Professional Documents

Culture Documents

QSP-10 Procedure_for_advanced_Product_Quality_Planning

QSP-10 Procedure_for_advanced_Product_Quality_Planning

Uploaded by

sigmaqcs02Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QSP-10 Procedure_for_advanced_Product_Quality_Planning

QSP-10 Procedure_for_advanced_Product_Quality_Planning

Uploaded by

sigmaqcs02Copyright:

Available Formats

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

PROCEDURE FOR ADVANCED PRODUCT

QUALITY PLANNING

– SP/QSP/10

AMENDMENT SHEET

Issue No. & Rev. No. & Approved

# Description Page No. Issued By

Date Date By

00 & 00 &

01 Initial Release All Suresh Ramesh

11.04.2022 11.04.2022

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 1 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

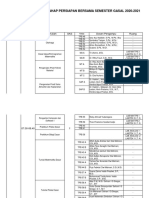

1.Guidelines

Start

Receipt of enquiry, Drawing, Specification from Customer

Form CFT

Review Drawing, Specification received from Customer

New Part Change in the existing part

No No

Prepare Team feasibility commitment

Inform customer if Not feasible Inform customer if Not feasible

Yes Yes

If feasible Prepare ECN Note & Inform

If feasible Inform customer customer

Decide the Product Development category & Prepare APQP matrix

Follow all the phases of APQP as called for in APQP matrix

Review the progress of the activity as per APQP matrix

If there is any delay observed, Record the Reason for the Delay & follow up

action

Is all the Phases of APQP has been completed & Results satisfactory

If Yes

If No Submit Pilot lot with documents for

Customer end SOP

If Yes

Obtain feedback from customer till customer SOP gets over

Result satisfactory?

If No

Prepare Quality plan Sign off & Follow Initial Production Control

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 2 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

1. PURPOSE

This Procedure is to defining new product development and Changes in existing Parts

(ECN)/(PCN) and to define the process needed for the Product Quality planning process to

ensure that:

1. Resources are directed to satisfy the customer.

2. To promote early identification of problems / changes to avoid late changes

3. To provide a quality product on time at the lowest cost.

4. Use of CFT approach & Simultaneous engineering during design and development

process.

5. To Ensure flaw less launch.

2. SCOPE

Applicable to all new development parts and Changes in existing Parts (ECN Parts) and/or its

process (PCN).

From receipt of order to SOP at customer end.

3. RESPONSIBILITY

It is the responsibility of the Plant Head to ensure that this procedure is latest, implemented

and understood by all appropriate personnel across the organization.

It is the responsibility of the CFT & relevant functional heads to ensure that this procedure is

implemented in their respective departments.

1. PROCEDURE

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 3 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

Phase – I (Plan and Define the program / Pre contract review)

Sl. Responsibility/ Document No

Activity

No. Authority

Select NPD category based on nature of development from APQP

Activities matrix (SP/NPD-AM/01) & defining responsibility

accordingly.

AA - Absolutely new component: No Experience of Production

so far.

A - That the part happens to be similar to what had been APQP Activities

produced so far but there happens to be large-scale difference in

Matrix

raw material, Machining Methodology, In the structure or in the

function. Plant Head /

4.1.0 SP/NPD-AM/01

B - That Whenever there happens to be a Minor Deviation in the

CFT

Component produced so far(To implement only for inspection of

initial product) ECN & DCN Parts

C - That whenever there happens to be extremely minor change

in details related to the component, so much so that even the

inspection

becomes non mandatory(It becomes more of checks in regard to

monitoring of the points of variation in regard to 4M

D - That whenever there happens to be changed in production

site

Receive enquiry / Customer drawing / Customer provided

sample / any standards and specifications from CUSTOMER, By Email

4.1.1 Plant Head

Customer Milestone (T0,T1,T2, Sample submission time

requirement & SOP) (If any).

Perform enquiry review and the details will be entered in Enquiry

4.1.2 Register The details shall be reviewed for adequacy if engineering Plant Head SP/NPD-ENQ/01

drawing were provided by the customer.

Identify the Customer drawing, standards, if given by putting

`MASTER COPY’ on the rear side of the drawing and standard.

Mark the date of receipt suitably handwritten on the rear side Quality Engineer SP/MLD/01

4.1.3 and update the master list of customer drawing immediately. In

case if any drawings received for reference purpose as design

input, it can be considered only for reference by putting

`Reference only’ on the rear side of the drawing.

