Professional Documents

Culture Documents

Bhf Removal

Bhf Removal

Uploaded by

bendavid.talCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bhf Removal

Bhf Removal

Uploaded by

bendavid.talCopyright:

Available Formats

Engine, Manual Transmission, ...

10 – Engine Assembly

Removal and Installation

Engine, Manual Transmission, Removing

Engine, Removing

With lock carrier removed, engine is removed downward with transmission and

subframe.

t Old Oil Collecting and Extracting Device -V.A.G 1782-

t Hose Clamp Pliers -V.A.G 1921-

t Spark Plug Connector Pliers -V.A.G 1922-

t Step Ladder -VAS 5085-

t Scissor Lift Platform -VAS 6131 A- with support set for Audi -VAS 6131/10-

t Supplementary Set -VAS 6131/11-

t Drip tray for Workshop Crane -VAS 6208-

t Ring Screw -3368-

t Tension Strap -T10038-

If engine and transmission are to be separated after removal, the -VAS

6131/11- will also be required.

Procedure

t Drained coolant must be stored in a clean container for disposal or reuse.

t All cable ties opened or cut during engine removal must be reinstalled at

the same locations during installation.

– Remove plenum chamber cover rubber seal.

– Remove plenum chamber cover -1-toward front -arrows-.

Observe procedures when connecting battery. Refer to Electrical

Equipment:Removal and Installation-27.

– With ignition switched off, disconnect battery Ground (GND) cable -arrow-.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 1 of 36

:

1

– Discharge refrigerant circuit. Refer to Refrigerant R134a -

Servicing:Description and Operation-87.

– Extract hydraulic oil for power-steering from reservoir using old oil collecting

and extracting device -V.A.G 1782- .

Cover cap of expansion tank with rag and open carefully, as hot steam

i.e. hot coolant may escape when opening.

– Open cap of coolant expansion tank.

– Remove both front wheels.

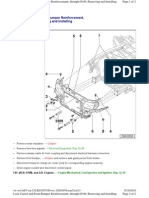

– Remove quick-release fasteners -1-, remove screws -2-and remove noise

insulation.

– Remove bracket for noise insulation -arrows-.

– Remove left and right front wheel housing liners. Refer to Body

Exterior:Removal and Installation-66.

– Remove front bumper cover. Refer to Body Exterior:Removal and

Installation-63.

– Remove left air guide -arrow-in front of auxiliary cooler.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 2 of 36

:

1

Remove right air guide -arrow-in front of auxiliary cooler.

– Place drip tray for workshop crane -VAS 6208- under engine.

– Remove drain plug -arrow-on coolant thermostat housing and drain

coolant from engine.

– Disconnect lower coolant hose from radiator -arrow-and drain residual

coolant.

– Place -V.A.G 1782- under engine.

– Disconnect hydraulic lines to cooling coil at left rear of bumper -arrows-.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 3 of 36

:

1

Remove cover -1-in engine compartment (left side).

– Remove cover -1-in engine compartment (right side).

– Disengage Evaporative Emission (EVAP) Canister Purge Regulator Valve 1

-N80- -1-from air guide.

– Remove bolts -arrows-.

– Remove air duct -2-.

– Disconnect top coolant hose -arrow-from radiator.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 4 of 36

:

1

Remove electrical harness connectors -1 and 2-from bracket and

disconnect them.

– Free up wires to lock carrier.

– Disconnect electrical harness connector -arrow-for headlamps at both

sides of the vehicle.

– Free up electrical wiring.

– Disconnect electrical harness connector -arrow-for left and right airbag

sensors on lock carrier.

– Free up cables.

– Remove hood cable at lock carrier. Refer to Body Exterior:Removal and

Installation-55.

– Disconnect electrical harness connector -arrow-for right fan.

To prevent damage to condenser and also to the refrigerant lines/hoses,

ensure that the pipes and hoses are not stretched, kinked or bent.

– Remove refrigerant line -arrow-leading to Air Conditioning (A/C)

compressor.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 5 of 36

:

1

– Remove refrigerant line -arrow-leading to A/C evaporator.

– Remove bolts -arrows-at left and right side of bumper.

– Pull off hood seal from lock carrier and fender edges.

– Remove bolts at impact absorbers -arrows-at left and right.

A second technician is required to remove the lock carrier.

– Remove lock carrier and set aside so it cannot fall.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 6 of 36

:

1

Remove rear engine cover -arrows-.

– Remove front engine cover -arrows 1 and 2-.

– Remove coolant hoses -1-and -2-.

– Remove coolant expansion tank -arrow-.

– Disconnect electrical wiring to Engine Coolant Level (ECL) Warning Switch

-F66- at bottom of expansion tank.

– Disconnect vacuum line -arrow-to brake booster at bulkhead.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 7 of 36

:

1

Unclip coolant hose -arrow-from bracket on bulkhead.

