clogged, and

surely connected.

Check that the ballast valve is

open. (Only for NeoDry36E)

Nebulizer Run Nebulizer test, take

appropriate action as

indicated

Shield contact, Torch box Clean

contact plate Replace shield plate as

needed

Cooling fluid Check level and condition*1

6 Months Foreline Pump Change oil (refer to

page 104)

Annually Foreline Pump oil mist filter Check / replace mist filter

Water strainer Check and clean

Cooling Fluid Replace

50 7800/7850/7900 ICP-MS Hardware Maintenance Manual

3 Maintenance

Scheduling Maintenance

Table 6. Maintenance Schedule (continued)

Frequency Component Task/Action Remarks

4 Years Foreline Pump (NeoDry36E) Maintenance free for 4 years Replace the pump as

needed*2

Periodically Sample Introduction area parts: Clean

(Maintenance frequency of these such as Spray chamber, End

components is highly dependent cap

on lab conditions, sample

throughput, and sample type. They Torch Clean Replace as needed

should be checked periodically, at

Electron Multiplier Check Replace as needed*3

least on an annual basis, and

appropriate action taken) Plasma gas, auxiliary gas Check Replace as needed

tubing

Argon gas filter Replace Replace as needed

Graphite gasket Replace Replace when surface or

shape is damaged.

Extraction/Omega Lenses Check Clean as needed

(refer to page 97)

Octopole Replace Replace as needed

Cell entrance lens, Cell exit lens, Clean Clean as needed

Plate bias lens, Deflect lens

*1 Generally the cooling fluid requires replacement annually, however, if the cooling fluid shows noticeable

deterioration it may be necessary to replace sooner.

*2Contact your Agilent representative for the pump replacement after 4 years use.

*3 Contact your Agilent representative to arrange engineer visit if replacement needed. Note: The time for EM

replacement can be judged by the EM voltage (Analog HV and Pulse HV). The EM can be used until the

Analog HV reaches 3500 V or the Pulse HV reaches 2000 V, after adjusting the EM voltage. However, it is

recommended to replace EM well in advance.

Refer to the following sections on Maintenance for further guidance about when

NOTE maintenance may be needed.

The maintenance frequency is highly dependent on lab conditions, sample

throughput, and sample type.

Depending on the samples introduced, the foreline pump oil may degrade

C AU T I O N sooner than normal and turn black in color. Change the oil before the six-month

period if this occurs. Continued use with degraded oil may result in damage to

the foreline pump. Be aware that coverage does not extend to maintenance

neglect.

7800/7850/7900 ICP-MS Hardware Maintenance Manual 51

3 Maintenance

Scheduling Maintenance

The frequency of maintenance indicated for these parts is a general guideline

NOTE only. Actual cleaning regimen may be infrequent, dependant on local

lab/workload variables.

This chapter contains operator maintenance procedures for the ICP-MS.

To repair any component not listed, call your Agilent Technologies service

representative.

For maintenance of the computer workstation or a peripheral, refer to the

manuals for that equipment.

52 7800/7850/7900 ICP-MS Hardware Maintenance Manual

You might also like

- Maintenance & Troubleshoot AHUDocument11 pagesMaintenance & Troubleshoot AHUEva Sulistiany100% (2)

- PSA Oxymat Servicio de MantenimientoDocument28 pagesPSA Oxymat Servicio de Mantenimientovictor hugo valqui lopezNo ratings yet

- AIB XRHS 836 CD ENDocument27 pagesAIB XRHS 836 CD ENcristianrblr100% (1)

- Wartsila - 18V34SG Maintenance ScheduleDocument8 pagesWartsila - 18V34SG Maintenance ScheduleironiteNo ratings yet

- API DocumentDocument5,210 pagesAPI Documentfjl100% (1)

- G3666-90005_ScheduleDocument3 pagesG3666-90005_SchedulealpatsukruNo ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- maintenance chart - 8UDocument16 pagesmaintenance chart - 8UVofchikNo ratings yet

- Filters For Compressed AirDocument11 pagesFilters For Compressed AirNiaz MalikNo ratings yet

- Picture 1Document1 pagePicture 1bashar3324No ratings yet

- Worthington IA Dryer PM PlanDocument1 pageWorthington IA Dryer PM PlanUmair A. KhanNo ratings yet

- Honeywell Gas Detector MaintenanceDocument1 pageHoneywell Gas Detector MaintenanceXiao Zhen TanNo ratings yet

- Hpdi Main ScheduleDocument2 pagesHpdi Main Schedulefabbromauricioyahoo.com.arNo ratings yet

- Engine Power Train Case Final Drive Oil & Coolant Type and Capacity NO. Unit Komatsu D85Ess-2Document5 pagesEngine Power Train Case Final Drive Oil & Coolant Type and Capacity NO. Unit Komatsu D85Ess-2luthelapu4100% (2)

- Maintenance List - AK Stage V - 2020Document4 pagesMaintenance List - AK Stage V - 2020André SilvaNo ratings yet

- Yudo Standard Maintanance Manual (Eng) 120523Document16 pagesYudo Standard Maintanance Manual (Eng) 120523hasan 125No ratings yet

