Professional Documents

Culture Documents

4

4

Uploaded by

Daniel LliguayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4

4

Uploaded by

Daniel LliguayCopyright:

Available Formats

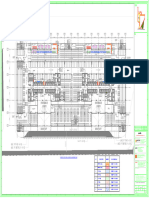

1 2 3 4 5 6 7 8 9 10 11 12

A1

mm

A A

750 O.D. LIFTING L2A L4A

C5

LUIG S1 16x EQUIDISTANTS HOLES

PLATE C PLATE C 1

Ø 27 mm [1 16 in] INTERS

BOARDING

FEET

BOARDING

FEET

O.D. 1000

1170

5

CLOSE WELD

B C C.D. 850 B

1221

S3

L1A L3A

750 O.D.

x5 CLM

4 3 4 I.D. 750

C1

SEAM TO SEAM

CYLINDER 4 0º 250

L4A

3115 1

C2 C3 C4 C5 t = 8 mm

C S2

C

CLOSE WELD CLOSE WELD 2

2765

C4 2340 3 4 S1

15

5 x 350 = 1750 2640

VERTICAL

2415 CENTER TO CENTER

6 PLATE TO PLATE

270º

15 120

CLOSE WELD

3770 1221 C1

VERTICAL 750 O.D. DETAIL MK "2"

x5 CLM

4 DETAIL MK "1"

D PLATE TO PLATE

L3A (Details of Rigidizers) D

SEAM TO SEAM

CYLINDER 3

2065 (For Flange B' ) Esc: 1:2,5

Esc: 1:5

2x 655 1221 1221

S3 750 O.D. 750 O.D. 750 O.D. 120

350 x5 CLM . x5 CLM x5 CLM 0º

1715 S2 SEAM TO SEAM SEAM TO SEAM SEAM TO SEAM

CLOSE WELD CYLINDER 1 &2 CYLINDER 3 CYLINDER 4

CLOSE WELD 45º 315º

O.D. 1000

CLOSE WELD

E C3 MAIN COLUMN EXTENSION DEVELOPMENT E

655 1365 Esc: 1:25

750 O.D. 3 L2A 120 60

x5 CLM BOARDING BOARDING 7

FEET FEET I.D. 750

SEAM TO SEAM

CYLINDER 2 S3 B S4 2

S2

90º 270º 180º 0º 270º

CLOSE WELD CLOSE WELD

2 2 90º

2 2

S1

B C2 895

COLUMN

F 655

VERTICAL 1 F

750 O.D. S3 PLATE TO PLATE

1 136

x5 CLM 3 L1A

SEAM TO SEAM LOWER

COLUMN

CYLINDER 1 435 B RIGIDIZERS 1

2 225º

LOWER PLATE B'

RIGIDIZERS

135º

1 120 S4 S4

PLATE B'

C1 136 1 C1 8x PAIR OF RIGIDIZERS

S1

G 180º

(Equidistants) G

DETAIL "B" CUT "B" SECTION B

ELEVATION VIEW -AXIS "A" ELEVATION VIEW -AXIS "B" (Assembly of Rigidizers) (Welding of Rigidizers) (Details of Rigidizers)

Esc: 1:15 Esc: 1:15 Esc: 1:5 Esc: 1:4 Esc: 1:10

212

R 375

0º

H O.D. 720 110 H

S4

S4 10 350 9

10 10

S5 S5 Ø25 S1 t = 8 mm 212

40 280

50 t = 8 mm

COLUMN

9

COLUMN

COLUMN R 20 8 168 288

9 9

S4

90º 270º

10

S4 350

100 300 120 S5 S5

I 45° 212

CENTER TO CENTER I

6 DETAIL MK "9" DETAIL MK "10"

t = 10 mm

(For Saddle Nerve) (For Chair Plate)

COLUMN DETAIL "C" Esc: 1:5 Esc: 1:5

(For Boarding Feet )

20 Esc: 1:10

180º

GENERAL NOTES

DETAIL MK "6" DETAIL MK "5" DETAIL MK "8" - MEASUREMENTS ARE IN MILLIMETERS [INCHES], UNLESS OTHERWISE STATED.

J (For Stairs) (For Lift Ears) (For Cover Plate C) - THE WELDING DETAILS FOR THIS SHEET WHICH REFERS TO THE MAIN COLUMN AND THE COLUMN EXTENSION. THIS

WELDING PROCESS IS APPLIED TO SHEET Nº 04 ST: 03:00 AND SHEET Nº 03 ST: 02:00.

