Professional Documents

Culture Documents

Catalogo Consumibles Soldadura Lincoln Australia

Catalogo Consumibles Soldadura Lincoln Australia

Uploaded by

ll vvCopyright:

Available Formats

You might also like

- IOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 5 OF 5-REV.01Document1 pageIOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 5 OF 5-REV.01subudhiprasannaNo ratings yet

- Catalog 2023 - Aerogas Industrial Supply SDN BHDDocument20 pagesCatalog 2023 - Aerogas Industrial Supply SDN BHDapi-677550906No ratings yet

- 3M - Motor Leads - 78-8096-4636-3Document12 pages3M - Motor Leads - 78-8096-4636-3alcibiades romeroNo ratings yet

- Streamline Copper Tube Medical Gas Submittal Sheet 1596827Document4 pagesStreamline Copper Tube Medical Gas Submittal Sheet 1596827Harvendra SinghNo ratings yet

- Everite CouplingDocument2 pagesEverite CouplingibrahimfahadNo ratings yet

- Dresser Style 63 Expansion JointDocument1 pageDresser Style 63 Expansion JointAnthonyNo ratings yet

- Brosur Ground RodDocument2 pagesBrosur Ground Rodahmad yusufNo ratings yet

- Penn Union 1-Hole (Long Barrel)Document2 pagesPenn Union 1-Hole (Long Barrel)khalidNo ratings yet

- Armature Air Gap GaugeDocument1 pageArmature Air Gap GaugeArnold StevenNo ratings yet

- Armature Air Gap Gauge PDFDocument1 pageArmature Air Gap Gauge PDFmansoor hussainNo ratings yet

- 2021 Tefen Fittings Catalogue-Pages-5Document1 page2021 Tefen Fittings Catalogue-Pages-5NMNo ratings yet

- Types Ks & Ks-3: Mechanical Burndy ProductsDocument1 pageTypes Ks & Ks-3: Mechanical Burndy Productsjuan yenqueNo ratings yet

- CT - 195962 - 5 - AEROQUIP 306 HoseDocument12 pagesCT - 195962 - 5 - AEROQUIP 306 HoseJayant GhawalkarNo ratings yet

- Travelingblock 273 1Document4 pagesTravelingblock 273 1kbgwseNo ratings yet

- Cast Iron Foot Valves: Features MaterialsDocument1 pageCast Iron Foot Valves: Features MaterialsAnonymous ehqz93YNo ratings yet

- Bleed RingDocument3 pagesBleed RingXxavierNo ratings yet

- Carefusion LaryngoscopeDocument10 pagesCarefusion Laryngoscoperubenr25No ratings yet

- J J Plum Block-PlDocument6 pagesJ J Plum Block-Plmanoj_doshi_1No ratings yet

- Magnum ProDocument6 pagesMagnum ProJuan Jose Ramos CortesNo ratings yet

- AME Clad Metal BrochureDocument4 pagesAME Clad Metal BrochureEalumalai MuthuNo ratings yet

- Elevator Catalogue: Brushes, Springs, and HoldersDocument26 pagesElevator Catalogue: Brushes, Springs, and HoldersMMMOH200No ratings yet

- Laser Sintering of Tungsten Carbide Cutter Shafts With Integrated Cooling ChannelsDocument7 pagesLaser Sintering of Tungsten Carbide Cutter Shafts With Integrated Cooling Channelssiva kumarNo ratings yet

- UntitledDocument4 pagesUntitledAdam KnottNo ratings yet

- LT0099 19Document7 pagesLT0099 19Jhampier Sánchez ZambranoNo ratings yet

- OpenROV Bill of Materials - Single QuantityDocument13 pagesOpenROV Bill of Materials - Single QuantityalliejaNo ratings yet

- Streamline Copper Tube HVACR Submittal Sheet 1596838Document4 pagesStreamline Copper Tube HVACR Submittal Sheet 1596838JaysonNo ratings yet

- BSR Presentation For TOTALDocument16 pagesBSR Presentation For TOTALGharib HashemNo ratings yet

- Jindal Saw - SS Welded and Seamless PipesDocument9 pagesJindal Saw - SS Welded and Seamless PipesRajat ChhabraNo ratings yet

- Stock 18 AgtDocument30 pagesStock 18 AgtSyifaul QulubNo ratings yet

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-040 - Fuel Filter and LinesDocument3 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-040 - Fuel Filter and LinesMANUALES100% (1)

- 220 - Válvula de GloboDocument1 page220 - Válvula de GloboRafael SalazarNo ratings yet

