Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsLean101-PrinciplesofLeanManu

Lean101-PrinciplesofLeanManu

Uploaded by

rodrigoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Create 24 - 7 - The Blueprint To Build A 6-Figure Twitter BusinessDocument7 pagesCreate 24 - 7 - The Blueprint To Build A 6-Figure Twitter BusinessEmmanuel0% (2)

- Demon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Document12 pagesDemon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Gokul M PNo ratings yet

- Lean and Agile Manufacturing: Prepared By: Pallavi JoshiDocument25 pagesLean and Agile Manufacturing: Prepared By: Pallavi Joshipallaveejoshi100% (1)

- 5.0. PPT - Jit and Lean Operation - CegDocument6 pages5.0. PPT - Jit and Lean Operation - Cegchristian garciaNo ratings yet

- La Fábrica VisualDocument33 pagesLa Fábrica VisualNelson A. Morbán TorresNo ratings yet

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocument52 pagesJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainSwapnil Jayawant100% (1)

- JIT & Lean ManufacturingDocument57 pagesJIT & Lean ManufacturingBaljeetNo ratings yet

- Adidas - Standard Work, Cell Design, Line BalanceDocument139 pagesAdidas - Standard Work, Cell Design, Line BalanceNUR NOBINo ratings yet

- CI Overview PresentationDocument36 pagesCI Overview PresentationGanesh SrinivasNo ratings yet

- You Exec - Agile Project Management CompleteDocument15 pagesYou Exec - Agile Project Management CompleteanmNo ratings yet

- Class 14 Lean Systems Q4.22.23Document52 pagesClass 14 Lean Systems Q4.22.23Nhi LinhNo ratings yet

- Lean Manufacturing: Dr. V.Ramesh, Fie Professor, Sjce MysoreDocument36 pagesLean Manufacturing: Dr. V.Ramesh, Fie Professor, Sjce MysoreVajram Ramesh - IPNo ratings yet

- CH 1 LEAN SS IntroductionDocument39 pagesCH 1 LEAN SS IntroductionandullaNo ratings yet

- PDF Lean Implementation at Siemens Kalwa Plant DL - PDFDocument8 pagesPDF Lean Implementation at Siemens Kalwa Plant DL - PDFNamit BaserNo ratings yet

- A Strategy For Performance ExcellenceDocument73 pagesA Strategy For Performance Excellenceravi.youNo ratings yet

- Continuous Process Improvement: Subject: Total Quality Management Instructor: Sumera KaziDocument10 pagesContinuous Process Improvement: Subject: Total Quality Management Instructor: Sumera Kazidua tanveerNo ratings yet

- Chapter TwoDocument32 pagesChapter TwoKidan AmareNo ratings yet

- 1.2 Current Trends in Op - MGMTDocument50 pages1.2 Current Trends in Op - MGMTVishal SakpalNo ratings yet

- Kaizen Tools PDFDocument5 pagesKaizen Tools PDFSanjay MehrishiNo ratings yet

- Advanced Process ControlDocument2 pagesAdvanced Process ControlhbakriNo ratings yet

- LAM Lecture 10-12 PDFDocument37 pagesLAM Lecture 10-12 PDFHayl KhadhamiNo ratings yet

- Unit 7: The Lean/ Just-in-Time Concept and Repetitive ManufecturingDocument39 pagesUnit 7: The Lean/ Just-in-Time Concept and Repetitive ManufecturingpercyNo ratings yet

- Kaizen 2Document60 pagesKaizen 2Israfi MaulanaNo ratings yet

- ME Lecture Slides1 01Document13 pagesME Lecture Slides1 01SaravanaKumar ChinnaswamyNo ratings yet

- AQMDocument28 pagesAQMPushkarNo ratings yet

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocument53 pagesJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDivya SudarsananNo ratings yet

- Unit Iv CMSDocument43 pagesUnit Iv CMSsuganthNo ratings yet

- Application of Lean Six Sigma Methodology Application in Banking FINALDocument58 pagesApplication of Lean Six Sigma Methodology Application in Banking FINALimran24No ratings yet

- PPT5 - Topik5 - R0 - Lean Concept and Repetitive ManufacturingDocument28 pagesPPT5 - Topik5 - R0 - Lean Concept and Repetitive ManufacturingmrikyNo ratings yet

