Professional Documents

Culture Documents

Key Success Factors for the Implementation of Digital Technologies in the Context of Industry 4.0 2

Key Success Factors for the Implementation of Digital Technologies in the Context of Industry 4.0 2

Uploaded by

PRATEEK SARKARCopyright:

Available Formats

You might also like

- Sample Petition For Land RegistrationDocument4 pagesSample Petition For Land RegistrationToti Alfonso100% (3)

- 12amy Accounting Outline Fall 2005Document73 pages12amy Accounting Outline Fall 2005Seungmi ParkNo ratings yet

- RR 10-08Document30 pagesRR 10-08matinikki100% (1)

- manuscript_key_success_factors_I40_v6_camera_ready_2Document7 pagesmanuscript_key_success_factors_I40_v6_camera_ready_2PRATEEK SARKARNo ratings yet

- Industry 4.0 Carabajo - MizqueroDocument3 pagesIndustry 4.0 Carabajo - MizqueroDaniel Mizquero Zarate0% (1)

- Big Data As A Promoter of Industry 4.0: Lessons of The Semiconductor IndustryDocument6 pagesBig Data As A Promoter of Industry 4.0: Lessons of The Semiconductor IndustryHorst SmogerNo ratings yet

- 02 Drivers and Barriers For Industry 4.0 Readiness and PracticeDocument10 pages02 Drivers and Barriers For Industry 4.0 Readiness and PracticeVanessa SantosNo ratings yet

- 10-Lechvajderova Kadarova Industry 3 2022Document8 pages10-Lechvajderova Kadarova Industry 3 2022Sunil SharmaNo ratings yet

- Implementation of Industry 4 0 Concept in Companies Empirical Evidences PDFDocument19 pagesImplementation of Industry 4 0 Concept in Companies Empirical Evidences PDFMateo Cuadros HerreraNo ratings yet

- Industry4 161112133940Document19 pagesIndustry4 161112133940Tran Anh100% (1)

- Implementation of Industry 4.0 Smart Manufacturing: MD Rafiqul Islam KhanDocument9 pagesImplementation of Industry 4.0 Smart Manufacturing: MD Rafiqul Islam KhanJatin SinghNo ratings yet

- 17 - Industry 4.0 An Amanofacturing EcosysDocument28 pages17 - Industry 4.0 An Amanofacturing Ecosysorlando moraNo ratings yet

- 3D Systems in Industrial Renaissance 4Document4 pages3D Systems in Industrial Renaissance 4sunithaNo ratings yet

- Eclipse IoT White Paper - Open Source Software For Industry 4.0Document18 pagesEclipse IoT White Paper - Open Source Software For Industry 4.0ricardo prezziNo ratings yet

- Nokia White Paper - Evaluating Digitalization Progress With The Industry 4.0Document13 pagesNokia White Paper - Evaluating Digitalization Progress With The Industry 4.0MD TANVIR FAISALNo ratings yet

- Assesing Industry 4.0 ReadinessDocument7 pagesAssesing Industry 4.0 ReadinessAdrian PugnaNo ratings yet

- Industry 4.0: An Overview: July 2018Document7 pagesIndustry 4.0: An Overview: July 2018Romancing LoveNo ratings yet

- Revolution of Lean Six Sigma 4.0Document9 pagesRevolution of Lean Six Sigma 4.0Felipe EcheverryNo ratings yet

- The Relationship Between The Implementation Levels of Industry 4.0 Technologies and Advanced Manufacturing TechnologiesDocument9 pagesThe Relationship Between The Implementation Levels of Industry 4.0 Technologies and Advanced Manufacturing TechnologiesaghowelNo ratings yet

- Industry 4.0: An Overview: July 2018Document7 pagesIndustry 4.0: An Overview: July 2018Steve StevenNo ratings yet

- McKinsey Explainer-What - Are - Industry - 4 - 0 - The - Fourth - Industrial - Revolution - and - 4irDocument7 pagesMcKinsey Explainer-What - Are - Industry - 4 - 0 - The - Fourth - Industrial - Revolution - and - 4irYudhi PermadiNo ratings yet

- Digitalisation and Innovation in The Steel IndustrDocument25 pagesDigitalisation and Innovation in The Steel IndustrYana KholodovaNo ratings yet

- ImplementationofIndustry4 0SmartManufacturingRDocument9 pagesImplementationofIndustry4 0SmartManufacturingRravivpsNo ratings yet

- MITI On IR4.0Document18 pagesMITI On IR4.0deanNo ratings yet

- Industrie 4.0 Enabling Technologies (2015)Document6 pagesIndustrie 4.0 Enabling Technologies (2015)lazarNo ratings yet

- Assessing Industry 4.0 Readiness of EnterpriseDocument6 pagesAssessing Industry 4.0 Readiness of Enterprisemonika panghalNo ratings yet

- 1 s2.0 S294973612200001X MainDocument17 pages1 s2.0 S294973612200001X MainJerri Bernardes de SouzaNo ratings yet

- DI Digital Industrial TransformationDocument12 pagesDI Digital Industrial TransformationPaul Vintimilla CarrascoNo ratings yet

- Automotive Industry in The Context of Industry 40Document5 pagesAutomotive Industry in The Context of Industry 40Nurul Aisyah Binti RamlanNo ratings yet

- Industry 4.0: Industrial Revolutions and Future ViewDocument5 pagesIndustry 4.0: Industrial Revolutions and Future ViewCharith LiyanageNo ratings yet

- Industry 4.0: The Role of Iiot in Digital Transformation of The Manufacturing SectorDocument16 pagesIndustry 4.0: The Role of Iiot in Digital Transformation of The Manufacturing SectorAhmed TorchaniNo ratings yet

- A Review of Cybersecurity Guidelines For Manufacturing Factories in Industry 4.0Document29 pagesA Review of Cybersecurity Guidelines For Manufacturing Factories in Industry 4.0jermNo ratings yet

- Industry 4.0 Technology Implementation in SMEs - A Survey in The Danish-German Border RegionDocument9 pagesIndustry 4.0 Technology Implementation in SMEs - A Survey in The Danish-German Border RegionNur Alia ElkaNo ratings yet

- 1 - Industry 4.0 IntoductionDocument33 pages1 - Industry 4.0 IntoductionRidwanNo ratings yet

- Industry 4.0 An OverviewDocument20 pagesIndustry 4.0 An Overviewambika1969in100% (1)

- Essence of Business 4 0Document2 pagesEssence of Business 4 0Editor IJTSRDNo ratings yet

- Ir 4 NotesDocument9 pagesIr 4 NotesNadrah HassanNo ratings yet

- Gei NotesDocument24 pagesGei NotesNadrah HassanNo ratings yet

- Educating The Industry 4.0 WorkforceDocument3 pagesEducating The Industry 4.0 WorkforceDhillukshanNo ratings yet

- The Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature ReviewDocument34 pagesThe Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature ReviewMimnun NNo ratings yet

- Teknologi YogurthDocument8 pagesTeknologi YogurthADELLO TOGARIO SINAGANo ratings yet

- Industy 4.0 AppliedDocument17 pagesIndusty 4.0 Appliedcagan.ulNo ratings yet

- Industry 4.0 TechnologiesDocument34 pagesIndustry 4.0 Technologies08.reap-sendersNo ratings yet

- Industry 4 0Document52 pagesIndustry 4 0CRISTHIAN DAVID FERNANDEZ MORALES100% (1)

- Industry 4.0: Top Challenges For Chemical Manufacturing: R&D Solutions For ChemicalsDocument8 pagesIndustry 4.0: Top Challenges For Chemical Manufacturing: R&D Solutions For ChemicalsAkın ÖztürkNo ratings yet

- Artikel 2 (Pendukung) Preparing-For-The-Next-Normal-Via-Digital-Manufacturings-Scaling-PotentialDocument10 pagesArtikel 2 (Pendukung) Preparing-For-The-Next-Normal-Via-Digital-Manufacturings-Scaling-PotentialErik GunawanNo ratings yet

- Rishabh IIOT ReportDocument4 pagesRishabh IIOT ReportRishabh DesaiNo ratings yet

- Applied Sciences: Machine Learning in Manufacturing Towards Industry 4.0: From For Now' To Four-Know'Document32 pagesApplied Sciences: Machine Learning in Manufacturing Towards Industry 4.0: From For Now' To Four-Know'Abhijna AdigaNo ratings yet