- Filtre PDFDocument18 pagesFiltre PDFCatalin StanNo ratings yet

- Filtros Cuno 3M 70-0201-8754-1Document2 pagesFiltros Cuno 3M 70-0201-8754-1vandoNo ratings yet

- A325 Structural BoltsDocument1 pageA325 Structural Boltsbayu_sukmaperdanaNo ratings yet

- PROCO Flexible JointsDocument4 pagesPROCO Flexible Jointsaverois ibn roisNo ratings yet

- Hamerlug Unions (Anson)Document15 pagesHamerlug Unions (Anson)Leonardo ViannaNo ratings yet

- pipe-clamps-section-from-pipe-hanger-catalogsDocument36 pagespipe-clamps-section-from-pipe-hanger-catalogsAndrew JacksonNo ratings yet

- Numero de Partes de Todos Los YenkosDocument1 pageNumero de Partes de Todos Los YenkosJose Antonio AcostaNo ratings yet

- 491 TechdataDocument11 pages491 Techdatahugo.vicenteNo ratings yet

- Clamps ColorDocument19 pagesClamps ColorGerson SuarezNo ratings yet

- EstiloDocument2 pagesEstiloJosé EnriqueNo ratings yet

- A Guide To The Use of Steel SlagDocument35 pagesA Guide To The Use of Steel SlagGreissy Margory Reynaga CalderonNo ratings yet

- Dresser 38 - 2Document3 pagesDresser 38 - 2Garcia Rodriguez Omar danielNo ratings yet

- WTI UK Screw Thread Inserts and Kits CatalogueDocument16 pagesWTI UK Screw Thread Inserts and Kits CatalogueThor InternationalNo ratings yet

- Turnbuckles: Vanguard Steel LTDDocument9 pagesTurnbuckles: Vanguard Steel LTDJeanne DangNo ratings yet

- Hub Myers de 3-4Document5 pagesHub Myers de 3-4pruebaprueba1No ratings yet

- Engine Mounting 580dDocument2 pagesEngine Mounting 580dJESUS0% (1)

- Helium SLA Disc 7E1 Passport 2017 PDFDocument8 pagesHelium SLA Disc 7E1 Passport 2017 PDFPieter Baobab BoomNo ratings yet

- Build Master PricelistDocument2 pagesBuild Master PricelistAngel TeshiNo ratings yet

- Pipe Schedule and Thickness RevisedDocument4 pagesPipe Schedule and Thickness Revisedrajaram100% (1)

- NEW Electroweld Pricelist - APR 25 2022Document7 pagesNEW Electroweld Pricelist - APR 25 2022ernst gencayaNo ratings yet

- Ca3v 4Document119 pagesCa3v 4Ayub Anwar M-SalihNo ratings yet

- MKT 001 Rev 02 Rotary Shoulder Handbook RS PDFDocument116 pagesMKT 001 Rev 02 Rotary Shoulder Handbook RS PDFKarla Hernandez0% (1)

- Selectrode: 317L Flux Coated TigDocument3 pagesSelectrode: 317L Flux Coated TigUta GilangNo ratings yet

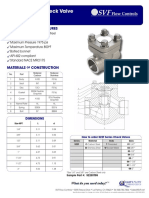

- SVF 522F Data Sheet-2020Document1 pageSVF 522F Data Sheet-2020Karla FordNo ratings yet

- Calculos Catarinas PDFDocument48 pagesCalculos Catarinas PDFHéctor Rodriguez RubioNo ratings yet

- Weald Motorsport Accessories CatalogueDocument11 pagesWeald Motorsport Accessories Catalogueharold.busNo ratings yet

- Tank-Accessories HandholeDocument7 pagesTank-Accessories HandholeAsep DarojatNo ratings yet

- Samsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsFrom EverandSamsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsRating: 1 out of 5 stars1/5 (1)

- Manual Soldadura en CampoDocument32 pagesManual Soldadura en Campoll vvNo ratings yet

- Catalogo Posicionadores de Soldadura Koike ArnsonDocument40 pagesCatalogo Posicionadores de Soldadura Koike Arnsonll vvNo ratings yet

- MSA Example WorkbookDocument41 pagesMSA Example Workbookll vvNo ratings yet

- MSA-Attribute GR R FORMATDocument17 pagesMSA-Attribute GR R FORMATll vvNo ratings yet

- LinearityDocument4 pagesLinearityll vvNo ratings yet

- Sigma Calc GRAPHICS DMPODocument2 pagesSigma Calc GRAPHICS DMPOll vvNo ratings yet