- Applying Lean Concepts To Supply Chains:: The Power From Effective PartnershipDocument15 pagesApplying Lean Concepts To Supply Chains:: The Power From Effective PartnershipFranklin Manuel Cortez PatiñoNo ratings yet

- CMMI® For Development,: Improving Processes For Developing Better Products and ServicesDocument156 pagesCMMI® For Development,: Improving Processes For Developing Better Products and Servicesaramaky2001No ratings yet

- Req 6Document37 pagesReq 6sam zakNo ratings yet

- Six Sigma (Vijayvignesh N S 2020606042)Document12 pagesSix Sigma (Vijayvignesh N S 2020606042)N S Vijay VigneshNo ratings yet

- 02 Lean - Advanced Lean - Pull Systems v1Document176 pages02 Lean - Advanced Lean - Pull Systems v1lrff1950No ratings yet

- LEAN - What Does Kaizen MeanDocument25 pagesLEAN - What Does Kaizen MeanaaaNo ratings yet

- Chapter 18 (Production of Goods & Services) - 17.02.08Document24 pagesChapter 18 (Production of Goods & Services) - 17.02.08Kelvin LauNo ratings yet

- Operations Management MBA (Term II) : Session Objective(s)Document14 pagesOperations Management MBA (Term II) : Session Objective(s)Jaswinder SinghNo ratings yet

- TPM BasicsDocument33 pagesTPM BasicsRajeev ChadhaNo ratings yet

- SAP QM WorrkshopDocument48 pagesSAP QM WorrkshopRamhesh BabuNo ratings yet

- Lean ManufacturingDocument3 pagesLean Manufacturingyeimyyamilet760No ratings yet

- Milliken Performance System TPM 1656557395Document14 pagesMilliken Performance System TPM 1656557395David Armando Chico OreNo ratings yet

- Feasibility Study-MergedDocument1,619 pagesFeasibility Study-MergedamulyaNo ratings yet

- Process Technology 2Document30 pagesProcess Technology 2pavan hydNo ratings yet

- Certified Lean Practitioner Day 2Document218 pagesCertified Lean Practitioner Day 2Basu ShaivaNo ratings yet

- Principles of Six SigmaDocument36 pagesPrinciples of Six SigmaSatish BindumadhavanNo ratings yet

- Department of Mechanical Engg. Andhra PradeshDocument33 pagesDepartment of Mechanical Engg. Andhra Pradeshprabhu5545No ratings yet

- World Class ManufacturingDocument32 pagesWorld Class ManufacturingVIPUL SHETTYNo ratings yet

- Lean ManufacturingDocument24 pagesLean ManufacturingBaljeetNo ratings yet

- Leanbook FordDocument197 pagesLeanbook FordArturo TorresNo ratings yet

- Cert Study Part 3Document22 pagesCert Study Part 3Ariunjargal GanboldNo ratings yet

- Introduction To Lean ManagementDocument20 pagesIntroduction To Lean ManagementrohanaNo ratings yet

- Dr.N.G.P. Institute of Technology: Department of Mechanical EngineeringDocument33 pagesDr.N.G.P. Institute of Technology: Department of Mechanical Engineeringvasanthmech092664No ratings yet

- Lesson 14 - Continuous Improvement - Part 1Document39 pagesLesson 14 - Continuous Improvement - Part 1MAURICIO CARDOZONo ratings yet

- Just-In-Time Systems: Submitted To-Submitted by - Ms. Neha Gulati Tanvi VermaDocument35 pagesJust-In-Time Systems: Submitted To-Submitted by - Ms. Neha Gulati Tanvi VermaPankaj Khindria100% (1)

- Standardized Work v4.0Document62 pagesStandardized Work v4.0Rodrigo SolisNo ratings yet

- Session 7Document29 pagesSession 7gefifa9794No ratings yet

- Just-In-Time Manufacturing: A Powerpoint Presentation by Swati (54), Meenal (39), Reenu (45), JayaDocument30 pagesJust-In-Time Manufacturing: A Powerpoint Presentation by Swati (54), Meenal (39), Reenu (45), JayaPranav ParikhNo ratings yet