– If installed, disconnect vacuum line -arrow-to vacuum reservoir.

– Disconnect vacuum hose -arrow-from intake manifold.

– Disconnect coolant hose -arrow-to heater core at rear coolant pipe on

engine.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 8 of 36

:

1

If installed, disconnect vacuum line at area designated with -arrow-.

– If installed, disconnect electrical harness connector -arrow-for after-run

coolant pump -V51- (behind auxiliary cooler at left) and free up electrical

wire.

Place a rag under separating point to catch escaping hydraulic fluid.

– Disconnect hose -1-from power steering fluid reservoir.

Ignore -2-.

– Disconnect coolant hoses at positions indicated by -arrows-.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 9 of 36

:

1

– Disconnect coolant hoses at positions indicated by -arrows-.

– Disconnect coolant hose to oil cooler -arrow-.

– Disconnect coolant hoses at positions indicated by -arrows-.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 10 of 36

:

1

– Remove bolts -1 and 2-.

– Remove right auxiliary cooler together with coolant hoses.

The hose -arrow-can remain connected at auxiliary cooler.

Note rules of cleanliness for working on the fuel injection system.

Refer to Clean Working Conditions.

Fuel system is under pressure! Before opening system, place clean

rags around the connection. Then release pressure by carefully

loosening the connection.

– Remove fuel hose from connection on fuel rail pipe. To do so, counterhold

using an open-end wrench at hex head -1 and 3-and remove union nut

-2-.

– Disconnect electrical harness connector -2-from Evaporative Emission

(EVAP) canister purge regulator valve 1 -N80- .

– Disconnect electrical harness connector -3-at Mass Airflow (MAF) sensor -

G70- .

– Disconnect hose -1-to Secondary Air Injection (AIR) pump.

– Disconnect air guide hose -4-at MAF sensor .

– Move wiring harness clear at air filter housing.

– Remove clip -arrow-and remove air filter housing with Mass Air Flow

sensor.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 11 of 36

:

1

– Disconnect air hose -arrow-at right on engine.

– Remove bracket for electrical harness connectors -1 to 4-at right from

bulkhead.

– Remove nut -1-and remove fuse strip on plus wire terminal clamp.

– Disconnect positive cable -2-on battery positive terminal.

– Pull positive cable through bulkhead toward front.

– Free up wiring harness.

Disregard -3-.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 12 of 36

:

1

Pry off both covers -3-using a screwdriver.

– Loosen hex-nuts -4-by several turns.

– Loosen wiper arms -2-from respective wiper axle by tilting slightly.

– Remove nuts completely and remove wiper arms.

To prevent the cowl grille -5-from tearing when removing, coat

transition between windshield and cowl grille with a soapy solution

and pull grille up vertically out of fastening strip beginning at edge of

window.

– Disconnect securing clips -1-and remove cowl grille -5-.

– Remove cover for E-Box in plenum chamber -arrows-.

– Using a screwdriver, carefully pry off mounting bracket -arrow-and remove

Engine Control Module (ECM) from E-Box.

Engine Control Module remains connected at wiring harness.

– Release retaining hooks -arrows-toward outside and remove retaining

bracket.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 13 of 36

:

1

– Disconnect all electrical harness connectors on connector station -2-using -

V.A.G 1922- .

– Remove electrical wire connection -1-.

– Disengage locking mechanisms -arrows-and remove secondary relay

carrier in E-Box toward top.

– Disengage engine wiring harness at E-Box and bulkhead.

– Remove Ground (GND) connection -arrow-.

– Remove bracket for electrical harness connectors -1 to 4-at left from

bulkhead.

– Free up wiring harness.

– Set electrical wiring harness on engine and secure Engine Control Module

against falling down.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 14 of 36

:

1

Disconnect electrical harness connector -1-at AIR pump motor -V101- .

– Remove Ground (GND) cable -2-on longmember.

– Place -V.A.G 1782- under engine.

– Disconnect hydraulic pressure line for power-steering -arrow-at left next to

oil pan.

To prevent damage to condenser and also to the refrigerant lines/hoses,

ensure that the pipes and hoses are not stretched, kinked or bent.

– Remove bolts -1 and 2-.

– Remove right refrigerant line from A/C compressor.

The left refrigerant line will be removed at a later point in time.

– Seal open connections on Air Conditioning (A/C) compressor using clean

plugs.

– Remove left bracket for refrigerant line -arrows-.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 15 of 36

:

1

– Remove refrigerant line on bracket -arrow-.

– Remove bolt -arrow-and disconnect refrigerant line to A/C compressor.

– Have a second technician press brake pedal.

To loosen collar bolt for drive axle, the wheel bearing must not be

under load (vehicle must not be standing on its wheels).

– Remove collar bolt -2-at left and right drive axles -1-.