- Thread Turning ToolsDocument22 pagesThread Turning ToolsАндрейNo ratings yet

- General Hss End Mills Yg1Document60 pagesGeneral Hss End Mills Yg1bayuwiroNo ratings yet

- Stainless Steel International StandardsDocument3 pagesStainless Steel International StandardsAmir MusaibNo ratings yet

- Mar 18 AvlDocument1 pageMar 18 AvlBala KrishnanNo ratings yet

- Titan Ys-61Document2 pagesTitan Ys-61JUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Pipe Material ASTM CodesDocument2 pagesPipe Material ASTM CodesShreekanthKannathNo ratings yet

- Ferrous Alloys Stainless SteelsDocument41 pagesFerrous Alloys Stainless SteelsSumedh SinghNo ratings yet

- List of Copper Alloys - WikipediaDocument1 pageList of Copper Alloys - WikipediaMarcel KuhneNo ratings yet

- Classification of Different Welding Processes With PDFDocument4 pagesClassification of Different Welding Processes With PDFMadhu NNo ratings yet

- Rab Rehab Kantor Agama KonutDocument14 pagesRab Rehab Kantor Agama KonutLa Ode Muhamad SalehNo ratings yet

- 6063 Aluminium Alloy - WikipediaDocument3 pages6063 Aluminium Alloy - WikipediaNinad PawarNo ratings yet

- Visual Report For PF POSITIONDocument33 pagesVisual Report For PF POSITIONKyNo ratings yet

- Phase Transformation 12Document20 pagesPhase Transformation 12Guilherme Dos Santos MoreiraNo ratings yet

- ASTMDocument23 pagesASTMchiragpatel6650% (1)

- Steelgrades 2Document6 pagesSteelgrades 2dexterisNo ratings yet

- Materials Selection Assignment. LiveDocument10 pagesMaterials Selection Assignment. Liverichward5No ratings yet

- Yc Inox Co., LTD.: Inspection CertificateDocument1 pageYc Inox Co., LTD.: Inspection CertificateMuneer KonajeNo ratings yet

- Welding Consumables For Cast SteelDocument4 pagesWelding Consumables For Cast Steelmehul20110% (1)

- Material Groups PDFDocument3 pagesMaterial Groups PDFAnonymous B1AOOsmRMiNo ratings yet

- Eglin SteelDocument3 pagesEglin SteelShaun LeeNo ratings yet

- Material With Electrode SelectionDocument3 pagesMaterial With Electrode SelectionpmkarNo ratings yet

- Astm A530Document2 pagesAstm A530Thiruvengadam75% (4)

- Prevention of Vibration With Irregular Helix Flutes.: B133E VFMHV VFMHVRB VFJHV Vf6Mhv Vf6MhvrbDocument12 pagesPrevention of Vibration With Irregular Helix Flutes.: B133E VFMHV VFMHVRB VFJHV Vf6Mhv Vf6MhvrbNAHRUDIN KOLIĆNo ratings yet

- Pengelasan - 2 - Materials - 1Document82 pagesPengelasan - 2 - Materials - 1Reza Rachman DarmawanNo ratings yet

- AESW016Document10 pagesAESW016aslam.ambNo ratings yet

- Valve Material TypesDocument3 pagesValve Material TypesimanadbNo ratings yet

- Material Spec Chart 1Document1 pageMaterial Spec Chart 1mr.dennis73No ratings yet

- ASTM F568M (General Engineering Application)Document1 pageASTM F568M (General Engineering Application)Stephen Rey CaldeaNo ratings yet

- Monel Alloy 400 UNS N04400 Round Bar Stockiest, Suppliers & Exporters in IndiaDocument3 pagesMonel Alloy 400 UNS N04400 Round Bar Stockiest, Suppliers & Exporters in IndiaOZAIRTRADELINKNo ratings yet

- ElectrodosDocument14 pagesElectrodosanon-635614100% (6)

Catalogo Consumibles Soldadura Lincoln Australia

Catalogo Consumibles Soldadura Lincoln Australia

Uploaded by

ll vvCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalogo Consumibles Soldadura Lincoln Australia

Catalogo Consumibles Soldadura Lincoln Australia

Uploaded by

ll vvCopyright:

Available Formats

BLUESHIELDTM Stainless Steel Welding Consumables

High quality 308, 309 and 316 Stainless Steel Welding

Consumables

BLUESHIELD stainless steel products go through a rigorous

quality control system, which ensures a consistent quality

product time after time. Teaming these high-quality

consumables up with BLUESHIELD/Arcal™ shielding gases

provides the end user with reliable performance and improved

welder appeal. Whether thick or thin material is being welded,

we have the right consumables to meet your needs.