- Title 1 IR4.0Document10 pagesTitle 1 IR4.0F1061 SafadilaNo ratings yet

- Industry 4.0 and Society 5.0: Opportunities and Threats: Revised Manuscript Received On January 15, 2020Document4 pagesIndustry 4.0 and Society 5.0: Opportunities and Threats: Revised Manuscript Received On January 15, 2020gizex2013No ratings yet

- Digital Twin in Industry 4.0 Technologies Applications and ChallengesDocument6 pagesDigital Twin in Industry 4.0 Technologies Applications and ChallengesAshwani SinghNo ratings yet

- Toward New Generation Intelligent ManufacturingDocument10 pagesToward New Generation Intelligent Manufacturing传林李No ratings yet

- Industry 4.0 PDFDocument12 pagesIndustry 4.0 PDFEliza Mara Lozano CostaNo ratings yet

- Data Management in Industry 4.0: State of The Art and Open ChallengesDocument43 pagesData Management in Industry 4.0: State of The Art and Open ChallengesEng Tennyson SigaukeNo ratings yet

- A Maturity Model For Assessing Industry 4.0 Readiness and Maturity of Manufacturing EnterprisesDocument7 pagesA Maturity Model For Assessing Industry 4.0 Readiness and Maturity of Manufacturing EnterprisesAB1984No ratings yet

- Industry 4.0: Tools and Implementation: September 2019Document12 pagesIndustry 4.0: Tools and Implementation: September 2019Ibrahim KukićNo ratings yet

- "How Industry 4.0 Is Changing How We Manage Value Creation": White PaperDocument12 pages"How Industry 4.0 Is Changing How We Manage Value Creation": White PaperShenna VieraNo ratings yet

- Advances in Digitalization ofDocument16 pagesAdvances in Digitalization ofkeyachemNo ratings yet

- Manufacturing Operations Management - The Smart Backbone of Industry 4.0Document6 pagesManufacturing Operations Management - The Smart Backbone of Industry 4.0Raviteja GogineniNo ratings yet

- I4-2022!1!10 Application of Ergonomic Software Solutions in The Concept of Industry 4.0Document4 pagesI4-2022!1!10 Application of Ergonomic Software Solutions in The Concept of Industry 4.0arra mabbonNo ratings yet

- 2-Industry 4.0 - KusminDocument12 pages2-Industry 4.0 - KusminJ'obbanii StgoNo ratings yet

- Digital TransformationDocument6 pagesDigital TransformationbthncengizNo ratings yet

- IoT Standards with Blockchain: Enterprise Methodology for Internet of ThingsFrom EverandIoT Standards with Blockchain: Enterprise Methodology for Internet of ThingsNo ratings yet

- Rubrics For A Well Written and Technology Enhanced Lesson PlanDocument5 pagesRubrics For A Well Written and Technology Enhanced Lesson PlanValencia John EmmanuelNo ratings yet

- Tool Thiết Kế Tuyến VibaDocument23 pagesTool Thiết Kế Tuyến VibaTrương Văn LinhNo ratings yet

- The Effect of Implant Abutment Junction Position On Crestal Bone Loss A Systematic Review and Meta AnalysisDocument17 pagesThe Effect of Implant Abutment Junction Position On Crestal Bone Loss A Systematic Review and Meta AnalysisBagis Emre GulNo ratings yet

- Application Form For Certificate For English Proficiency Migration Bonafide StudentsDocument1 pageApplication Form For Certificate For English Proficiency Migration Bonafide StudentsE-University OnlineNo ratings yet

- NG160 - 16 To 160A Modular Incoming Circuit BrakersDocument27 pagesNG160 - 16 To 160A Modular Incoming Circuit BrakerssomeontorrenteNo ratings yet

- Signal Cable Connection To Input/Output Modules (For FIO)Document15 pagesSignal Cable Connection To Input/Output Modules (For FIO)cepia sobayhakiNo ratings yet

- Excel VBA Create A Worksheet List BoxDocument6 pagesExcel VBA Create A Worksheet List BoxRamonMalaveNo ratings yet

- GPOADmin Quick Start Guide 58Document25 pagesGPOADmin Quick Start Guide 58Harikrishnan DhanapalNo ratings yet

- Office of The Sangguniang Barangay: EXECUTIVE ORDER No. 005 of 2021Document2 pagesOffice of The Sangguniang Barangay: EXECUTIVE ORDER No. 005 of 2021michelle100% (2)

- SC Judgement On Criminal AntecedentsDocument27 pagesSC Judgement On Criminal AntecedentsAbhinav Rakesh MaruNo ratings yet

- Advertisement No 03.2022 Tehsildar Excise InspectorDocument3 pagesAdvertisement No 03.2022 Tehsildar Excise InspectorMian Musa RiazNo ratings yet

- Q Tut Ch2Document8 pagesQ Tut Ch2Damien MarleyNo ratings yet

- Mangune v. ErmitaDocument19 pagesMangune v. ErmitaElise Rozel DimaunahanNo ratings yet

- In The Matter of The Estate of JohnsonDocument3 pagesIn The Matter of The Estate of JohnsonDerick TorresNo ratings yet

- Analysis and Identification of Nonconforming Products by 5W2H MethodDocument10 pagesAnalysis and Identification of Nonconforming Products by 5W2H MethodkkkkoaNo ratings yet

- 45R-08 Scheduling Claims Protection MethodsDocument10 pages45R-08 Scheduling Claims Protection MethodsHatem HejaziNo ratings yet

- Jio ReportDocument36 pagesJio ReportHimanshu Singh100% (1)

- Cost Chat GPTDocument3 pagesCost Chat GPTAnushkaa DattaNo ratings yet

- Asaan Movers Thesis 8.0Document66 pagesAsaan Movers Thesis 8.0Qasim KhanNo ratings yet

- Individual AssignmentDocument5 pagesIndividual AssignmentHao LimNo ratings yet

- 20462D ENU CompanionDocument194 pages20462D ENU CompanionjiindooNo ratings yet

- Nitration of Methyl BenzoateDocument7 pagesNitration of Methyl BenzoateJanel Pauline G. Chua100% (1)

- 03 09 Saw Waterproofing Membranes TunnelDocument3 pages03 09 Saw Waterproofing Membranes TunnelParashuram ChauhanNo ratings yet

- Walk-in-Interview at S.V.Ayurvedic College, TTD, TirupatiDocument3 pagesWalk-in-Interview at S.V.Ayurvedic College, TTD, TirupatiKirankumar MutnaliNo ratings yet

- Atdp Es 000212Document35 pagesAtdp Es 000212peetholNo ratings yet

- 5 23 1e PDFDocument16 pages5 23 1e PDFkats2404No ratings yet

- Benchmarking: Ana Maria Bahamon Arias 4700274Document4 pagesBenchmarking: Ana Maria Bahamon Arias 4700274Juan José BahamónNo ratings yet

Key Success Factors for the Implementation of Digital Technologies in the Context of Industry 4.0 2

Key Success Factors for the Implementation of Digital Technologies in the Context of Industry 4.0 2

Uploaded by

PRATEEK SARKARCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Key Success Factors for the Implementation of Digital Technologies in the Context of Industry 4.0 2

Key Success Factors for the Implementation of Digital Technologies in the Context of Industry 4.0 2

Uploaded by

PRATEEK SARKARCopyright:

Available Formats

Key Success Factors for the Implementation of

Digital Technologies in the Context of Industry 4.0

Alexander Stocker Manfred Rosenberger Michael Schmeja

NVH and Information Systems NVH and Information Systems NVH and Information Systems

Virtual Vehicle Research GmbH Virtual Vehicle Research GmbH Virtual Vehicle Research GmbH

Graz, Austria Graz, Austria Graz, Austria

alexander.stocker@v2c2.at manfred.rosenberger@v2c2.at michael.schmeja@v2c2.at

Germar Schneider

Infineon Technologies Dresden GmbH

& Co. KG

Dresden, Germany

germar.schneider@infineon.com

Abstract— The implementation of digital technologies in industry. From this perspective, Industry 4.0 describes the on-

general and in the context of Industry 4.0 in particular is a socio- going "informatisation" of traditional factories. In connection

organisational challenge. After an introduction into Industry 4.0 with Industry 4.0, Internet of Things, Cyber-Physical Produc-

and a summary of its key enabling technologies, this paper pre- tion Systems, Big Data and Artificial Intelligence represent

sents a qualitative analysis of key factors that can influence the possible key technological components [4]. In further,

success of implementing digital technologies into organizations broader definition attempts, Industry 4.0 is even referred to

from the literature as well as from a single industrial case study as complete digitization over the entire product life cycle, in

at a semiconductor manufacturer. Identified key success factors which, beginning with concept definition over product devel-

are assigned to two different non-technical dimensions, manage-

opment, production, use and service, action and decision-rel-

ment, and processes (organizational dimension), as well as cor-

porate culture and employees (social dimension). They include

evant knowledge is collected and integrated in a way that pur-

for example, the creation of a common understanding of the as- poseful analyses are made possible [16], [23].

