Professional Documents

Culture Documents

MTC-ENERGY-DN 97

MTC-ENERGY-DN 97

Uploaded by

cmanrekCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTC-ENERGY-DN 97

MTC-ENERGY-DN 97

Uploaded by

cmanrekCopyright:

Available Formats

INDUSTRIAL CABLE MANAGEMENT SYSTEMS CO. W.L.L.

P. O. BOX: 22108, DOHA QATAR

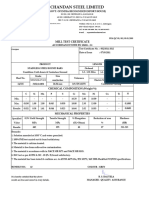

COATING INSPECTION AND TEST CERTIFICATE

INSPECTION AND TESTING IN ACCORDANCE WITH ISO 10204 FOR COMPLIANCE WITH ASTM A 123 / BS EN ISO 1461: 2009

CERTIFICATE # 24-06-14673 DATE 30-May-24

Name of Customer Energy Tec

Client DO # ET/DN/ICMS/24/97

OUR JOB #

Coating Thickness (in microns) Average Mass of Zn

Item # Part No. Item Description Qty UOM Coating (in gms / sq.

Thickness m)

R1 R2 R3 R4 R5

SUPPLY HOT DIP GALVAZING AND DELIVERY

1 04 NOS PCS 105 117 103 110 101 107.2 765.408

OF HEB 120X6 MTR LENGTH

THE V BRACKET SIZE – 50X70X50X80X6MM

2 07 NOS PCS 124 117 122 104 106 114.6 818.244

THICK 2MTR

THE STEEL PLATE SIZE-

3 1200MMX800MMX6MM THICK 24 MM DIA 04 NOS PCS 124 106 118 107 130 117 835.38

HOLE

ZINC COATING APPEARANCE

The accepatability of the coating finish is judged by the inspection condition laid down in BS EN 1461 - under- coating properties - point

No. 6 on page 6.

Zinc coating is free of gross surface imperfection of bare spots, heavy lumps and blisters.

ADHESION TEST.

Zinc Coating does not lift of in large flakes when tested with pivoted hammer and stout knife as per ASTM A 123

THIS IS TO CERTIFY THAT ABOVE MATERIALS HAVE BEEN HOT DIP GALVANIZED TO ASTM A 123 / BS EN ISO 1461: 2009

STANDARD

QC Inspector QA / QC Manager

Gal –F-104/Rev 0/ Dated 10/01/2017

You might also like

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- CRCADocument10 pagesCRCAsingaravelan narayanasamyNo ratings yet

- BoeingDocument42 pagesBoeingHarsh SaxenaNo ratings yet

- Premiere Product Excersice AnswersDocument7 pagesPremiere Product Excersice AnswersCarlos VallejosNo ratings yet

- Mtc-Energy-Dn 103Document1 pageMtc-Energy-Dn 103cmanrekNo ratings yet

- Varilla B7 3-8 X 144 MT (B7)Document1 pageVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Eva - RenewsysDocument1 pageEva - RenewsysShashwata ChattopadhyayNo ratings yet

- Zamil MTCDocument1 pageZamil MTCs.khanNo ratings yet

- CA3-23-219 (TDS TAWQ 90 MM) Option-2 (REV 01)Document1 pageCA3-23-219 (TDS TAWQ 90 MM) Option-2 (REV 01)ahmed ahmadNo ratings yet

- Spacer JumperDocument9 pagesSpacer JumperibnuilyasNo ratings yet

- Shell Final Dimension - J1Document1 pageShell Final Dimension - J1Agni DuttaNo ratings yet

- Material Test Certificate: Doc No: A1 FENCE/QAD/QC-FORM-06 Rev No: 00 DTD 20/09/2020Document2 pagesMaterial Test Certificate: Doc No: A1 FENCE/QAD/QC-FORM-06 Rev No: 00 DTD 20/09/2020adipur aartiNo ratings yet

- Material Specification: Astm A 193 Gr. B7: Ed-2021Document2 pagesMaterial Specification: Astm A 193 Gr. B7: Ed-2021Precision EngineeringNo ratings yet

- Sample Test Cert. 07.09.2011 - 02Document1 pageSample Test Cert. 07.09.2011 - 02Vipul PanchalNo ratings yet

- Pebax Product Range and PropertiesDocument2 pagesPebax Product Range and Propertiesabhishek_negi_41No ratings yet

- CBH-21-079 Flange Nut M4 WZP 8Document1 pageCBH-21-079 Flange Nut M4 WZP 8qualityNo ratings yet

- 1 1mm 2 2mm 3 3mm 4 4mm 5 5mm 6 6mm 7 8mm 8 10mm 9 12mm 10 15mm 11 20mm 12 25mmDocument22 pages1 1mm 2 2mm 3 3mm 4 4mm 5 5mm 6 6mm 7 8mm 8 10mm 9 12mm 10 15mm 11 20mm 12 25mmJagdish GhogareNo ratings yet

