Professional Documents

Culture Documents

Annex-IX Objectives Mach Rejection(1)

Annex-IX Objectives Mach Rejection(1)

Uploaded by

prajapatim00Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex-IX Objectives Mach Rejection(1)

Annex-IX Objectives Mach Rejection(1)

Uploaded by

prajapatim00Copyright:

Available Formats

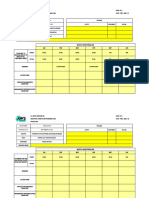

Quality objectives & Process Parameters Monitoring

Year : 2022

Sr.No. Process Parameter Responsibility Target How to Achieve Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Total/Avg. Action plan Remarks

Switch off lights, fans when not in

Energy Consumption Maintenance incharge <4.51 Units Per motor use. 2.08 1.74 1.48 2.78 2.10 1.97 1.87 1.91 1.53 2.23 1.49 1.36 1.88

Avoid idle running of machines

Avoiding air leakages.

Compressor running hours (M-73) Maintenance incharge <500 hours per month Eliminating repeatitive sources of 293 329 374 331 331 379 378 348 373 291 321 325 339.42

leakages.

Improving awareness of workers.

3 Maintenance Near Miss Incidents Production head At least 1 per month Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil

Encouraging of near miss reporting.

Improving awareness of workers.

First Aid Incidents Production head Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil

Encouraging of near miss reporting.

Improving awareness of workers.

Reportable Accident Production head Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil

Encouraging of near miss reporting.

[Process Parameters & Quality objectives Monitoring] [Annexure-IX] from[Rev.0/01.01.2019] Page 1 of 1

Quality objectives & Process Parameters Monitoring

Year : 2022

How to Achieve

Sr.No. Process Parameter Responsibility Target Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Total/Avg. Action plan Remarks

Monitoring of internal audit and

Conduct Internal audit as per plan Management 100% MRM plan

Conduct Management review at Monitoring of internal audit and

Management 100% MRM plan

defined frequency

Monitoring of all process Collection of all relevant data for all

1 EOHSMS Management 100% months

performance

Monitoring effectiveness of all

instances of justified adverse operational controls, Reducing

communication from external Management Nil impacts of all significant aspects

interested parties

Switch off lights, fans, when not in

Energey Consumption <4.51 units per motor use. Avoid idle running of machines 2.28 1.78 1.62 3.02 2.45 2.04 2.16 2.37 1.65 2.57 1.38 1.49 2.07

Avoid leakages/spillages improving

Process Waste and residues material handling practices

<10 gm per motor 10.36 7.83 6.76 11.03 10.11 8.45 9.10 9.37 6.22 6.91 8.36 6.79 8.44

generated

Avoid leakages/spillages avoiding

Water consumption <20 lit per motor idle running of taps 17.47 13.19 12.81 16.19 14.80 16.23 18.14 17.82 15.29 15.10781 13.21149 13.86049 15.34

Avoid leakage/spillages. Improving

Varnish Consumption <0.055 lit per motor material handling practices 0.04 0.03 0.04 0.04 0.04 0.04 0.04 0.04 0.03 0.02 0.02 0.03 0.03

2 Production/QC

Improving awareness of workers.

Encouraging of near miss reporting

Near Miss Incidents At least 1 per month 0 0 0 0 0 0 0 0 0 0 0 0 0

Improving awareness of workers.

Encouraging of near miss reporting

First Aid Incidents Nil 0 0 0 0 0 0 0 0 1 0 0 0 0

Improving awareness of workers.

Encouraging of near miss reporting

Reportable Accident Nil 0 0 0 0 0 0 0 0 0 0 0 0 0

Switch off lights, fans when not in

Energy Consumption Maintenance incha <4.51 Units Per motor use. 2.28 1.78 1.62 3.02 2.45 2.04 2.16 2.37 1.65 2.57 1.38 1.49 2.07

Avoid idle running of machines

Avoiding air leakages.

Compressor running hours (M-73) Maintenance incha<500 hours per month Eliminating repeatitive sources of 293 329 374 331 331 379 363 348 373 291 321 325 338.17

leakages.

Improving awareness of workers.