is situation, the challenge to be solved and the envisaged to-be From this perspective, Industry 4.0 does not exclusively

situation after technology implementation among all relevant refer to the production process, but also includes upstream

stakeholders. Equally important, however, is active support of processes such as product development, or downstream pro-

top management to promote implementation projects and a ded- cesses such as product operation and service. According to a

icated project manager with sufficient technical expertise in all

pioneering strategy document by Kagermann et. al [55], three

related technical domains.

integration features can be linked to the Industry 4.0 concept:

Keywords—Success factors, industry 4.0, digitalisation Horizontal integration refers to the integration of different

ICT systems in the various stages of the manufacturing and

I. INTRODUCTION AND MOTIVATION planning processes in a company, vertical integration refers

to the integration of different IT systems at various hierar-

Referring to a Fourth Industrial Revolution in which the

chical levels (e.g., actuator and sensor level, manufacturing

worlds of production and network connectivity are integrated

and execution level, production level and corporate planning

through information and communications technology (ICT),

level) and end-to-end digitization refers to the integration of

Industry 4.0 is an umbrella term for a wide variety of tech-

different IT systems across the entire engineering process, so

nologies, methods and applications for improving production

that the digital and real worlds are integrated across the entire

processes and their supporting processes [2], [4], [17]. Origi-

supply chain of a product and even across companies [5].

nally initiated in Germany, Industry 4.0 can generally be in-

terpreted as the digitization or digital transformation of the Implementing digital technologies such as the Internet of

industry, which is taking place as a result of the increasing Things, Digital Twins, Augmented and Virtual Reality, Mo-

adoption of digital technologies in the manufacturing sector. bile and Collaborative technologies or Artificial Intelligence

in organizations is a complex challenge, because organisa-

Digitization as the progressive convergence of the real

tions are socio-technical systems. As knowledge about the

and virtual world is becoming the main driver for innovation

factors that contribute to the success of technology imple-

and change in all sectors of our economy [7]. Major social,

mentation projects is fundamental, the authors pose the fol-

economic and political triggers for Industry 4.0 are in partic-

lowing research question: What are key success factors for

ular shorter development and innovation periods, individual-

the implementation of digital technologies in the context of

isation on demand and increasing individualisation of prod-

Industry 4.0? To answer this research question, the authors

ucts and – in extreme cases – of ‘batch size one’, higher flex-

first conduct a literature review to derive key success factors

ibility in development and production, decentralisation in-

and then pursue a single case study to validate them.

volving a reduction of organisational hierarchies, and re-

source efficiency due to an increase of prices, as well as a II. THEORETICAL BACKGROUND

social change in the context of ecological aspects requiring

an intensified focus on environmental sustainability [6]. A. Internet of Things and Digital Twins

The digital transformation of manufacturing companies is As an umbrella term for the interconnectedness of physi-

being decisively shaped by numerous players from the ICT cal objects by using internet technologies, Internet of Things

technologies play a central role in the context of Industry 4.0,

too [35]. Therefore, many speak of an Industrial Internet or

978-3-903176-32-4 © 2021 IFIP

IFIP/IEEE IM 2021 Workshop on Management for Industry 4.0 (MFI4.0)

Authorized licensed use limited to: Indian Institute of Technology (ISM) Dhanbad. Downloaded on September 17,2023 at 20:07:46 UTC from IEEE Xplore. Restrictions apply.

920

an Industrial Internet of Things [48], [49] and refer in sum- a particular problem while more inexperienced people could

mary to the increased networking of production machines take advantage of the mobile app to identify solutions that

with machines or the networking of the production process were successful in the past.

with the product to be manufactured.

D. Machine Learning and Artificial Intelligence

In the context of digitization, the digital twin is playing an Operating complex production machines requires not

increasingly important role. A digital twin is able to connect only technical knowledge about the machine to be operated,

the physical (real) world with the digital world [31]. In gen- but also domain experience and process knowledge Artificial

eral, digital twin has mutated into a main concept in connec- intelligence requires to integrate human process knowledge

tion with the Industry 4.0 wave. A digital twin provides vir- into models to (semi-)automate decision making. Therefore,

tual representations of systems along their life cycles [33] and Artificial intelligence technologies such as Machine Learning

can be described as the intelligent, digital image of a real or Deep Learning are increasingly in demand in production

product or process [34]. For example, a digital production environments. The aim is to identify, for example, faults in

twin can digitally map the production process and thus enable production processes such as vibrations that can lead to devi-

a targeted, controlling [18], planning [32] and intervention in ations in product quality and manifest themselves in a short-

the production process, if the digital twin is continuously syn- ened product life or in severe application problems [21]. An

chronized with the physical production environment. A digi- almost unmanageable number of existing Machine Learning

tal twin uses data provided by sensors installed in the produc- methods are contrasted with an equally large number of pos-

tion process on the one hand and technologies from the Inter- sible areas of use and application [26], [27]. Therefore, expe-

net of Things on the other. Wireless sensor networks (WSN) rienced industrial data scientists are a prerequisite to address

and Radio-frequency identification (RFID) are used to form identified problems with machine learning approaches. The

an extensive network for supporting IoT [2] for the further use of data science and modern methods of data analysis

deployment of services. The future state of a fully connected plays an important role in the analysis of production data

manufacturing system that operates primarily without human [50]. For instance, Stanisavljevic et al. [16] have shown that

workforce by generating, transferring, receiving and pro- different engine configurations can be identified from analys-

cessing the necessary data to perform all the tasks required to ing values measured on an engine test bench using methods

manufacture all types of goods is often referred to as a Smart from data science.

Factory [14].

E. Organisations as socio-technical systems

B. Augmented and Virtual Reality

In the context of Industry 4.0 and the digital transfor-

The augmentation of the physical environment through mation of companies, the role of human beings is also closely

digital information (Augmented Reality) and the interaction of examined. Due to the rapid pace of technological change, it

a user in a completely virtual world (Virtual Reality) show a can be clearly seen that the role of employees in the manu-

promising potential. Augmented reality has become an inte- facturing industry is constantly changing. The increasing au-

gral part of Industry 4.0, as it enables workers to access digital tomation of manufacturing processes has already dramati-

information and overlay that information with the physical cally reduced the amount of manual work, while the growing

world [3]. With Augmented, Virtual and Mixed Reality tech- complexity of manufacturing systems and processes requires

nologies, knowledge-based tasks of production employees can the remaining employees to have both increasingly broader

be supported by using modern assistance systems [15] and and deeper qualifications [28].

thereby can exert a positive influence on productivity. By im-

proving the supply of information at work while leaving both In order to emphasize that the human being should also

hands free and not restricting employees in their manual work be at the centre of tomorrow's factories, there is a constant

practices, data glasses are often today as innovative and useful debate about the additional empowerment of humans through

devices for employees in production, service and quality man- digital technologies [1], [10], [24]. Information and commu-

agement [20]. For example, data glasses can be used to pro- nication technology can help employees in collaborative pro-

vide production workers with helpful information for the com- duction environments [12], for example, because digital tech-

pletion of their tasks, as quality information, 3D exploded nologies better support problem-solving and decision-making

views or other supporting additional information can be easily processes, or because access to action and decision-relevant

displayed in a person’s field of view [20]. information is further improved for employees [46]. How-

ever, digital technologies cannot only support human work,

C. Mobile and Collaborative Technologies but also partially or even completely automate it. To generate

Recent developments in digitization, such as social soft- cost savings, individual components of knowledge work are

ware and mobile technologies, also offer promising opportu- increasingly being automated under the guise of "robotic pro-

nities to help knowledge workers in production environments cess automation" in addition to the classic production process

by supporting knowledge processes, decision making and so- automation in factories [11]. Similar to the robots in classical

cial interaction [1], [30]. In collaborative production environ- production automation, the standardizable parts of

ments, improving knowledge building, decision making and knowledge work usually performed by humans is conducted

social interaction between team members is an important is- by software agents, which often use modern data analysis and

sue. Mobile technologies enable a social network based col- machine learning.

laborative problem-solving method utilizing for instance root

Digital technologies such as Augmented or Mixed Real-

cause analysis to formalise problem solving instructions and

expert opinions described in natural language, given that em- ity, Machine Learning and Artificial Intelligence, Digital

ployees overcome their hesitations to share knowledge, as- Twins or Robotic Process Automation for knowledge-based

sure their commitment to report new problems and avoid dis- work processes are playing a key role in the digital transfor-

tracting them with the use of mobile devices on the shop floor mation of companies [2]. Because modern work always in-

[8]. Thereby experienced engineering can identify causes for volves a structured interaction of people with information and

IFIP/IEEE IM 2021 Workshop on Management for Industry 4.0 (MFI4.0)

Authorized licensed use limited to: Indian Institute of Technology (ISM) Dhanbad. Downloaded on September 17,2023 at 20:07:46 UTC from IEEE Xplore. Restrictions apply.