- Prefabricated Vertical Drain Test ReportDocument1 pagePrefabricated Vertical Drain Test Reporttrichandra maharjanNo ratings yet

- Abs 70SRDocument2 pagesAbs 70SRmohamad mostafaviNo ratings yet

- Bis-Dk-Ut-1109 - 1220-36-Le01Document3 pagesBis-Dk-Ut-1109 - 1220-36-Le01TomasPavlovicNo ratings yet

- CBH-21-012 Stud Bolt M12 X 2000 HDG 8.8Document1 pageCBH-21-012 Stud Bolt M12 X 2000 HDG 8.8qualityNo ratings yet

- Technical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Document16 pagesTechnical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Biprojit HoreNo ratings yet

- PlugDocument2 pagesPlugJalal AlbadriNo ratings yet

- Page 1 of 0Document1 pagePage 1 of 0lich0312No ratings yet

- A MC Msi 1 CP PM DS 007 Ace R01Document17 pagesA MC Msi 1 CP PM DS 007 Ace R01vijender07No ratings yet

- Jyoti Engineering Works: Chemical AnalysisDocument8 pagesJyoti Engineering Works: Chemical AnalysisKristin CrawfordNo ratings yet

- NM1 Product ManualDocument11 pagesNM1 Product ManualJorge Antonio Cossio RamirezNo ratings yet

- Láminas FR4 Doble Faz - KB-6150Document2 pagesLáminas FR4 Doble Faz - KB-6150Julian QuinteroNo ratings yet

- Renewsys EPE Data SheetDocument4 pagesRenewsys EPE Data SheetShashwata ChattopadhyayNo ratings yet

- Slip StreamDocument1 pageSlip StreamvietsdsNo ratings yet

- GK 3164 Serti̇fi̇kaDocument1 pageGK 3164 Serti̇fi̇kanedim cılızNo ratings yet

- Technical Specification: Senior India PVT LTDDocument4 pagesTechnical Specification: Senior India PVT LTDDeepak GargNo ratings yet

- MSB-TPL-REW-BV-HYD-8705-FIR 003 Dated 16-02-2023Document4 pagesMSB-TPL-REW-BV-HYD-8705-FIR 003 Dated 16-02-2023pl_arunachalam79No ratings yet

- ST Sub Figrc2Document2 pagesST Sub Figrc2Logistica 1No ratings yet

- 304 Hex Nut M10-1.5Document1 page304 Hex Nut M10-1.5ugi putriNo ratings yet

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document1 pageMill'S Test Certificate ACC. TO EN 10204 / 3.1vcumutNo ratings yet

- Ee4293-Lca - Lce-Mto - 12-04-2024 4Document5 pagesEe4293-Lca - Lce-Mto - 12-04-2024 4sjdrs65pjpNo ratings yet

- Page 2 Tsi MTC 150x4 (MTC - 247)Document2 pagesPage 2 Tsi MTC 150x4 (MTC - 247)trayojam.rilNo ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- Aei2883 24.12.2021.Document3 pagesAei2883 24.12.2021.quality fluconNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- Compressive Strength of Concrete Core BS EN 12504-1: Project InformationDocument2 pagesCompressive Strength of Concrete Core BS EN 12504-1: Project Informationraja qammar100% (1)

- Hydroflux Ep tcm14-62558Document1 pageHydroflux Ep tcm14-62558Azis GPBNo ratings yet

- Indrani Technocrafts: Metallurgical Test CertificateDocument1 pageIndrani Technocrafts: Metallurgical Test CertificateAditya ChouguleNo ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document11 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- Test Certificate: CM/L-NO:5530357Document2 pagesTest Certificate: CM/L-NO:5530357pranav kariaNo ratings yet

- Fiber Glass Wool Insulation 100MM THKDocument12 pagesFiber Glass Wool Insulation 100MM THKmahmoud husseinNo ratings yet

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhDocument4 pagesDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 203, - , - : Heat-Treatable Steel, Carbon SteelDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 203, - , - : Heat-Treatable Steel, Carbon Steelbaskaran ayyapparaj100% (1)

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 351, - , - : Cast Stainless Steel, Cr-Ni-AlloyedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 351, - , - : Cast Stainless Steel, Cr-Ni-AlloyedgraduateNo ratings yet

- NEPRO Conduit Pvc1Document16 pagesNEPRO Conduit Pvc1chaouch.najehNo ratings yet

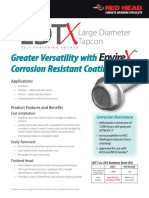

- Greater Versatility With Corrosion Resistant Coating: ApplicationsDocument2 pagesGreater Versatility With Corrosion Resistant Coating: Applicationsblessed cccNo ratings yet

- Wurth WIT-PE - 500Document26 pagesWurth WIT-PE - 500Igor DzuklevskiNo ratings yet

