Professional Documents

Culture Documents

Inverted One Pager

Inverted One Pager

Uploaded by

abhayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inverted One Pager

Inverted One Pager

Uploaded by

abhayCopyright:

Available Formats

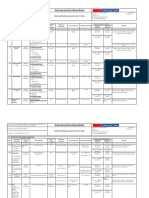

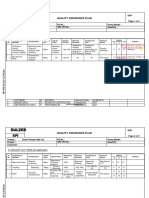

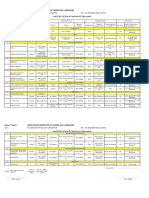

Inverted battery Asset Assessment

Section Topic Rating (1-5)Evidence (Comments

PCMs)filled/ is

rationale

used for thermal management, therefore Definitions / benchmarks

Asset quality 4 repair and servicability of cells is possible. Rating

Built 1

through Rating 3 and tested Proprietary

from tried Rating 5 with simulation tools as

- Design - Maturity 5 Audit Report 4. Total 32 member team ; details given at the end of experimentation product well dedicated

>15 as on-ground testingfolks

research

- R&D 4 Audit Report summary

1000 cycles with degradation curve. at 1000 cycles No R&D team (excluding ancillary roles)

80% from consistent, accredited

- Suppliers ( Main component- Cell supplier 4 Audit Report degradation

to be workingis on

85%developing BMS inhouse as well. Adhoc supplier base Indian

80% fromsuppliers

consistent, accredited

- BMS supplier 4 Audit Report Adhoc supplier base Indianfrom

80% suppliers

consistent, accredited

- Busbar 4 Audit Report Copperthereby

coated nickel for 2W thermal heat dissipation).

reducing Adhoc supplier base Indian suppliers

- Outer body 5 Audit Report Top Cover

1.Basic is MS with for

methodology cutput

IQC.for IOT communication e.g. drive train, batteries, body

- Operations - Incoming quality 3 Audit Report 2.Cell storage

Basic grading mechanism.

is done on sampling

They arebasis

moving to new facility and in Only test-drive

Only assembly post panels with specialised test

checks

- Material Storage 4 Audit Report processes of setting

(Data validating up storage

this claim has been asked - they might get the assembly equipment

processes incld Quality circle,

- Production Process 4 Audit Report data from machine supplier). Not implemented Kaizen, FMEA

Uniformed, charts

trained etc with

workers

- Manpower 4 Audit Report Well trained manpower and defined task & work bench Manual with basic specialised tools, specific roles

- In-Process quality 4 Audit Report In process

-Cell Checksdone

level testing in place.

but on sampling basis. tools equipment Key processes automated

- Quality assurance 3 Audit Report -Module/Battery level testing done on sample basis not 100%

- PDI 3 Audit Report Pack Level

FRAME HAS PDI beingASKED

BEEN done. - DATA AWAITED)

- Customer feedback NA Detractors In-different Advocates

- Dealer feedback NA TBD Detractors In-different Advocates

Ease of maintenance / repairability 3.6 sourced from Inverted itself. All key components locally

- General - Spare parts availability 4 Audit Report other

Fairly parts

simple- standard

assembly using spot welding. However stations manufactured

- Manufacturing complexity 4 Audit Report are electronics

No well definedexcept BMS used in Battery. BMS is No dedicated equipment required

- Extent of onboard electro 3 Audit Report outsourced

Ludhiana, Bhubaneshwar, Highservice

No e.g. forcentre

4W EVs Low coverage in all cities with

100%

- Company support - Service centres 4 Malappuram,

3 years or 40KHyderabad

KM which (Kondapur)

ever is earlier (Warranty Document support spare parts stock

- Warranty 3 Warranty DocumeReceived)

Detractors In-different Advocates

Inverted is ready to give cloud acess data for the IOT ; by

Ease of recovery 4 which Electrifi can monitor health of battery remotely.

- IoT enablement 3 Audit Report IOT enabled No Yes

4. Inverted has sold 45,000 to BatterySsmart till date. Application at Battery smart is worst abuse of the battery.

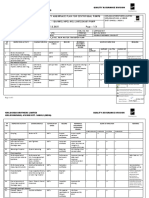

Summary message

Satisfaction Level Score

R&D team details are : Good 4+

List of Details Asked Status Ok 3

Spec sheet of battery 51.8V Recieved a. Electronics team / BMS development team : 8 people Not ok <3

18650-26Ecycle life @25 deg Recieved b. Mechanical team : 14 people

Bill of purchase Recieved c. Electrical team : 6 people

Warranty Document Recieved d. Testing & Validation team : 6 members

R&D team data Recieved Total R&D team size is : 32 people

PDI data sheet Not recieved

Battery pack testing Not recieved

You might also like

- Plating Process Audit Checksheet 9332E-XDocument3 pagesPlating Process Audit Checksheet 9332E-Xabhionlyster67% (9)