Photocopies of the customer drawing affixed with `CONTROLLED Quality Engineer --

4.1.4

COPY’ stamp can be used for reference purpose

Top management shall constitute a Manufacturing Cross SP/NPD-CFT/01

Functional Team consisting of members from Marketing, Plant Head

4.1.5

Production, Maintenance, Quality, and Purchasing to carry out

the Advanced Product Quality Planning. List of CFT Members

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 4 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

Drawing Review: The drawing shall be reviewed by Plant Head. In SP/NPD-DRG/RE/

case of samples received from the customer, it can be used for 01

Comparative purpose only and does not absolve the CFT to CFT

comply with customer requirement as stated in the assembly

4.1.6 drawing.

Clarification from customer, If required:

During drawing review if any incomplete information is found,

Marketing

the marketing person shall interact with customer to get the

relevant required information.

---

Additionally CFT Team shall collect information on Internal voices

/ Past History based on:

a) In house rejections / Rework

b) Customer complaints

4.1.7 CFT SP/NPD-PH/01

c) Process changes and their impact

d) SPC results

e) TGR / TGW reports (Things Gone Wrong & Things Gone Right)

Pre – Feasibility Study: SP/NPD-PF/01

Conduct Pre-feasibility study to understand the manufacturer CFT

ability of new product within 15 days of drawing receipt.

For feasible products, a final Process details shall be prepared.

Engineering Change Note for the change in existing part is --

prepared. Engineering change Note shall be prepared within 10 CFT /

4.1.8

Working days & the same to be communicated to the customer.

Plant Head

The final Process details, and then is reviewed by MANAGER for

preparation of cost data sheet and facilitating submission of

Quotation.

If found not feasible, CFT shall send regret letter intimating the --

Plant Head

customer the inability to service this enquiry.

Reliability and Quality, Goals: (If required)

CFT Team shall identify goals in the form of: SP/NPD-QG/01

4.1.9 1.Product cycle time CFT

2.In-Process Rejection PPM

3. Process capability requirement

Bill of Materials: Plant Head /

4.1.10 CFT shall prepare a tentative material Parts List if required based --

Marketing

on Parts List, Purchase shall prepare an early subcontractor list.

Preliminary Process flow Chart:

4.1.11 Tentative process flow chart (Block diagram) shall be prepared by CFT SP/NPD-PFC/01

the CFT.

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 5 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

Marketing shall provide a Quotation to the customer with lead-

time and validity of quote. Marketing shall resolve any difference

with the customer with regard to the quotation. Marketing to

monitor the status of the quote and shall be closed when

--

4.1.12 reasonable period of extension based on the interactions with MARKETING

the customer is over.

If at a later stage, the customer revises the same enquiry, it shall

be the prerogative / discretion of the Marketing / Top

Management to consider the enquiry at the earlier quote.

CFT Review: CFT Members will review the project status every

week & the same will be recorded in MOM. If any delay found, it Plant Head / SP/NPD-MRM/01

4.1.13 will be reviewed & corrective action planned. Timing plan also APQP

updated accordingly if required. This CFT review should be Champion

conducted for all the phases.

CFT Members shall appraise the Top Management about the

status and analysis for any variance to provide further SP/NPD-MRM/01

appropriate supports (Interims of Resource Requirements) and CFT / APQP

4.1.14

the same are minuted in Management support & Review Champion

Meeting Report. For Long duration project, the same shall be

reviewed month wise instead of phase wise.

Phase –II – (Product Design & Development, Team Feasibility Commitment)

4.2.1 Marketing shall accept a Purchase Order / LOI from the customer. Marketing By mail

4.2.2 CFT shall also conduct Contract Review If required. Plant Head --

The CFT shall be specific to the product and if required CFT --

4.2.3

representatives from other functions may be inducted

CFT develops New Product Development Plan (Master & Micro) as SP/NPD-MAP/

required by the organization, in-line with APQP Matrix (SP/ NPD - 01&

AM/01) based on category defined. SP/NPD-MIP/01

4.2.4 Master plan is prepared for overall monitoring process & Micro CFT

Plan: Process which involves more time are monitored through

Micro Level planning such as a tool / fixture development &

inspection testing establishment & process validation.