Esc: 1:2,5 Esc: 1:2,5 Esc: 1:10

10 4 PL 350 x 212 x 8 ASTM A 36 4.659 18.639 CHAIR PLATE

9 8 PL 280 x 212 x 8 ASTM A 36 3.727 29.822 NERVE PLATE

8 1 PL O.D. 720 x t 8 ASTM A 36 27.743 27.743 TO COVER THE COLUMN

7 16 THREADED STUD UNC 1 x 2 1/2 in & NUTS ASTM A 325 0.8 12.8 ANCHOR FLANGE WITH PLATE

WELDING DETAILS ALIGMENT TOLERANCE BUTT WELDS

6 15 BARS O.D. 1/2 in x 600 mm LG ASTM A 706 0.529 7.935 STAIR BAR

JOINT CATEGORY MAXIMUN ALLOWABLE OFFSET 5 2 PL 120 x 90 x 10 ASTM A 36 0.847 1.696 PLATE FOR LIFT EARS

Circunferential Weld Shell X = MIN (t1, t2) S.2 Circunferential Weld Shell Longitudinal Weld Shell

S.1 S.3 S.4 Joint Category A & B S.5 Joint Category E A 8[5/16] xt = 8 [5/16] 4 2 PL 2340 x 1220 x 5 ASTM A 36 112.051 224.102 PLATE FOR CYLINDER

Shell - Close Shell - Close Joint Category A

K Joint Category B & D Joint Category A Max. 2.4 60°±5 X = MIN (t1, t2) X = MIN (t1, t2) B 5 [3/16] xt = 8 [5/16] 3 2 PL 1220 x 650 x 5 ASTM A 36 31.1226 62.251 PLATE FOR CYLINDER

Max. 4 [3/32] t2 C 8 [5/16] xt = 16 [5/8] 2 16 PL 250 x 120 x 8 ASTM A 36 0.909 14.555 PLATE FOR RIGIDIZERS

t2 [5/32] 60°±5 t1 5 [3/16] xt = 16 [5/8] 1 1 PL O.D. 1000 x I.D. 750 x t 16 ASTM A 36 43.569 43.569 PLATE FOR FLANGE

t1 D

E 5 [3/16] xt = 12 [1/2] CANT DENOMINACION P.W. P. TOTAL

MK MATERIAL [Kg] W. TOTAL [Kg] OBSERVATION

/QTY DESCRIPTION

FILLET WELDS 04 de 06 1 de 1 St: 03:00 FM-MIM-MEF-AB-CE-P-001-04-2024 IPEC ESPOCH

cj_lalon@hotmail.com / cristian.lalon@espoch.edu.ec FACULTAD DE MECÁNICA

0962859932 MAESTRÍA EN INGENIERÍA MECÁNICA

1.6 ~ 3.2 LEG LENGTH TOLERANCES

ADVERTISING

INSIDE

Datos Nombre Firma Fecha Peso (T) Tolerancia Escala Registro

INSIDE

I.D.

1.6 ~ 3.2 [1/16 ~1/8 ] LESS THAN 3.2 [1/8] -0/+3.2 [1/8]

BILLBOARD

I.D.

L SHELL [1/16 ~1/8 ] 1.6 ~ 3.2 Ing. Chávez J.

t2 t2 OVER 3.175 [1/8] TO 6.35 [1/4] -0/+3.2 [1/8] Proyectó Ing. Chávez C. 07/04/24 [COLUMN EXTENSION]

t2 T [1/16 ~1/8 ] 0.47 ± 0.5 ---

t1 1.6 ~ 3.2 SHELL OVER 6.35 [1/4] TO 12.7 [1/2] -0/+3.2 [1/8]

Dibujó Ing. Rs. Lalón C. 09/04/24

[1/16 ~1/8 ] T IPEC-ESPOCH-FM-MIM-MEF-AB-PA-P-001-S5 OVER 12.7 [1/2] TO 25.4 [1] -0/+4.76 [3/16]

IPEC-ESPOCH-FM-MIM-MEF-AB-CE-P-001-S1 IPEC-ESPOCH-FM-MIM-MEF-AB-CE-P-001-S2 IPEC-ESPOCH-FM-MIM-MEF-AB-CE-P-001-S3 IPEC-ESPOCH-FM-MIM-MEF-AB-CE-P-001-S4 Revisó Msc. Hernández J. 28/04/24 ESTE DOCUMENTO ES PROPIEDAD INTELECTUAL DE:

UP TO 25.4 [1] -0/+6.35 [1/4] Carbon Steel Lalón C. CUALQUIER USO Y REPRODUCCIÓN TOTAL O

PARCIAL NO AUTORIZADA CONSTITUYE VIOLACIÓN

DE LOS DERECHOS RESERVADOS DEL AUTOR

1 2 3 4 5 6 7 8 9 Aprobó Msc. Hernández J. 28/04/24 STRUCTURE ADVERTISING BILLBOARD.dwg

PENADA POR LA LEY.