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Document1 page201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Manufacturing Quality Plan: Page 1 of 11Document11 pagesManufacturing Quality Plan: Page 1 of 11Nagaraju ChNo ratings yet

- 20.external and Internal IssuesDocument4 pages20.external and Internal IssuesChahid Ali86% (7)

- MSIL Audit Cheklist 16Document39 pagesMSIL Audit Cheklist 16jineshdmehta100% (10)

- Farm Tools in Agricultural Crop ProductionDocument6 pagesFarm Tools in Agricultural Crop ProductionJohnLesterDeLeon67% (15)

- Physiology PF PuerperiumDocument34 pagesPhysiology PF PuerperiumKholoud Kholoud100% (4)

- Log9 One PagerDocument1 pageLog9 One PagerabhayNo ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- Production Part ApprovalDocument3 pagesProduction Part Approvalvidya410gmailcomNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Bps Product Certification Scheme Surveillance Audit Form: Company ProfileDocument1 pageBps Product Certification Scheme Surveillance Audit Form: Company ProfileLenin Rey PolonNo ratings yet

- MSIL Audit Cheklist 16Document90 pagesMSIL Audit Cheklist 16mallarjun0010No ratings yet

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

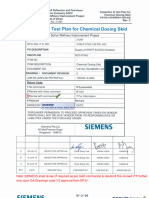

- Siemens Internship ReportDocument17 pagesSiemens Internship ReportmirfanbilalNo ratings yet

- QMS 04 A Interested Parties FreeDocument5 pagesQMS 04 A Interested Parties FreeLisardo ConstelaNo ratings yet

- FQP For Brick WorkDocument1 pageFQP For Brick WorkHimanshu ChaudharyNo ratings yet

- Form Supplier Audit Rev A5 (2021)Document6 pagesForm Supplier Audit Rev A5 (2021)syisyi87No ratings yet

- Signed - SOP for RCA quality reviewDocument6 pagesSigned - SOP for RCA quality reviewsaifNo ratings yet

- PQR Overview 2016Document24 pagesPQR Overview 2016ike mayaNo ratings yet

- Nuclear Power Corporation of India Limited: Quality Assurance PlanDocument2 pagesNuclear Power Corporation of India Limited: Quality Assurance PlanRavindra TiwariNo ratings yet

- Moisture Content TestsDocument3 pagesMoisture Content Testsghaghra bridgeNo ratings yet

- Methodology for PQCDocument14 pagesMethodology for PQCVîkās S. RāthødNo ratings yet

- (2-19) Audit Check SheetDocument1 page(2-19) Audit Check SheetKumaravelNo ratings yet

- Master Sheet Process Audit Check SheetDocument11 pagesMaster Sheet Process Audit Check SheetRakesh S100% (1)

- JBSESB-MP004 Quality Management PlanDocument1 pageJBSESB-MP004 Quality Management PlanNaqib Levis SolNo ratings yet

- 4M: Corrective Action Plan: No Name Set Date: Fty Area Product TypeDocument1 page4M: Corrective Action Plan: No Name Set Date: Fty Area Product TypeBayu IrawanNo ratings yet

- PCP-00 Rev.0 Process Control Plan AuditDocument7 pagesPCP-00 Rev.0 Process Control Plan AuditVinod SaleNo ratings yet

- QAP Final - ASSAMNZRMM11Document2 pagesQAP Final - ASSAMNZRMM11Jaspreet SinghNo ratings yet

- Inspection & Test Plan Advance Valves Butterfly ValvesDocument2 pagesInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNo ratings yet

- Draft in QA SP XX Viewing BoardDocument6 pagesDraft in QA SP XX Viewing BoardSuraj RawatNo ratings yet

- Supplier Initial Assesment Check Sheet 07.2.19Document13 pagesSupplier Initial Assesment Check Sheet 07.2.19Prathmesh BandNo ratings yet

- PP Qsu PR 0002 r0 Scar Procedure PDFDocument8 pagesPP Qsu PR 0002 r0 Scar Procedure PDFHoàng Việt NguyễnNo ratings yet

- Kpi Appraisal Sheet - Project EnggDocument1 pageKpi Appraisal Sheet - Project EnggRknight BNo ratings yet

- ITP Low Tempt Test - RevDocument6 pagesITP Low Tempt Test - RevAgus GunawanNo ratings yet

- Quality Assurance Plan: Page 1 of 2 Vendor: Pump Model: Project: Quantity: CustomerDocument4 pagesQuality Assurance Plan: Page 1 of 2 Vendor: Pump Model: Project: Quantity: CustomerDeepak UpadhyayNo ratings yet