Identify customer defined special characteristics, Check for Quality / SP/NPD-SCM/01

4.2.5

Availability of published standards and record the details. Plant Head

Product error proofing, as appropriate: ----

4.2.6 CFT

CFT shall review for any Poka Yoke requirements to ensure the

error proofing / mistake proofing.

4.2.7 Engineering Drawings / Specifications / Material Specifications: CFT

CFT shall prepare process drawings and material specifications

based on Customer Drawing input if required. In addition to the ---

above, wherever applicable all engineering changes shall be as per

Process Manual for Document Control Process. Purchase shall

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 6 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

insist through P.O. the traceability requirements like date and

month code to be followed wherever feasible on the Brought out.

New equipment/ Tooling / Gauges / Testing equipment / SP/NPD-TECL/01

4.2.8 Facilities requirements: & SP/NPD-CAL/01

CFT

Identify New Equipment, Toolings / Gauges / testing equipment

and Facilities Requirements to complete the project.

CFT shall review for other facilities, equipments and other --

CFT

resources that are required for the New product that is to be

4.2.9

developed.

Training for New process or operator that are required for new SP/NPD-TFC/01

HR

product will be provided.

Appropriate personnel of CFT shall prepare Proto Control Plan for

all processes as per the preliminary Process flow Chart. Control SP/QCPC

4.2.10 CFT

Plan shall be prepared based on APQP Manual / customer

approved methodology.

Evaluate feasibility through Product Data and Team Feasibility

Report. Marketing / Customer Representative shall interact with CFT / Plant SP/NPD/TFC-01

4.2.11 customer for any clarifications.

Head

Team feasibility Commitment Report shall be signed by the CFT

and the team now agrees to develop the new product.

CFT Review: CFT Members will review the project status every SP/NPD-MRM/02

Plant Head /

week & the same will be recorded in MOM. If any delay found, it

4.2.12 APQP

will be reviewed & corrective action planned. Timing plan also

Champion

updated accordingly if required.

CFT Members shall appraise the Top Management about the SP/NPD-MRM/02

status and analysis for any variance to provide further appropriate

supports (Interims of Resource Requirements) and the same are CFT / APQP

4.2.13

minuted in Management support & Review Meeting Report. For Champion

Long duration project, the same shall be reviewed month wise

instead of phase wise.

PHASE –III (Process Design & Development)

Appropriate personnel of CFT shall ensure that the following --

4.3.1 CFT

activities are carried out thru simultaneous Engineering method

CFT shall prepare Packaging standards / specifications that are --

required for the new product that is being developed

Decide Packaging Specifications Quality /

4.3.2 Reflect Packaging Specifications in Work Instruction

CFT

If Customer provides the packaging specification, the same shall

be used.(Materials are dispatch in customer allocated

bins/Crates/Trolleys/Carton Box).

4.3.3 CFT shall review the entire Quality System Documentation thru CFT SP/NPD-PQSR/01

Product / Process quality system review to ensure that the existing

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 7 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

quality system is adequate to meet the requirements of new

product.

CFT shall prepare Process flow diagram as per the format to cover SP/PFD/01

4.3.4 CFT

the incoming source of variation and expected deliverables

Floor Plan Layout:

CFT shall prepare proposed floor plan layout in-line with PFC --

4.3.5 CFT

sequence. If the product is similar to the existing no need to

prepare floor plan layout.

CFT shall prepare Characteristics matrix (if required) for the new

product that is being developed. SP/NPD-SCM/01

4.3.6 CFT

CFT to list all special Characteristic;

Identify appropriate techniques for Process Control.

CFT shall conduct Process Failure Mode and Effect analysis SP/PFMEA/01

4.3.7 (PFMEA) for all value adding processes as per the PFMEA Manual / CFT

methodology given in Customer Supplier Development Manual.

Appropriate personnel of CFT shall prepare Pre-launch Control Plan SP/QCPC

for all processes as per the Process flow diagram. Control Plan shall

4.3.8 CFT

be prepared based on APQP Manual / customer approved

methodology.

Appropriate personnel of CFT shall prepare Process instructions

(Work Instructions) for all processes as the PFD.

Develop Process Instructions based on the output of the above SP/WI/01

4.3.9 CFT

steps.

Ensure Process Instruction referred in the Control Plan.

Identify Special Characteristics Symbol in process Instructions.