3 Maintenance Near Miss Incidents Production head At least 1 per month Encouraging of near miss reporting. 0 0 0 0 0 0 0 0 0 0 0 0 Nil

Improving awareness of workers.

First Aid Incidents Production head Nil Encouraging of near miss reporting. Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil

Improving awareness of workers.

Reportable Accident Production head Nil Encouraging of near miss reporting. Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil Nil

Avoid leakages/spillages improving

Paint Consumption Store Incharge <0.025 lit per motor material handling practices 0.02 0.01 0.02 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01 0.01

Avoid leakages/spillages improving

Generation of process Residue Store Incharge <10 gm per motor material handling practices 10.36 7.83 6.76 11.03 10.11 8.45 9.10 9.37 6.22 6.91 8.36 6.79 8.44

Improving awareness of workers

4 Stores Near Miss Incidents Store Incharge At least 1 per month Encouraging of near miss reporting 0 0 0 0 0 0 0 0 0 0 0 0 0

Improving awareness of workers

First Aid Incidents Store Incharge Nil Encouraging of near miss reporting 0 0 0 0 0 0 0 0 0 0 0 0 0

Improving awareness of workers

Reportable Accident Store Incharge Nil Encouraging of near miss reporting 0 0 0 0 0 0 0 0 0 0 0 0 0

instances of justified adverse Monitoring effectiveness of all

5 Marketing/Purchase communication from external Marketing Head Nil operational controls, Reducing 0 0 0 0 0 0 0 0 0 0 0 0 0

interested parties impacts of all significant aspects

[Process Parameters & Quality objectives Monitoring] [Annexure-IX] from[Rev.0/01.01.2019] Page 1 of 1

Quality objectives Monitoring Year: 2023-2024

Sr.No. Process Parameter Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Average Action plan Remarks

M/c Shop prodution (In Kg) 12188 13372 22607 9036 22876 8317 13845 14336 7225 0 12380

1 M/C SHOP M/c Shop rejection (In Kg) 736.8 251 0 721.8 159.4 284.6 168 599.9 419.7 0 334

M/c Shop Rejection% 6.0 1.9 0.0 8.0 0.7 3.4 1.2 4.2 5.8 #DIV/0! #DIV/0! #DIV/0! 2.7

[Quality objectives Monitoring] [Annexure-V] from[Rev.0/01.01.2019] Page 1 of 1

M/c Shop prodution(In Kg) M/c Shop rejection%

25000 9.0

22607 22876 8.0

8.0

20000

7.0

6.0 5.8

6.0

15000 13845 14336

13372

12188 12380 5.0

4.2

4.0 3.4

10000 9036

8317

7225 3.0 2.7

1.9

5000 2.0

1.2

1.0 0.7

0 0.0

0 0.0

Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Average Apr May Jun Jul Aug Sep Oct Nov Dec Jan Feb Mar Average

You might also like

- The Essentials of Psychodynamic PsychotherapyDocument6 pagesThe Essentials of Psychodynamic PsychotherapyMarthaRamirez100% (3)

- KRA - GRA - Maintenance. 22-23Document14 pagesKRA - GRA - Maintenance. 22-23PravinNo ratings yet

- 01 Quality Objectives SummaryDocument1 page01 Quality Objectives Summaryarylananyla100% (1)

- Lab2 PDFDocument3 pagesLab2 PDFMd.Arifur RahmanNo ratings yet

- BIACS 2 - Seville Biennial: The Unhomely (Review)Document3 pagesBIACS 2 - Seville Biennial: The Unhomely (Review)foggy_notionNo ratings yet

- IPPTA 153 101 104 Strategy To AchieveDocument4 pagesIPPTA 153 101 104 Strategy To AchieveKory SantiagoNo ratings yet

- Skill Advancement: Utilities Equipment Maintenance ImprovementDocument8 pagesSkill Advancement: Utilities Equipment Maintenance ImprovementSetiawan HatmajiNo ratings yet

- Schedule of Monitoring Activities: Control Monitoring Activity Responsibilities TimelinesDocument4 pagesSchedule of Monitoring Activities: Control Monitoring Activity Responsibilities TimelinesWai Man LeeNo ratings yet

