Professional Documents

Culture Documents

Fosroc_Conbextra_C_TDS

Fosroc_Conbextra_C_TDS

Uploaded by

sashilaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fosroc_Conbextra_C_TDS

Fosroc_Conbextra_C_TDS

Uploaded by

sashilaCopyright:

Available Formats

Fosroc®

Conbextra® C constuctive solutions

High flow, dual shrinkage Description

compensated, precision cementitious General purpose shrinkage compensated, non-shrink

grout cementitious grout, is supplied as a ready to use dry powder.

The addition of a controlled amount of clean water produces

Uses a flowing shrinkage compensated grout for gap thicknesses

from 10mm up to 100mm.

General grouting of gaps from 10mm to 100mm, where high

flow is required along with dual shrinkage compensation Conbextra C is a blend of Portland cement, specially graded

(previously Class A/Class C). Applications include grouting fillers and additives which impart controlled expansion in

of: the plastic and hardened state whilst minimising water

demand. The low water demand ensures high early strength.

Baseplates and soleplates of machines The graded filler is designed to assist uniform mixing and

Structural steel column baseplates produce a consistent, flowable grout.

Voids between precast concrete and infilling blockwork Conbextra C is not hazardous in accordance with Australian

Inventory of Industrial Chemicals. Contains <0.1% RCS.

Advantages Maximum aggregate size for pumping is 0.3mm.

Dual expansion system compensates for shrinkage in In applications where the maximum flow properties and flow

both the plastic and hardened states retention times are required, Conbextra HF should be

High ultimate strength and low permeability ensure the considered.

durability of the hardened grout

Can be dry packed/rammed, trowelled, flowed and

Standards Compliance

pumped AS 1478.2-2005 Appendix E : Test for Early Volume

Change.

Hydrogen free gas expansion

AS 1478.2-2005 Table 4.1.2.2 : Test for Consistency.

Prepackaged material overcomes potential on-site

mixing variations

No metallic iron content to cause rusting

RCS (Respirable Crystalline Silica) Hazard Free

Non-shrink - according to ASTM C1107:2020

Properties

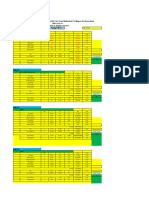

Test Method Standard Result

Compressive Strength AS 1478.2:2005 Consistency 1 Day 7 Days 28 Days

(MPa): Stiff 45 60 70

Plastic 35 50 60

Flowable 25 45 55

Flexural Strength (Modulus AS 1012.11 - 2000 1 Day 5.0 MPa

of Rupture) 7 Days 9.5 MPa

28 Days 9.6 MPa

Indirect Tensile Strength AS 1012.10.2000 1 Day 2.7 MPa

7 Days 4.4 MPa

28 Days 4.8 MPa

Fresh Wet Density ASTM C185:2020 2100 kg/m3 - depending on consistency used

Alkali reactive particles Rapid Mortar Bar Non-reactive

Test (RTA T363)

Flow Characteristics AS 1478.2:2005 400 - 600mm (Flow Trough)

Minimum Thickness 10mm

Maximum Thickness 100mm

The typical properties given above are derived from laboratory testing at 230C. Test results obtained will vary if carried out

to an alternative standard or sample dimensions are used.

Nov 2023 Page 1

Fosroc®

Conbextra® C

Test Results to ASTM Specification C1107: 2020

Test Method Standard Result

Flow Consistency: ASTM C939:2016a >145%

Setting Time: ASTM C953:2017 Initial: 300 mins

Final: 360 mins

Volume Change at Early Age

ASTM C827:2016 +0.40

(Final setting) %:

Volume Change of Hardened ASTM C1090:2015 1 day +0.01

Grout (moist cured) %: 3 days +0.02

7 days +0.02

28 days +0.03

28 day + 28 days in air +0.01

Compressive Strength (N/mm²): ASTM C109:2020b 1 day 23.3

3 days 38.0

7 days 45.1

28 days 56.2

Note: All tests were carried out at 25oC ± 2oC until the age of the test. All above test results are independent third party

results. Copies of these test results are available on request. The tests were carried out at a water addition rate of 3.6L

per 20kg.

Application Instructions Pre-soaking

Pre-soaking the formed grouting area with clean water helps

Preparation

to ensure good adhesion of the grout at the interface of the

Foundation surface concrete foundation and improves the flow of the grout during

The substrate surface must be free from oil, grease or any the installation. The area should be filled with clean water

loosely adherent material. If the concrete surface is defective for a minimum 2 hours before the grouting takes place.

or has laitance, it must be cut back to a sound base. For Immediately before grouting takes place, any free water

maximum bond, surfaces should be abraded or roughened, should be removed by draining or vacuum.

preferably by mechanical means such as needle gun, grit

blasting, grinding. Bolt holes or fixing pockets must be blown Particular care should be taken to blow out any bolt holes

clean of any dirt or debris. These may need to be grouted and pockets.

beforehand.