Appropriate personnel of CFT shall prepare MSA plan as per the

requirement for which MSA to be conducted.

4.3.10 CFT

Develop MSA Plan indicating the process, type of MME, Product F/SPC/28

and Process Tolerance and the Appraiser and the time.

Appropriate personnel of CFT shall prepare Preliminary process

capability study plan

Prepare Plan indicating the process, Equipment and the qualified

4.3.11 appraiser and Tolerances; CFT

F/SPC/28

SPC Plan shall be for processes where there are special

characteristics as defined by the customer and / or as defined by

the CFT.

CFT Review: CFT Members will review the project status every SP/NPD-MRM/03

Plant Head /

week & the same will be recorded in MOM. If any delay found it

4.3.12 APQP

will be reviewed & corrective action planned. Timing plan also

champion

updated accordingly if required.

4.3.13 CFT Members shall appraise the Top Management about the status CFT / APQP SP/NPD-MRM/03

and analysis for any variance to provide further appropriate champion

supports (Interims of Resource Requirements) and the same are

minuted in Management support & Review Meeting Report. For

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 8 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

Long duration, project shall be reviewed month wise instead of

phase wise.

PHASE – IV (Product and Process Validation)

CFT shall perform Job Verification setups. Produce samples for

initial product and process Establishment. Depending on the --

4.4.1 CFT

model, the actual quantity can be decided by the respective

CFT / based on customer requirement.

Production Trial Run :

Produce samples as per pre-launch control plan for initial SP/NPD-TR/01 &

sample submission to the customer with PPAP SP/NPD-PDCA/01

Documentation for Customer requirements.

Ensure significant production run quantity for PPAP run for

customers identified depending on the model the actual

quantity can be decided by the respective CFT / Customer.

Follow up Results: Collect all issues found at

internal/customer end problem during trial run. CFT shall

4.4.2 conduct the analysis on the issues identified & take CFT

appropriate actions to solve the issue, same shall be

recorded in the PDCA .

Whenever there is an issue in form, Fit and function during

trial, it should be analyzed & 8D to be prepared for the issue

reported.

If any ECN identified at the time of production trial run pre-

ECN parts will be identified and stored with identification

tag- RED TAG and shall be moved/scraped based on

customer input.

4.4.3 During the Production Trial Run, CFT shall ensure that : CFT SP/MSA-R/01,

1. MSA study is conducted with follow-up action for SP/SPC, SP/NPD-

marginal/non capable system. PDCA/01 &

2. Preliminary Process capability study is conducted and

SP/PPAP

action plan is established where Cpk Values do not meet

customer / Default requirements.

3. Layout inspection: Conduct a lay out inspection in line with

the drawing shared by customer and prepare a report.

4. Production Part Approval Process (PPAP) as per customer

requirement Production Validation testing;

5. Process Validation: Conduct test that validate the products

made from production tools and processes meet

Engineering requirement ;

6. PFC Review (if required): Incase if required, review or

revise the process flow based on the need.

7. Packaging Evaluation is carried out.

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 9 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

Conduct trials and assess results,

Carry out corrective actions,

Freeze packaging standards and specifications.

8. Logistics: Marketing shall discuss with Customer on the

logistics front. Adopt the suitable & mutual agreed logistics

modem.

CFT shall prepare :

Production Control Plan

Production Process control standard SP/QCPC

Other documents as required (Statuary & regulatory, Health &

safety ,Environmental requirements)

4.4.4 CFT

Develop production Process control standard which is a logical

extension of pre-launch control plan and catering to all the

requirements of Production control plan

CFT shale ensure relevant Statuary & regulatory, Health &

safety, Environmental requirements are met if required.

CFT shall sign Quality planning sign off with production team to SP/NPD-QPS/01

assure that the new product developed has met the customer

4.4.5 CFT

requirements and that all tools, equipments, facilities, testing

requirements are in line with customer expectations

CFT Review: CFT Members will review the project status every SP/NPD-MRM/04

Plant Head /

week & the same will be recorded in MOM. If any delay found, it

APQP

will be reviewed & corrective action planned. Timing plan also

champion

updated accordingly if required.

CFT Members shall appraise the Top Management about the SP/NPD-MRM/04

status and analysis for any variance to provide further

appropriate supports (Interims of Resource Requirements) and CFT / APQP

4.4.6

the same are minuted in Management support & Review champion

Meeting Report. For Long duration project, the same shall be

reviewed month wise instead of phase wise.