- Lean Manufacturing: Introduction: Click To ProceedDocument8 pagesLean Manufacturing: Introduction: Click To ProceedUDAYAN SHAHNo ratings yet

- Ch12. JIT & Lean ManufacturingDocument59 pagesCh12. JIT & Lean ManufacturingmoovmoovNo ratings yet

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocument52 pagesJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainNeha Jigar PatelNo ratings yet

- IT Success!: Towards a New Model for Information TechnologyFrom EverandIT Success!: Towards a New Model for Information TechnologyRating: 3 out of 5 stars3/5 (1)

- Hots Advance MiraeDocument36 pagesHots Advance MiraeHabibie BoilerNo ratings yet

- Chapter 4 - Group 3 - Behavioral Processes in Marketing ChannelsDocument26 pagesChapter 4 - Group 3 - Behavioral Processes in Marketing ChannelsJanine Mariel LedesmaNo ratings yet

- DLL - Co.q2 Science IVDocument16 pagesDLL - Co.q2 Science IVAllyn MadeloNo ratings yet

- Scope: Airport Planning ManualDocument4 pagesScope: Airport Planning ManualclebersjcNo ratings yet

- BE1 Final Without Recheckreassessment - 453112Document1 pageBE1 Final Without Recheckreassessment - 453112MoloNo ratings yet

- Lesson A Worksheets. Print or Copy in Your Notebook-1Document3 pagesLesson A Worksheets. Print or Copy in Your Notebook-1Martha Lucia Arcila HenaoNo ratings yet

- What A Body Can DoDocument26 pagesWhat A Body Can DoMariana Romero Bello100% (1)

- Basic Law 01Document33 pagesBasic Law 01MitchNo ratings yet

- Adetunji CVDocument5 pagesAdetunji CVAdetunji AdegbiteNo ratings yet

- International Documentary Festival of Ierapetra Awards - 2016 ProgrammeDocument26 pagesInternational Documentary Festival of Ierapetra Awards - 2016 ProgrammeZois PagNo ratings yet

- Caro PresentationDocument33 pagesCaro PresentationVIJAY GARGNo ratings yet

- Better Get 'It in Your SoulDocument4 pagesBetter Get 'It in Your SoulJeremiah AnnorNo ratings yet

- Palm Oil MillDocument52 pagesPalm Oil MillengrsurifNo ratings yet

- MLR LLRDocument41 pagesMLR LLRKUNNAMPALLIL GEJO JOHNNo ratings yet

- Ax88796B With Ali M3602 Mcu Reference Schematic IndexDocument4 pagesAx88796B With Ali M3602 Mcu Reference Schematic IndexdistefanoNo ratings yet

- Atr Summary Assignment 1Document6 pagesAtr Summary Assignment 1Livingstone OlekanmaNo ratings yet

- Crim Pro 2004-2010 Bar QuestionsDocument4 pagesCrim Pro 2004-2010 Bar QuestionsDennie Vieve IdeaNo ratings yet

- Module 2 The Self From Philosophical and Anthropological PerspectivesDocument10 pagesModule 2 The Self From Philosophical and Anthropological PerspectivesAjhay BonghanoyNo ratings yet

- Lathe Machine and Its ComponentsDocument13 pagesLathe Machine and Its ComponentsEinstein RahatNo ratings yet

- Jgs 14518 PDFDocument8 pagesJgs 14518 PDFDes LastrianiNo ratings yet

- Written Report: Lydia Hall: Care, Cure, Core Nursing TheoryDocument12 pagesWritten Report: Lydia Hall: Care, Cure, Core Nursing TheoryAldrin Limcuando100% (1)

- Shashikala SummaryDocument2 pagesShashikala SummaryKhushbakht FarrukhNo ratings yet

- Will Love Make You HappyDocument2 pagesWill Love Make You HappyMuhammad Musa HaiderNo ratings yet

- Lê Thị Thu Thuỷ - Luận vănDocument97 pagesLê Thị Thu Thuỷ - Luận vănĐào Nguyễn Duy TùngNo ratings yet

- Module 4Document5 pagesModule 4Engelbert RespuestoNo ratings yet

- 107 Hand Tool Field Maintenance v0311Document8 pages107 Hand Tool Field Maintenance v0311rabbit_39No ratings yet