- Unit 2 5 MarksDocument1 pageUnit 2 5 MarksBipul VermaNo ratings yet

- TPMDocument42 pagesTPMSrinivasan VenkatNo ratings yet

- TO Amega West Services: A Carpenter CompanyDocument34 pagesTO Amega West Services: A Carpenter CompanyKamatchiNo ratings yet

- FR2 Asset ManagementDocument49 pagesFR2 Asset Managementjuan dela cruzNo ratings yet

- Quality Culture: To Build Quality BusinessDocument26 pagesQuality Culture: To Build Quality BusinessJAFFERNo ratings yet

- Sop: Kaizen Implementation& Evaluation: DefinitionDocument11 pagesSop: Kaizen Implementation& Evaluation: DefinitionDhrubo BaruaNo ratings yet

- TPM A Key Strategy For Productivity ImprDocument8 pagesTPM A Key Strategy For Productivity ImprkhurshedlakhoNo ratings yet

- Effective Performance ManagementDocument2 pagesEffective Performance ManagementBrendan CrowleyNo ratings yet

- Total Productive Maintenance (TPM)Document27 pagesTotal Productive Maintenance (TPM)Muhammad KamranNo ratings yet

- Sheq TargetsobjectivesDocument2 pagesSheq TargetsobjectivesbabjihanumanthuNo ratings yet

- Otp 2019Document2 pagesOtp 2019Lamtua Purba100% (1)

- Continual Improvement Using Jishu Hozen Pillar of Total Productive Maintenance in Manufacturing OrganizationDocument7 pagesContinual Improvement Using Jishu Hozen Pillar of Total Productive Maintenance in Manufacturing OrganizationPE QANo ratings yet

- Operational Excellence in Textile Industry Case Study: East AfricaDocument3 pagesOperational Excellence in Textile Industry Case Study: East AfricafarooquintuNo ratings yet

- Zero Defect and Zero Effect: - Maturity ModelDocument8 pagesZero Defect and Zero Effect: - Maturity ModelYash BelaniNo ratings yet

- 03 AF L1 Flow of The Audit LM 00 LSLDocument21 pages03 AF L1 Flow of The Audit LM 00 LSLJosephine LimNo ratings yet

- B S V S S VARMA, EHS Task-1Document16 pagesB S V S S VARMA, EHS Task-1sravan BattulaNo ratings yet

- Roles and Repsonsibilities - Production Manager/EstimatorDocument5 pagesRoles and Repsonsibilities - Production Manager/EstimatortrainershipsolutionsNo ratings yet

- TPM 8 PillarsDocument6 pagesTPM 8 Pillarsarajamani78No ratings yet

- Job Description - AllDocument9 pagesJob Description - Allpuput utomoNo ratings yet

- NTPC - Power To Empower Impact MetricsDocument15 pagesNTPC - Power To Empower Impact MetricsNageswar MakalaNo ratings yet

- A Strategy For Performance ExcellenceDocument73 pagesA Strategy For Performance Excellenceravi.youNo ratings yet

- Step 0 and 1 Management Part 1Document14 pagesStep 0 and 1 Management Part 1murilocabriniNo ratings yet

- APEX SeminarDocument34 pagesAPEX SeminarAlsayed DiabNo ratings yet

- Oee in PracticeDocument30 pagesOee in PracticeAlois AmaldNo ratings yet

- Chap 7 Maintenance PlanningfDocument32 pagesChap 7 Maintenance PlanningfAbeyu AssefaNo ratings yet

- Total Productive Maintenance (TPM)Document25 pagesTotal Productive Maintenance (TPM)chaitanya_kumar_13No ratings yet

- Autonomus Maintenance - Maintenance MonthDocument92 pagesAutonomus Maintenance - Maintenance MonthBakhsheesh100% (1)

- Setting A New Standard in Alarm ManagementDocument16 pagesSetting A New Standard in Alarm ManagementemadNo ratings yet

- Shri Vishwakarama Skill University: Name Lalit Kumar ROLL NO. 20L5DMM14105 Topic Documents Use in IndustryDocument41 pagesShri Vishwakarama Skill University: Name Lalit Kumar ROLL NO. 20L5DMM14105 Topic Documents Use in IndustryVishal NarwalNo ratings yet

- Appraisal: Dwi ApriliyantoDocument4 pagesAppraisal: Dwi ApriliyantoDwi April YantoNo ratings yet