– Remove bolts and nuts -arrows-uniformly at left and right.

– Remove stabilizer.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 16 of 36

:

1

– Disconnect electrical harness connector at left front level control system

sensor -G78- .

– Unclip operating rod for left front level control system sensor at bottom on

control arm.

– Remove outer suspension strut bolt from left and right of engine

compartment.

– Rotate -3368- at left and right in suspension strut mount hole from below.

Only install Ring Screw -3368- until it is flush with upper edge of

suspension strut mount so that hood is not damaged when closed.

– Tie up wheel bearing housing at left and right with -T10038- as shown in

illustration.

To prevent upper control arm joints from being damaged, wheel

bearing housing must be supported before loosening lower

suspension strut bolts.

– Remove suspension strut from control arm -arrow-.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 17 of 36

:

1

– Remove expanding clips -arrows-.

– Remove nut -1-and remove cover behind wheel housing.

– Remove guide control arm -1-and control arm -2-on subframe.

– Pivot guide control arm -1-and control arm -2-outward.

Guide control arm and control arm must not hang free. Tie up both

control arms on wheel bearing housing -arrows-as shown in

illustration.

– Repeat work procedure on opposite side of the vehicle.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 18 of 36

:

1

– Remove heat shield -1-for left drive axle.

– Remove drive axle from transmission flanged shaft.

– Swing left wheel bearing housing outward and remove drive axle.

– Repeat work procedure on opposite side of the vehicle.

Do not bend the flex joint in front of the exhaust pipe more than 10° or it could

be damaged.

– Disconnect exhaust system at double clamps -arrows-.

– Remove heat shield -A-for driveshaft -arrows-.

– Remove bolts at transmission/driveshaft flange.

– Push driveshaft together with rear final drive. The constant velocity joints

can move axially.

– Tie up driveshaft to body.

Prepare Scissor Lift Platform

– Equip scissor lift platform -VAS 6131 A- with support set for Audi -VAS

6131/10- as follows:

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 19 of 36

:

1

Platform

Parts of support set for Audi -VAS 6131/10-

coordinates

B4 /10-1 /10-4 /10-5 /10-11

G3 /10-1 /10-4 /10-5 /10-11

B10 /10-1 /10-2 /10-5 /10-8

G10 /10-1 /10-2 /10-5 /10-8

C14 /10-1 /10-3 /10-5 /10-7

E14 /10-1 /10-3 /10-5 /10-7

– Install attachments on scissor lift table by hand first.

– Place -VAS 6131 A- in horizontal position.

l Note bubble level (sight glass) on support platform.

– Drive -VAS 6131 A- under engine/transmission subassembly.

– Position support elements from -VAS 6131/10- at front on engine as shown

in illustration.

– Position support elements from -VAS 6131/10- at left and right on subframe

as shown in illustration.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 20 of 36

:

1

– Position support elements from -VAS 6131/10- at left and right on tunnel

cross member as shown in illustration.

– Twist all spindles of support elements upward far enough until all support

pins make contact at support points.

– Tighten base plates for support elements to 20 Nm on -VAS 6131 A- .

– Mark installation position of subframe and of both engine mount brackets to

longmembers using a felt-tip marker.

– Remove bolts -1 to 4-in diagonal sequence and in stages.

t Verify that all hoses and lines between engine/transmission subassembly

and body have been disconnected.

t While lowering, carefully guide engine/transmission subassembly with

subframe out of engine compartment in order to prevent damage.

– Lower engine/transmission subassembly using -VAS 6131 A- first only

approximately dimension -a-.

l Dimension -a-= 100 mm.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 21 of 36

:

1

– Disconnect connecting rod -2-off shift rod.

– Remove socket head bolt of pivot rod -1-.

– Remove nut -arrow-and remove lever from selector shaft.

– Remove clutch slave cylinder -arrow-, do not disconnect lines.

– Tie up clutch slave cylinder together with shift rods.

– Lower engine/transmission subassembly downward.

– Push -VAS 6131 A- with engine/transmission subassembly under vehicle.

Engine and Transmission, Separating

t Scissor Lift Platform -VAS 6131 A-

t Support set for Audi -VAS 6131/10- and -VAS 6131/11-

t Adapter -T40058-

Procedure

l Engine/transmission unit removed and attached to -VAS 6131 A- .

t All cable ties opened or cut during engine removal must be reinstalled at

the same locations during installation.

t All heat insulation sleeves removed during engine removal must be

reinstalled at the same locations during installation.

– Twist spindles of support elements from -VAS 6131/10- at left and right at

subframe completely downward.

– Remove support pins from spindles.

– Remove subframe to the side.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 22 of 36

:

1

– Remove bottom engine/transmission connecting bolts -arrows-.