921

communication technologies, the digitalisation of industry success of introducing information systems also depends

can by no means be reduced to a mere technical dimension. much on how these information systems are perceived by us-

In companies, people work together in an organized manner ers in advance. It is primarily the user perception that deter-

to fulfil tasks within an organizational structure. Digital tech- mines the initial intention to use a novel system [36]. There-

nologies can help people to perform their tasks better. Never- fore, measures to stimulate a positive user perception in ad-

theless, some technologies push existing forms of organiza- vance are required to enhance the success of implementation

tion to their limits. Therefore, the organization of work and projects [39].

the technologies used in the work must be aligned.

III. A REVIEW OF KEY SUCCESS FACTORS

Enterprises are socio-technical systems, and the introduc-

tion of digital technologies in companies is a socio-technical The successful design of digital workflows or digitally

undertaking: Because Industry 4.0 implementation projects supported workflows usually requires an integrated, interdis-

always have to involve people from a wide range of different ciplinary, participative and agile approach that enables the

fields and disciplines [17], it is important, for example, to de- identification, analysis and best possible support of human

termine the benefits of Industry 4.0 projects in advance at the work practices and their context in a predominantly digital

three levels, people, organization, and technology [24], [25] environment [10]. Therefore, the implementation of techno-

and to communicate them to the key stakeholders accord- logical solutions always requires a compatible and optimal

ingly. This should ensure that the technical solutions devel- design of the associated physical workflows. Only then can

oped in implementation projects can be transferred as employees successfully integrate digital solutions into their

smoothly as possible into productive operation. The techno- work practices. Offered digital technologies must therefore

logical solutions must also be tightly integrated into organi- go hand in hand with digital work processes. The socio-tech-

zational processes and structures. It is obvious that although nical design of a new, digital solution must be evaluated with

digital technologies and digital design of work can signifi- the help of a suitable methodology [53].

cantly modernize work processes, stakeholders must be ac- The introduction of digital technologies in the context of

tively involved in these change processes and must be con- Industry 4.0 is complex, since development and introduction

vinced to adopt the new solution approaches accordingly projects usually must involve people from a wide range of

[46]. disciplines and fields [17]. To create a consistent picture for

F. Implications from Information Systems Research all involved actors already before the factual implementation

phase and eliminate communication problems between stake-

Although terms such as digital technologies, digital trans- holders coming from different disciplines and using a differ-

formation, or digital innovation have arrived in the German- ent vocabulary, a systematic approach for the documentation

speaking mainstream in recent years, many findings from es- and structuring of Industry 4.0 use cases to be communicated

tablished research on information systems can be applied to to the involved stakeholders should be applied [17]. This use

the introduction of digital technologies in the context of In- case description includes the actual situation with the cur-

dustry 4.0, too. For example, it must always be borne in mind rently used technology, the organizational challenge the en-

that in addition to the design of technical systems to support visaged digital solution should solve, the expected target sit-

information and knowledge sharing, the design of organiza- uation after implementing the solution and the expected ben-

tional measures is at least as important [19]. There is no doubt efits for different stakeholders gained from the introduction.

that digitization and digital transformation affect not only the Having this information at hand before starting the imple-

technological work environment, but also a wide range of so- mentation project will increase the probability that the in-

cial aspects such as processes, organizational structures, em- volved stakeholders will support the implementation project

ployee skills and corporate culture [42]. sufficiently.

Well-known, frequently cited explanatory models from Richter et al. [10] rely on a careful survey of the current

information system research, such as the technology ac- situation and a coordinated definition of the target situation

ceptance model [36] or the information system success model in the sense of a ‘digital work design’ - in cooperation with

[37], [38] already provide a large number of indications of the relevant stakeholders - and recommend the use of per-

success factors for the introduction of new technologies and sonas, activity scenarios and early, non-functional proto-

solutions. From the technology acceptance model, essential types for solution validation. This user-centred approach fo-

factors such as perceived usability and perceived usefulness cuses on the current working practices of employees, but with

of the technology to be implemented can be derived [36], the strong intention to optimally adapt them later. To support

while the information system success model focuses on the work practices in the best possible way, or to transfer them

necessity of the positive effects of introduced information into digitally supported work practices, the physical work

systems on the levels of employees ("individual impact") and practices must first be captured and understood in depth.

organization ("organizational impact"). Information quality, Through such a process, employees can best learn how to use

system quality and service quality also play a major role in new technology and have their work practices best supported

the success of the introduction of information systems, since by digital technologies [40].

these aspects influence the intention whether people will use

an information system or not [37], [38]. Thus, both models As with many digital technologies, and especially those

explain from different perspectives the relationship between designed to support communication and interaction between

the information system, the development of a behavioural in- employees, it is important that stakeholders are involved

tention to use the information system and the stimulated first early in the development and deployment process and can

or continuing use of the information system. quickly perceive the benefits (from first-time use). The active

persuasion of users by the project management plays a sig-

From both models it can be deduced that non-technical nificant role in this process [29]. Here, the project manage-

factors in particular play a driving role in the success of a new ment can even take on the role of a solution ambassador and

technical solution with end users. Furthermore, the expected

IFIP/IEEE IM 2021 Workshop on Management for Industry 4.0 (MFI4.0)

Authorized licensed use limited to: Indian Institute of Technology (ISM) Dhanbad. Downloaded on September 17,2023 at 20:07:46 UTC from IEEE Xplore. Restrictions apply.

922

encourage employees to try out and then continue using the IV. INDUSTRIAL CASE STUDY: WAFER PRODUCTION

new solution through targeted actions such as individual

training, usage incentives or rapid transfer of user require- A. As-is situation and challenge

ments into the solution [30]. The case company is a semiconductor manufacturer that

produces high-quality chips with complex production tech-

Success factors that specifically apply to the introduction nology based on 200/ 300 mm silicon wafers for innovative

of knowledge-based documentation systems include the ini- applications in automotive electronics, security, smart cards,

tial provision of a sufficiently high number of useful energy management and multimarket applications.

knowledge contributions immediately after the solution

rollout as well as the motivation of suitable persons in the The development of new products requires a high degree

company who act as multipliers and in turn motivate other of domain expertise and knowledge about the interrelation-

employees to use and contribute to the new solution [22], ships and effects of individual manufacturing sub-processes

[56]. Digital technologies must be compatible with organiza- on the manufactured product. The impact of new or modified

tional processes. A further success factor is the successive process sequences must therefore be repeatedly tested and

preparation of the organization for the change that the intro- evaluated by conducting experiments on the production line.

duction of digital technologies will bring, including the in- Experiment management is an important business process in

volvement and training of users and the adaptation and rede- the case company because experience management creates

sign of organizational processes to ensure that technology and the fundament for faster and more efficient product develop-

processes are aligned [41]. ment, but also for the associated production process develop-

ment. The new experiment management system should work

The role of the management in the introduction of digital across several production sites - in the sense of a Smart Fac-

technologies is central [9]: However, a distinction must be tory Cluster. Manual interventions by process operators dur-

made between different levels such as management attention ing the conduction should no longer be necessary and should

to an implementation project, management support, and the be replaced by an automated control system. The virtualiza-

direct use of the new solution by the management [22]. The tion of experiment management (i.e., the implementation of a

strongest impact on implementation success is achieved when new digital technology) will empower employees to plan and

the management is perceived by employees not only as solu- control experiments at other locations, or to plan and control

tion promoter, but even as an active user [39]. these experiments completely independently of their physical

The existence of a concrete and understandable digitali- workstations, e.g., also during a business trip or from the

zation strategy helps to better classify digitalization projects home office.

within the company and to set the appropriate framework to The goal was to create a tool that is easy and intuitive to

implement them [47], [54]. Designing such a strategy is a use, with which experiments can be planned and performed.