- Lean System Thinking - Overview-Awareness SessionDocument97 pagesLean System Thinking - Overview-Awareness SessionBayoumy ElyanNo ratings yet

- Operations Planning & Control: SR - No Description Option1 Option2 Option3 Option4 ADocument9 pagesOperations Planning & Control: SR - No Description Option1 Option2 Option3 Option4 AKrish KrishNo ratings yet

- Kaizen 2018 Part 2Document29 pagesKaizen 2018 Part 2Maxell TohshinNo ratings yet

- B S V S S VARMA, EHS Task-1Document16 pagesB S V S S VARMA, EHS Task-1sravan BattulaNo ratings yet

- All Pillar OverviewDocument29 pagesAll Pillar OverviewSIVAKUMAR SHANMUGASUNDARAMNo ratings yet

- Faber Infinite Case Study Equipment Performance Improvement in Textile IndustryDocument3 pagesFaber Infinite Case Study Equipment Performance Improvement in Textile IndustryfarooquintuNo ratings yet

- Assignment 4Document21 pagesAssignment 4Hina SaleemNo ratings yet

- Implement Innovative Processes: Submission DetailsDocument13 pagesImplement Innovative Processes: Submission DetailsMuhammad Sheharyar MohsinNo ratings yet

- Group 4 3simbDocument19 pagesGroup 4 3simbquen anatasyaNo ratings yet

- Autonomous Operator Training Step 0 PDFDocument17 pagesAutonomous Operator Training Step 0 PDFjesusmemNo ratings yet

- Rohit Raj - BFT - 5 - MM Assign1Document9 pagesRohit Raj - BFT - 5 - MM Assign1Rohit RajNo ratings yet

- Core ObjectiveDocument1 pageCore ObjectiveMatthew LeeNo ratings yet

- t870 - Industrial Orientation n3 Aug Memo 2019 Signed OffDocument5 pagest870 - Industrial Orientation n3 Aug Memo 2019 Signed OffAbiodun IloriNo ratings yet

- Total Productive Maintenance: Production Production Maintenance MaintenanceDocument42 pagesTotal Productive Maintenance: Production Production Maintenance Maintenance123456789No ratings yet

- Modelling and Simulation in Process Industry by MobatecDocument22 pagesModelling and Simulation in Process Industry by MobatecAhmed MokhtarNo ratings yet

- S.No. Category Parameters Weightage Target Measure Source RemarksDocument1 pageS.No. Category Parameters Weightage Target Measure Source RemarksVanajaNo ratings yet

- Selling Planning, Coordination, and Scheduling To Management and OperationsDocument10 pagesSelling Planning, Coordination, and Scheduling To Management and OperationsRafik BenhendaNo ratings yet

- Support Your Business Goals With SKF Maintenance Strategy ReviewDocument4 pagesSupport Your Business Goals With SKF Maintenance Strategy ReviewAndresNo ratings yet

- MANMGT2 First Grading ReviewerDocument5 pagesMANMGT2 First Grading Reviewerpout poutNo ratings yet

- TPMDocument36 pagesTPMKajal MattuNo ratings yet

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisAzad pravesh khanNo ratings yet

- Objective Target Responsible AccountabilityDocument1 pageObjective Target Responsible AccountabilityMehrab AliNo ratings yet

- FRM QUA 506 Process Audit Sheet 1Document2 pagesFRM QUA 506 Process Audit Sheet 1Ravi javaliNo ratings yet

- Production OTAPDocument10 pagesProduction OTAPPablo EstebanNo ratings yet

- Essay by MariemDocument2 pagesEssay by MariemMatthew MaxwellNo ratings yet

- Dual-Band Wearable Rectenna For Low-Power RF Energy HarvestingDocument10 pagesDual-Band Wearable Rectenna For Low-Power RF Energy HarvestingbabuNo ratings yet

- Iii Iihiiiiiiiiiiii 111111: Does User-Oriented Gas Turbine Research Pay Off?Document7 pagesIii Iihiiiiiiiiiiii 111111: Does User-Oriented Gas Turbine Research Pay Off?Morteza YazdizadehNo ratings yet