– Equip -VAS 6131 A- with -VAS 6131/10- and -VAS 6131/11- as follows:

Platform Parts of support set for Audi -VAS 6131/10- and -

coordinates VAS 6131/11-

B4 Support

elements

/10-1 /10-4 /10-5 /10-11

remain

unchanged.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 23 of 36

:

1

G3 Support

elements /10-1 /10-4 /10-5 /10-11

remain

unchanged.

C7 /10-1 /10-4 /10-5 /10-12

G7 /10-1 /10-4 /10-5 /10-12

F10 /10-1 /10-4 /10-5 /11-3

D12 /10-1 /10-2 /10-5 /11-2

C14 Support

elements

/10-1 /10-3 /10-5 /10-7

remain

unchanged.

E14 Support

elements

/10-1 /10-3 /10-5 /10-7

remain

unchanged.

1) Support elements remain unchanged.

– Position support elements from -VAS 6131/10- and -VAS 6131/11- at left on

engine/transmission as shown in illustration.

– Position support elements from -VAS 6131/10- and -VAS 6131/11- at right

on engine/transmission as shown in illustration.

– Twist spindles of attachments upward far enough until all support pins make

contact at support points.

– Tighten base plates for support elements to 20 Nm on -VAS 6131 A- .

– Remove electrical harness connectors -1-and -4-from bracket and

disconnect.

– Remove heat insulation sleeve on wiring harness and free up individual

wires.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 24 of 36

:

1

In the illustration, the electrical harness connectors are depicted as installed.

– Remove bolt -arrow-at strap for left front exhaust pipe.

– Remove nuts -1 to 3-for left front exhaust pipe/exhaust manifold.

– Remove front exhaust pipe with pre and main catalytic converters.

– Remove electrical harness connectors -2-and -4-from bracket and

disconnect.

– Free up the wiring harnesses.

In the illustration, the electrical harness connectors are depicted as installed.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 25 of 36

:

1

Remove bolt -arrow-at strap for right front exhaust pipe.

– Remove nuts -1 to 3-for right front exhaust pipe/exhaust manifold.

– Remove front exhaust pipe with pre and main catalytic converters.

– Remove Engine Speed (RPM) sensor -G28- on transmission -arrow-.

– Disconnect electrical harness connector -arrow-at back-up lamp switch -

F4- and free up electrical wire.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 26 of 36

:

1

– Remove engine/transmission threaded connections -1 to 7-.

– Loosen side clamping bolts -1-on scissor lift platform -VAS 6131 A- and

pull rear platform top with transmission toward rear -arrow-,

simultaneously push torque converter through opening of drive plate while

doing this.

Engine, Securing to Engine and Transmission Holder

t Shackle -10-222 A/12-

t Lifting tackle -3033-

t Engine and Transmission Holder -VAS 6095- with Holder for V8 Engine

Audi S4, allroad quattro -VAS 6095/1-6- or Holder for V8 Engine Audi S4,

allroad quattro -VAS 6095/1-6A-

t Shop crane -VAS 6100-

t Lift Arm Extension for Workshop Crane -VAS 6101-

t Additional Hooks -10-222 A/2-

Procedure

– Remove wiring harness bracket at right engine console -arrows-.

– Disconnect electrical harness connector -1-at right engine mount.

– Remove bolts -arrows-and remove right engine mount.

Shown without engine mount bracket to provide a better illustration.

– Repeat work procedure on opposite side of the vehicle.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 27 of 36

:

1

– Disconnect vacuum hose -1-.

– Disconnect air guide hose -2-from throttle valve control module.

– Secure shackle -10-222 A/12- to right rear engine lifting eyelet.

– Hook additional hook -10-222 A/2- on shackle -10-222 A/12- .

– Engage engine sling -3033- on additional hook -10-222 A/2- and on

workshop crane -VAS 6100- with lift arm extension for workshop crane -

VAS 6101- as shown in the illustration.

– Lift engine from support elements of scissor lift platform -VAS 6131 A- .

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 28 of 36

:

1

– Secure engine using the holder for V8 engine Audi S4, allroad quattro -VAS

6095/1-6- or holder for V8 engine Audi S4, allroad quattro -VAS 6095/1-6A-

, secured to the engine and transmission holder -VAS 6095- and tightened

to 42 Nm as shown in the illustration.

Engine, Installing

t During assembly, replace self-locking nuts and bolts.

t Always replace bolts that are tightened to torque as well as sealing rings,

gaskets and O-rings.

t Secure all hose connections using hose clamps appropriate for the model

type. Refer to the Parts Catalog.

t During installation, re-install all heat insulation sleeves at the same

locations.

t During installation, all cable ties must be re-installed at the same location.

– When installing a new clutch disc in combination with a used SAC clutch

pressure plate (self-adjusting pressure plate), the adjustment ring of the

pressure plate must be turned back to impact. Otherwise the pressure plate

works with decreased contact pressure (clutch slips). Refer to Manual

Transmission:Removal and Installation-30.

t If clutch disc is not being replaced, the adjustment ring must not be turned

back.

t New SAC-pressure plates are already pre-adjusted and must not be reset.