management task. In any strategy development, it is im- Mechanisms were integrated into the tool, which can detect

portant to work out which goals should be associated with the possible errors in the planning of experiments at an early

introduction of digital technologies in the company and then stage or ultimately prevent them. Thus, more complex pro-

set the appropriate mechanism to monitor goal achievement. duction processes across several production sites should be

Two approaches to the introduction of digital technologies possible, but also controllable. The users of the new system

can be distinguished, but they can also be combined [43]. In included people who have some form of control over the pro-

an exploration-centred strategy, the exact way in which the duction process.

solution should be used by the users is initially left to the us-

ers within the framework of a participatory approach and ap- B. Key success factors of the implementation project

plication scenarios are gradually identified by users them- The automation of production and production processes

selves, whereas in the promotion-centred strategy, the new is a strategically anchored project in the case company to in-

solution and its modes of use are communicated to users in a crease quality and efficiency and to develop and produce in a

coordinated manner from the very beginning, with the close more resource-saving way. The implementation project de-

support of management, and then specifically trained. scribed here is also part of this strategic framework. In the

The corporate culture plays a significant role in the suc- case company, all key stakeholders, both individuals and in-

cess of the introduction of technological solutions [22], [13], terest groups, were involved in the development process. This

[44]. An open, innovative, and participatory culture in which was to consider the complexity of the topic, which makes it

information is shared is much better suited than a closed, in- no longer possible for individual persons to have an overview

novation-hostile culture in which information and knowledge of the entire topic.

are, in extreme cases, understood as a personal good and The new technical solution will affect many processes and

therefore not shared at all [44]. Since implementation pro- employees in the company. It was therefore important that

cesses are usually controlled by the management, but affect these highly motivated employees were involved in the defi-

employees strongly, the way employees and managers inter- nition of requirements and approaches to solutions at an early

act and communicate with each other plays an essential role. stage. In this sense, it was important to disregard hierarchical

As a rule, shaping the corporate culture is a management company structures and to organize the project development

task. Managers must exemplify a culture based on trust and team in a very flexible way. Thereby, it was possible to put

mutual appreciation [45]. If the corporate culture is not open, together a highly motivated team with the appropriate ex-

employees may see a new solution as a threat to their job. perts from various fields, such as IT and MES systems and

production at the connected sites.

A matrix organization, consisting of a line and a project

organization, enabled the participating experts to fulfill both

their daily business in the company and to participate in the

IFIP/IEEE IM 2021 Workshop on Management for Industry 4.0 (MFI4.0)

Authorized licensed use limited to: Indian Institute of Technology (ISM) Dhanbad. Downloaded on September 17,2023 at 20:07:46 UTC from IEEE Xplore. Restrictions apply.

923

implementation project. For this to work smoothly, it was im- success factors include the adaptation of the relevant (manual

portant to provide experts involved with sufficient resources and digital) processes, the initiation of training and persua-

and, above all, time for the implementation project, so that sion processes among all users, the involvement of all rele-

they could provide the best possible support for the imple- vant stakeholders in the implementation process, and the ac-

mentation project. Nevertheless, or especially in such a pro- tive support of the management on shaping an innovation-

ject organization it was necessary to push the project results friendly corporate culture. Furthermore, a holistic under-

and not to lose sight of the project goals. This project coordi- standing of the current situation, the organizational challenge,

nation and management task was performed by a dedicated and the expected target situation after the implementation of

project manager who, although not an expert in all technical digital technologies is to be formed by involving all internal

areas, had sufficient technical understanding to be able to me- and external stakeholders in this discussion process. Future

diate in conflict situations. Even if this may not appear effi- studies should explore multiple use cases to derive further

cient at first glance, a development team must also be able to success factors and try to quantify them. However, the digital

pursue approaches to solutions in a complex environment that technologies themselves are not success factors, as success

ultimately prove unsuccessful. factors are factors that should facilitate the adoption of tech-

nologies. The authors' notion of key success factors as socio-

V. SUMMARY AND CONCLUSION organisational constructs reflects the interesting combination

Although the Covid-19 pandemic has helped to spread the of people, organisation, and technology.

use of digital technologies, especially computer-based collab-

oration tools, enormously due to the "lockdowns" imposed by ACKNOWLEDGMENT

governments around the world [51], a "normal situation" in The iDev40 project has received funding from the ECSEL

companies requires a well thought-out and structured intro- Joint Undertaking (JU) under grant agreement No 783163.

duction process in order to be successful. While Covid#19 The JU receives support from the European Union’s Horizon

left companies and employees no other option to use remote 2020 research and innovation programme. It is co-funded by

collaboration technologies that were already "available" as the consortium members, grants from Austria, Germany, Bel-

infrastructure, implementation projects in the field of Indus- gium, Italy, Spain and Romania.

try 4.0 must be treated in a differentiated way [52].

REFERENCES

After a short introduction into Industry 4.0, the role of

[1] L. Hannola, A. Richter, S. Richter, A. Stocker, „Empowering

digital technologies in the context of Industry 4.0 and the production workers with digitally facilitated knowledge processes–a

presentation of concrete, relevant digital technologies, this conceptual framework”, International Journal of Production Research,

paper has presented key success factors that – if considerate 56(14), pp.4729-4743, 2018.

– can significantly improve the implementation of digital [2] L.D. Xu, E.L. Xu, L. Li, “Industry 4.0: state of the art and future

technologies. Knowledge of success factors and the adapta- trends”, International Journal of Production Research. 2018 Apr

18;56(8):2941-62.

tion of one's own actions regarding the identified success fac-

tors can increase the success of implementation projects. [3] T. Masood, J. Egger, “Augmented reality in support of Industry 4.0—

Implementation challenges and success factors”, Robotics and

However, there is - as usual in success factor research - no Computer-Integrated Manufacturing. 2019 Aug 1;58:181-95.

guarantee that success will be increased. While this paper was [4] Y. Lu, “Industry 4.0: A survey on technologies, applications and open

a qualitative study of key success factors based on a literature research issues”, Journal of industrial information integration. 2017.

review and a single-case study, future works should carefully [5] Y. Liao, F. Deschamps, E.D. Loures, L.F. Ramos, “Past, present and

examine several cases to validate key success factors and also future of Industry 4.0 - a systematic literature review and research

try to quantify them. agenda proposal”, International journal of production research. 2017

Jun 18;55(12):3609-29. E

[6] H. Lasi, P. Fettke, H.G. Kemper, T. Feld, M. Hoffmann, „Industry 4.0.

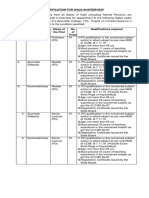

Culture Management Business & information systems engineering”, 2014 Aug 1;6(4):239-

Organizational Dimension

• Foster openness in • Have and communicate a 42.E

communication digitalization strategy

• Facilitate openness in • Build-up digitalization [7] H. Kagermann, “Change through digitization—Value creation in the

age of Industry 4.0”, In Management of permanent change 2015 (pp.

Social Dimension

cooperation capabilities

• Living innovation- • Shape the digitalization 23-45). Springer Gabler, Wiesbaden.

friendliness culture

• Support change and

[8] D. Mourtzis, M. Doukas, N. Milas, “A knowledge-based social

• Create a participatory

culture persuade stakeholders networking app for collaborative problem-solving in manufacturing”,

Manufacturing Letters. 2016 Oct 1;10:1-5.

[9] Vogelsang K, Liere-Netheler K, Packmohr S, Hoppe U. Success

• Involvement in • Identify, investigate and factors for fostering a digital transformation in manufacturing

development and operation understand problems companies. Journal of Enterprise Transformation. 2018 Apr 3;8(1-

• Build digitalization • Joint elaboration of as-is 2):121-42.

competencies and to-be situation

• Anticipate new ways of • Understand working [10] A. Richter, Pf. Heinrich, A. Stocker, G. Schwabe, „Digital work

working practices design“, Business & Information Systems Engineering, 60(3), pp.259-

• Acquire and use • Align digital processes with 264, 2018.

multipliers work practices

[11] W.M.Van der Aalst, M. Bichler, A. Heinzl, „Robotic process

Workforce Processes automation”, Business & Information Systems Engineering, Volume

60, pages 269–272, 2018.

Fig. 1. Key success factors for digital technology implementation projects [12] M. Leyer, A. Richter, M. Steinhüser, „Power to the workers.

Empowering shop floor workers with worker-centric digital designs”.

