Professional Documents

Culture Documents

Tightening Torque, Drop Box

Tightening Torque, Drop Box

Uploaded by

p3lmrambangniru0 ratings0% found this document useful (0 votes)

3 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views1 pageTightening Torque, Drop Box

Tightening Torque, Drop Box

Uploaded by

p3lmrambangniruCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Service Information

Document Title: Function Group: Information Type: Date:

Tightening torque 430 Service Information 2/5/2014 1

Profile:

ART, A40E [GB]

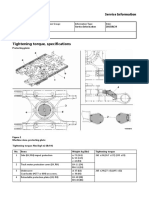

Tightening torque

Dropbox

Figure 1

Pos. Tightening torques

Nm lbf ft

1. Bolt between rubber pad and mount in frame 230 ±23 169.6 ±17.0

2. Bolt between rubber pad and mount in dropbox 230 ±23 169.6 ±17.0

Bolt through mount, frame, and cap

3. Lock nut, position monitor for longitudinal differential lock, SE4607 80 ±8 59 ±5.9

4. Level plug 80 ±8 59 ±5.9

5. Bolts that hold bearing caps [T1] 80 59

6. Bolts that hold washer and drive flange [T2] [T3] 115 84.8

7 Speed sensor, output rpm SE4309 (ATC) 25 18.4

8 Bolt between mount and cap 230 ±23 169.6 ±17.0

9 Bolt through mount, frame, and cap 230 ±23 169.6 ±17.0

[T1]When installing, apply sealant (Loctite 510 or equivalent) on the bearing cap's contact face.

[T2]Before the washer that holds the drive flange is installed, apply sealant (Loctite 518 or equivalent) on the washer's

bevelled edge. Apply lock fluid (Loctite 243 or equivalent) on the bolts when installing.

[T3]When installing, the drive flange is warmed to 100 °C (212 °F). Bolts are torqued when the drive flange has cooled down.

You might also like

- VOLVO EC140 LC EC140LC EXCAVATOR Service Repair Manual PDFDocument20 pagesVOLVO EC140 LC EC140LC EXCAVATOR Service Repair Manual PDFsekfsekmddde60% (5)

- Jenbacher: 1902-0228E Screwing and Tightening Torque J 6..GS-EDocument6 pagesJenbacher: 1902-0228E Screwing and Tightening Torque J 6..GS-EArîf100% (2)

- VOLVO EC210B NC EC210BNC EXCAVATOR Service Repair Manual PDFDocument23 pagesVOLVO EC210B NC EC210BNC EXCAVATOR Service Repair Manual PDFfjjsjekdmme100% (1)

- Trio CT3042S Jaw Crusher Parts Manual (SN. 262, 279, 284, 285)Document20 pagesTrio CT3042S Jaw Crusher Parts Manual (SN. 262, 279, 284, 285)GUILLERMO OSIMANI100% (3)

- Tightening Torque IL-1 & IL-2Document1 pageTightening Torque IL-1 & IL-2p3lmrambangniruNo ratings yet

- Diff Tightening TorqueDocument3 pagesDiff Tightening TorqueHendra MonoNo ratings yet

- Superfort 630-4 4.0 + 2.0 Betahete 800 Moulded Edges (1 X 220.0m) +GBDocument1 pageSuperfort 630-4 4.0 + 2.0 Betahete 800 Moulded Edges (1 X 220.0m) +GBIulian BarbuNo ratings yet

- Clutch 430Document17 pagesClutch 430Shivam GuptaNo ratings yet

- Calculation Results: SKF Belt Frequency Meter (PHL FM 10/400) Belt Tension Pen Gauge (PUB PSD C1/007)Document2 pagesCalculation Results: SKF Belt Frequency Meter (PHL FM 10/400) Belt Tension Pen Gauge (PUB PSD C1/007)Jean Manuel Plasencia MasNo ratings yet

- EC480D - Tightening Torque, SpecificationsDocument1 pageEC480D - Tightening Torque, Specificationseck yuwanNo ratings yet