PHASE V (Feedback Assessment and Corrective Action)

4.5.1 Track customer feedback after pilot lot SOP at customer end and --

IPC submission and its Corrective action. The overall objective of

this process shall be:

Reduced variation CFT

Incorporate ongoing process performance meeting

Cpk>1.67 for all special characteristics.

Identify CI projects to reduce variations

SOP at Customer end: CFT --

Get the start of production plan at customer end and work towards

to achieve the same. this has to be monitored through timing plan

Customer satisfaction

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 10 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

Evaluate customer Satisfaction

Delivery

Monitor 100 % delivery performance.

CFT shall prepare Things Gone Right (TGR) and Things Gone SP/NPD-PDCA/01

4.5.2 Wrong (TGW) TGR/TGW Report and also define corrective CFT

actions that are required.

CFT Review: CFT Members will review the project status every SP/NPD-MRM/05

Plant Head /

week & the same will be recorded in MOM. If any delay found, it

4.5.3 APQP

will be reviewed & corrective action planned. Timing plan also

champion

updated accordingly if required.

CFT Members shall appraise the Top Management about the SP/NPD-MRM/05

status and analysis for any variance to provide further

appropriate supports (Interims of Resource Requirements) and CFT / APQP

4.5.4

the same are minuted in Management support & Review champion

Meeting Report. For Long duration project, the same shall be

reviewed month wise instead of phase wise.

Start of initial production control Plant Head & QSP / 12

4.5.5

Quality Head

CROSS REFERENCES:

Document Reference

Sl. No. Description Reference

1 Procedure for Marketing --

2 Procedure for Breakdown & Preventive Maintenance QSP/15

Record Reference

Sl. No. Description Reference

1 APQP Activities Matrix SP/NPD-AM/01

2 List of CFT Members SP/NPD-CFT/01

3 Enquiry Register SP/NPD-ENQ/01

4 Experience Sharing SP/NPD-ES/01

5 Team Feasibility Commitment SP/NPD-TFC/01

6 New Product Development Master Plan SP/NPD-MAP/01

7 New Product Development Micro Plan SP/NPD-MIP/01

8 Management Of Review Meeting SP/NPD-MRM

9 Cost Estimation ----

10 Quotation ------

11 Purchase Order -----

12 Contract Review -----

13 List of new equipment’s / Tooling / Gauges / Facilities SP/NPD-TECL/01

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 11 of 12

PROCEDURE FOR ADVANCED PRODUCT

SP QUALITY PLANNING

SP/QSP/10

14 Risk Analysis SP/NPD-RA/01

15 Team Feasibility Commitment SP/NPD-TFC/01

16 Packaging standards / specifications ---

17 Product / Process quality system review SP/NPD-PQS/01

18 Process flow diagram SP/PFD/01

19 List of Special Characteristics Matrix SP/NPD-SCM/01

20 Potential Process FMEA SP/PFMEA

21 Target For Productivity, Process Capability & Cost SP/NPD-QG/01

22 Proto type Control Plan SP/QCPC/01

23 Manufacturing Feasibility Review Report SP/NPD-MFR/01

24 Product/Process Quality System Review Checklist SP/NPD-PQS/01

25 Control Plan- Prelaunch SP/QCPC

26 Process instructions (Work Instructions) SP/WI-SOP

27 MSA Reports SP/MSA

28 SPC Reports SP/SPC

29 PPAP Reports SP/PPAP

30 Control Plan- Production SP/QCPC

31 Checking Aids List SP/NPD/CA/01

32 Quality Planning Sign Off SP/NPD-QPS/01

33 PDCA( Trial Report) SP/NPD-PDCA/01

• - Customer Representative shall maintain copies of the above records in the APQP file for

each part.

