Professional Documents

Culture Documents

MTC-ENERY-DN 98

MTC-ENERY-DN 98

Uploaded by

cmanrekCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTC-ENERY-DN 98

MTC-ENERY-DN 98

Uploaded by

cmanrekCopyright:

Available Formats

INDUSTRIAL CABLE MANAGEMENT SYSTEMS CO. W.L.L.

P. O. BOX: 22108, DOHA QATAR

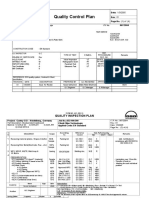

COATING INSPECTION AND TEST CERTIFICATE

INSPECTION AND TESTING IN ACCORDANCE WITH ISO 10204 FOR COMPLIANCE WITH ASTM A 123 / BS EN ISO 1461: 2009

CERTIFICATE # 24-06-14672 DATE 1-Jun-24

Name of Customer Energy Tec

Client DO # ET/DN/ICMS/24/98

OUR JOB #

Coating Thickness (in microns) Average Mass of Zn

Item # Part No. Item Description Qty UOM Coating (in gms / sq.

Thickness m)

R1 R2 R3 R4 R5

Access Ladder -1 , Pipe Dia 42x1.5mm -

1 1 PCS 122 133 105 118 110 117.6 839.664

Dimension – 829(L)x660(W)x2429(H)

Access Ladder -2 , Pipe Dia 42x1.5mm -

2 1 PCS 100 109 120 112 138 115.8 826.812

Dimension – 829(L)x660(W)x2429(H)

Access Ladder -3 , Pipe Dia 42x1.5mm -

3 1 PCS 106 112 135 110 104 113.4 809.676

Dimension – 829(L)x660(W)x2429(H)

ZINC COATING APPEARANCE

The accepatability of the coating finish is judged by the inspection condition laid down in BS EN 1461 - under- coating properties - point

No. 6 on page 6.

Zinc coating is free of gross surface imperfection of bare spots, heavy lumps and blisters.

ADHESION TEST.

Zinc Coating does not lift of in large flakes when tested with pivoted hammer and stout knife as per ASTM A 123

THIS IS TO CERTIFY THAT ABOVE MATERIALS HAVE BEEN HOT DIP GALVANIZED TO ASTM A 123 / BS EN ISO 1461: 2009

STANDARD

QC Inspector QA / QC Manager

Gal –F-104/Rev 0/ Dated 10/01/2017

You might also like

- PRP A-01 PDFDocument47 pagesPRP A-01 PDFPablo di Pasquo100% (1)

- 652-100-FINAL (ITP) Rev1Document4 pages652-100-FINAL (ITP) Rev1Anonymous AdofXEYAgENo ratings yet

- Trane CVHE, F, G-SB-33CDocument28 pagesTrane CVHE, F, G-SB-33CWestbournerd100% (8)

- (N) TMCGEH3S 3x120sqmm Orange TPU JacketDocument3 pages(N) TMCGEH3S 3x120sqmm Orange TPU JacketAbl Jara MamaniNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1501-3AA23-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1501-3AA23-4AB4-ZAtiqah Putri Sari100% (1)

- CRCADocument10 pagesCRCAsingaravelan narayanasamyNo ratings yet

- Five Generic Business Level Strategies Thompson Et Al Chap5Document28 pagesFive Generic Business Level Strategies Thompson Et Al Chap5chirag_arora_1100% (1)

- Hyundai Ioniq Marketing PlanDocument17 pagesHyundai Ioniq Marketing PlanRadwa.mansourNo ratings yet

- MTC-ENERGY-DN 97Document1 pageMTC-ENERGY-DN 97cmanrekNo ratings yet

- Mtc-Energy-Dn 103Document1 pageMtc-Energy-Dn 103cmanrekNo ratings yet

- MTC-ENERGY-DN 100Document1 pageMTC-ENERGY-DN 100cmanrekNo ratings yet

- Kabelindo NYY 3X2.5mmDocument1 pageKabelindo NYY 3X2.5mmfirdaus cahyadinNo ratings yet