- QAP HMEL 7480000754 L08722A501-SignedDocument3 pagesQAP HMEL 7480000754 L08722A501-SignedSuyog GawandeNo ratings yet

- DTP - Supplier Management SOP QA.008Document13 pagesDTP - Supplier Management SOP QA.008Faizah LokmanNo ratings yet

- Only Upon GA Drawings Code 1/2 Approval From DPJV.: by Sekar - Rajesh at 6:43 PM, Aug 25, 2015Document4 pagesOnly Upon GA Drawings Code 1/2 Approval From DPJV.: by Sekar - Rajesh at 6:43 PM, Aug 25, 2015Rahmat BasukiNo ratings yet

- MSIL Audit Cheklist 16Document22 pagesMSIL Audit Cheklist 16Pravin Balasaheb GunjalNo ratings yet

- Iktva Smes Forum & Exhibition 2017: Saudi Aramco Engineering Requirements For Technical and Quality Approval (Ertqa)Document7 pagesIktva Smes Forum & Exhibition 2017: Saudi Aramco Engineering Requirements For Technical and Quality Approval (Ertqa)Anupam NathNo ratings yet

- QAP For Overall Mechanical ActivitiesDocument2 pagesQAP For Overall Mechanical ActivitiesMaheshwar polepallyNo ratings yet

- MIDC Buti Bori: Audit Observation SheetDocument1 pageMIDC Buti Bori: Audit Observation SheetAnkush ChourasiaNo ratings yet

- APQP ChecklistDocument5 pagesAPQP ChecklistAlan ValadezNo ratings yet

- Supplier Audit Check SheetDocument5 pagesSupplier Audit Check SheetMotive Post100% (2)

- 01 Manufacturer - Qualification - ISPE PDFDocument15 pages01 Manufacturer - Qualification - ISPE PDFMillicent SongsterNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- Ammj273 May 2014. Asset Menagement, ISO 55000Document61 pagesAmmj273 May 2014. Asset Menagement, ISO 55000Srđan KrsteljNo ratings yet

- Gpe-Fat OverviewDocument5 pagesGpe-Fat Overviewn.hartonoNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- 109-RR-AMT-ITP-02-Fall Arrest SystemDocument1 page109-RR-AMT-ITP-02-Fall Arrest SystemSher DilNo ratings yet

- 18 Management ReviewDocument1 page18 Management Reviewkumarnitesh173No ratings yet

- How To Audit Fmeas Using Quality ObjectivesDocument41 pagesHow To Audit Fmeas Using Quality ObjectivesAmir KhakzadNo ratings yet

- Api 1Document19 pagesApi 1Siddheshwarr JabagoudarNo ratings yet

- Inspection and Test Plan-LIT Project - 3.1.2024Document11 pagesInspection and Test Plan-LIT Project - 3.1.2024rhannie garciaNo ratings yet

- F 392 0 r01 Supplier Quality AssessmentDocument12 pagesF 392 0 r01 Supplier Quality AssessmentSiddheshwarr JabagoudarNo ratings yet

- Green: Tenneco Automotive India Pvt. LTDDocument1 pageGreen: Tenneco Automotive India Pvt. LTDsatrughana patraNo ratings yet

- Cuestionario VdaDocument33 pagesCuestionario Vdaing1amm100% (1)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Annual Product Quality Review (APQR) in Pharmaceutical ManufacturingFrom EverandAnnual Product Quality Review (APQR) in Pharmaceutical ManufacturingNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and Auditors with CD ROMFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and Auditors with CD ROMNo ratings yet

- OpTransactionHistoryUX527!04!2024 (1)Document2 pagesOpTransactionHistoryUX527!04!2024 (1)abhayNo ratings yet

- Adobe Scan 18 Apr 2024Document2 pagesAdobe Scan 18 Apr 2024abhayNo ratings yet

- Invoice Tv00152 Tamaria Ventures Mukesh Meena (1)Document2 pagesInvoice Tv00152 Tamaria Ventures Mukesh Meena (1)abhayNo ratings yet

- Invoice Tv00141 Tamaria Ventures Nazar Ali (2)Document1 pageInvoice Tv00141 Tamaria Ventures Nazar Ali (2)abhayNo ratings yet

- BluSmart-21732168Document3 pagesBluSmart-21732168abhayNo ratings yet

- Invoice Tv0024 Tamaria Ventures Dhanraj MaliDocument1 pageInvoice Tv0024 Tamaria Ventures Dhanraj MaliabhayNo ratings yet

- Invoice Tv00149 Tamaria Ventures Tamaria and Sons (2)Document1 pageInvoice Tv00149 Tamaria Ventures Tamaria and Sons (2)abhayNo ratings yet

- NN232SKZBWYFESNM7102 (1)Document1 pageNN232SKZBWYFESNM7102 (1)abhayNo ratings yet