Date of Issue:

Issued By Approved By Rev. No. & Date

14.03.2022

Ramesh Suresh 00 & 11.04.2022 Page : 12 of 12

You might also like

- SAFE LAUNCH ProcedureDocument2 pagesSAFE LAUNCH ProcedurePRAMOD88% (8)

- NR 508 Test Bank PharmacologyDocument224 pagesNR 508 Test Bank PharmacologyChris100% (2)

- 5M CHANGE ProcedureDocument8 pages5M CHANGE ProcedurePk Nimiwal100% (1)

- Kruth Patricia + Stobart Henry (Eds.) - Sound (Darwin College Lectures, 11) (1968, 2000)Document242 pagesKruth Patricia + Stobart Henry (Eds.) - Sound (Darwin College Lectures, 11) (1968, 2000)mersenne2No ratings yet

- APQP Flow Chart and ProcedureDocument7 pagesAPQP Flow Chart and Procedurearun100% (1)

- EFSET (B2 Upper Intermediate)Document3 pagesEFSET (B2 Upper Intermediate)chandran_witts100% (1)

- QSP-13 Procedure For 5M ChangeDocument20 pagesQSP-13 Procedure For 5M Changesigmaqcs02No ratings yet

- QSP-02 Procedure For Process Control StandardsDocument4 pagesQSP-02 Procedure For Process Control Standardssigmaqcs02No ratings yet

- Sop for Iso Implementation at PsqcDocument4 pagesSop for Iso Implementation at Psqcauditor2No ratings yet

- 9) Determination of Customer SatisfactionDocument4 pages9) Determination of Customer SatisfactionSagar DaundNo ratings yet

- MACE Green Activity Timing PlanDocument1 pageMACE Green Activity Timing PlanshinuNo ratings yet

- 3 - Objectives and TargetsDocument3 pages3 - Objectives and TargetsAlaaNo ratings yet

- QSP-13 Procedure - For - Handling - Suspect - PartsDocument5 pagesQSP-13 Procedure - For - Handling - Suspect - Partssigmaqcs02No ratings yet

- FM-QA-057 - Supplier AuditDocument4 pagesFM-QA-057 - Supplier Auditamarrabakas2No ratings yet

- Mannan Shahid Forgings (PVT) LTD.: Informational Presentation byDocument29 pagesMannan Shahid Forgings (PVT) LTD.: Informational Presentation bybhimraNo ratings yet

- MKT Procedure - Evaluating Customer Satisfaction P1Document1 pageMKT Procedure - Evaluating Customer Satisfaction P1sumanNo ratings yet

- JRG MGT P 03 Continual ImprovementDocument6 pagesJRG MGT P 03 Continual ImprovementManish ChoudharyNo ratings yet

- QSP-06. Procedure for PurchaseDocument6 pagesQSP-06. Procedure for Purchasesigmaqcs02No ratings yet

- Iso Master FileDocument187 pagesIso Master FileSangram KandekarNo ratings yet

- Standard Operating Procedures: Enquiry, Pricing & Payment Terms FinalizationDocument5 pagesStandard Operating Procedures: Enquiry, Pricing & Payment Terms FinalizationIan YongNo ratings yet

- Supplier Training-SREA DeviationDocument28 pagesSupplier Training-SREA Deviationsharwankumar28No ratings yet

- (QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Document9 pages(QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Gourav SainiNo ratings yet

- QSP-09 PROCEDURE FOR CONTROL OF MEASURING AND MONITORING EQUIPMENTS CALIBRATIONDocument4 pagesQSP-09 PROCEDURE FOR CONTROL OF MEASURING AND MONITORING EQUIPMENTS CALIBRATIONsigmaqcs02No ratings yet

- Audit Process Maps SampleDocument4 pagesAudit Process Maps SampleAnonymous SLI4aG100% (1)

- Pawan Kumar Dubey: ProfileDocument4 pagesPawan Kumar Dubey: Profilepawandubey9No ratings yet

- QA-SQA-003 Supplier Quality System Audit CAPA by SupplierDocument11 pagesQA-SQA-003 Supplier Quality System Audit CAPA by SupplierAbhishek AllenNo ratings yet

- Review Effectiveness Form MayDocument1 pageReview Effectiveness Form Mayحفیظ محمدNo ratings yet

- QSP-19. Procedure for ReworkDocument5 pagesQSP-19. Procedure for Reworksigmaqcs02No ratings yet

- Qad Sop 004Document15 pagesQad Sop 004Hemendra DaveNo ratings yet

- General SOP No. 001Document10 pagesGeneral SOP No. 001sohankumar.mahaleNo ratings yet

- QSP-16 New HR ProcedureDocument13 pagesQSP-16 New HR Proceduresigmaqcs02No ratings yet

- Kaizen: A Lean Manufacturing Tool For Continuous ImprovementDocument24 pagesKaizen: A Lean Manufacturing Tool For Continuous ImprovementSamrudhi PetkarNo ratings yet