You might also like

- Atlas Copco cd24 Air Dryer Manual PDFDocument43 pagesAtlas Copco cd24 Air Dryer Manual PDFChriss Vzz100% (3)

- 17IPS20Document2 pages17IPS20Antonio Verdu AlfonsoNo ratings yet

- Ar PRM TDR Phase 02 Dde 0001Document1 pageAr PRM TDR Phase 02 Dde 0001Thota NageshNo ratings yet

- Pumping Circuit SDocument1 pagePumping Circuit SmhmdraqylyrbyNo ratings yet

- Schematic - Class-D Sub Monoblok - 2021-07-18Document1 pageSchematic - Class-D Sub Monoblok - 2021-07-18Sneha NamdevNo ratings yet

- Bassbutler Final Corrected 3Document1 pageBassbutler Final Corrected 3Beckenbauer ErnstbergerNo ratings yet

- Elevation: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetDocument1 pageElevation: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetParikh DhavalNo ratings yet

- Ar PRM TDR Phase 02 Dse 0006Document1 pageAr PRM TDR Phase 02 Dse 0006Thota NageshNo ratings yet

- Etihad Rail Network: Longitudinal Section DDocument1 pageEtihad Rail Network: Longitudinal Section DDanielVadjkeVađinaNo ratings yet

- Bridge Design Sample Autocad-1Document1 pageBridge Design Sample Autocad-1DINESHNo ratings yet

- EGS002EG2113Document1 pageEGS002EG2113Ahmad D. TaufiqNo ratings yet

- Layout PCB Sony Xperia z1 c6902 c6903 c6906 c6943 l39h WwwlemcellcombrDocument2 pagesLayout PCB Sony Xperia z1 c6902 c6903 c6906 c6943 l39h WwwlemcellcombrDiscovery UzNo ratings yet

- 220 M6 0330 00006Document1 page220 M6 0330 00006jhonNo ratings yet

- 0-ModelDocument1 page0-Modeljoselito navarroNo ratings yet

- Amb-Agcc02-Tun Ce 1002 - P0Document1 pageAmb-Agcc02-Tun Ce 1002 - P0Sugam JainNo ratings yet

- OOLSGV-MSP-ZZ-XX-DR-P-008700-C00 - 2023.11.27 Pool Step DetailsDocument1 pageOOLSGV-MSP-ZZ-XX-DR-P-008700-C00 - 2023.11.27 Pool Step DetailsNitin SeenauthNo ratings yet

- 6 Drawing 3D 2Document1 page6 Drawing 3D 2wassimwalha2016No ratings yet

- Str.09-Foundation Layout-Bored Pile Reinforement of M3Document1 pageStr.09-Foundation Layout-Bored Pile Reinforement of M3Khoi DuongNo ratings yet

- Nguyenthan D.P.Luu 20 FEB 2024 IssuedDocument1 pageNguyenthan D.P.Luu 20 FEB 2024 Issuedrajitkumar.3005No ratings yet

- Ar PRM TDR Phase 02 Dde 0002Document1 pageAr PRM TDR Phase 02 Dde 0002Thota NageshNo ratings yet

- DD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewDocument1 pageDD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewDavid Adi KaruniaNo ratings yet

- Etihad Rail Network: Longitudinal Section DDocument1 pageEtihad Rail Network: Longitudinal Section DDanielVadjkeVađinaNo ratings yet

- DD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewwDocument1 pageDD - de - 86.1-H19118 Schematic Diagram of Air Conditioning Control NewwDavid Adi KaruniaNo ratings yet

- Vu 1105 070822Document1 pageVu 1105 070822api-3698996No ratings yet

- STR 052 04 JR2 GA20 ModelDocument1 pageSTR 052 04 JR2 GA20 ModelSigit PurnomoNo ratings yet

- Induction MotorsDocument1 pageInduction MotorsElectrifying GuyNo ratings yet

- SP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Document1 pageSP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Hector HernandezNo ratings yet