- SM (3)Document1 pageSM (3)abhayNo ratings yet

- AMC Document 3W (2)Document6 pagesAMC Document 3W (2)abhayNo ratings yet

- UGC NET PAPER - 01 Complete Study MaterialDocument12 pagesUGC NET PAPER - 01 Complete Study MaterialMaha Lakshmi100% (1)

- Feasibility Study - SamplesDocument14 pagesFeasibility Study - SamplesAi Zy67% (3)

- Eaton Fuller RTLO 16618A Transmission Parts ManualDocument36 pagesEaton Fuller RTLO 16618A Transmission Parts ManualJavi SG100% (1)

- Eng4 LM U4 PDFDocument108 pagesEng4 LM U4 PDFDan August GalliguezNo ratings yet

- Diary of An Insurance Seller AllDocument9 pagesDiary of An Insurance Seller AllPriyanka Patel100% (1)

- Copper LeachingDocument13 pagesCopper LeachingLutfi ムハンマドNo ratings yet

- Chinhoyi University of Technology: Morning Session MONDAY, 08 MARCH 2021 (0900 HOURS)Document5 pagesChinhoyi University of Technology: Morning Session MONDAY, 08 MARCH 2021 (0900 HOURS)oscarNo ratings yet

- Hu 2018Document11 pagesHu 2018avula43No ratings yet

- 2019 ACTINI Egg Processing EN Réduit PDFDocument8 pages2019 ACTINI Egg Processing EN Réduit PDFKimani MungaiNo ratings yet

- The Demand and Supply of Health InsuranceDocument6 pagesThe Demand and Supply of Health Insuranceannie:XNo ratings yet

- Barret Original 1988Document5 pagesBarret Original 1988ponggnopNo ratings yet

- Fire Hazards in Chemical Plant From Friction Sparks Involving The Thermite ReactionDocument10 pagesFire Hazards in Chemical Plant From Friction Sparks Involving The Thermite ReactionDavidNo ratings yet

- P2 Ped 030 ReviewerDocument6 pagesP2 Ped 030 ReviewerFrancis DeocaresNo ratings yet

- Emergency Response Operations Manual (Erom) : Indonesia National Slum Upgrading Project (NSUP-P154782)Document73 pagesEmergency Response Operations Manual (Erom) : Indonesia National Slum Upgrading Project (NSUP-P154782)Aris RismatullahNo ratings yet

- Kronoxonic EN 2018Document12 pagesKronoxonic EN 2018vladimirmarkovski8119No ratings yet

- Case Study - : The Chubb CorporationDocument6 pagesCase Study - : The Chubb Corporationtiko bakashviliNo ratings yet

- Anhedonia Preclinical, Translational, and Clinical Integration (Ch. 1)Document30 pagesAnhedonia Preclinical, Translational, and Clinical Integration (Ch. 1)strillenNo ratings yet

- Disability Report V03 SinglePagesDocument44 pagesDisability Report V03 SinglePagesAmerlia AdzianNo ratings yet

- Part 1 Hydraulic Design Calculation 473Document13 pagesPart 1 Hydraulic Design Calculation 473shashi rajhansNo ratings yet

- VSTEP-Reading Test 9Document15 pagesVSTEP-Reading Test 9Lê Đặng Minh ThảoNo ratings yet

- Wa0001Document32 pagesWa0001shirou xNo ratings yet

- Computer Viruses - The Current State in ItalyDocument2 pagesComputer Viruses - The Current State in ItalyJohn GacheruNo ratings yet

- Combustion & Flame Chapter Notes - Science Class 8Document20 pagesCombustion & Flame Chapter Notes - Science Class 8Shree EntertainmentNo ratings yet

- Toyota Forklift 8fbet15!20!8fbekt16 18 8fbmt15 20 Repair ManualDocument22 pagesToyota Forklift 8fbet15!20!8fbekt16 18 8fbmt15 20 Repair Manualalexhughes210188dzo100% (133)

- Decoding RBI Grade B Phase 1 From Aspirant To Officer New 1Document79 pagesDecoding RBI Grade B Phase 1 From Aspirant To Officer New 1NITHYA SRI NNo ratings yet

- Bfe2218 Lazourdy 500gpm@6bar PDFDocument117 pagesBfe2218 Lazourdy 500gpm@6bar PDFYazan Tamimi50% (2)

- Bsi Ppe Factsheet Uk enDocument2 pagesBsi Ppe Factsheet Uk enRahul KrishnaNo ratings yet

- Assessing The Effectiveness of The Adapted Adversity Quotient Program in A Special Education SchoolDocument11 pagesAssessing The Effectiveness of The Adapted Adversity Quotient Program in A Special Education Schoolelly putriNo ratings yet