Professional Documents

Culture Documents

G3666-90005_Schedule

G3666-90005_Schedule

Uploaded by

alpatsukruCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G3666-90005_Schedule

G3666-90005_Schedule

Uploaded by

alpatsukruCopyright:

Available Formats

3 Maintenance

Scheduling Maintenance

Scheduling Maintenance

Routine maintenance extends the operating life of the components, and lets the

Agilent 8900 Triple Quadrupole ICP-MS perform at optimum level.

The following table shows the maintenance items/frequency for the 8900.

Table 3. Maintenance Schedule

Frequency Component Task/Action Remarks

Daily Argon gas Check argon gas pressure

As a matter of routine, check these and volume

items before starting work daily

and over the course of daily Drain vessel Check, empty if required Refer to note in

analysis Chapter 2, “Precautions”

Sample uptake tubing Check for

damage/deterioration

Weekly Sampling cone, Skimmer cone Check orifice for foreign Clean if required

matter, deformation and

enlargement

Monthly Foreline Pump (MS40+ and Check oil level and color.

NeoDry36E)

Check that the exhaust hose

from foreline pump is not

damaged or clogged, and is

securely connected.

Check that the ballast valve is

open. (Only for NeoDry36E)

Nebulizer Run Nebulizer test, take

appropriate action as

indicated

Shield contact, Torch box Clean

contact plate

Cooling fluid Check level and condition*1

6 Months Foreline Pump (MS40+) Change oil

50 8900 Triple Quadrupole ICP-MS Hardware Maintenance Manual

3 Maintenance

Scheduling Maintenance

Table 3. Maintenance Schedule (continued)

Frequency Component Task/Action Remarks

Annually Foreline Pump oil mist filter Check / replace mist filter

(MS40+)

Water strainer Check and clean

Cooling Fluid Replace

Argon gas purifier (Only for 8900 Replace Refer to the argon gas

#100/#200) purifier’s (Big Universal

Trap’s) instruction.

4 Years Foreline Pump (NeoDry36E) Maintenance free for 4 years Replace the pump as

needed*2

Periodically Sample Introduction area parts: Clean

Maintenance frequency of these such as Spray chamber, End cap

components is highly dependent

on lab conditions and sample Torch Clean Replace as needed

throughput. Check them Electron Multiplier Check Replace as needed *3

periodically, at least annually and

take appropriate action. Plasma gas, auxiliary gas tubing Check Replace as needed

Argon gas and Optional gas filter Replace Replace as needed

Graphite gasket Replace Replace when surface or

shape is damaged.

Extraction/Omega Lenses Check Clean as needed

*1 Generally the cooling fluid requires replacement annually, however, if the cooling fluid shows noticeable

deterioration it may be necessary to replace sooner.

*2 Contact your Agilent representative for the pump replacement after 4 years use.

*3 Contact your Agilent representative to arrange engineer visit if replacement needed. Note: The time for EM

replacement can be judged by the EM voltage (Analog HV and Pulse HV). The EM can be used until the

Analog HV reaches 3500V or the Pulse HV reaches 2000V, after adjusting the EM voltage. However, it is

recommended to replace EM well in advance.

Depending on the samples introduced, the foreline pump oil may degrade

C AU T I O N sooner than normal and turn black in color. Change the oil before the six-month

period if this occurs. Continued use with degraded oil may result in damage to

the foreline pump. Be aware that warranty coverage does not extend to

maintenance neglect.

8900 Triple Quadrupole ICP-MS Hardware Maintenance Manual 51

3 Maintenance

Scheduling Maintenance

The lifetime of the argon gas purifier (Big Universal Trap) may decrease if the

C AU T I O N argon gas is not pure enough. Use enough high-grade argon gas as described

in the Site Preparation Checklist for trace Silicon and Sulfur applications.

The frequency of maintenance indicated for these parts is a general guideline

NOTE only. Actual cleaning regimen may be infrequent, depending on local

lab/workload variables.

This chapter contains maintenance procedures for the Agilent 8900 that can be

performed by your lab personnel.

To repair any Agilent 8900 component that is not listed, call your Agilent

Technologies service representative. For maintenance of the MassHunter

Workstation or a peripheral, refer to the manuals for that equipment.