- Pdf24 MergedDocument32 pagesPdf24 MergedMechwell DesignNo ratings yet

- STB 01 SchematicDocument1 pageSTB 01 SchematicTu DoNo ratings yet

- STB 01 SchematicDocument1 pageSTB 01 SchematicTu DoNo ratings yet

- Pbr2-3 Pbr2-3: El.+130.300平台平面布置图 (1) A A1 ADocument1 pagePbr2-3 Pbr2-3: El.+130.300平台平面布置图 (1) A A1 AJesus Manuel Juarez MamaniNo ratings yet

- Plan at Ground Floor: A-08 W.V. CoscolluelaDocument1 pagePlan at Ground Floor: A-08 W.V. CoscolluelaEljoy C. AgsamosamNo ratings yet

- Precast Boundary Wall Layout: Key PlanDocument1 pagePrecast Boundary Wall Layout: Key PlanBleep NewsNo ratings yet

- MD 502 3000 Eg CV Dal 00X1 - Rev A02Document1 pageMD 502 3000 Eg CV Dal 00X1 - Rev A02Pro FRGWNo ratings yet

- VA DO How-To FloneDocument1 pageVA DO How-To FlonettNo ratings yet

- G90 Ssigbd 2.0.6 Gai03Document1 pageG90 Ssigbd 2.0.6 Gai03my_scribd_20100607No ratings yet

- Section A-A Section B-B Section C-C Section D-D: Bill of MaterialDocument1 pageSection A-A Section B-B Section C-C Section D-D: Bill of MaterialPinak ProjectsNo ratings yet

- Hanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDocument1 pageHanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDenkaNo ratings yet

- P020c30ug01tmh Dras Civstrdwg 10006 01Document1 pageP020c30ug01tmh Dras Civstrdwg 10006 01NAVANEETHA KRISHNANNo ratings yet

- KC Me Eer 031 Rev. 1Document9 pagesKC Me Eer 031 Rev. 1danielNo ratings yet

- 17ips20-semaDocument2 pages17ips20-semaİnan ÇökelekciNo ratings yet

- Samb108 sch0.8 - de - EfrcomDocument8 pagesSamb108 sch0.8 - de - EfrcomHotel WijayaNo ratings yet

- Toughining Upto 40-45 HRC: Thread RelifDocument1 pageToughining Upto 40-45 HRC: Thread RelifChandru ChristurajNo ratings yet

- SC Ring-ModulatorDocument1 pageSC Ring-Modulatordima.estralinNo ratings yet

- ST - SARMIENTO8823 (1) EqwwqeDocument4 pagesST - SARMIENTO8823 (1) Eqwwqebenedictpuzon.8No ratings yet

- Gre Eec D 99 CL P 13909 13 155 00Document1 pageGre Eec D 99 CL P 13909 13 155 00RodrigoNo ratings yet

- Isometric View F G (1:5) Typ.: Welds As Per Danieli STD 2.8.006Document1 pageIsometric View F G (1:5) Typ.: Welds As Per Danieli STD 2.8.006rajitkumar.3005No ratings yet

- RM01 DRG 3000 Me Acd B1 01 101Document1 pageRM01 DRG 3000 Me Acd B1 01 101rizwan8291No ratings yet

- VG 1012 070820Document1 pageVG 1012 070820api-3698996No ratings yet

- Philips 715g3214-1 32pfl5604 PsuDocument4 pagesPhilips 715g3214-1 32pfl5604 PsuMarcelo SilvaNo ratings yet

- 2023 Thouse Ceiling&Me 03 24 FullDocument7 pages2023 Thouse Ceiling&Me 03 24 FullYudha Dwi HarjantoNo ratings yet

- Component Placing Layout Xperia Z3+ Plus E6553, E6553 PDFDocument2 pagesComponent Placing Layout Xperia Z3+ Plus E6553, E6553 PDFCelublack CkNo ratings yet

- Ground Floor Plan: Scale 1:100Document2 pagesGround Floor Plan: Scale 1:100CSEC Uganda Ltd.No ratings yet

- Power Supply Inverter Vestel 17IPS20P-R3Document2 pagesPower Supply Inverter Vestel 17IPS20P-R3maciekreNo ratings yet

- Vestel 17ips20p-R5 SCHDocument2 pagesVestel 17ips20p-R5 SCHAnonymous XoW23y58O100% (1)

- Binder - Equipment LoadingDocument11 pagesBinder - Equipment LoadingKiran JoshiNo ratings yet

- Agcc02 11718a CRD RKM Co Wod 90533Document1 pageAgcc02 11718a CRD RKM Co Wod 90533Faizuddin SiddiquiNo ratings yet