- CONSORT-EHEALTH (V 1.6.1) - Submission/Publication Form: RequiredDocument49 pagesCONSORT-EHEALTH (V 1.6.1) - Submission/Publication Form: RequiredStefan HlNo ratings yet

Lean101-PrinciplesofLeanManu

Lean101-PrinciplesofLeanManu

Uploaded by

rodrigo0 ratings0% found this document useful (0 votes)

2 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views3 pagesLean101-PrinciplesofLeanManu

Lean101-PrinciplesofLeanManu

Uploaded by

rodrigoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

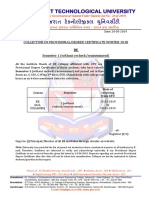

Principles of Lean Manufacturing (Lean 101)

CEQAL 591

A Lean Enterprise produces more with existing resources by eliminating non-

value added activities. Manufacturers are facing increased worldwide

competition and the stakes are high. The winners in this competition work to

eliminate overproduction caused by traditional scheduling systems and only

make what customers want when they want it. Lean establishes a systematic

approach to eliminating these wastes and creating flow throughout the whole

company. It also helps you develop and implement a long-term plan to

streamline your operations for success.

Who Should Attend: All employees interested in how to utilize lean

operating Systems to eliminate waste and improve

profitability.

Prereqisite: None

CEU’S Credit: .8

Duration: 1 day course – 8 Hours.

Course Description: At this workshop you'll learn the principles of Lean

Manufacturing and how to apply them. During the

simulation exercises-as a member of the

production team for Buzz Electronics-you'll apply

Lean concepts such as standardized work, visual

signals, batch-size reduction, pull systems, and

more. Experience firsthand how Lean improves

quality, reduces cycle time, improves delivery

performance, and reduces Work-in-Process (WIP)

and enables Buzz to show a profit. Previous

participants have been able to immediately apply the

principles that were learned in this course and began

seeing financial impact.

2/2/2006 8:22 AM Principles of Lean Manufacturing Lean 101 - SCMEP

Benefits:

• Reduce cycle time

• Reduce inventory

• Reduce Work-in-Process (WIP)

• Reduce costs

• Increase capacity

• Improve lead times

• Increase sales

• Increase productivity

• Improve quality

• Increase profits

Course Outline:

• Overview of Buzz Electronics

• Assignment of plant jobs

Round One Simulation

• Typical manufacturing layout (non-Lean)

• 20 minute simulation

• Debrief

Introduction to Lean Manufacturing

• Lean definitions/terminology, history and concepts

• Eight Wastes of Lean

Introduction to Lean Components

• Standardized Work

• Work Place Organization/5s

• Visual Controls

• Plant Layout

Round Two Simulation

• Application of Lean concepts

• 20 minute simulation

• Debrief

Continued Introduction of Lean Components

• Teams- importance of cross-training/multi-skilled

employees

• Quick Changeover

• Batch Size Reduction

• Point-of-Use Storage (POUS)

• Quality at the Source

2/2/2006 8:22 AM Principles of Lean Manufacturing Lean 101 - SCMEP

Round Three Simulation

• Application of Lean concepts

• 20 minute simulation

• Debrief

Continued Introduction of Lean Components

• Pull/Kanban- Pull vs. Push System

• Cellular Flow- Setting up Workcells

• Calculating Takt time

• Line balancing

• Total Productive Maintenance (TPM)

Final Round Simulation

• Application of Lean concepts

• 20 minute simulation

• Debrief

Review/Wrap up

• Continuous Improvement and Barriers

• Success Factors

• Typical Benefits of Lean

• Overcoming Objectives

• Value Stream Mapping

• Lean vs. Traditional

Each participant will receive a comprehensive manual and a

Certificate of Completion at the close of the seminar

2/2/2006 8:22 AM Principles of Lean Manufacturing Lean 101 - SCMEP

You might also like

- Create 24 - 7 - The Blueprint To Build A 6-Figure Twitter BusinessDocument7 pagesCreate 24 - 7 - The Blueprint To Build A 6-Figure Twitter BusinessEmmanuel0% (2)