52 8900 Triple Quadrupole ICP-MS Hardware Maintenance Manual

You might also like

- Maintenance Program JenbacherDocument11 pagesMaintenance Program JenbacherHelder Pinto100% (1)

- Maintenance & Troubleshoot AHUDocument11 pagesMaintenance & Troubleshoot AHUEva Sulistiany100% (2)

- Instruction For RBP250-3 and RBP300-3: Anti-Heeling PumpDocument13 pagesInstruction For RBP250-3 and RBP300-3: Anti-Heeling PumpJan MaarschalkerweerdNo ratings yet

- PSA Oxymat Servicio de MantenimientoDocument28 pagesPSA Oxymat Servicio de Mantenimientovictor hugo valqui lopezNo ratings yet

- AIB XRHS 836 CD ENDocument27 pagesAIB XRHS 836 CD ENcristianrblr100% (1)

- Wartsila - 18V34SG Maintenance ScheduleDocument8 pagesWartsila - 18V34SG Maintenance ScheduleironiteNo ratings yet

- Eastar SpecificationsDocument2 pagesEastar SpecificationsUmar ShamsudinNo ratings yet

- G8400-90015_Schedule (1)Document3 pagesG8400-90015_Schedule (1)alpatsukruNo ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- maintenance chart - 8UDocument16 pagesmaintenance chart - 8UVofchikNo ratings yet

- Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingDocument4 pagesCustomer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- Filters For Compressed AirDocument11 pagesFilters For Compressed AirNiaz MalikNo ratings yet

- Maintenance Manual - TD-TSP-0004-2A PDFDocument19 pagesMaintenance Manual - TD-TSP-0004-2A PDFSidhartha Mallick100% (1)

- Picture 1Document1 pagePicture 1bashar3324No ratings yet

- MOL MOL Pakistan Oil & Gas Co. B.V. Makori Gas Processing FacilityDocument2 pagesMOL MOL Pakistan Oil & Gas Co. B.V. Makori Gas Processing FacilityJaadi 786No ratings yet

- 1b PARTE MERCURY V6Document9 pages1b PARTE MERCURY V6Antonio VillafuerteNo ratings yet

- Power Transformer Inspection and Maintenance Essential: Engr. Iñigo V. Escopete, JR., PeeDocument21 pagesPower Transformer Inspection and Maintenance Essential: Engr. Iñigo V. Escopete, JR., PeeSun TzuNo ratings yet

- Fd4.25f Alegria Maintance Checklist 3 2012-01Document1 pageFd4.25f Alegria Maintance Checklist 3 2012-01Mosab BabikirNo ratings yet

- Service Manual: Troubleshooting Guide and Instruction For ServiceDocument28 pagesService Manual: Troubleshooting Guide and Instruction For Servicewtf911No ratings yet

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- Manual Mantenimiento Yanmar 4TNV98TDocument29 pagesManual Mantenimiento Yanmar 4TNV98Tdavid ignacioNo ratings yet

- VR8304 Intermittent Pilot Combination Gas Control: ApplicationDocument8 pagesVR8304 Intermittent Pilot Combination Gas Control: ApplicationGregorio Mata MartínezNo ratings yet

- Fifi SystemDocument21 pagesFifi Systemwashi1349No ratings yet

- KOWA Procedure 1Document46 pagesKOWA Procedure 1Sonofwill Auger OdagledNo ratings yet

- KOWADocument111 pagesKOWAgilar herliana putraNo ratings yet

- Turbocharger Troubleshooting: 1 Compressor SurgingDocument3 pagesTurbocharger Troubleshooting: 1 Compressor SurgingJatin JainNo ratings yet

- 360-0027-01rD AP20S ManualDocument16 pages360-0027-01rD AP20S ManualetchegarayfNo ratings yet

- Algas Direct Fired RepairDocument6 pagesAlgas Direct Fired RepairJessie JohnsonNo ratings yet

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-20Document4 pagesPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-20Tolias Egw100% (1)

- Compressed Air Preventative Maintenance: Checklist & LogsDocument3 pagesCompressed Air Preventative Maintenance: Checklist & Logsvibin globalNo ratings yet

- Hpdi Main ScheduleDocument2 pagesHpdi Main Schedulefabbromauricioyahoo.com.arNo ratings yet

- General Pump Inspection and Maintenance Schedule: Split Case PumpsDocument1 pageGeneral Pump Inspection and Maintenance Schedule: Split Case PumpsNunung MCANo ratings yet