Identified key success factors (cf. Fig 1) can be assigned International Journal of Operations & Production Management, Vol.

39 No. 1, pp. 24-42., 2019.

to two different non-technical domains, management, and

processes (organizational domain), as well as corporate cul- [13] A. Ghadge, M.E. Kara, H. Moradlou, M. Goswami, “The impact of

Industry 4.0 implementation on supply chains”, Journal of

ture and employees (social domain), while technologies Manufacturing Technology Management, 2020, Mar 8.

themselves cannot considered a success factor. Identified key

IFIP/IEEE IM 2021 Workshop on Management for Industry 4.0 (MFI4.0)

Authorized licensed use limited to: Indian Institute of Technology (ISM) Dhanbad. Downloaded on September 17,2023 at 20:07:46 UTC from IEEE Xplore. Restrictions apply.

924

[14] P. Osterrieder, L. Budde, T. Friedli, “The smart factory as a key [35] H. Kagermann, W.D. Lukas, W. Wahlster, „Industrie 4.0: Mit dem

construct of industry 4.0: A systematic literature review”, International Internet der Dinge auf dem Weg zur 4. industriellen Revolution“. VDI

Journal of Production Economics. 2020 Mar 1;221:107476. nachrichten, 13(1), 2011.

[15] M. Spitzer, M. Rosenberger, A. Stocker, I. Gsellmann, M. Hebenstreit, [36] F.D. Davis, “A technology acceptance model for empirically testing

M. Schmeja, „Digitizing Human Work Places in Manufacturing new end-user information systems: Theory and results” (Doctoral

Through Augmented and Mixed Reality”. In Digital Transformation in dissertation, Massachusetts Institute of Technology), 1985.

Semiconductor Manufacturing (pp. 75-87). Springer, Cham, 2018. [37] W.H. DeLone and E.R.McLean, “Information systems success: The

[16] D. Stanisavljevic, M. Rosenberger, G. Lechner, S. Körner, R. Kern, B. quest for the dependent variable”, Information systems research, 3(1),

Jeitler, A. Stocker, „Ein Industrie 4.0-Use Case in der pp.60-95, 1992.

Motorenproduktion“, Mensch und Computer 2018-Workshopband, [38] W.H. DeLone and E.R. McLean, “The DeLone and McLean model of

2018. information systems success: a ten-year update. Journal of

[17] M. Rosenberger and A. Stocker, „ Eine Vorgehensweise zur management information systems”, 19(4), pp.9-30, 2003.

Unterstützung der Einführung von Industrie-4.0-Technologien“, [39] A. Stocker and J. Müller, “Exploring factual and perceived use and

Mensch und Computer 2019-Workshopband, 2017. benefits of a web 2.0-based knowledge management application: The

[18] A. Botthof and M. Bovenschulte, “Das „Internet der Dinge “–die siemens case References+”, In Proceedings of the 13th International

Informatisierung der Arbeitswelt und des Alltags. Erläuterungen einer Conference on Knowledge Management and Knowledge

neuen Basistechnologie“, (176), 2009. Technologies, 2013.

[19] T. Herrmann, M. Diefenbruch, A. Kienle, „Erfolgsfaktoren bei der [40] A. Richter, A. Stocker, S. Müller, S. and G. Avram, „Knowledge

Einführung von Wissensmanagementsystemen in die Praxis“, management goals revisited. A cross-sectional analysis of social

Informatik-Spektrum, 25(3), pp.210-214, 2002. software. adoption in corporate environments”, Vine, Vol. 43 No. 2,

[20] A. Stocker, M. Spitzer, C. Kaiser, M. Rosenberger, M. Fellmann, pp. 132-148., 2013.

„Datenbrillengestützte Checklisten in der Fahrzeugmontage“ [41] T. Masood, and J. Egger, “Augmented reality in support of Industry

Informatik-Spektrum, 40(3), pp.255-263, 2017. 4.0—Implementation challenges and success factors”, Robotics and

[21] D. Stanisavljevic, D. Cemernek, H. Gursch, G. Urak, G. and G. Computer-Integrated Manufacturing, 58, pp.181-195, 2019.

Lechner, „Detection of interferences in an additive manufacturing [42] G. Dreisiebner, B. Fachbach, G. Taffner, P. Slepcevic-Zach, A.

process: an experimental study integrating methods of feature selection Stocker, M. Stock, „Future Engineering Lab–Planspielentwicklung in

and machine learning”, International Journal of Production Research, der Fahrzeugindustrie“. Berufs-und Wirtschaftspädagogik online,

58(9), pp.2862-2884, 2020. 2019(209), 2019.

[22] A. Stocker, A. Richter, P. Hoefler, K. Tochtermann, „Exploring [43] A. Richter and A. Stocker, „Exploration & Promotion:

appropriation of enterprise wikis”, Computer Supported Cooperative Einführungsstrategien von Corporate Social Software“, In Proceedings

Work (CSCW), 21(2-3), pp.317-356, 2012. of the 10th International Conference on Wirtschaftsinformatik, 2011.

[23] E. Armengaud, C. Sams, C. Von Falck, G. List, C. Kreiner, A. Riel, [44] A. Stocker and K. Tochtermann, “Exploring the value of enterprise

„Industry 4.0 as digitalization over the entire product lifecycle: wikis-a multiple-case study”, In International Conference on

Opportunities in the automotive domain”. In European Conference on Knowledge Management and Information Sharing (Vol. 2, pp. 5-12).

Software Process Improvement (pp. 334-351). Springer, Cham, 2017. SCITEPRESS, 2009.

[24] A. Richter, P. Heinrich, A. Stocker, W. Unzeitig, „Der Mensch im [45] N. Homma, and R. Bauschke, „Unternehmenskultur und Führung: Den

Mittelpunkt der Fabrik von morgen“, HMD Praxis der Wandel gestalten-Methoden, Prozesse, Tools“, Springer-Verlag, 2015.

Wirtschaftsinformatik, 52(5), pp.690-712, 2015. [46] W. Unzeitig, M. Wifling, A. Stocker, M. Rosenberger, “Industrial

[25] M. Rosenberger, A. Stocker, M. Lütkemeyer, A. Sala, G. Lechner, A. challenges in human-centred production”. In MOTSP 2015-

Felsberger, G. Reiner, „Eine Vorgehensweise zur Evaluierung von lnternational Conference Management of Technology (pp. 10-12),

Industrie 4.0 Use Cases“, Mensch und Computer 2019-Workshopband, 2015.

2019. [47] C.A. Albayrak and A. Gadatsch, „Sind kleinere und mittlere

[26] T. Wuest, D. Weimer, C. Irgens, K.D. Thoben, “Machine learning in Unternehmen (KMU) bereits auf die Digitale Transformation

manufacturing: advantages, challenges, and applications”, Production vorbereitet". Multikonferenz Wirtschaftsinformatik, Lüneburg, 2018.

& Manufacturing Research, 4(1), pp.23-45, 2016. [48] S. Jeschke, C. Brecher, T. Meisen, D. Özdemir, T. Eschert, “Industrial

[27] A. Diez-Olivan, J. Del Ser, D. Galar, B. Sierra, “Data fusion and internet of things and cyber manufacturing systems”. In Industrial

machine learning for industrial prognosis: Trends and perspectives internet of things (pp. 3-19). Springer, Cham, 2017.

towards Industry 4.0”, Information Fusion, 50, pp.92-111, 2019. [49] A. Gilchrist, “Industry 4.0: the industrial internet of things”, Apress,

[28] G. Campatelli, A. Richter, A. Stocker „Participative knowledge 2016.

management to empower manufacturing workers”, International [50] C.M. Flath and N. Stein, “Towards a data science toolbox for industrial

Journal of Knowledge Management (IJKM), 12(4), pp.37-50, 2016. analytics applications”. Computers in Industry, 94, pp.16-25, 2018.

[29] A. Stocker and J. Müller, „Exploring use and benefit of corporate social [51] A. Richter, “Locked-down digital work”, International Journal of

software” Journal of Systems and Information Technology, 2016. Information Management, Volume 55, December 2020.

[30] J. Müller and A. Stocker, „Enterprise microblogging for advanced [52] A. Felsberger, C. Wankmüller, A. Stocker, G. Lechner, M.

knowledge sharing: The references@ BT case study”, J. UCS, 17(4), Lütkemeyer, A. Sala, G. Reiner, “Current state of digitalization in the

pp.532-547, 2011. European Electronic Components and Systems industry: A multiple

[31] M. Dietz and G. Pernul, „Digital twin: Empowering enterprises case study analysis”, In Proceedings of the 26th EurOMA Conference,

towards a system-of-systems approach”, Business & Information Hrsg. G. Kovács and M. Kuula, 2019.