- Demon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Document12 pagesDemon Slayer Kimetsu No Yaiba Free Download Anime Calendar 2022Gokul M PNo ratings yet

- Lean and Agile Manufacturing: Prepared By: Pallavi JoshiDocument25 pagesLean and Agile Manufacturing: Prepared By: Pallavi Joshipallaveejoshi100% (1)

- 5.0. PPT - Jit and Lean Operation - CegDocument6 pages5.0. PPT - Jit and Lean Operation - Cegchristian garciaNo ratings yet

- La Fábrica VisualDocument33 pagesLa Fábrica VisualNelson A. Morbán TorresNo ratings yet

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocument52 pagesJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainSwapnil Jayawant100% (1)

- JIT & Lean ManufacturingDocument57 pagesJIT & Lean ManufacturingBaljeetNo ratings yet

- Adidas - Standard Work, Cell Design, Line BalanceDocument139 pagesAdidas - Standard Work, Cell Design, Line BalanceNUR NOBINo ratings yet

- CI Overview PresentationDocument36 pagesCI Overview PresentationGanesh SrinivasNo ratings yet

- You Exec - Agile Project Management CompleteDocument15 pagesYou Exec - Agile Project Management CompleteanmNo ratings yet

- Class 14 Lean Systems Q4.22.23Document52 pagesClass 14 Lean Systems Q4.22.23Nhi LinhNo ratings yet

- Lean Manufacturing: Dr. V.Ramesh, Fie Professor, Sjce MysoreDocument36 pagesLean Manufacturing: Dr. V.Ramesh, Fie Professor, Sjce MysoreVajram Ramesh - IPNo ratings yet

- CH 1 LEAN SS IntroductionDocument39 pagesCH 1 LEAN SS IntroductionandullaNo ratings yet

- PDF Lean Implementation at Siemens Kalwa Plant DL - PDFDocument8 pagesPDF Lean Implementation at Siemens Kalwa Plant DL - PDFNamit BaserNo ratings yet

- A Strategy For Performance ExcellenceDocument73 pagesA Strategy For Performance Excellenceravi.youNo ratings yet

- Continuous Process Improvement: Subject: Total Quality Management Instructor: Sumera KaziDocument10 pagesContinuous Process Improvement: Subject: Total Quality Management Instructor: Sumera Kazidua tanveerNo ratings yet

- Chapter TwoDocument32 pagesChapter TwoKidan AmareNo ratings yet

- 1.2 Current Trends in Op - MGMTDocument50 pages1.2 Current Trends in Op - MGMTVishal SakpalNo ratings yet

- Kaizen Tools PDFDocument5 pagesKaizen Tools PDFSanjay MehrishiNo ratings yet

- Advanced Process ControlDocument2 pagesAdvanced Process ControlhbakriNo ratings yet

- LAM Lecture 10-12 PDFDocument37 pagesLAM Lecture 10-12 PDFHayl KhadhamiNo ratings yet

- Unit 7: The Lean/ Just-in-Time Concept and Repetitive ManufecturingDocument39 pagesUnit 7: The Lean/ Just-in-Time Concept and Repetitive ManufecturingpercyNo ratings yet

- Kaizen 2Document60 pagesKaizen 2Israfi MaulanaNo ratings yet

- ME Lecture Slides1 01Document13 pagesME Lecture Slides1 01SaravanaKumar ChinnaswamyNo ratings yet

- AQMDocument28 pagesAQMPushkarNo ratings yet

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocument53 pagesJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDivya SudarsananNo ratings yet

- Unit Iv CMSDocument43 pagesUnit Iv CMSsuganthNo ratings yet

- Application of Lean Six Sigma Methodology Application in Banking FINALDocument58 pagesApplication of Lean Six Sigma Methodology Application in Banking FINALimran24No ratings yet

- PPT5 - Topik5 - R0 - Lean Concept and Repetitive ManufacturingDocument28 pagesPPT5 - Topik5 - R0 - Lean Concept and Repetitive ManufacturingmrikyNo ratings yet

- Applying Lean Concepts To Supply Chains:: The Power From Effective PartnershipDocument15 pagesApplying Lean Concepts To Supply Chains:: The Power From Effective PartnershipFranklin Manuel Cortez PatiñoNo ratings yet