- Engine Power Train Case Final Drive Oil & Coolant Type and Capacity NO. Unit Komatsu D85Ess-2Document5 pagesEngine Power Train Case Final Drive Oil & Coolant Type and Capacity NO. Unit Komatsu D85Ess-2luthelapu4100% (2)

- Mooney M20 100hour PDFDocument2 pagesMooney M20 100hour PDFsplyn100% (1)

- 420 Maintenance ScheduleDocument4 pages420 Maintenance Scheduleicyan.ahmad.tiNo ratings yet

- Light Repair and WashingDocument29 pagesLight Repair and Washingfrenz2kiranNo ratings yet

- Procedure of Maintenance of DG SETDocument8 pagesProcedure of Maintenance of DG SETVatsavai Appala Narasimha RajuNo ratings yet

- Introduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownDocument51 pagesIntroduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownKenneth John BrownNo ratings yet

- Mercury 115 Manual 1bDocument13 pagesMercury 115 Manual 1bMomed MdNo ratings yet

- Scanboilerr TextDocument7 pagesScanboilerr TextAntonio AvilesNo ratings yet

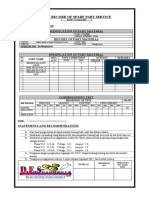

- Test Record of Spare Part Service: Spesification of Part Material History of Part MaterialDocument4 pagesTest Record of Spare Part Service: Spesification of Part Material History of Part MaterialKhalidperkasaNo ratings yet

- Series: Oil Sampling ValveDocument2 pagesSeries: Oil Sampling Valvemarran almarranyNo ratings yet

- Ficha Tecnica Medidor Gpi 01a31gmDocument2 pagesFicha Tecnica Medidor Gpi 01a31gmGustavo EgasNo ratings yet

- Dwifarid Alifandi d85Document28 pagesDwifarid Alifandi d85gemabasilius53No ratings yet

- Owner's: L'HinDocument114 pagesOwner's: L'HinxistormanexNo ratings yet

- Yearly RoutinesDocument8 pagesYearly RoutinesRuwinda BandaraNo ratings yet

- TransformerDocument1 pageTransformerFaiz AnNo ratings yet

- Anti-Heeling Pump ManualDocument13 pagesAnti-Heeling Pump ManualAndrey BogorodskiyNo ratings yet

- Gestion Mantenimiento Puente GruaDocument11 pagesGestion Mantenimiento Puente GruaBryan Esteban Casas ZapataNo ratings yet

- AHU Checklsit - Dilapidation SurveyDocument2 pagesAHU Checklsit - Dilapidation SurveyibrahimsirpiNo ratings yet

- Soft TROUBLE SHOOTING & PMPDocument10 pagesSoft TROUBLE SHOOTING & PMPLaur IriNo ratings yet

- RASYIDDocument25 pagesRASYIDAbdur RasyidNo ratings yet

- P8217 Checklist Fire Pump PDFDocument7 pagesP8217 Checklist Fire Pump PDFQuynh NguyenNo ratings yet

- TP1033 WebDocument2 pagesTP1033 Webnunezjorgeaaol.comNo ratings yet

- Honeywell Gas Detector MaintenanceDocument1 pageHoneywell Gas Detector MaintenanceXiao Zhen TanNo ratings yet

- Maintenance Program For HFO Diesel EngineDocument11 pagesMaintenance Program For HFO Diesel EngineUmit CengNo ratings yet

- Service Routines HV2-210Document1 pageService Routines HV2-210Suraj SinghNo ratings yet

- Work Instructions: Standard Work Instruction - QSK60 Gas A Service Planned - ReactiveDocument13 pagesWork Instructions: Standard Work Instruction - QSK60 Gas A Service Planned - ReactiveTareq MollaNo ratings yet

- Tool Box 031-Service of Cartridge Extinguishers: Made Fully Aware of Safe Working Practices and Any Dangers InvolvedDocument9 pagesTool Box 031-Service of Cartridge Extinguishers: Made Fully Aware of Safe Working Practices and Any Dangers InvolvedArty BatizNo ratings yet

- Periodical Service Ud Truck Cwe370: Maintenance SheetDocument2 pagesPeriodical Service Ud Truck Cwe370: Maintenance SheetIkipiyeNo ratings yet