Systems Engineering, pp.1-6, 2019. [53] M. Schafler, F.J. Lacueva-Pérez, L. Hannola, S. Damalas, J. Nierhoff,

[32] T.H.J. Uhlemann, C. Lehmann, R. Steinhilper, „The digital twin: and T. Herrmann, “Insights into the Introduction of Digital

Realizing the cyber-physical production system for industry 4.0”. Interventions at the shop floor”, In Proceedings of the 11th PErvasive

Procedia Cirp, 61, pp.335-340, 2017. Technologies Related to Assistive Environments Conference, 2018.

[33] E. Negri, L. Fumagalli, and M. Macchi, “A review of the roles of digital [54] D. Plekhanov and T.H. Netland, “Digitalisation stages in firms:

twin in cps-based production systems”, Procedia Manufacturing, 11, towards a framework”, In 26th EurOMA Conference 2019.

pp.939-948, 2017. [55] H. Kagermann, W. Wahlster, and J. Helbig, “Recommendations for

[34] R. Klostermeier, S. Haag, A. Benlian, „Digitale Zwillinge–Eine Implementing the Strategic Initiative INDUSTRIE 4.0”, Berlin:

explorative Fallstudie zur Untersuchung von Geschäftsmodellen“. Industrie 4.0 Working Group of Acatech, 2013.

HMD Praxis der Wirtschaftsinformatik, 55(2), pp.297-311, 2018. [56] A. Stocker, M. Strohmaier, K. Tochtermann, “Studying knowledge

transfer with weblogs in small and medium enterprises: An exploratory

case study”, Scalable Computing: Practice and Experience. 2008;9(4)

IFIP/IEEE IM 2021 Workshop on Management for Industry 4.0 (MFI4.0)

Authorized licensed use limited to: Indian Institute of Technology (ISM) Dhanbad. Downloaded on September 17,2023 at 20:07:46 UTC from IEEE Xplore. Restrictions apply.

925

You might also like

- Sample Petition For Land RegistrationDocument4 pagesSample Petition For Land RegistrationToti Alfonso100% (3)

- 12amy Accounting Outline Fall 2005Document73 pages12amy Accounting Outline Fall 2005Seungmi ParkNo ratings yet

- RR 10-08Document30 pagesRR 10-08matinikki100% (1)

- manuscript_key_success_factors_I40_v6_camera_ready_2Document7 pagesmanuscript_key_success_factors_I40_v6_camera_ready_2PRATEEK SARKARNo ratings yet

- Industry 4.0 Carabajo - MizqueroDocument3 pagesIndustry 4.0 Carabajo - MizqueroDaniel Mizquero Zarate0% (1)

- Big Data As A Promoter of Industry 4.0: Lessons of The Semiconductor IndustryDocument6 pagesBig Data As A Promoter of Industry 4.0: Lessons of The Semiconductor IndustryHorst SmogerNo ratings yet

- 02 Drivers and Barriers For Industry 4.0 Readiness and PracticeDocument10 pages02 Drivers and Barriers For Industry 4.0 Readiness and PracticeVanessa SantosNo ratings yet

- 10-Lechvajderova Kadarova Industry 3 2022Document8 pages10-Lechvajderova Kadarova Industry 3 2022Sunil SharmaNo ratings yet

- Implementation of Industry 4 0 Concept in Companies Empirical Evidences PDFDocument19 pagesImplementation of Industry 4 0 Concept in Companies Empirical Evidences PDFMateo Cuadros HerreraNo ratings yet

- Industry4 161112133940Document19 pagesIndustry4 161112133940Tran Anh100% (1)

- Implementation of Industry 4.0 Smart Manufacturing: MD Rafiqul Islam KhanDocument9 pagesImplementation of Industry 4.0 Smart Manufacturing: MD Rafiqul Islam KhanJatin SinghNo ratings yet

- 17 - Industry 4.0 An Amanofacturing EcosysDocument28 pages17 - Industry 4.0 An Amanofacturing Ecosysorlando moraNo ratings yet

- 3D Systems in Industrial Renaissance 4Document4 pages3D Systems in Industrial Renaissance 4sunithaNo ratings yet

- Eclipse IoT White Paper - Open Source Software For Industry 4.0Document18 pagesEclipse IoT White Paper - Open Source Software For Industry 4.0ricardo prezziNo ratings yet

- Nokia White Paper - Evaluating Digitalization Progress With The Industry 4.0Document13 pagesNokia White Paper - Evaluating Digitalization Progress With The Industry 4.0MD TANVIR FAISALNo ratings yet

- Assesing Industry 4.0 ReadinessDocument7 pagesAssesing Industry 4.0 ReadinessAdrian PugnaNo ratings yet

- Industry 4.0: An Overview: July 2018Document7 pagesIndustry 4.0: An Overview: July 2018Romancing LoveNo ratings yet

- Revolution of Lean Six Sigma 4.0Document9 pagesRevolution of Lean Six Sigma 4.0Felipe EcheverryNo ratings yet

- The Relationship Between The Implementation Levels of Industry 4.0 Technologies and Advanced Manufacturing TechnologiesDocument9 pagesThe Relationship Between The Implementation Levels of Industry 4.0 Technologies and Advanced Manufacturing TechnologiesaghowelNo ratings yet

- Industry 4.0: An Overview: July 2018Document7 pagesIndustry 4.0: An Overview: July 2018Steve StevenNo ratings yet

- McKinsey Explainer-What - Are - Industry - 4 - 0 - The - Fourth - Industrial - Revolution - and - 4irDocument7 pagesMcKinsey Explainer-What - Are - Industry - 4 - 0 - The - Fourth - Industrial - Revolution - and - 4irYudhi PermadiNo ratings yet

- Digitalisation and Innovation in The Steel IndustrDocument25 pagesDigitalisation and Innovation in The Steel IndustrYana KholodovaNo ratings yet

- ImplementationofIndustry4 0SmartManufacturingRDocument9 pagesImplementationofIndustry4 0SmartManufacturingRravivpsNo ratings yet

- MITI On IR4.0Document18 pagesMITI On IR4.0deanNo ratings yet

- Industrie 4.0 Enabling Technologies (2015)Document6 pagesIndustrie 4.0 Enabling Technologies (2015)lazarNo ratings yet

- Assessing Industry 4.0 Readiness of EnterpriseDocument6 pagesAssessing Industry 4.0 Readiness of Enterprisemonika panghalNo ratings yet

- 1 s2.0 S294973612200001X MainDocument17 pages1 s2.0 S294973612200001X MainJerri Bernardes de SouzaNo ratings yet

- DI Digital Industrial TransformationDocument12 pagesDI Digital Industrial TransformationPaul Vintimilla CarrascoNo ratings yet

- Automotive Industry in The Context of Industry 40Document5 pagesAutomotive Industry in The Context of Industry 40Nurul Aisyah Binti RamlanNo ratings yet

- Industry 4.0: Industrial Revolutions and Future ViewDocument5 pagesIndustry 4.0: Industrial Revolutions and Future ViewCharith LiyanageNo ratings yet

- Industry 4.0: The Role of Iiot in Digital Transformation of The Manufacturing SectorDocument16 pagesIndustry 4.0: The Role of Iiot in Digital Transformation of The Manufacturing SectorAhmed TorchaniNo ratings yet

- A Review of Cybersecurity Guidelines For Manufacturing Factories in Industry 4.0Document29 pagesA Review of Cybersecurity Guidelines For Manufacturing Factories in Industry 4.0jermNo ratings yet

- Industry 4.0 Technology Implementation in SMEs - A Survey in The Danish-German Border RegionDocument9 pagesIndustry 4.0 Technology Implementation in SMEs - A Survey in The Danish-German Border RegionNur Alia ElkaNo ratings yet

- 1 - Industry 4.0 IntoductionDocument33 pages1 - Industry 4.0 IntoductionRidwanNo ratings yet

- Industry 4.0 An OverviewDocument20 pagesIndustry 4.0 An Overviewambika1969in100% (1)

- Essence of Business 4 0Document2 pagesEssence of Business 4 0Editor IJTSRDNo ratings yet

- Ir 4 NotesDocument9 pagesIr 4 NotesNadrah HassanNo ratings yet

- Gei NotesDocument24 pagesGei NotesNadrah HassanNo ratings yet

- Educating The Industry 4.0 WorkforceDocument3 pagesEducating The Industry 4.0 WorkforceDhillukshanNo ratings yet