- CMMI® For Development,: Improving Processes For Developing Better Products and ServicesDocument156 pagesCMMI® For Development,: Improving Processes For Developing Better Products and Servicesaramaky2001No ratings yet

- Req 6Document37 pagesReq 6sam zakNo ratings yet

- Six Sigma (Vijayvignesh N S 2020606042)Document12 pagesSix Sigma (Vijayvignesh N S 2020606042)N S Vijay VigneshNo ratings yet

- 02 Lean - Advanced Lean - Pull Systems v1Document176 pages02 Lean - Advanced Lean - Pull Systems v1lrff1950No ratings yet

- LEAN - What Does Kaizen MeanDocument25 pagesLEAN - What Does Kaizen MeanaaaNo ratings yet

- Chapter 18 (Production of Goods & Services) - 17.02.08Document24 pagesChapter 18 (Production of Goods & Services) - 17.02.08Kelvin LauNo ratings yet

- Operations Management MBA (Term II) : Session Objective(s)Document14 pagesOperations Management MBA (Term II) : Session Objective(s)Jaswinder SinghNo ratings yet

- TPM BasicsDocument33 pagesTPM BasicsRajeev ChadhaNo ratings yet

- SAP QM WorrkshopDocument48 pagesSAP QM WorrkshopRamhesh BabuNo ratings yet

- Lean ManufacturingDocument3 pagesLean Manufacturingyeimyyamilet760No ratings yet

- Milliken Performance System TPM 1656557395Document14 pagesMilliken Performance System TPM 1656557395David Armando Chico OreNo ratings yet

- Feasibility Study-MergedDocument1,619 pagesFeasibility Study-MergedamulyaNo ratings yet

- Process Technology 2Document30 pagesProcess Technology 2pavan hydNo ratings yet

- Certified Lean Practitioner Day 2Document218 pagesCertified Lean Practitioner Day 2Basu ShaivaNo ratings yet

- Principles of Six SigmaDocument36 pagesPrinciples of Six SigmaSatish BindumadhavanNo ratings yet

- Department of Mechanical Engg. Andhra PradeshDocument33 pagesDepartment of Mechanical Engg. Andhra Pradeshprabhu5545No ratings yet

- World Class ManufacturingDocument32 pagesWorld Class ManufacturingVIPUL SHETTYNo ratings yet

- Lean ManufacturingDocument24 pagesLean ManufacturingBaljeetNo ratings yet

- Leanbook FordDocument197 pagesLeanbook FordArturo TorresNo ratings yet

- Cert Study Part 3Document22 pagesCert Study Part 3Ariunjargal GanboldNo ratings yet

- Introduction To Lean ManagementDocument20 pagesIntroduction To Lean ManagementrohanaNo ratings yet

- Dr.N.G.P. Institute of Technology: Department of Mechanical EngineeringDocument33 pagesDr.N.G.P. Institute of Technology: Department of Mechanical Engineeringvasanthmech092664No ratings yet

- Lesson 14 - Continuous Improvement - Part 1Document39 pagesLesson 14 - Continuous Improvement - Part 1MAURICIO CARDOZONo ratings yet

- Just-In-Time Systems: Submitted To-Submitted by - Ms. Neha Gulati Tanvi VermaDocument35 pagesJust-In-Time Systems: Submitted To-Submitted by - Ms. Neha Gulati Tanvi VermaPankaj Khindria100% (1)

- Standardized Work v4.0Document62 pagesStandardized Work v4.0Rodrigo SolisNo ratings yet

- Session 7Document29 pagesSession 7gefifa9794No ratings yet

- Just-In-Time Manufacturing: A Powerpoint Presentation by Swati (54), Meenal (39), Reenu (45), JayaDocument30 pagesJust-In-Time Manufacturing: A Powerpoint Presentation by Swati (54), Meenal (39), Reenu (45), JayaPranav ParikhNo ratings yet

- Lean Manufacturing: Introduction: Click To ProceedDocument8 pagesLean Manufacturing: Introduction: Click To ProceedUDAYAN SHAHNo ratings yet

- Ch12. JIT & Lean ManufacturingDocument59 pagesCh12. JIT & Lean ManufacturingmoovmoovNo ratings yet