– Clean input shaft splines and (in case of used clutch plates) clean hub

splines, remove corrosion and apply only a very thin coating of lubricant.

Refer to the Parts Catalog on splines. Do not grease the guide sleeve.

– If necessary, check centering of clutch drive plate.

– Check clutch release bearing for wear and replace if necessary.

If plastic ring of clutch release bearing is loose:

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 29 of 36

:

1

– Adhere clutch release bearing plastic ring to bearing ring, adhesive. Refer

to the Parts Catalog.

l 3 rectangular tabs -arrows-of the plastic ring reach into the cutouts of the

bearing ring.

l If grooves with depth of more than 0.5 mm are present, the release bearing

must be replaced.

– Make sure centering sleeves for engine to transmission are installed in

cylinder block. Install if necessary.

– Install intermediate plate between engine and transmission onto alignment

bushings.

– Bolt transmission to engine.

t Tightening specifications only apply to lightly greased, oiled, phosphated or

blackened nuts and bolts.

t Additional lubricants, such as engine or transmission oil are permissible,

although lubricants containing graphite are not.

t Do not use any degreased parts.

t Tolerance for torque specifications ±15%.

Engine/transmission, fastening

Item Bolt Nm

1, 2 M12×120 65

3 M12×110 65

4, 5 M12×105 65

6 M12×130 65

7 M12×170 65

8, 9, 10 M10x60 45

A Alignment sleeves for centering

The rest of the installation is performed in reverse order of removal, noting the

following:

– Install front exhaust pipes with catalytic converters. Refer to: Left Left

Front Exhaust Pipe with Primary and Main Catalytic Converter,

Vehicles with Manual Transmission, right Right Front Exhaust Pipe

with Primary and Main Catalytic Converter, Vehicles with

Automatic Transmission.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 30 of 36

:

1

– Always clean threaded bores in transmission flanged shaft for driveshaft of

locking fluid residue using a tap before installation.

– Rotate spindles of support elements downward at left of

engine/transmission assembly.

– Remove both base plates for left support element on scissor lift platform -

VAS 6131 A- .

– Rotate spindles of support elements downward at right of

engine/transmission assembly.

– Remove both base plates for right support element on Scissor Lift Table -

VAS 6131 A- .

The support points for front of engine and tunnel cross member remain

unchanged.

– Equip -VAS 6131 A- with -VAS 6131/10- as follows:

Platform

Parts of support set for Audi -VAS 6131/10-

coordinates

B4 Support

elements

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 31 of 36

:

1

remain /10-1 /10-4 /10-5 /10-11

unchanged.

G3 Support

elements

/10-1 /10-4 /10-5 /10-11

remain

unchanged.

/10-8 Only

install

support

B10 /10-1 /10-2 /10-5 elements

after

installing

subframe.

/10-8 Only

install

support

G10 /10-1 /10-2 /10-5 elements

after

installing

subframe.

C14 Support

elements

/10-1 /10-3 /10-5 /10-7

remain

unchanged.

E14 Support

elements

/10-1 /10-3 /10-5 /10-7

remain

unchanged.

2) Support elements remain unchanged.

3) Only install support elements after installing subframe.

– Position subframe on both attachments -VAS 6131/10-8- .

– Twist spindles of support elements upward on both sides.

– Tighten base plates for support elements to 20 Nm on scissor lift platform -

VAS 6131 A- .

– Using scissor lift platform -VAS 6131 A- , slowly guide engine/transmission

unit with subframe into body from below.

– Lift engine/transmission subassembly using scissor lift platform -VAS 6131

A- until dimension -a-is reached.

l Dimension -a-= 100 mm.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 32 of 36

:

1

– Secure clutch slave cylinder with a new bolt -arrow-.

– Install lever for selector shaft -arrow-.

– Install connecting rod -2-on shift rod.

– Install pivot rod socket head bolt -1-.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 33 of 36

:

1

– Align subframe, engine bearing brackets and tunnel cross member

according to markings applied on longmembers during removal.

– Tighten bolts for subframe, engine mount brackets as well as tunnel

crossmember only to specified torque. Do not tighten further (tighten bolts

only after axle alignment).

1 - 65 Nm

2 - 110 Nm

3 - 110 Nm

4 - 75 Nm

Vehicle must not be driven in this condition.

– Install drive axles. Refer to Suspension, Wheels, Steering:Removal

and Installation-40.

– Install guide control arm, control arm, stabilizer bar and suspension strut.

Refer to Suspension, Wheels, Steering:Removal and Installation-

40.