- Brkarc-2350 - 2014Document128 pagesBrkarc-2350 - 2014Sarah AnandNo ratings yet

- Ultra Dense NetworkDocument27 pagesUltra Dense NetworkYounesNo ratings yet

- Unit 1 Nissim Ezekiel and Eunice de Souza: 1.0 ObjectivesDocument14 pagesUnit 1 Nissim Ezekiel and Eunice de Souza: 1.0 ObjectivesJasmineNo ratings yet

- Demography Is The: Statistical Study Human PopulationDocument17 pagesDemography Is The: Statistical Study Human PopulationYash SejpalNo ratings yet

- Planificare Calendaristică Anuală Pentru Limba Modernă 1 - Studiu Intensiv. Engleză. Clasa A Vi-ADocument6 pagesPlanificare Calendaristică Anuală Pentru Limba Modernă 1 - Studiu Intensiv. Engleză. Clasa A Vi-Acatalina marinoiuNo ratings yet

- Interactive Physics ManualDocument13 pagesInteractive Physics ManualMarciano SantamaríaNo ratings yet

- ECE 5325/6325 Fall 2009: Exam 1 SolutionsDocument2 pagesECE 5325/6325 Fall 2009: Exam 1 Solutionswilfred godfreyNo ratings yet

- 134.4902.06 - DM4170 - DatasheetDocument7 pages134.4902.06 - DM4170 - DatasheetVinicius MollNo ratings yet

- StaircasesDocument11 pagesStaircasesatiNo ratings yet

- Revit Programming For Beginners: Dan Mapes Senior BIM Coordinator/Developer at ME EngineersDocument17 pagesRevit Programming For Beginners: Dan Mapes Senior BIM Coordinator/Developer at ME EngineersjeanNo ratings yet

- The Dino GameDocument1 pageThe Dino Game296 004 Aditya ChaudhariNo ratings yet

- Learning Activity Sheet Computing Probabilities and Percentiles Under The Normal CurveDocument5 pagesLearning Activity Sheet Computing Probabilities and Percentiles Under The Normal CurveJhon Loyd Nidea Pucio100% (1)

- Cantilever Slab (Unlocked)Document3 pagesCantilever Slab (Unlocked)WRay TanNo ratings yet

- Earth SpecificationDocument20 pagesEarth SpecificationMohammad Hafiz MahadzirNo ratings yet

- Shree Vijaya Engineering and Construction PVT LTD: Ehs Risk AnalysisDocument8 pagesShree Vijaya Engineering and Construction PVT LTD: Ehs Risk AnalysisReda MashalNo ratings yet

- Job Posting Groups ListDocument3 pagesJob Posting Groups ListShrutika singhNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- Statistical Methods For Spatial Data AnalysisDocument3 pagesStatistical Methods For Spatial Data Analysissakali ali0% (1)

- Error - Failed To Compute Elastoplastic Strain Variables - 1150 - Knowledge Base PDFDocument3 pagesError - Failed To Compute Elastoplastic Strain Variables - 1150 - Knowledge Base PDFmatinNo ratings yet

- Thesis PDFDocument120 pagesThesis PDFPrajwal NiraulaNo ratings yet

- Aptis Writing C1Document33 pagesAptis Writing C1Sanjar JumayevNo ratings yet

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocument6 pagesLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNo ratings yet

- Asme Sa-29 1018Document1 pageAsme Sa-29 1018Nelson RangelNo ratings yet

- 900FH&1000FH TurbinesDocument12 pages900FH&1000FH TurbinesRyanNo ratings yet

- Exercise Oracle Forms 6i TrainingDocument5 pagesExercise Oracle Forms 6i TrainingFarooq Shahid100% (1)

- 12B TB Book PDF-1 PDFDocument113 pages12B TB Book PDF-1 PDFامل العودة طالب100% (1)

- 1001076002-HT8911 Datasheet - V1.1Document13 pages1001076002-HT8911 Datasheet - V1.1Zhang EthanNo ratings yet

- Strategic Management LBdA3TJvQgDocument420 pagesStrategic Management LBdA3TJvQgSazzad HossainNo ratings yet

- Oxford Thesis CollectionDocument5 pagesOxford Thesis Collectionkimberlybundypittsburgh100% (2)