- SEPG Plan - 2.0Document10 pagesSEPG Plan - 2.0Gopinath RNo ratings yet

- Annex 5. Questionnaire For New Suppliers Vendor of Calibration ProviderDocument5 pagesAnnex 5. Questionnaire For New Suppliers Vendor of Calibration ProviderAndre PrimaNo ratings yet

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocument9 pagesGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNo ratings yet

- Be-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Document2 pagesBe-Pdp-Fr-07-E Papso Form Roanoke To Sa - j7Ricardo Frank CordeiroNo ratings yet

- Pinga Solutions (P) LTD.: Annual Appraisal FormDocument6 pagesPinga Solutions (P) LTD.: Annual Appraisal FormashishNo ratings yet

- QSP-D&D-06 Child Part Development ProcedureDocument1 pageQSP-D&D-06 Child Part Development ProcedureDeepak KumarNo ratings yet

- 1) Quality Policy DeploymentDocument3 pages1) Quality Policy DeploymentSagar DaundNo ratings yet

- Project Handling ProcedureDocument8 pagesProject Handling ProcedurePk NimiwalNo ratings yet

- Ogive Technology LLP Quality System Procedure: TrainingDocument5 pagesOgive Technology LLP Quality System Procedure: TrainingtriveshNo ratings yet

- SOP-QA-7.3.6.3-001 Production Part Approval Process (PPAP)Document7 pagesSOP-QA-7.3.6.3-001 Production Part Approval Process (PPAP)XionNo ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Performance Improvement Plan (PIP) TemplateDocument4 pagesPerformance Improvement Plan (PIP) TemplatePia MontielNo ratings yet

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- (QSP-MR-04) MRMDocument2 pages(QSP-MR-04) MRMBASAVA ENGINEERINGNo ratings yet

- JProducts_QA_TestPlan.doc-revHEAD.svn000.tmpDocument10 pagesJProducts_QA_TestPlan.doc-revHEAD.svn000.tmpmi5.mrityunjayNo ratings yet

- Audit Process MapsDocument10 pagesAudit Process MapsSarala ChaudhariNo ratings yet

- IMPROVEMENT ACTION PLAN (Risk & Opportunities) : Pt. Vs Technology IndonesiaDocument3 pagesIMPROVEMENT ACTION PLAN (Risk & Opportunities) : Pt. Vs Technology IndonesiaRidwanNo ratings yet

- Refresh WPC Paiton - 24 Mar 10 - KonsepDocument52 pagesRefresh WPC Paiton - 24 Mar 10 - KonsepJhoni WNo ratings yet

- Fund Management Approach V2 21052024Document8 pagesFund Management Approach V2 21052024abdullahalkayyaliNo ratings yet

- QSP-08 PROCEDURE_FOR_CUSTOMER_COMPLAINTDocument8 pagesQSP-08 PROCEDURE_FOR_CUSTOMER_COMPLAINTsigmaqcs02No ratings yet

- NAME: Abhijeet Patil 9833721120: Name Module / Modules Designation/Grade Country ExperienceDocument3 pagesNAME: Abhijeet Patil 9833721120: Name Module / Modules Designation/Grade Country ExperienceYashpal SinghNo ratings yet

- SAP SD - Abhijeet PatilDocument3 pagesSAP SD - Abhijeet PatilYashpal SinghNo ratings yet

- KRA-KPI, Mr. Shubham Patil - QA&QC - QA OfficerDocument2 pagesKRA-KPI, Mr. Shubham Patil - QA&QC - QA OfficerqaNo ratings yet

- Preparation and Management of Working StandardDocument9 pagesPreparation and Management of Working StandardSakib ChowdhuryNo ratings yet

- APQP ProcedureDocument6 pagesAPQP ProcedureluckydaysNo ratings yet

- KPI - Objectives Achievement PlanDocument4 pagesKPI - Objectives Achievement PlaninsaanNo ratings yet

- SOP-RD-7.1-001 Advanced Product Quality PlanningDocument13 pagesSOP-RD-7.1-001 Advanced Product Quality PlanningXionNo ratings yet

- SOP05 Internal AuditDocument8 pagesSOP05 Internal AuditAna Hidayah Syuhada100% (1)