BLUESHIELD stainless steel consumables synonym of

performance and reliability.

1-800-817-7697 www.airliquide.ca www.blueshield.ca

Rev Oct/06, 1140-234E

Stainless Steel Welding Consumables

BLUESHIELD 620, 622 and 624 – SMAW Stainless Consumables

Like the carbon steel for father LA 7018, BLUESHIELD 620, 622 and

624 stainless steel electrodes offer the same consistency in operator

appeal, quality and performance that industry has come to expect. These

electrodes are characterized by their distinctive, smooth, spray-type

metal transfer, self-peeling slag, minimal spatter and superior weld bead

profile for welding the most common grades of austenitic stainless

steels.

BLUESHIELD 620, 622 and 624 stainless steel electrodes offer enhanced all-position welding

characteristics, specifically designed for vertical-up and overhead welding. These electrodes are

characterized by their fast-freezing slag, spray-type metal transfer, easy slag removal, minimal spatter

and a smooth, flat bead profile for welding the most common grades of austenitic stainless steel.

DIAMETER PACKAGING

NAME AWS CLASS

mm in kg lb

2.5 3/32 3 x 3.4 3 x 7.5

3.2 1/8 3 x 4.1 3 x 9.0

BLUESHIELD 620-308L E308L-17

4.0 5/32 3 x 3.9 3 x 8.8

5.0 3/16 3 x 4.9 3 x 10.8

2.5 3/32 3 x 3.4 3 x 7.5

BLUESHIELD 620P-308L E308L-17

3.2 1/8 3 x 4.1 3 x 9.0

2.5 3/32 3 x 3.4 3 x 7.5

3.2 1/8 3 x 4.1 3 x 9.0

BLUESHIELD 622-316L E316L-17

4.0 5/32 3 x 3.9 3 x 8.8

5.0 3/16 3 x 4.9 3 x 10.8

2.5 3/32 3 x 3.4 3 x 7.5

BLUESHIELD 622P-316L E316L-17

3.2 1/8 3 x 4.1 3 x 9.0

2.5 3/32 3 x 3.4 3 x 7.5

3.2 1/8 3 x 4.1 3 x 9.0

BLUESHIELD 624-309L E309L-17

4.0 5/32 3 x 3.9 3 x 8.8

5.0 3/16 3 x 4.9 3 x 10.8

2.5 3/32 3 x 3.4 3 x 7.5

BLUESHIELD 624P-309L E309L-17

3.2 1/8 3 x 4.1 3 x 9.0

1-800-817-7697 www.airliquide.ca www.blueshield.ca

Rev Oct/06, 1140-234E

Stainless Steel Welding Consumables

BLUESHIELD 630 – GTAW (TIG) Stainless Consumables

All BLUESHIELD 630 series GTAW (TIG) stainless steel consumables

are laser imprinted with positive AWS identification and heat numbers to

provide full product traceability for those demanding code quality jobs.

The standard packaging is convenient: 4.5 kg / 10 lb tubes, with three

tubes per master carton (13.6 kg / 30 lb).

DIAMETER PACKAGING

NAME AWS CLASS

mm in kg lb

BLUESHIELD 630-308L ER308L 1.6 to 3.2 1/16 to 1/8 3 x 4.5 3 x 10

BLUESHIELD 630-316L ER316L 1.6 to 3.2 1/16 to 1/8 3 x 4.5 3 x 10

BLUESHIELD 630-309L ER309L 1.6 to 3.2 1/16 to 1/8 3 x 4.5 3 x 10

BLUESHIELD 640 – GMAW Stainless Consumables

BLUESHIELD 640 series stainless steel wires are designed for those

high-quality stainless welding jobs. All products are packaged on

convenient plastic spools and precision level wound (PWL) to ensure

maximum feed ability and weld quality.