Mixing

Base plate A forced-action mixer is essential. Mix for 3 to 5 minutes at

It is essential that this is clean and free from oil, grease, a slow speed (400/500rpm) in a suitably sized drum using

scale, paint or coating of any kind. Air pressure relief holes appropriate equipment such as a 140mm helical mixing

should be provided to allow venting of any isolated high paddle fitted to a heavy-duty 1600W mixer.

spots.

The selected water content should be accurately measured

Levelling shims into the mixing bucket. While mixing, slowly add the total

contents of the Conbextra C bag, mix continuously for 3 to

If these are to be removed after the grout has hardened,

5 minutes, ensuring a smooth, even consistency is obtained.

they should be treated with a thin layer of grease.

Aways add the powder to the water.

Formwork

Required Litres of water Yield - litres of

The formwork should be constructed to be leakproof. This Consistency added per 20kg bag mixed material

can be achieved by using foam rubber strip or construction

Stiff 2.6 - 3.4 10.4

silicone sealant beneath the constructed formwork and

between joints. Plastic 3.4 - 3.6 10.7

The formwork should include outlets for pre-soaking. Flowable 3.6 - 3.9 10.8

Generally the gap width between the perimeter formwork

and the plate edge should not exceed 150mm on the pouring

side and 50mm on the opposite side. It is advisable where

practical to have no gap at the flank sides.

constructive solutions Page 2

Fosroc®

Conbextra® C

Mixing larger volumes Flow properties of mixed grout

Larger quantities will require a high shear vane mixer. Do The flow distances given below in (mm) are intended as a

not use a colloidal impeller mixer. guide. Actual flow distances will vary depending on site

conditions:

To enable the grouting operation to be carried out

continuously, it is essential that sufficient mixing capacity Gap Depth Flowable Flowable

and labour are available. The use of a grout holding tank (mm)

with provision to gently agitate the grout may be required. 100mm head 250mm head (mm)

(mm)

Mixing part bags 10 320 1080

It is recommended that full bags be mixed, however for 20 850 2300

applications where smaller quantities of product are required, 30 1350 2700

experienced applicators may elect to mix half bags by

40 2000 2700+

weighing out (the correct quantity of product) and mixing

with half the recommended quantity of water. In doing so 50 2700 2700+

the contractor accepts the risk of any off-ratio mixing. Agitate

the dry product before weighing out to minimise any Pumping

segregation. Reliable scales should be used to weigh out Where large volumes have to be placed Conbextra C

individual components. may be pumped. A heavy duty diaphragm pump is

recommended for this purpose. Screw feed and piston pumps

Placing may also be suitable. Maximum aggregate size for pumping

At 23oC place the grout within 20 minutes of mixing to gain is 0.3mm. Ensure the selected pump is capable of pumping

full benefit of the expansion process. this size aggregate.

Conbextra C can be placed in thicknesses from 10mm up Curing

to 100mm in a single pour when used as an underplate

grout. Where the grouting gap beneath the base plate On completion of the grouting operation, exposed areas

exceeds the maximum thickness allowed, then the grout should be thoroughly cured. This should be done by the use

can filled / bulked out with Conbextra Grout Aggregate* to of Concure curing membrane or continuous application of

minimise exotherm heat build up. Alternatively Conbextra water and/or wet hessian.

Deep Pour is available for pours up to 500mm thick.

Cleaning

Filling/bulking out of the grout should not exceed a ratio of Conbextra C should be removed from tools and equipment

2:1 (grout:aggregate by weight). Please refer to the Conbextra with clean water immediately after use. Cured material can

Grout Aggregate TDS for more guidance on bulking out of be removed mechanically.

cement based grouts.

Any bolt pockets must be grouted prior to grouting between Limitations

the substrate and the base plate.

Low temperature working

Continuous grout flow is essential. Sufficient grout must be

prepared before starting. The time taken to pour a batch When the air or contact surface temperatures are 5°C or

must be regulated to the time to prepare the next one. below on a falling thermometer, grouting should be

postponed.

Pouring should be from one side of the void to eliminate any

air or pre-soaking water becoming trapped under the For ambient temperatures below 10°C the formwork should

baseplate. It is advisable to pour the grout across the shortest be kept in place for at least 36 hours.

distance of travel. The grout head must be maintained at all Normal precautions for winter working with cementitious

times so that a continuous grout front is achieved. materials should then be adopted.