- Quadzero TDS 312ipDocument2 pagesQuadzero TDS 312ipTheAnh TranNo ratings yet

- Prefabricated Vertical Drain Test ReportDocument1 pagePrefabricated Vertical Drain Test Reporttrichandra maharjanNo ratings yet

- CQ 50THQDocument1 pageCQ 50THQ2021thiennhanNo ratings yet

- NEPRO Conduit Pvc1Document16 pagesNEPRO Conduit Pvc1chaouch.najehNo ratings yet

- 2) Data Sheet VDek-703 Standard 2021 FTDocument1 page2) Data Sheet VDek-703 Standard 2021 FTJean CausilNo ratings yet

- Especificación Membrana GeotextilDocument1 pageEspecificación Membrana GeotextilMiguel RamírezNo ratings yet

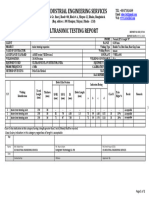

- UT ReportDocument1 pageUT ReportAmit HasanNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- Protodur NYY 0,6/1 KV CPR Eca: ApplicationDocument4 pagesProtodur NYY 0,6/1 KV CPR Eca: ApplicationAlin MireaNo ratings yet

- J0231 HV TR - FINAL变压器1Document23 pagesJ0231 HV TR - FINAL变压器1SerhiiNo ratings yet

- Bis-Dk-Ut-1109 - 1220-36-Le01Document3 pagesBis-Dk-Ut-1109 - 1220-36-Le01TomasPavlovicNo ratings yet

- MS Data Sheet TanqueDocument2 pagesMS Data Sheet TanqueLION_FIRENo ratings yet

- Sika Anchorfix 2 PDFDocument7 pagesSika Anchorfix 2 PDFUnited Construction Est. TechnicalNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- Kalpa Electrikal PVT - LTD,: H.O: Rajajinagar, BangaloreDocument1 pageKalpa Electrikal PVT - LTD,: H.O: Rajajinagar, BangaloreImi KalpaelectrikalNo ratings yet

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Document32 pagesSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNo ratings yet

- Geco Industrial Co., LTD: Land Drain - LD 90Document2 pagesGeco Industrial Co., LTD: Land Drain - LD 90Gisella Mariel RubilarNo ratings yet

- D.10 E.1 Jembo STD INQ 1259 PT. Gracia DikatamasDocument4 pagesD.10 E.1 Jembo STD INQ 1259 PT. Gracia DikatamasStanislaus NurcahyoNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNo ratings yet

- Standard Fire Performance CableDocument3 pagesStandard Fire Performance CablepolliartNo ratings yet

- 23C5366A-SA1A.02-Inquiry list-MINDA INFRASTRUCTURE LLP - Case-01 - DLP 5% For 60 Months - PC Rates - SDocument8 pages23C5366A-SA1A.02-Inquiry list-MINDA INFRASTRUCTURE LLP - Case-01 - DLP 5% For 60 Months - PC Rates - SswapnilNo ratings yet

- 6 RR FR LSHDocument1 page6 RR FR LSHGaurav MittalNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- Medintech MedintoneDocument2 pagesMedintech MedintoneJose Luis Cortes CamperoNo ratings yet

- Pipeline Cathodic Protection Design - Compress PDFDocument20 pagesPipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- A MC Msi 1 CP PM DS 007 Ace R01Document17 pagesA MC Msi 1 CP PM DS 007 Ace R01vijender07No ratings yet

- Fireproof ROOF Panels Technical InformationDocument4 pagesFireproof ROOF Panels Technical InformationMarko MiticNo ratings yet

- ST Sub Figrc2Document2 pagesST Sub Figrc2Logistica 1No ratings yet

- Ti Oxydur Ive LC 222 enDocument10 pagesTi Oxydur Ive LC 222 enChinthamani PandiNo ratings yet

- Quality NDT Services: To, Techspeq SolutionsDocument1 pageQuality NDT Services: To, Techspeq Solutionsomkar.baswar99No ratings yet