AWS DIAMETER PACKAGING

NAME

CLASS mm in kg lb

0.8 0.030 11.3 25

BLUESHIELD 640-308L ER308L

1.6 to 3.2 0.035 to 0.062 13.6 30

0.8 0.030 11.3 25

BLUESHIELD 640-308L HiSil ER308LSi

1.6 to 3.2 0.035 to 0.062 13.6 30

0.8 0.030 11.3 25

BLUESHIELD 640-316L ER316L

1.6 to 3.2 0.035 to 0.062 13.6 30

0.8 0.030 11.3 25

BLUESHIELD 640-316L HiSil ER316LSi

1.6 to 3.2 0.035 to 0.062 13.6 30

0.8 0.030 11.3 25

BLUESHIELD 640-309L ER309L

1.6 to 3.2 0.035 to 0.062 13.6 30

0.8 0.030 11.3 25

BLUESHIELD 640-309L HiSil ER309LSi

1.6 to 3.2 0.035 to 0.062 13.6 30

1-800-817-7697 www.airliquide.ca www.blueshield.ca

Rev Oct/06, 1140-234E

Stainless Steel Welding Consumables

BLUESHIELD 650, 652, 654 and LEXAL – FCAW Stainless Consumables

BLUESHIELD 650, 652, 654 and LEXAL 2209 stainless steel wires

offer the same consistency in operator appeal, quality and performance

that industry has come to expect of our BLUESHIELD carbon steel

FCAW wires. These wires offer a distinctive, smooth, spray-type, metal

transfer, self-peeling slag, minimal spatter and superior weld bead

profile.

BLUESHIELD 650, 652, 654 and LEXAL 2209P stainless steel wires offer enhanced all-

position welding characteristics, specifically designed for vertical-up and overhead welding. These

wires are characterized by their fast-freezing slag, spray-type metal transfer, easy slag removal,

minimal spatter and a smooth, flat bead profile for welding in vertical-up or overhead positions.