High temperature working

At ambient temperatures above 35°C cool water (below

20°C) should be used for mixing the grout prior to placement.

constructive solutions Page 3

Fosroc®

Conbextra® C

Supply

Conbextra C is supplied in 20kg moisture resistant plastic

bags.

Conbextra C 20kg: FC501040-20KG

Yield

Consistency Yield

(AS 1478.2-2005 Table (Litres of mixed

4.1.2.2) material)

Stiff 10.4

Plastic 10.7

Flowable 10.8

Storage

Conbextra C has a shelf life of 36 months from date of

manufacture if kept in the original, unopened bags. Refer

to the manufacture date indicated on the packaging. Do not

use if there are lumps in the product, or a loss of workability

(requiring more water to be added) is experienced.

Important notice

A Safety Data Sheet (SDS) is available from the Fosroc website. Read the SDS and TDS carefully prior to use as application or performance data may change from time to time. In emergency,

contact any Poisons Information Centre (phone 13 11 26 within Australia) or a doctor for advice.

Product disclaimer

This Technical Data Sheet (TDS) summarises our best knowledge of the product, including how to use and apply the product based on the information available at the time. You should read

this TDS carefully and consider the information in the context of how the product will be used, including in conjunction with any other product and the type of surfaces to, and the manner in

which, the product will be applied. Our responsibility for products sold is subject to our standard terms and conditions of sale. Parchem does not accept any liability either directly or indirectly for

any losses suffered in connection with the use or application of the product whether or not in accordance with any advice, specification, recommendation or information given by it.

*Manufactured and sold under license from Fosroc Parchem Construction Supplies Pty Ltd

International Limited. Fosroc, Conbextra and the 1956 Dandenong Rd Clayton VIC 3168

Fosroc logo are trade marks of Fosroc International Ph: 1800 812 864

Limited, used under license. . www.fosroc.com.au ABN 80 069 961 968

Distributed in New Zealand by: Concrete Plus Ltd

constructive solutions 150 Hutt Park Road Gracefield Ph: 0800 657 156

Page 4 www.fosroc.co.nz NZBN 9429033691282

You might also like

- FS 600 Data SheetDocument1 pageFS 600 Data SheetNguyen Hong67% (3)

- Aircraft Materials HistoryDocument15 pagesAircraft Materials Historymahaprabhu78No ratings yet

- Fosroc Conbextra HF TDSDocument4 pagesFosroc Conbextra HF TDSRicky JayaNo ratings yet

- Fosroc Conbextra GP TDSDocument4 pagesFosroc Conbextra GP TDSmukesh baghelNo ratings yet

- Pds CPD D30 SikaGrout 300 PT UsDocument2 pagesPds CPD D30 SikaGrout 300 PT UsJonathan FelixNo ratings yet

- Fosroc Conbextra HS: Constructive SolutionsDocument4 pagesFosroc Conbextra HS: Constructive SolutionsCatherine Fatima Mae LeynoNo ratings yet

- Fosroc Conbextra GP TDSDocument4 pagesFosroc Conbextra GP TDSKAVINNo ratings yet

- Tds Conbextra Ep150 Saudi ArabiaDocument4 pagesTds Conbextra Ep150 Saudi ArabiaALWIN T RAJNo ratings yet

- Conbextra EP150: Constructive SolutionsDocument4 pagesConbextra EP150: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- CIKOgrout GPDocument2 pagesCIKOgrout GPelieraffoul98No ratings yet

- TDS Conbextra EP160 Saudi ArabiaDocument4 pagesTDS Conbextra EP160 Saudi ArabiajasonNo ratings yet

- Sabic Fortify C5070D TDSDocument2 pagesSabic Fortify C5070D TDSmiya079127No ratings yet

- SABIC_B5429Document2 pagesSABIC_B5429yohannesafework07No ratings yet

- Data - Sheet-Non-Shrink Precision Grout 1585-00 PDFDocument2 pagesData - Sheet-Non-Shrink Precision Grout 1585-00 PDFJeffry Daud BarrungNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- 01 Vetotop CL530 - 141221 JODocument2 pages01 Vetotop CL530 - 141221 JOassala HaddadNo ratings yet

- Thermalbond v2200 Foam Tape Tds 1067 PDFDocument2 pagesThermalbond v2200 Foam Tape Tds 1067 PDFDario DiazNo ratings yet