- Fd4.25f Alegria Maintance Checklist 3 2012-01Document1 pageFd4.25f Alegria Maintance Checklist 3 2012-01Mosab BabikirNo ratings yet

- DX Service and MaintDocument20 pagesDX Service and MaintCarlos MenaNo ratings yet

- MotorsDocument1 pageMotorsMamoonurrasheedNo ratings yet

- 1b PARTE MERCURY V6Document9 pages1b PARTE MERCURY V6Antonio VillafuerteNo ratings yet

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- Troubeshootings 8 Wheeler DHTC Detc-1Document27 pagesTroubeshootings 8 Wheeler DHTC Detc-1khan11k100% (1)

- Manual PDS55S - 5B2 - E1 - (2) (39600 - 78420)Document22 pagesManual PDS55S - 5B2 - E1 - (2) (39600 - 78420)singoNo ratings yet

- AHU Checklsit - Dilapidation SurveyDocument2 pagesAHU Checklsit - Dilapidation SurveyibrahimsirpiNo ratings yet

- Manual Mantenimiento Yanmar 4TNV98TDocument29 pagesManual Mantenimiento Yanmar 4TNV98Tdavid ignacioNo ratings yet

- Calavar Condor 446q8 Operators Maintenance and Part ManualDocument20 pagesCalavar Condor 446q8 Operators Maintenance and Part ManualMichelle100% (63)

- Maintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyDocument1 pageMaintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyGaurav JhaNo ratings yet

- Fuel System: 1. Description 2. Fuel Filter (Paper-Element Cartridge Type)Document8 pagesFuel System: 1. Description 2. Fuel Filter (Paper-Element Cartridge Type)Purnama AbhieNo ratings yet

- ReferenceDocument2 pagesReferenceToan VanNo ratings yet

- Section 5: Maintenance, Repair and Adjustment: 5.1 Maintenance Schedule 5.1. List of Required Regular Maintenance WorksDocument1 pageSection 5: Maintenance, Repair and Adjustment: 5.1 Maintenance Schedule 5.1. List of Required Regular Maintenance WorksVijay BhureNo ratings yet

- 5 Liter Serv Maint Log - A-1007RevIDocument2 pages5 Liter Serv Maint Log - A-1007RevIsamsonNo ratings yet

- Baghouse Collectors (Non-Compressed Air) Examples: Rugged Pleat (RP) & RF SeriesDocument2 pagesBaghouse Collectors (Non-Compressed Air) Examples: Rugged Pleat (RP) & RF SeriesALI TAVAKOLINIANo ratings yet

- Cooling Tower ChecklistDocument2 pagesCooling Tower ChecklistLaiq100% (5)

- Chiller MaintenanceDocument4 pagesChiller MaintenancePhuNguyenHoangNo ratings yet

- Maintenance ProgramDocument3 pagesMaintenance ProgramEdgar Jr SuyatNo ratings yet

- Ce 41Document40 pagesCe 41Ravi Shankar JoshiNo ratings yet

- Fifi SystemDocument21 pagesFifi Systemwashi1349No ratings yet

- Check List For Commissioning Fire Protection SystemDocument4 pagesCheck List For Commissioning Fire Protection SystemMANIKANDANo ratings yet

- Maintenance PlanDocument7 pagesMaintenance PlanAris Bagoes MaladhiNo ratings yet

- Soft TROUBLE SHOOTING & PMPDocument10 pagesSoft TROUBLE SHOOTING & PMPLaur IriNo ratings yet

- Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingDocument4 pagesCustomer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Chapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsDocument16 pagesChapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsГоран ГорановNo ratings yet

- 420 Maintenance ScheduleDocument4 pages420 Maintenance Scheduleicyan.ahmad.tiNo ratings yet

- SM 112Document210 pagesSM 112jhon greigNo ratings yet

- IMEE-6 Maintenance PDFDocument8 pagesIMEE-6 Maintenance PDFHirakNo ratings yet

- 1 Intro and Pumps (0321)Document42 pages1 Intro and Pumps (0321)Jorge RicaurteNo ratings yet

- Service Routines HV2-210Document1 pageService Routines HV2-210Suraj SinghNo ratings yet

- Manual XP-702 SET (En) PDFDocument28 pagesManual XP-702 SET (En) PDFnguyễn quốc hoànNo ratings yet

- GC Recommended Maintence ScheduleDocument2 pagesGC Recommended Maintence ScheduleGastón G.No ratings yet

- Agilent GC System Recommended Maintenance ScheduleDocument2 pagesAgilent GC System Recommended Maintenance ScheduleLuthfi Nurfari ArifinNo ratings yet

- Mercury 115 Manual 1bDocument13 pagesMercury 115 Manual 1bMomed MdNo ratings yet

- Maintenance Manual - TD-TSP-0004-2A PDFDocument19 pagesMaintenance Manual - TD-TSP-0004-2A PDFSidhartha Mallick100% (1)

- Excessive Exhaust S M O K E: Downloaded From Manuals Search EngineDocument11 pagesExcessive Exhaust S M O K E: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- TP1033 WebDocument2 pagesTP1033 Webnunezjorgeaaol.comNo ratings yet