- Free Online Course On PLS-SEM Using SmartPLS 3.0 - Moderator and MGADocument31 pagesFree Online Course On PLS-SEM Using SmartPLS 3.0 - Moderator and MGAAmit AgrawalNo ratings yet

- Fped 07 00310Document6 pagesFped 07 00310Fariz HidayatNo ratings yet

- The Quiescent Benefits and Drawbacks of Coffee IntakeDocument6 pagesThe Quiescent Benefits and Drawbacks of Coffee IntakeVikram Singh ChauhanNo ratings yet

- Clinical Emergency Management Program: Advanced WorkshopDocument4 pagesClinical Emergency Management Program: Advanced WorkshopNataraj ThambiNo ratings yet

- Edo Mite GenealogiesDocument23 pagesEdo Mite GenealogiesPeace Matasavaii LeifiNo ratings yet

- Task Force On Sexual Assault and Interpersonal Violence Final Report 2014-15Document16 pagesTask Force On Sexual Assault and Interpersonal Violence Final Report 2014-15Fourth EstateNo ratings yet

- Investments AssignmentDocument5 pagesInvestments Assignmentapi-276011473No ratings yet

- UNIT 3 Part 1-Propositional LogicDocument11 pagesUNIT 3 Part 1-Propositional LogicVanshika ChauhanNo ratings yet

- Current Affairs October 2013kDocument76 pagesCurrent Affairs October 2013kKanthi Rekha VardhiNo ratings yet

- Ordinary People Summary ChartDocument2 pagesOrdinary People Summary Chartangela_cristiniNo ratings yet

- Installation Manual: Enclosed Type Switching Power Supply (Families: G3, NE, LRS, SE, PFC, HSP, SPV, USP, RST, G5, MSP)Document2 pagesInstallation Manual: Enclosed Type Switching Power Supply (Families: G3, NE, LRS, SE, PFC, HSP, SPV, USP, RST, G5, MSP)Aicky IkrackNo ratings yet

- Artificial Intelligence and Patent LawDocument4 pagesArtificial Intelligence and Patent LawSaksham TyagiNo ratings yet

- CBWorld August1981 PDFDocument64 pagesCBWorld August1981 PDFbobbyunlockNo ratings yet

- Roger Dale Stafford, Sr. v. Ron Ward, Warden, Oklahoma State Penitentiary at McAlester Oklahoma Drew Edmondson, Attorney General of Oklahoma, 59 F.3d 1025, 10th Cir. (1995)Document6 pagesRoger Dale Stafford, Sr. v. Ron Ward, Warden, Oklahoma State Penitentiary at McAlester Oklahoma Drew Edmondson, Attorney General of Oklahoma, 59 F.3d 1025, 10th Cir. (1995)Scribd Government DocsNo ratings yet

- PYF Biennial Conference Vawi 19-NaDocument1 pagePYF Biennial Conference Vawi 19-NaMizoram Presbyterian Church SynodNo ratings yet

- Reply of DV ComplaintDocument17 pagesReply of DV Complaintparveensaini2146No ratings yet

- A Biblical Philosophy of MinistryDocument11 pagesA Biblical Philosophy of MinistryDavid Salazar100% (4)

- Muscle Memo Workout - Guitar Coach MagDocument28 pagesMuscle Memo Workout - Guitar Coach Magpeterd87No ratings yet

- 11.02.2022-PHC ResultsDocument6 pages11.02.2022-PHC ResultsNILAY TEJANo ratings yet

- Annual Return For A Company Limited by GuaranteeDocument4 pagesAnnual Return For A Company Limited by GuaranteeAtisang Tonny SethNo ratings yet

- Sap Fico Blueprint-1Document32 pagesSap Fico Blueprint-1Deepak AggarwalNo ratings yet

- Metals and Non Metals NotesDocument3 pagesMetals and Non Metals NotesVUDATHU SHASHIK MEHERNo ratings yet

- Government of Karnataka: Only For Birth Verification PurposeDocument1 pageGovernment of Karnataka: Only For Birth Verification PurposeAmit VantagodiNo ratings yet

- Chinas Legal Strategy To Cope With US Export ContDocument9 pagesChinas Legal Strategy To Cope With US Export Contb19fd0013No ratings yet