- J0231 LV TR - FINAL变压器2Document21 pagesJ0231 LV TR - FINAL变压器2SerhiiNo ratings yet

- (H) RADOXDATABUS120OHMnx0.5XMDocument3 pages(H) RADOXDATABUS120OHMnx0.5XM다원시스No ratings yet

- Coating Inspection Report: MC-A-004-MT - Site Testing of Protective CoatingsDocument4 pagesCoating Inspection Report: MC-A-004-MT - Site Testing of Protective CoatingsSiva KumarNo ratings yet

- Spacer JumperDocument9 pagesSpacer JumperibnuilyasNo ratings yet

- NOV Drill Bits New Technologies Helios Cutters and Hybrid FuseTek Bit To Drill Silurian and Ordivician On Rotary ModeDocument27 pagesNOV Drill Bits New Technologies Helios Cutters and Hybrid FuseTek Bit To Drill Silurian and Ordivician On Rotary ModeSlim.BNo ratings yet

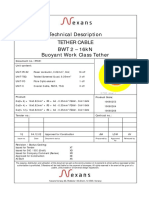

- Technical Description Tether Cable BWT 2 - 16kN Buoyant Work Class TetherDocument6 pagesTechnical Description Tether Cable BWT 2 - 16kN Buoyant Work Class TetherRich ManNo ratings yet

- 1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enDocument1 page1LE1503-1EB43-4JA4-Z B02+N06 Datasheet enavinash mathurNo ratings yet

- HP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03Document6 pagesHP - ENI - Package - ORF ENI Jangkrik - Pip Technical Specification 2015-12-03ANDI JAYANo ratings yet

- 72F-Non Metallic Duct HDPE Cable-Technical Offer-18Document6 pages72F-Non Metallic Duct HDPE Cable-Technical Offer-18GUY-FABRE DJILENo ratings yet

- UmaPET EC104 - 140Document2 pagesUmaPET EC104 - 140Luz Angela GuerreroNo ratings yet

- Airmaster HVAC Ducting BrochureDocument12 pagesAirmaster HVAC Ducting BrochureWaseem NaamoNo ratings yet

- Rdso SPN TC 97 2012Document13 pagesRdso SPN TC 97 2012Rahul MauryaNo ratings yet

- 1LE1523-2DC23-4JA4 Datasheet enDocument1 page1LE1523-2DC23-4JA4 Datasheet enAdalbertoNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- 315020-DOC-3483 - (V-4083 Condensate Accumulator) - RevADocument7 pages315020-DOC-3483 - (V-4083 Condensate Accumulator) - RevAAnwar SadatNo ratings yet

- G-FIRE Figure 716 Flexible Reducing Coupling - TFP1830 - 08 - 2022Document5 pagesG-FIRE Figure 716 Flexible Reducing Coupling - TFP1830 - 08 - 2022Leila DinizNo ratings yet

- ZTT PV Cables Ztt23xj28593-2Document6 pagesZTT PV Cables Ztt23xj28593-2Andres DelgadoNo ratings yet

- 1LE1504-3AB23-4AB4 Datasheet enDocument1 page1LE1504-3AB23-4AB4 Datasheet enOkke BoykeNo ratings yet

- Chemonit 181Document4 pagesChemonit 181Zack OsNo ratings yet

- MTC-ENERGY-DN 97Document1 pageMTC-ENERGY-DN 97cmanrekNo ratings yet

- Certificate of Analysis Coa: Test Result Min - MaxDocument1 pageCertificate of Analysis Coa: Test Result Min - MaxcmanrekNo ratings yet

- Daily NSP 10.03.24Document3 pagesDaily NSP 10.03.24cmanrekNo ratings yet

- ET-RA - BlastingDocument5 pagesET-RA - BlastingcmanrekNo ratings yet

- Palsar User GuideDocument69 pagesPalsar User GuideVladimirodipostovNo ratings yet

- 3M Venture Tape 1599B TDS v12-2017Document2 pages3M Venture Tape 1599B TDS v12-2017Hernan Romero RomeroNo ratings yet