- Series: Oil Sampling ValveDocument2 pagesSeries: Oil Sampling Valvemarran almarranyNo ratings yet

- Yearly RoutinesDocument8 pagesYearly RoutinesRuwinda BandaraNo ratings yet

- Cooling Tower MaintenanceDocument1 pageCooling Tower MaintenanceUrvashiNo ratings yet

- KOWA Procedure 1Document46 pagesKOWA Procedure 1Sonofwill Auger OdagledNo ratings yet

- The New Epoch - Character Sheet 2Document2 pagesThe New Epoch - Character Sheet 2Jonathan FriedmanNo ratings yet

- Drone Delivery Risk Analysis ReportDocument16 pagesDrone Delivery Risk Analysis Reportfamily imtiazNo ratings yet

- Advanced Digital Speedometer For Vehicles and Machinaries (Used As Odometer Too)Document27 pagesAdvanced Digital Speedometer For Vehicles and Machinaries (Used As Odometer Too)Shanky Kumar100% (2)

- SAP HANA EIM Installation and Configuration Guide enDocument598 pagesSAP HANA EIM Installation and Configuration Guide enGabriele ZuccaroNo ratings yet

- Quality Risk Management Ich Q9Document57 pagesQuality Risk Management Ich Q9prakash deshmukhNo ratings yet

- Enrique Granados: Danza Espanola No.2 (Oriental)Document7 pagesEnrique Granados: Danza Espanola No.2 (Oriental)JuanSubelsaNo ratings yet

- API 614 Comments Mac-Su-3563-EDocument17 pagesAPI 614 Comments Mac-Su-3563-EJESUSNo ratings yet

- Iwt PracticalDocument18 pagesIwt Practical[04] - Abrar ShahNo ratings yet

- Digital Twins For Precision HealthcareDocument20 pagesDigital Twins For Precision HealthcarevikaashNo ratings yet

- QELQ2430-02 SCOM GC LRC SalesgramDocument8 pagesQELQ2430-02 SCOM GC LRC SalesgramCarlos Indigoyen LimaymantaNo ratings yet

- Controlling Children Using ComputerDocument2 pagesControlling Children Using ComputerLeliNo ratings yet

- Tugas DMD GROUP 01Document8 pagesTugas DMD GROUP 01ulviqhj354No ratings yet

- ZTT Fittings 21-XJ03014 7.31Document26 pagesZTT Fittings 21-XJ03014 7.31jaiver28No ratings yet

- Crouzet Millenium - Mascable Programming CableDocument2 pagesCrouzet Millenium - Mascable Programming CableFeras AdvertisementsNo ratings yet

- Starting An IVR Transaction Activation - PressDocument2 pagesStarting An IVR Transaction Activation - Presstakoda johnstoneNo ratings yet

- System InformationDocument26 pagesSystem InformationSala SotoNo ratings yet

- 2 Combination StrategyDocument4 pages2 Combination Strategyxomavi8122No ratings yet

- Trimod Besta - Complete Catalogue (LTKEN1610)Document46 pagesTrimod Besta - Complete Catalogue (LTKEN1610)gustavoaponteunoNo ratings yet

- Frequency Response Analysis and Short-Circuit Impedance Measurement in Detection of Winding Deformation Within Power TransformersDocument8 pagesFrequency Response Analysis and Short-Circuit Impedance Measurement in Detection of Winding Deformation Within Power TransformersRoyer Guerra huamanNo ratings yet

- Fault Code 27 Fmi 7 fc64 Fmi7 Set Active After Eca Installation TAIB0996Document3 pagesFault Code 27 Fmi 7 fc64 Fmi7 Set Active After Eca Installation TAIB0996rpmjasa0No ratings yet

- Full Auto Vacuum BCT Production Line - TenghuDocument11 pagesFull Auto Vacuum BCT Production Line - TenghuImad HassenNo ratings yet

- Osmobsc Vty ReferenceDocument272 pagesOsmobsc Vty Referencelong leeNo ratings yet

- PARTIIOUTPUTDEVICEDocument333 pagesPARTIIOUTPUTDEVICEFiras BEN HMIDANo ratings yet

- Ee6402 Scad MSM PDFDocument111 pagesEe6402 Scad MSM PDFJecintha CarolinNo ratings yet

- Film Sound Production Project BriefDocument3 pagesFilm Sound Production Project BriefREYNOLD ABRAHAMNo ratings yet

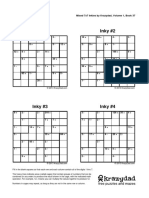

- 7x Inky Puzzles by KrazyDad Book 37Document3 pages7x Inky Puzzles by KrazyDad Book 37jessyNo ratings yet

- List Alat DopDocument2 pagesList Alat Dopmuayyedboys95No ratings yet

- Window FunctionsDocument29 pagesWindow FunctionsdiekoNo ratings yet

- KV DH1L 5 - DatasheetDocument1 pageKV DH1L 5 - DatasheetWSR indiaNo ratings yet