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocument52 pagesJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainNeha Jigar PatelNo ratings yet

- IT Success!: Towards a New Model for Information TechnologyFrom EverandIT Success!: Towards a New Model for Information TechnologyRating: 3 out of 5 stars3/5 (1)

- Hots Advance MiraeDocument36 pagesHots Advance MiraeHabibie BoilerNo ratings yet

- Chapter 4 - Group 3 - Behavioral Processes in Marketing ChannelsDocument26 pagesChapter 4 - Group 3 - Behavioral Processes in Marketing ChannelsJanine Mariel LedesmaNo ratings yet

- DLL - Co.q2 Science IVDocument16 pagesDLL - Co.q2 Science IVAllyn MadeloNo ratings yet

- Scope: Airport Planning ManualDocument4 pagesScope: Airport Planning ManualclebersjcNo ratings yet

- BE1 Final Without Recheckreassessment - 453112Document1 pageBE1 Final Without Recheckreassessment - 453112MoloNo ratings yet

- Lesson A Worksheets. Print or Copy in Your Notebook-1Document3 pagesLesson A Worksheets. Print or Copy in Your Notebook-1Martha Lucia Arcila HenaoNo ratings yet

- What A Body Can DoDocument26 pagesWhat A Body Can DoMariana Romero Bello100% (1)

- Basic Law 01Document33 pagesBasic Law 01MitchNo ratings yet

- Adetunji CVDocument5 pagesAdetunji CVAdetunji AdegbiteNo ratings yet

- International Documentary Festival of Ierapetra Awards - 2016 ProgrammeDocument26 pagesInternational Documentary Festival of Ierapetra Awards - 2016 ProgrammeZois PagNo ratings yet

- Caro PresentationDocument33 pagesCaro PresentationVIJAY GARGNo ratings yet

- Better Get 'It in Your SoulDocument4 pagesBetter Get 'It in Your SoulJeremiah AnnorNo ratings yet

- Palm Oil MillDocument52 pagesPalm Oil MillengrsurifNo ratings yet

- MLR LLRDocument41 pagesMLR LLRKUNNAMPALLIL GEJO JOHNNo ratings yet

- Ax88796B With Ali M3602 Mcu Reference Schematic IndexDocument4 pagesAx88796B With Ali M3602 Mcu Reference Schematic IndexdistefanoNo ratings yet

- Atr Summary Assignment 1Document6 pagesAtr Summary Assignment 1Livingstone OlekanmaNo ratings yet

- Crim Pro 2004-2010 Bar QuestionsDocument4 pagesCrim Pro 2004-2010 Bar QuestionsDennie Vieve IdeaNo ratings yet

- Module 2 The Self From Philosophical and Anthropological PerspectivesDocument10 pagesModule 2 The Self From Philosophical and Anthropological PerspectivesAjhay BonghanoyNo ratings yet

- Lathe Machine and Its ComponentsDocument13 pagesLathe Machine and Its ComponentsEinstein RahatNo ratings yet

- Jgs 14518 PDFDocument8 pagesJgs 14518 PDFDes LastrianiNo ratings yet

- Written Report: Lydia Hall: Care, Cure, Core Nursing TheoryDocument12 pagesWritten Report: Lydia Hall: Care, Cure, Core Nursing TheoryAldrin Limcuando100% (1)

- Shashikala SummaryDocument2 pagesShashikala SummaryKhushbakht FarrukhNo ratings yet

- Will Love Make You HappyDocument2 pagesWill Love Make You HappyMuhammad Musa HaiderNo ratings yet

- Lê Thị Thu Thuỷ - Luận vănDocument97 pagesLê Thị Thu Thuỷ - Luận vănĐào Nguyễn Duy TùngNo ratings yet

- Module 4Document5 pagesModule 4Engelbert RespuestoNo ratings yet

- 107 Hand Tool Field Maintenance v0311Document8 pages107 Hand Tool Field Maintenance v0311rabbit_39No ratings yet

- CONSORT-EHEALTH (V 1.6.1) - Submission/Publication Form: RequiredDocument49 pagesCONSORT-EHEALTH (V 1.6.1) - Submission/Publication Form: RequiredStefan HlNo ratings yet