– Install driveshaft. Refer to: Rear Final Drive 0AR:Driveshaft, Assembly

Overview-39 or Rear Final Drive 01R:Driveshaft, Assembly

Overview-39 .

– Align exhaust system free of tension. Refer to Exhaust System,

Installing.

– Install refrigerant lines. Refer to Heating, Ventilation and Air

Conditioning:Removal and Installation-87.

– Secure fuel hose to connection on fuel rail pipe. To do so, counterhold using

an open-end wrench at each hex head -1-and -3-and tighten union nut -2-

to 22 Nm.

– Install lock carrier with attachments. Refer to Body Exterior:Description

and Operation-50.

– Place torque support on rubber buffer for torque support and tighten bolts -

arrows-.

– Install front bumper cover. Refer to Body Exterior:Removal and

Installation-63.

– Electrical connections and routing. Refer to → .

– Observe safety precautions after connecting battery. Refer to Electrical

Equipment:Removal and Installation-27.

Do not use a battery charger for starting assistance! There is the risk

that the vehicle control modules could be damaged.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 34 of 36

:

1

– Mount wiper arms and adjust. Refer to Electrical Equipment:Removal

and Installation-92.

– Check oil level. Refer to Oil Level, Checking.

– Before starting engine for the first time, fill power steering vacuum reservoir

with hydraulic oil. Refer to Suspension, Wheels, Steering:General

Information-48.

Power-steering pump must not run dry.

– Fill with coolant Filling.

t Only reuse drained coolant if cylinder head or engine block was not

replaced.

t Dirty coolant must not be re-used.

– Fill refrigerant circuit. Refer to Refrigerant R134a -

Servicing:Description and Operation-87.

– Align subframe and both engine bearing brackets. Refer to Suspension,

Wheels, Steering:Removal and Installation-40

– Perform axle alignment. Refer to Suspension, Wheels,

Steering:Description and Operation-44.

After axle alignment, tighten subframe bolts to final torque.

– Check headlight adjustment. Refer to → 803 or → 805 .

Tightening Specifications

t Tightening specifications only apply to lightly greased, oiled, phosphated or

blackened nuts and bolts.

t Additional lubricants, such as engine or transmission oil are permissible,

although lubricants containing graphite are not.

t Do not use any degreased parts.

t Tolerance for torque specifications ±15%.

Component Nm

Bolts/nuts M6 9

M8 20

M10 40

M12 65

Exceptions:

42 Insert using

locking

compound;

Engine support to engine locking

compound.

Refer to the

Parts Catalog.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 35 of 36

:

1

Clutch slave cylinder to transmission 23 Replace bolt.

Selector shaft lever to transmission 23

Pivot rod on transmission 40

Shift rod connecting rod on transmission 23

Heat shield for driveshaft to transmission 23

Hydraulic pressure line 40

Torque support stop to lock carrier 28

Fuel hose to fuel line 22

4) Insert using locking compound; locking compound. Refer to the Parts

Catalog.

5) Replace bolt.

Portions of materials contained herein have been reprinted under license from Volkswagen Group of America, Inc.,

License Agreement 09507VWA.

Copyright 2011 - 2013 Service Repair Solutions, Inc.

https://dh.identifix.com/ServiceManuals/Index?ROID=3805145 nguageId=1&TocTreePath=137374_9799_0%7C137375_9799_0 6/25/24, 12 26 AM

Page 36 of 36

:

1

You might also like

- Audi B6 AMB Engine Removing and Installing PDFDocument27 pagesAudi B6 AMB Engine Removing and Installing PDFjugoslavdjurdj100% (4)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Touareg 2003-07 Engine RepairsDocument317 pagesTouareg 2003-07 Engine RepairsZayd Majoka80% (5)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Bayer Clinitek - Service ManualDocument172 pagesBayer Clinitek - Service ManualAngeles Lagunes100% (2)

- R8 Spyder V10 - Engine RemovalDocument41 pagesR8 Spyder V10 - Engine RemovalohshafiNo ratings yet

- Audi A4/b4 Engine TDI 1.9 (1Z and AHU) - Service ManualDocument276 pagesAudi A4/b4 Engine TDI 1.9 (1Z and AHU) - Service ManualAdrian Hofnăr86% (7)

- Skoda Fabia - Removing and Installing EngineDocument8 pagesSkoda Fabia - Removing and Installing Enginebuerebista100% (1)

- Audi 100Document93 pagesAudi 100Dalibor Angelovski100% (1)

- 2008 Nissan Teana J32 Service Manual-CODocument27 pages2008 Nissan Teana J32 Service Manual-COMrihexNo ratings yet

- Body MK5 Jetta GolfDocument549 pagesBody MK5 Jetta Golfvixentd100% (3)

- Revue Technique Audi A4 B5 1997 2000Document1,323 pagesRevue Technique Audi A4 B5 1997 2000Datoman75% (4)