- Masterflow 870 TdsDocument3 pagesMasterflow 870 TdsemilNo ratings yet

- Masterflow - 410 v3Document2 pagesMasterflow - 410 v3amr.yousry.91No ratings yet

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaNo ratings yet

- Data - Sheet-Cgfs Dot Mix 1244-56 - 58Document2 pagesData - Sheet-Cgfs Dot Mix 1244-56 - 58miguelq_scribdNo ratings yet

- 18 Vetogrout EG340 - 180321Document2 pages18 Vetogrout EG340 - 180321Maha MuflehNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Tec 304 VHS (KSA) : Very High Strength Shrinkage Compensated GroutDocument2 pagesTec 304 VHS (KSA) : Very High Strength Shrinkage Compensated Groutmanikandan4strlNo ratings yet

- Dokumen - Tips - High Performance Waterborne Epoxy Formulation For 2019 03 06 19 Table 1 Epoxy ModifiedDocument3 pagesDokumen - Tips - High Performance Waterborne Epoxy Formulation For 2019 03 06 19 Table 1 Epoxy ModifiedLong An ĐỗNo ratings yet

- Fosroc Conbextra UW: Formulated Anti-Wash Out, Specialist Grout For Underwater Grouting Applications Uses DescriptionDocument3 pagesFosroc Conbextra UW: Formulated Anti-Wash Out, Specialist Grout For Underwater Grouting Applications Uses DescriptionSetyo poernomoNo ratings yet

- Deesa Pipe Gasket Catal - 230310 - 121140Document10 pagesDeesa Pipe Gasket Catal - 230310 - 121140Pietro MachadoNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- PETRONAS Slideway Series v2. 13 07 2016Document3 pagesPETRONAS Slideway Series v2. 13 07 2016Isay Quiroga VargasNo ratings yet

- Epoxy Asphalt ConcreteDocument4 pagesEpoxy Asphalt Concretefatemeh.ahmadkhaniNo ratings yet

- basf-masterflow-928-tdsDocument4 pagesbasf-masterflow-928-tdsisabelporlanNo ratings yet

- Data - Sheet-Cgfs Repair Mortar 1241-60 - 20Document2 pagesData - Sheet-Cgfs Repair Mortar 1241-60 - 20miguelq_scribdNo ratings yet

- Sto Skim Coat 82216 Guide Specifications B26371Document4 pagesSto Skim Coat 82216 Guide Specifications B26371Anthony Al Lakiss100% (1)

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- Resin Binder Enhanced Friction Surface Treatment, Item SPV.0180.XXDocument5 pagesResin Binder Enhanced Friction Surface Treatment, Item SPV.0180.XXMarco Dela CruzNo ratings yet

- MasterFlow - 410 v1Document2 pagesMasterFlow - 410 v1Anonymous XVEucVMsENo ratings yet

- Titanpro 6531 MDocument1 pageTitanpro 6531 MErnesto CheguavaraNo ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- Lotte Titanpro PM903 Product DataDocument1 pageLotte Titanpro PM903 Product DataJoni Sie MssNo ratings yet

- 107 Ps - rv3.13052019Document2 pages107 Ps - rv3.13052019LuckyNo ratings yet

- Conbextra EP120 TDS PDFDocument3 pagesConbextra EP120 TDS PDFzulfikarNo ratings yet

- Lotte Titanpro PM803 Product DataDocument1 pageLotte Titanpro PM803 Product DataJoni Sie MssNo ratings yet

- Structural Concrete: Product DescriptionDocument2 pagesStructural Concrete: Product DescriptionAram HovsepianNo ratings yet

- Titanpro PD701 Product Data PDFDocument1 pageTitanpro PD701 Product Data PDFJoni Sie MssNo ratings yet

- TDS Conbextra 621 Saudi ArabiaDocument4 pagesTDS Conbextra 621 Saudi ArabiaMichael MazoNo ratings yet

- LOCTITEDocument2 pagesLOCTITEHrNo ratings yet

- Product Data: Titanpro Sm198Document1 pageProduct Data: Titanpro Sm198李万福No ratings yet

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- Cx5 14 Single Use Film Validation Guide REFER For ABOUT FILMDocument15 pagesCx5 14 Single Use Film Validation Guide REFER For ABOUT FILMCampaign MediaNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFabhay_joshi2002No ratings yet

- SABIC®️_HDPE_P5616N_Global_Technical_Data_Sheet-3[1]Document1 pageSABIC®️_HDPE_P5616N_Global_Technical_Data_Sheet-3[1]Amit VermaNo ratings yet

- Evaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSDocument14 pagesEvaluating The Strength Gain and Structural Properties of Self-Compacting Concrete by Incorporating Robo Sand and GGBSumadevi rangaswamyNo ratings yet

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Document1 pageLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Cemtec NS Grout-V1Document2 pagesCemtec NS Grout-V1Raja muruganNo ratings yet

- Api STD 570: Video Training Handout ClassworkDocument6 pagesApi STD 570: Video Training Handout ClassworkNaresh KumarNo ratings yet

- AB - Optibent NT10 - enDocument5 pagesAB - Optibent NT10 - enMoatz HamedNo ratings yet

- CV322 8 AdmixturesDocument20 pagesCV322 8 AdmixturesKrishitva R GowdaNo ratings yet

- Ibraim Overview Influence of Pozzolanic Materials PDFDocument12 pagesIbraim Overview Influence of Pozzolanic Materials PDFrobertsj21No ratings yet

- Combination Capacity Factors: For Conducting Flow Tests of Rupture Discs, Pressure Relief Valves AND Combinations ThereofDocument8 pagesCombination Capacity Factors: For Conducting Flow Tests of Rupture Discs, Pressure Relief Valves AND Combinations ThereofWormInchNo ratings yet

- Flammability Testing Servicefor Building MaterialsDocument1 pageFlammability Testing Servicefor Building MaterialsHendri WaeNo ratings yet

- Hot Dip GalvanizingDocument3 pagesHot Dip Galvanizingapply19842371No ratings yet

- What Is The Correct Procedure of Concreting An RCC Slope Roof Slab - QuoraDocument4 pagesWhat Is The Correct Procedure of Concreting An RCC Slope Roof Slab - QuoraAddisNo ratings yet

- Ferro CementDocument18 pagesFerro CementVara PrasadNo ratings yet

- Practical Advice.: Valuable Tips On Purging and Root BackingDocument7 pagesPractical Advice.: Valuable Tips On Purging and Root BackingcarlosNo ratings yet

- Eng Bobtail Flyer-Web ResDocument2 pagesEng Bobtail Flyer-Web Ress_padu3003@yahoo.comNo ratings yet

- ITP Table For Flange (Stock)Document6 pagesITP Table For Flange (Stock)Hamid Taghipour ArmakiNo ratings yet

- Boysen ProductsDocument2 pagesBoysen ProductsAly MendozaNo ratings yet

- InnoPlus HD8100MDocument1 pageInnoPlus HD8100MLe Minh TuanNo ratings yet

- TDS 8201 PT NewDocument2 pagesTDS 8201 PT NewWahyudi Rendiana NyotoNo ratings yet

- Concrete Masonry Fire Resistance June 2016Document4 pagesConcrete Masonry Fire Resistance June 2016Hendrix TilloNo ratings yet

- Bolt Tightening Torques PDFDocument3 pagesBolt Tightening Torques PDFSH1961100% (3)

- LIIL RefractoryDocument33 pagesLIIL RefractoryMOHD AZAMNo ratings yet

- Spot Weld - PresDocument96 pagesSpot Weld - Presavinashbatra1100% (1)

- ASTM B574 - 2006e1Document4 pagesASTM B574 - 2006e1Cesar ParadaNo ratings yet

- Tungsten Rod SelectionDocument2 pagesTungsten Rod SelectionManish MNo ratings yet

- UEP Bulletin 1724E-214Document70 pagesUEP Bulletin 1724E-214Hosam AlzubairyNo ratings yet

- General NotesDocument7 pagesGeneral NotesAzzirrenNo ratings yet

- CH1 - Cement - Part1Document22 pagesCH1 - Cement - Part1EilmohNo ratings yet

- 02-GB 50003-2011砌体结构设计规范 - en - newDocument114 pages02-GB 50003-2011砌体结构设计规范 - en - newyyyy071220No ratings yet

- Concrete Estimate For C-30Document5 pagesConcrete Estimate For C-30sm rashelNo ratings yet

- Industeel Tableau Nuances Special Carbon and Low AlloyDocument1 pageIndusteel Tableau Nuances Special Carbon and Low AlloyPravin VisputeNo ratings yet

- 07100Document4 pages07100sethu1091No ratings yet

- Building Technology 2: Arch - Carmela C. Quizana, MSCM, UapDocument17 pagesBuilding Technology 2: Arch - Carmela C. Quizana, MSCM, UapAngelae BorjaNo ratings yet

![SABIC®️_HDPE_P5616N_Global_Technical_Data_Sheet-3[1]](https://imgv2-1-f.scribdassets.com/img/document/749597839/149x198/235bce2adc/1720680338?v=1)