- VOLVO EC460C LD EC460CLD EXCAVATOR Service Repair Manual PDFDocument15 pagesVOLVO EC460C LD EC460CLD EXCAVATOR Service Repair Manual PDFfjjsjekdmmeNo ratings yet

- VOLVO EC210B FX EC210BFX EXCAVATOR Service Repair Manual PDFDocument19 pagesVOLVO EC210B FX EC210BFX EXCAVATOR Service Repair Manual PDFfjjsjekdmme100% (1)

- Calcul NR Curele Si Desene de Executie Role - Anexa 3Document2 pagesCalcul NR Curele Si Desene de Executie Role - Anexa 3Alina SmocotNo ratings yet

- Tecumseh TC300-3136 Parts Manual 9109901 (1999) WWDocument10 pagesTecumseh TC300-3136 Parts Manual 9109901 (1999) WWfairfaxcyclesNo ratings yet

- VOLVO EC460C HR EC460CHR EXCAVATOR Service Repair Manual PDFDocument25 pagesVOLVO EC460C HR EC460CHR EXCAVATOR Service Repair Manual PDFjfjkkskemmdmNo ratings yet

- Dyna BoltDocument2 pagesDyna BoltDimas Cahyo SNo ratings yet

- CTD8M-1600-12 Synchrochain CarbonDocument1 pageCTD8M-1600-12 Synchrochain CarbonViniciusCamargosNo ratings yet

- EM 260/410/510 Slitter Traction Unit BG 18: ArsomaDocument16 pagesEM 260/410/510 Slitter Traction Unit BG 18: ArsomaDeniMestiWidiantoNo ratings yet

- Axles, Tightening TorquesDocument2 pagesAxles, Tightening TorqueswawanNo ratings yet

- Power Grip & Power Grip PO ClutchesDocument16 pagesPower Grip & Power Grip PO ClutchesAslanbek KaparovNo ratings yet

- Diesel TradeDocument2 pagesDiesel TradeYantian G QuoiNo ratings yet

- 4cx Şanzıman 5Document2 pages4cx Şanzıman 5zaferzafer720No ratings yet

- Tyre Curing PressDocument10 pagesTyre Curing PressSiju mon.sNo ratings yet

- 20 Torque Calculation DIN946Document2 pages20 Torque Calculation DIN946Riyan EsapermanaNo ratings yet

- Belt Data Sheet - PhoenixDocument2 pagesBelt Data Sheet - PhoenixSeshuNo ratings yet

- Flange Input Data Values Description: FLGDocument4 pagesFlange Input Data Values Description: FLGAnonymous AyDvqgNo ratings yet

- Coupling - Hoist Cam Switch PDFDocument14 pagesCoupling - Hoist Cam Switch PDFvozefjadavNo ratings yet

- Qdoc - Tips Volvo Ec210b FX Ec210bfx Excavator Service RepairDocument19 pagesQdoc - Tips Volvo Ec210b FX Ec210bfx Excavator Service RepairhendrikNo ratings yet

- Calculation Results: SKF Belt Frequency Meter (PHL FM 10/400) Belt Tension Pen Gauge (PUB PSD C1/007)Document2 pagesCalculation Results: SKF Belt Frequency Meter (PHL FM 10/400) Belt Tension Pen Gauge (PUB PSD C1/007)Franklin Josue Ticona CoaquiraNo ratings yet

- Maintenance Manual - GF - NBG 150-125-315Document20 pagesMaintenance Manual - GF - NBG 150-125-315LenoiNo ratings yet

- Echnical Information: Oncept and Main ApplicationsDocument15 pagesEchnical Information: Oncept and Main ApplicationsJózek JózekNo ratings yet

- Conversion Table/ General Tightening Torque SpecificationsDocument6 pagesConversion Table/ General Tightening Torque SpecificationsioNo ratings yet