- DV Mechanical Adjustment ManualDocument19 pagesDV Mechanical Adjustment ManualPan SairaNo ratings yet

- 4B3.3 G1 Parts Manual 162-520Document77 pages4B3.3 G1 Parts Manual 162-520Panagiotis PanagosNo ratings yet

- Radiator RemovalDocument8 pagesRadiator RemovaliveyNo ratings yet

- A2 TorquesDocument25 pagesA2 TorquesGabriel CazacuNo ratings yet

- 03 - Removing and Installing Timing Chain Cover (Right-Side)Document4 pages03 - Removing and Installing Timing Chain Cover (Right-Side)ЖулиенИ.ВасилевNo ratings yet

- Mercedes - 220 - Workshop Manual - 1994 - 1995 - 2Document13,111 pagesMercedes - 220 - Workshop Manual - 1994 - 1995 - 2Juan Harmond Bambang Wirawan100% (1)

- 34-18 Transmission Remove & InstallDocument21 pages34-18 Transmission Remove & Installmefisto06cNo ratings yet

- 97-1 Relay Panel, Fuse Panel PDFDocument5 pages97-1 Relay Panel, Fuse Panel PDFmefisto06cNo ratings yet

- Removing and Installing Turbocharger Skoda PetrolDocument5 pagesRemoving and Installing Turbocharger Skoda Petrolfrancismci92No ratings yet

- R8 Spyder V10 - Side Radiator InstallationDocument5 pagesR8 Spyder V10 - Side Radiator InstallationohshafiNo ratings yet

- Desmontaje Filtro Particulas Skoda Fabia 1.6 TDIDocument7 pagesDesmontaje Filtro Particulas Skoda Fabia 1.6 TDIFrancisco José MarotoNo ratings yet

- C6 RS6 Replace Spark PlugsDocument11 pagesC6 RS6 Replace Spark PlugssorensavcorNo ratings yet

- Generator, Removing and InstallingDocument14 pagesGenerator, Removing and InstallingAdrianLungociNo ratings yet

- Fuel System: SectionDocument13 pagesFuel System: Sectiontomallor101No ratings yet

- FL PDFDocument19 pagesFL PDFSantiago LopezNo ratings yet

- 96-16 Lock Cylinder HeatingDocument2 pages96-16 Lock Cylinder Heatingmefisto06cNo ratings yet

- Fabia 2Document7 pagesFabia 2Mihai StoicaNo ratings yet

- Starter A8 ChangeDocument7 pagesStarter A8 ChangeJim JonesNo ratings yet

- K38 Rocker HousingDocument13 pagesK38 Rocker HousinghindraNo ratings yet

- LockCarrier RemoveandInstallDocument2 pagesLockCarrier RemoveandInstallDaniel McDonaldNo ratings yet

- Elsa Online. ElsaWin. ElsaWeb. Audi 1Document10 pagesElsa Online. ElsaWin. ElsaWeb. Audi 1Andrei Ionut UtaNo ratings yet

- 48-71 Steering Column Remove & Install PDFDocument14 pages48-71 Steering Column Remove & Install PDFmefisto06c100% (1)

- Removing and Installing Starter - Vehicles With 2.0 Ltr. TFSI EngineDocument3 pagesRemoving and Installing Starter - Vehicles With 2.0 Ltr. TFSI EngineAzj SonyNo ratings yet

- Change Storage Box in Centre ConsoleDocument12 pagesChange Storage Box in Centre ConsoleSmartTvHomeNo ratings yet

- 57-39 Central Locking SystemDocument11 pages57-39 Central Locking Systemmefisto06c100% (1)

- 0B5 Mechatronic - ServiceDocument6 pages0B5 Mechatronic - ServicepecirepiNo ratings yet

- Engine - Gearbox Assembly Removal2Document20 pagesEngine - Gearbox Assembly Removal2JohnnoNo ratings yet

- R8 Spyder V10 - Securing Engine To SupportsDocument7 pagesR8 Spyder V10 - Securing Engine To SupportsohshafiNo ratings yet

- 1233-1240 Система вентиляцииDocument8 pages1233-1240 Система вентиляцииalieks.klim1611No ratings yet

- Manual Clima PassatDocument48 pagesManual Clima PassatCatalin JianuNo ratings yet

- Exhaust System: SectionDocument11 pagesExhaust System: SectionRafaelCazalesFuentesNo ratings yet

- Alternator RemovalDocument5 pagesAlternator RemovalKevin HuangNo ratings yet

- 1 Removing and Installing EngineDocument22 pages1 Removing and Installing EngineDanielNo ratings yet

- Caution! Hot Vapor or Hot Coolant May Escape On Opening Reservoir. Cover Cap With Cloth and Open CarefullyDocument16 pagesCaution! Hot Vapor or Hot Coolant May Escape On Opening Reservoir. Cover Cap With Cloth and Open Carefullyscribd_com1889No ratings yet