- APQP Procedure - Updated-10.02.18Document10 pagesAPQP Procedure - Updated-10.02.18devendra shuklaNo ratings yet

- Ae-Qms-P-01 Procedure For Competence, Training and AwarenessDocument7 pagesAe-Qms-P-01 Procedure For Competence, Training and Awarenesspankaj66668No ratings yet

- Service Manual 40D3505ADocument51 pagesService Manual 40D3505ATheojtNo ratings yet

- G752VSK Rev2.0 PDFDocument83 pagesG752VSK Rev2.0 PDFAlexandru FloricicăNo ratings yet

- (Updated Constantly) : CCNA 1 (v5.1 + v6.0) Chapter 6 Exam Answers FullDocument16 pages(Updated Constantly) : CCNA 1 (v5.1 + v6.0) Chapter 6 Exam Answers Fullfitroh fitrohNo ratings yet

- Leopard 2A4M CANDocument1 pageLeopard 2A4M CANMobil BoyNo ratings yet

- NPCIL - Question PapersDocument3 pagesNPCIL - Question PapersRamnadh MandaliNo ratings yet

- Lab 1a RASPlib Installation Instructions R5 2016b-2017aDocument10 pagesLab 1a RASPlib Installation Instructions R5 2016b-2017aaleNo ratings yet

- Challenges Q&AsDocument12 pagesChallenges Q&AsRaneesha MadurawalaNo ratings yet

- Dynaco Mark VImanualDocument23 pagesDynaco Mark VImanualLeonardo MarraffiniNo ratings yet

- Guadalupe Talks Part II ProgramDocument6 pagesGuadalupe Talks Part II Programapi-197099686No ratings yet

- BRB 1288-Be-EghsDocument11 pagesBRB 1288-Be-EghsSofiNo ratings yet

- SHS Core - Reading and Writing CG PDFDocument8 pagesSHS Core - Reading and Writing CG PDFRoy Ivan Manuel Reyes67% (6)

- ICoMaSEdu Paper TemplateDocument6 pagesICoMaSEdu Paper TemplateRusly HidayahNo ratings yet

- Factors Affecting The Tardiness of Selected Senior High Students of Queen Anne School Santa Rosa S.Y. 2010-2020Document11 pagesFactors Affecting The Tardiness of Selected Senior High Students of Queen Anne School Santa Rosa S.Y. 2010-2020Shai Anne Cortez100% (2)

- Shuqaiq Steam Power Plant: OwnerDocument441 pagesShuqaiq Steam Power Plant: OwnerAaqib Mujtaba100% (1)

- E45 Laboratory4Document7 pagesE45 Laboratory4nickNo ratings yet

- JADWAL KULIAH TPB SMT GASAL TA 2020 2021 Rev 5Document49 pagesJADWAL KULIAH TPB SMT GASAL TA 2020 2021 Rev 5shin yongriNo ratings yet

- Propylene (Asia-Pacific) 31 Jan 2020Document5 pagesPropylene (Asia-Pacific) 31 Jan 2020Wira Nata S SinuhajiNo ratings yet

- Digital Fundamentals: FloydDocument17 pagesDigital Fundamentals: FloydadilNo ratings yet

- Market Structure - Single TableDocument24 pagesMarket Structure - Single TablegaurigopinathNo ratings yet

- Mowbray SlidesCarnivalDocument30 pagesMowbray SlidesCarnivalschaNo ratings yet

- Get All Employee Details From The Employee TableDocument23 pagesGet All Employee Details From The Employee TableSachin KumarNo ratings yet

- 6 Key Challenges For Financial Close and ReportingDocument7 pages6 Key Challenges For Financial Close and ReportingGodfrey KakalaNo ratings yet

- Consumer Behaviour Mod IIDocument50 pagesConsumer Behaviour Mod IIHarinder SinghNo ratings yet

- SimpleNursing Study GuidesDocument5 pagesSimpleNursing Study Guidessilgabernard100% (1)

- Current Trends in ComputingDocument5 pagesCurrent Trends in ComputingInfanta joneNo ratings yet

- Chapter 1: Why Study Money, Banking, and Financial Markets?Document23 pagesChapter 1: Why Study Money, Banking, and Financial Markets?Nguyễn Thanh TrangNo ratings yet

- Techciti: Managed ServicesDocument6 pagesTechciti: Managed ServicesTechciti TechnologiesNo ratings yet