- Steel Test ResultsDocument2 pagesSteel Test ResultsDevendra SinghNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document11 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- BPVC X q-115Document2 pagesBPVC X q-115Emma DNo ratings yet

- Tuerca Hex Inox M-5Document1 pageTuerca Hex Inox M-5luisquirica20No ratings yet

- Test CertificateDocument1 pageTest CertificatequalityNo ratings yet

- Especificación Membrana GeotextilDocument1 pageEspecificación Membrana GeotextilMiguel RamírezNo ratings yet

- 1LE1501 2DA03 4AA4 Datasheet enDocument1 page1LE1501 2DA03 4AA4 Datasheet enGismart 11No ratings yet

- InterimStmt 20231215-1Document9 pagesInterimStmt 20231215-1mitchellallie393No ratings yet

- Sanjib Kumar Saren - Review of Flexible Manufacturing System Based On Modeling and Simulation - v21 - 2Document6 pagesSanjib Kumar Saren - Review of Flexible Manufacturing System Based On Modeling and Simulation - v21 - 2Amrik SinghNo ratings yet

- WWW ThermopediaDocument6 pagesWWW ThermopediaAjaykumar TiwariNo ratings yet

- Grinding Errors and Possible SolutionsDocument6 pagesGrinding Errors and Possible SolutionsPinak ThankiNo ratings yet

- Pengantar Teknik MesinDocument5 pagesPengantar Teknik Mesin'biyandd NTuu AKkuu'No ratings yet

- Resume Matthew NelsonDocument2 pagesResume Matthew Nelsonmtn3077No ratings yet

- PDA DewanDocument4 pagesPDA Dewanariff.arifinNo ratings yet

- AGC AdDocument1 pageAGC AdehllNo ratings yet

- Standard Welding Symbol: Ir - Soeweify, M.EngDocument40 pagesStandard Welding Symbol: Ir - Soeweify, M.EngMizanNo ratings yet

- TBT 50 Roof Collapse PDFDocument2 pagesTBT 50 Roof Collapse PDFmohammad ashpakNo ratings yet

- Ex16xlch06gradercaphw - Delta Paint 15 InstructionsDocument2 pagesEx16xlch06gradercaphw - Delta Paint 15 InstructionsMartha PerezNo ratings yet

- Module - 4 - Shaper, Planer, Slotter, Grinding MachinesDocument70 pagesModule - 4 - Shaper, Planer, Slotter, Grinding MachinesIrfan ShaikhNo ratings yet

- Fundamentals of Information Systems Chapter 1Document66 pagesFundamentals of Information Systems Chapter 1Grant Net Carlo PunzalanNo ratings yet

- Mil-Std-1629a FmeaDocument80 pagesMil-Std-1629a FmeaE278738No ratings yet

- Tolerance Stack-Up Analysis Complete PaperDocument26 pagesTolerance Stack-Up Analysis Complete Papersantoshlad80% (5)

- Aerion AS2 A 5 Billion Supersonic SagaDocument11 pagesAerion AS2 A 5 Billion Supersonic Sagaflateric74@yandex.ruNo ratings yet

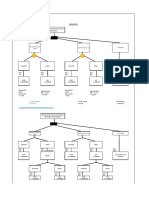

- Decision Tree ExampleDocument2 pagesDecision Tree Examplemuhammad saadNo ratings yet

- Byod Emear at A Glance CTP Aag en UsDocument2 pagesByod Emear at A Glance CTP Aag en Usmouhannadn.alrightNo ratings yet

- Resume Rahul - HSE Advisor NewDocument3 pagesResume Rahul - HSE Advisor NeweDtutors. inNo ratings yet

- Barden Cf6 Series Repair ProgramDocument2 pagesBarden Cf6 Series Repair ProgramNikooNo ratings yet

- Qap VelDocument81 pagesQap VelSachin PawarNo ratings yet

- Production-Technology-11 04 2020Document9 pagesProduction-Technology-11 04 2020Selvaraj SimiyonNo ratings yet

- BPO Future Forward IVDocument40 pagesBPO Future Forward IVSaurabh GuptaNo ratings yet

- 1NH16MAE10 Provisional Grade CardDocument1 page1NH16MAE10 Provisional Grade CardawarialocksNo ratings yet

- Hot Working Guide: A Compendium of Processing MapsDocument10 pagesHot Working Guide: A Compendium of Processing MapsAnket DeshmukhNo ratings yet

- Corona Probe BrochureDocument2 pagesCorona Probe Brochurediogoufrn-1No ratings yet

- Cable Gland Catalog EnglishDocument110 pagesCable Gland Catalog EnglishXiangping JiaoNo ratings yet

- DataSheet Project Management FrameworkDocument2 pagesDataSheet Project Management FrameworkJay AmirNo ratings yet