- AutomovelDocument49 pagesAutomovelCarlos BraiaNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionOmar RodriguezNo ratings yet

- 19607486-1982-1990 Chevrolet Blazer Service and Repair ManualDocument1,358 pages19607486-1982-1990 Chevrolet Blazer Service and Repair Manualgato0ariasNo ratings yet

- Rear Lid Vents - RemovalDocument5 pagesRear Lid Vents - RemovalohshafiNo ratings yet

- Demontare Caseta de DirectieDocument8 pagesDemontare Caseta de DirectieSerban SimiNo ratings yet

- b6 97 EngDocument104 pagesb6 97 EngdanielvasilievNo ratings yet

- Service Info: Assembly InstructionsDocument3 pagesService Info: Assembly Instructionsjose marquesNo ratings yet

- ECU RelaysDocument3 pagesECU RelaysdavidacarrickNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- UFN3-70B413: Fork SensorsDocument7 pagesUFN3-70B413: Fork SensorsJoan LamedaNo ratings yet

- Aa85-001 Intervox Ii™: Intercom System Data SheetDocument2 pagesAa85-001 Intervox Ii™: Intercom System Data SheetMilena Rocío LamonegaNo ratings yet

- Atlas Copco: Stationary Air CompressorsDocument100 pagesAtlas Copco: Stationary Air CompressorsJavier LópezNo ratings yet

- GS120 Light Curtain ManualDocument38 pagesGS120 Light Curtain ManualMichael Cox100% (1)

- Renishaw RGH24 Data SheetDocument10 pagesRenishaw RGH24 Data SheetVan hiếu PhạmNo ratings yet

- Operation Manual: (Wheel Balancer)Document14 pagesOperation Manual: (Wheel Balancer)hector castellanos rNo ratings yet

- PSU A17/38 Ancillary Power UnitDocument12 pagesPSU A17/38 Ancillary Power UnitjohnNo ratings yet

- Insulated Conductor Rail Single Powerline Program 0812: WWW - Conductix.UsDocument36 pagesInsulated Conductor Rail Single Powerline Program 0812: WWW - Conductix.UsHéctor FuentesNo ratings yet

- 980a3676 PDFDocument49 pages980a3676 PDFMichael Davenport0% (1)

- Catálogo COMPLETO JSGDocument36 pagesCatálogo COMPLETO JSGSebastian AudisioNo ratings yet

- Sensor CablesDocument8 pagesSensor CablesVirendrapratap SinghNo ratings yet

- Service Manual: Compact Component SystemDocument45 pagesService Manual: Compact Component SystemHarveysolar3916No ratings yet

- PD 250e PDFDocument26 pagesPD 250e PDFBL LNo ratings yet

- RZ A Installation Instruction 2Document19 pagesRZ A Installation Instruction 2john.woodworthiiiNo ratings yet

- Anisotropical Conductive Adhesives: IntroductionDocument10 pagesAnisotropical Conductive Adhesives: IntroductionSyarifahNo ratings yet

- MS2320 ConfigurationDocument4 pagesMS2320 Configurationnsm.transomNo ratings yet

- VHS Test and Calibrate 539B CDocument36 pagesVHS Test and Calibrate 539B CJennifer EdwardsNo ratings yet

- BCN-1310A-8001-1 - 1310A Quick Start GuideDocument2 pagesBCN-1310A-8001-1 - 1310A Quick Start GuidePrince Friday EkpoNo ratings yet

- Manual Banlanza Ohaus I5SDocument46 pagesManual Banlanza Ohaus I5SWilson Ramírez100% (1)

- SHR-2160/2162/2080/2082 User's ManualDocument184 pagesSHR-2160/2162/2080/2082 User's ManualAnonymous dfJF0NBAMFNo ratings yet

- Manual VDF SiemensDocument332 pagesManual VDF SiemensMarco Rojas100% (1)

- D92-1001 Tarea 2 ArranqueDocument4 pagesD92-1001 Tarea 2 ArranquemarioNo ratings yet

- Poynting - Wlan-A0056Document2 pagesPoynting - Wlan-A0056Izwan HafizNo ratings yet

- Kodak Impresora Placas Dryview 8900 - r3 - Service ManualDocument359 pagesKodak Impresora Placas Dryview 8900 - r3 - Service Manualmanolozamora100% (3)

- Regency Hotel BoqDocument5 pagesRegency Hotel BoqJohn Chester GayetaNo ratings yet

- Sailor 500/250 Fleetbroadband: User ManualDocument16 pagesSailor 500/250 Fleetbroadband: User ManualRoop randevNo ratings yet

- Fluiconnecto Adaptors CatalogueDocument232 pagesFluiconnecto Adaptors CatalogueFederico Quintero AngaritaNo ratings yet