- The Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature ReviewDocument34 pagesThe Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature ReviewMimnun NNo ratings yet

- Teknologi YogurthDocument8 pagesTeknologi YogurthADELLO TOGARIO SINAGANo ratings yet

- Industy 4.0 AppliedDocument17 pagesIndusty 4.0 Appliedcagan.ulNo ratings yet

- Industry 4.0 TechnologiesDocument34 pagesIndustry 4.0 Technologies08.reap-sendersNo ratings yet

- Industry 4 0Document52 pagesIndustry 4 0CRISTHIAN DAVID FERNANDEZ MORALES100% (1)

- Industry 4.0: Top Challenges For Chemical Manufacturing: R&D Solutions For ChemicalsDocument8 pagesIndustry 4.0: Top Challenges For Chemical Manufacturing: R&D Solutions For ChemicalsAkın ÖztürkNo ratings yet

- Artikel 2 (Pendukung) Preparing-For-The-Next-Normal-Via-Digital-Manufacturings-Scaling-PotentialDocument10 pagesArtikel 2 (Pendukung) Preparing-For-The-Next-Normal-Via-Digital-Manufacturings-Scaling-PotentialErik GunawanNo ratings yet

- Rishabh IIOT ReportDocument4 pagesRishabh IIOT ReportRishabh DesaiNo ratings yet

- Applied Sciences: Machine Learning in Manufacturing Towards Industry 4.0: From For Now' To Four-Know'Document32 pagesApplied Sciences: Machine Learning in Manufacturing Towards Industry 4.0: From For Now' To Four-Know'Abhijna AdigaNo ratings yet

- Title 1 IR4.0Document10 pagesTitle 1 IR4.0F1061 SafadilaNo ratings yet

- Industry 4.0 and Society 5.0: Opportunities and Threats: Revised Manuscript Received On January 15, 2020Document4 pagesIndustry 4.0 and Society 5.0: Opportunities and Threats: Revised Manuscript Received On January 15, 2020gizex2013No ratings yet

- Digital Twin in Industry 4.0 Technologies Applications and ChallengesDocument6 pagesDigital Twin in Industry 4.0 Technologies Applications and ChallengesAshwani SinghNo ratings yet

- Toward New Generation Intelligent ManufacturingDocument10 pagesToward New Generation Intelligent Manufacturing传林李No ratings yet

- Industry 4.0 PDFDocument12 pagesIndustry 4.0 PDFEliza Mara Lozano CostaNo ratings yet

- Data Management in Industry 4.0: State of The Art and Open ChallengesDocument43 pagesData Management in Industry 4.0: State of The Art and Open ChallengesEng Tennyson SigaukeNo ratings yet

- A Maturity Model For Assessing Industry 4.0 Readiness and Maturity of Manufacturing EnterprisesDocument7 pagesA Maturity Model For Assessing Industry 4.0 Readiness and Maturity of Manufacturing EnterprisesAB1984No ratings yet

- Industry 4.0: Tools and Implementation: September 2019Document12 pagesIndustry 4.0: Tools and Implementation: September 2019Ibrahim KukićNo ratings yet

- "How Industry 4.0 Is Changing How We Manage Value Creation": White PaperDocument12 pages"How Industry 4.0 Is Changing How We Manage Value Creation": White PaperShenna VieraNo ratings yet

- Advances in Digitalization ofDocument16 pagesAdvances in Digitalization ofkeyachemNo ratings yet

- Manufacturing Operations Management - The Smart Backbone of Industry 4.0Document6 pagesManufacturing Operations Management - The Smart Backbone of Industry 4.0Raviteja GogineniNo ratings yet

- I4-2022!1!10 Application of Ergonomic Software Solutions in The Concept of Industry 4.0Document4 pagesI4-2022!1!10 Application of Ergonomic Software Solutions in The Concept of Industry 4.0arra mabbonNo ratings yet

- 2-Industry 4.0 - KusminDocument12 pages2-Industry 4.0 - KusminJ'obbanii StgoNo ratings yet

- Digital TransformationDocument6 pagesDigital TransformationbthncengizNo ratings yet

- IoT Standards with Blockchain: Enterprise Methodology for Internet of ThingsFrom EverandIoT Standards with Blockchain: Enterprise Methodology for Internet of ThingsNo ratings yet

- Rubrics For A Well Written and Technology Enhanced Lesson PlanDocument5 pagesRubrics For A Well Written and Technology Enhanced Lesson PlanValencia John EmmanuelNo ratings yet

- Tool Thiết Kế Tuyến VibaDocument23 pagesTool Thiết Kế Tuyến VibaTrương Văn LinhNo ratings yet

- The Effect of Implant Abutment Junction Position On Crestal Bone Loss A Systematic Review and Meta AnalysisDocument17 pagesThe Effect of Implant Abutment Junction Position On Crestal Bone Loss A Systematic Review and Meta AnalysisBagis Emre GulNo ratings yet

- Application Form For Certificate For English Proficiency Migration Bonafide StudentsDocument1 pageApplication Form For Certificate For English Proficiency Migration Bonafide StudentsE-University OnlineNo ratings yet

- NG160 - 16 To 160A Modular Incoming Circuit BrakersDocument27 pagesNG160 - 16 To 160A Modular Incoming Circuit BrakerssomeontorrenteNo ratings yet

- Signal Cable Connection To Input/Output Modules (For FIO)Document15 pagesSignal Cable Connection To Input/Output Modules (For FIO)cepia sobayhakiNo ratings yet

- Excel VBA Create A Worksheet List BoxDocument6 pagesExcel VBA Create A Worksheet List BoxRamonMalaveNo ratings yet

- GPOADmin Quick Start Guide 58Document25 pagesGPOADmin Quick Start Guide 58Harikrishnan DhanapalNo ratings yet

- Office of The Sangguniang Barangay: EXECUTIVE ORDER No. 005 of 2021Document2 pagesOffice of The Sangguniang Barangay: EXECUTIVE ORDER No. 005 of 2021michelle100% (2)

- SC Judgement On Criminal AntecedentsDocument27 pagesSC Judgement On Criminal AntecedentsAbhinav Rakesh MaruNo ratings yet

- Advertisement No 03.2022 Tehsildar Excise InspectorDocument3 pagesAdvertisement No 03.2022 Tehsildar Excise InspectorMian Musa RiazNo ratings yet

- Q Tut Ch2Document8 pagesQ Tut Ch2Damien MarleyNo ratings yet

- Mangune v. ErmitaDocument19 pagesMangune v. ErmitaElise Rozel DimaunahanNo ratings yet

- In The Matter of The Estate of JohnsonDocument3 pagesIn The Matter of The Estate of JohnsonDerick TorresNo ratings yet

- Analysis and Identification of Nonconforming Products by 5W2H MethodDocument10 pagesAnalysis and Identification of Nonconforming Products by 5W2H MethodkkkkoaNo ratings yet

- 45R-08 Scheduling Claims Protection MethodsDocument10 pages45R-08 Scheduling Claims Protection MethodsHatem HejaziNo ratings yet

- Jio ReportDocument36 pagesJio ReportHimanshu Singh100% (1)

- Cost Chat GPTDocument3 pagesCost Chat GPTAnushkaa DattaNo ratings yet

- Asaan Movers Thesis 8.0Document66 pagesAsaan Movers Thesis 8.0Qasim KhanNo ratings yet

- Individual AssignmentDocument5 pagesIndividual AssignmentHao LimNo ratings yet

- 20462D ENU CompanionDocument194 pages20462D ENU CompanionjiindooNo ratings yet

- Nitration of Methyl BenzoateDocument7 pagesNitration of Methyl BenzoateJanel Pauline G. Chua100% (1)

- 03 09 Saw Waterproofing Membranes TunnelDocument3 pages03 09 Saw Waterproofing Membranes TunnelParashuram ChauhanNo ratings yet

- Walk-in-Interview at S.V.Ayurvedic College, TTD, TirupatiDocument3 pagesWalk-in-Interview at S.V.Ayurvedic College, TTD, TirupatiKirankumar MutnaliNo ratings yet

- Atdp Es 000212Document35 pagesAtdp Es 000212peetholNo ratings yet

- 5 23 1e PDFDocument16 pages5 23 1e PDFkats2404No ratings yet

- Benchmarking: Ana Maria Bahamon Arias 4700274Document4 pagesBenchmarking: Ana Maria Bahamon Arias 4700274Juan José BahamónNo ratings yet