- 7000 - Brake - Lathe CatalogoDocument12 pages7000 - Brake - Lathe CatalogoDonald's Frenos-RectificadosNo ratings yet

- S-WD 15C 5.5xL Coated Self-Drilling Wing Tip Screws: Product DataDocument2 pagesS-WD 15C 5.5xL Coated Self-Drilling Wing Tip Screws: Product DataHiệp Nguyễn VănNo ratings yet

- Ammco 7000 - PL - 940941 - 00Document10 pagesAmmco 7000 - PL - 940941 - 00Aleksandr NikitinNo ratings yet

- Draftguard Anti-Rotation Device Installation and Maintenance InstructionsDocument7 pagesDraftguard Anti-Rotation Device Installation and Maintenance InstructionsFarzadNo ratings yet

- VOLVO EC210B LR EC210BLR EXCAVATOR Service Repair Manual PDFDocument19 pagesVOLVO EC210B LR EC210BLR EXCAVATOR Service Repair Manual PDFsekfsekmddde100% (1)

- Technical Details: Piston SealsDocument2 pagesTechnical Details: Piston SealsRPINILLA (EICO S.A.)No ratings yet

- Alpha S Ia e 07 PDFDocument42 pagesAlpha S Ia e 07 PDFNoemiaNo ratings yet

- WA500-6 Pasadores BaldeDocument10 pagesWA500-6 Pasadores BaldeWaldo HuanchicayNo ratings yet

- VOLVO EC210B NLC EC210BNLC EXCAVATOR Service Repair Manual PDFDocument15 pagesVOLVO EC210B NLC EC210BNLC EXCAVATOR Service Repair Manual PDFsekfsekmdddeNo ratings yet

- PSI - Copy - KSB-PTPTP-P2207109-ENG-001 R2 NM6100B Oct 11, 2022Document10 pagesPSI - Copy - KSB-PTPTP-P2207109-ENG-001 R2 NM6100B Oct 11, 2022Cloud XNo ratings yet

- Pmi CatelogDocument101 pagesPmi CatelogdharmeshNo ratings yet

- Armado de Transmision 924G - 101803Document30 pagesArmado de Transmision 924G - 101803linko estradaNo ratings yet

- 4620 - Removal and Installation of The Two-Mass Flywheel Engine 104Document4 pages4620 - Removal and Installation of The Two-Mass Flywheel Engine 104Oscar ChohfiNo ratings yet

- 325CL 320CL Excavadora KomatsuDocument5 pages325CL 320CL Excavadora KomatsuOrlando RimarachinNo ratings yet

- VALFLON Sheet Gasket: Valqua No. 7010 Food Product Name VALFLON Pure PTFE GasketDocument4 pagesVALFLON Sheet Gasket: Valqua No. 7010 Food Product Name VALFLON Pure PTFE GasketMỹ Phạm AnhNo ratings yet

- Technical Data Sheet: 1. Table of Belt SizeDocument1 pageTechnical Data Sheet: 1. Table of Belt SizeVicky ImmanuelNo ratings yet

- RamsetDocument2 pagesRamsetAndrea GibsonNo ratings yet

- B70 Rock Breaker Care Operation Manual For TH86Document21 pagesB70 Rock Breaker Care Operation Manual For TH86Latifa EngineeringNo ratings yet

- MT 10 2019-10 enDocument10 pagesMT 10 2019-10 entemaquijaNo ratings yet

- Makita 3709 TeDocument4 pagesMakita 3709 TeeamigNo ratings yet

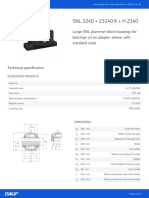

- SNL 3240 + 23240 K + H 2340: Large SNL Plummer Block Housings For Bearings On An Adapter Sleeve, With Standard SealsDocument4 pagesSNL 3240 + 23240 K + H 2340: Large SNL Plummer Block Housings For Bearings On An Adapter Sleeve, With Standard SealsRisheet AgheraNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)