- Global Economic Dimensions of SingaporeDocument21 pagesGlobal Economic Dimensions of SingaporeMykee CruzNo ratings yet

- Ramakrishna Myaka: Profile SummaryDocument2 pagesRamakrishna Myaka: Profile SummaryRamakrishna MyakaNo ratings yet

- Schiehallion FPSO Mooring Repair BP West of Shetland, UK: Contract: Client: LocationDocument1 pageSchiehallion FPSO Mooring Repair BP West of Shetland, UK: Contract: Client: LocationRavikumar mahadevNo ratings yet

- R03 C07B01 IKP WIR AR 0107 - CommentsDocument6 pagesR03 C07B01 IKP WIR AR 0107 - CommentsEleazar SacloloNo ratings yet

- CDM 2015 CIBSE TalkDocument44 pagesCDM 2015 CIBSE TalkJeduardo Ch-mezaNo ratings yet

- Resume - Mechanical Engineer - Format1Document2 pagesResume - Mechanical Engineer - Format1prince SinghNo ratings yet

- Technology Management: Unit 1Document40 pagesTechnology Management: Unit 1Vikas Ahuja100% (1)

- Arb 4x4 Accessories 1 Arb International Catalogue 2020 PDFDocument212 pagesArb 4x4 Accessories 1 Arb International Catalogue 2020 PDFЕвгений БабичNo ratings yet

- How To Create SAP PA-HR InfotypeDocument15 pagesHow To Create SAP PA-HR InfotypecharlesjungbeckNo ratings yet

- 2007 ClaytonDocument196 pages2007 ClaytonSami IslamNo ratings yet

- Technical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Document4 pagesTechnical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Trọng Nghĩa VõNo ratings yet

- Basic Hydraulics Learning System (850-H1)Document2 pagesBasic Hydraulics Learning System (850-H1)Ross Mel Bautista LingonNo ratings yet

- Davis Langdon Middle East Handbook 2012Document132 pagesDavis Langdon Middle East Handbook 2012Angelo Sanghoon HAN100% (1)

- NMMC Esr - 2015-2016Document136 pagesNMMC Esr - 2015-2016hiyogsNo ratings yet

- Quote Test1Document3 pagesQuote Test1GlozealNo ratings yet

- Requested FileDocument42 pagesRequested Fileedinson rojas ramosNo ratings yet

- VAM-GPS-2016 - 01012016-Wi CT Feedback HSZ CT V3Document29 pagesVAM-GPS-2016 - 01012016-Wi CT Feedback HSZ CT V3Nabila ApriantiNo ratings yet

- MJP 2500 IC - The Only 100% Wax 3d Printer For The Industrial Investment Casting IndustryDocument11 pagesMJP 2500 IC - The Only 100% Wax 3d Printer For The Industrial Investment Casting IndustryRajesh MNo ratings yet

- Chet Tina DuDocument36 pagesChet Tina DuDhivya RamachandranNo ratings yet

- Forged Steel Pipe Fittings (OK)Document18 pagesForged Steel Pipe Fittings (OK)truongNo ratings yet

- EPA 241 Engineering Authority For DesignDocument16 pagesEPA 241 Engineering Authority For DesignGuilhermeNo ratings yet

- Tesla Pricing Strategy Analysis: Take Model 3 As An Example: Jiangxi Ding, Yuting HeDocument5 pagesTesla Pricing Strategy Analysis: Take Model 3 As An Example: Jiangxi Ding, Yuting HePhương ThảoNo ratings yet

- R/C Soaring Digest - Feb 2005Document28 pagesR/C Soaring Digest - Feb 2005Aviation/Space History LibraryNo ratings yet

- Analizaer Period Close NoteDocument7 pagesAnalizaer Period Close Notejimbo2267No ratings yet

- Low-Noise Fast-Transient-Response 1.5-A Low-Dropout Voltage RegulatorsDocument28 pagesLow-Noise Fast-Transient-Response 1.5-A Low-Dropout Voltage RegulatorssinnlosNo ratings yet