- Notes:-: Timber Doors Key PlanDocument1 pageNotes:-: Timber Doors Key PlanKumudu PereraNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- Ch. 9 - Basic Router TroubleshootingDocument15 pagesCh. 9 - Basic Router TroubleshootingArad RezaNo ratings yet

- Fpso - LNG ProcessDocument15 pagesFpso - LNG ProcessYeshWaNth100% (1)

- Web Pages With MVC3 and Razor SyntaxDocument282 pagesWeb Pages With MVC3 and Razor Syntaxozamaro100% (1)

- European Ict Professional Role Profiles: Part 2: User GuideDocument37 pagesEuropean Ict Professional Role Profiles: Part 2: User GuideDaniele BalloNo ratings yet

- Laya Marxlenin - CE152P-2 - E02 - Experiment2 - Module1Document5 pagesLaya Marxlenin - CE152P-2 - E02 - Experiment2 - Module1Marxlenin LayaNo ratings yet

- Wiki DalidaDocument23 pagesWiki Dalidaclem454polNo ratings yet

- Identity As A Service For DummiesDocument53 pagesIdentity As A Service For DummiesDevendra GuptaNo ratings yet

- Technical SpecificationDocument14 pagesTechnical SpecificationbinodeNo ratings yet

- Ufc 3 301 01 2013Document168 pagesUfc 3 301 01 2013praveen0907No ratings yet

- CSCI207 Lab3Document3 pagesCSCI207 Lab3Ali Rida SiblaniNo ratings yet

- Marketing Plan Presentation RubricsDocument2 pagesMarketing Plan Presentation RubricsisabeloroseangelNo ratings yet

- The National Service Training Program Its Legal Basis, Objectives and SignificanceDocument13 pagesThe National Service Training Program Its Legal Basis, Objectives and SignificanceAngela Danielle TanNo ratings yet

- Electric Valve Actuators VA 7450 SeriesDocument7 pagesElectric Valve Actuators VA 7450 SeriescesarintiNo ratings yet

- 2252-Article Text-3992-1-10-20190421Document22 pages2252-Article Text-3992-1-10-20190421Etab BarakatNo ratings yet

- .. Thesis Title .Document31 pages.. Thesis Title .Tanut VongsoontornNo ratings yet

- E JB TutorialDocument141 pagesE JB TutorialManikandan ChellaNo ratings yet

- Packard Bell Sjm50Mv/Pu Service GuideDocument180 pagesPackard Bell Sjm50Mv/Pu Service Guideg321m46No ratings yet

- Ardrox AV 30: Material Safety Data SheetDocument5 pagesArdrox AV 30: Material Safety Data SheetMueed LiaqatNo ratings yet

- CANBUSDocument18 pagesCANBUSSamuel SimbolonNo ratings yet

- Sulphate Attack in Concrete and Its PreventionDocument21 pagesSulphate Attack in Concrete and Its PreventionvempadareddyNo ratings yet

- CMS Farming SystemDocument3 pagesCMS Farming SystemCarylSaycoNo ratings yet

- Karlovački MirDocument29 pagesKarlovački MirAnci PuenteNo ratings yet

- NMBM 15 Western RD - May 2023Document2 pagesNMBM 15 Western RD - May 2023Tshepo KauNo ratings yet

- HYUNDAI WIA Heavy Duty Cutting Horizontal Machining CenterDocument27 pagesHYUNDAI WIA Heavy Duty Cutting Horizontal Machining CentersrinivignaNo ratings yet

- Mathematics 3Document2 pagesMathematics 3Tony StarkNo ratings yet

- Strap Grid Tubular Plate - A New Positive Plate For Lead-Acid BatteriesDocument36 pagesStrap Grid Tubular Plate - A New Positive Plate For Lead-Acid Batteriesantony2288No ratings yet

- ISO 11820 - 1996 (En), Acoustics - Measurements On Silencers in Situ PDFDocument1 pageISO 11820 - 1996 (En), Acoustics - Measurements On Silencers in Situ PDFpighonNo ratings yet

- KADIMP Book Email 2Document116 pagesKADIMP Book Email 2ZINART MUSANo ratings yet

- Fungsi Protein - Andri Josua SianiparDocument30 pagesFungsi Protein - Andri Josua SianiparAndri Josua SianiparNo ratings yet

- Gaming Industry E Mail Id OnlyDocument4 pagesGaming Industry E Mail Id OnlySundararajan SrinivasanNo ratings yet