DIAMETER PACKAGING

NAME AWS CLASS

mm in kg lb

BLUESHIELD 650-308L E308LT0-1,4 1.2 and 1.6 0.045 and 0.062 12.7 28

BLUESHIELD 650P-308L E308LT1-1,4 1.2 and 1.6 0.045 and 0.062 12.7 28

BLUESHIELD 652-316L E316LT0-1,4 1.2 and 1.6 0.045 and 0.062 12.7 28

BLUESHIELD 652P-316L E316LT1-1,4 1.2 and 1.6 0.045 and 0.062 12.7 28

BLUESHIELD 654-309L E309LT0-1,4 1.2 and 1.6 0.045 and 0.062 12.7 28

BLUESHIELD 654P-309L E309LT1-1,4 1.2 and 1.6 0.045 and 0.062 12.7 28

LEXAL 2209 E2209LT0-1,4 1.2 0.045 12.7 28

LEXAL 2209P E2209LT1-1,4 1.2 0.045 12.7 28

1-800-817-7697 www.airliquide.ca www.blueshield.ca

Rev Oct/06, 1140-234E

Typical Stainless Steel Welding Parameters

SMAW STAINLESS STEEL WELDING PARAMETERS

FILLER ROD DIAMETER AMPERAGE

mm in A

2.5 3/32 40-80

3.2 1/8 65-120

4.0 5/32 95-160

5.0 3/16 130-200

GMAW STAINLESS STEEL WELDING PARAMETERS

ELECTRODE DIAMETER AMPERAGE WIRE FEED SPEED ARC VOLTAGE

SHIELDING GAS

mm in A ipm V

SHORT ARCAL 121 0.8 0.030 60-125 150-280 16-23

CIRCUIT or 0.9 0.035 75-160 125-280 16-23

TRANSFER BLUESHIELD 9 1.2 0.045 100-200 110-230 16-24

ARCAL 14 or 0.9 0.035 180-300 290-600 24-33

SPRAY

BLUESHIELD 4 or 1.2 0.045 200-450 250-475 24-35

TRANSFER

ARCAL 121 1.6 0.062 220-500 180-300 24-36

GTAW STAINLESS STEEL WELDING PARAMETERS

TUNGSTEN ELECTRODE FILLER ROD

METAL JOINT AMPERAGE GAS

DIAMETER DIAMETER

THICKNESS TYPE A

mm in mm in Type Flow-CFH

Butt 1.6 1/16 1.6 1/16 40-60 Argon 15

1.6 mm Lap 1.6 1/16 1.6 1/16 50-70 Argon 15

(1/16”) Corner 1.6 1/16 1.6 1/16 40-60 Argon 15

Fillet 1.6 1/16 1.6 1/16 50-70 Argon 15

Butt 2.4 3/32 2.4 3/32 65-85 Argon 15

3.2 mm Lap 2.4 3/32 2.4 3/32 90-110 Argon 15

(1/8”) Corner 2.4 3/32 2.4 3/32 65-85 Argon 15

Fillet 2.4 3/32 2.4 3/32 90-110 Argon 15

Butt 2.4 3/32 3.2 1/8 100-125 Argon 20

4.8 mm Lap 2.4 3/32 3.2 1/8 125-150 Argon 20

(3/16”) Corner 2.4 3/32 3.2 1/8 100-125 Argon 20

Fillet 2.4 3/32 3.2 1/8 125-150 Argon 20

Butt 3.2 1/8 4.0 5/32 135-160 Argon 20

6.4 mm Lap 3.2 1/8 4.0 5/32 160-180 Argon 20

(1/4”) Corner 3.2 1/8 4.0 5/32 135-160 Argon 20

Fillet 3.2 1/8 4.0 5/32 160-180 Argon 20

1-800-817-7697 www.airliquide.ca www.blueshield.ca

Rev Oct/06, 1140-234E

You might also like

- IOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 5 OF 5-REV.01Document1 pageIOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 5 OF 5-REV.01subudhiprasannaNo ratings yet

- Catalog 2023 - Aerogas Industrial Supply SDN BHDDocument20 pagesCatalog 2023 - Aerogas Industrial Supply SDN BHDapi-677550906No ratings yet

- 3M - Motor Leads - 78-8096-4636-3Document12 pages3M - Motor Leads - 78-8096-4636-3alcibiades romeroNo ratings yet

- Streamline Copper Tube Medical Gas Submittal Sheet 1596827Document4 pagesStreamline Copper Tube Medical Gas Submittal Sheet 1596827Harvendra SinghNo ratings yet

- Everite CouplingDocument2 pagesEverite CouplingibrahimfahadNo ratings yet

- Dresser Style 63 Expansion JointDocument1 pageDresser Style 63 Expansion JointAnthonyNo ratings yet

- Brosur Ground RodDocument2 pagesBrosur Ground Rodahmad yusufNo ratings yet

- Penn Union 1-Hole (Long Barrel)Document2 pagesPenn Union 1-Hole (Long Barrel)khalidNo ratings yet

- Armature Air Gap GaugeDocument1 pageArmature Air Gap GaugeArnold StevenNo ratings yet

- Armature Air Gap Gauge PDFDocument1 pageArmature Air Gap Gauge PDFmansoor hussainNo ratings yet

- 2021 Tefen Fittings Catalogue-Pages-5Document1 page2021 Tefen Fittings Catalogue-Pages-5NMNo ratings yet

- Types Ks & Ks-3: Mechanical Burndy ProductsDocument1 pageTypes Ks & Ks-3: Mechanical Burndy Productsjuan yenqueNo ratings yet

- CT - 195962 - 5 - AEROQUIP 306 HoseDocument12 pagesCT - 195962 - 5 - AEROQUIP 306 HoseJayant GhawalkarNo ratings yet

- Travelingblock 273 1Document4 pagesTravelingblock 273 1kbgwseNo ratings yet

- Cast Iron Foot Valves: Features MaterialsDocument1 pageCast Iron Foot Valves: Features MaterialsAnonymous ehqz93YNo ratings yet

- Bleed RingDocument3 pagesBleed RingXxavierNo ratings yet

- Carefusion LaryngoscopeDocument10 pagesCarefusion Laryngoscoperubenr25No ratings yet

- J J Plum Block-PlDocument6 pagesJ J Plum Block-Plmanoj_doshi_1No ratings yet

- Magnum ProDocument6 pagesMagnum ProJuan Jose Ramos CortesNo ratings yet

- AME Clad Metal BrochureDocument4 pagesAME Clad Metal BrochureEalumalai MuthuNo ratings yet

- Elevator Catalogue: Brushes, Springs, and HoldersDocument26 pagesElevator Catalogue: Brushes, Springs, and HoldersMMMOH200No ratings yet

- Laser Sintering of Tungsten Carbide Cutter Shafts With Integrated Cooling ChannelsDocument7 pagesLaser Sintering of Tungsten Carbide Cutter Shafts With Integrated Cooling Channelssiva kumarNo ratings yet

- UntitledDocument4 pagesUntitledAdam KnottNo ratings yet

- LT0099 19Document7 pagesLT0099 19Jhampier Sánchez ZambranoNo ratings yet

- OpenROV Bill of Materials - Single QuantityDocument13 pagesOpenROV Bill of Materials - Single QuantityalliejaNo ratings yet

- Streamline Copper Tube HVACR Submittal Sheet 1596838Document4 pagesStreamline Copper Tube HVACR Submittal Sheet 1596838JaysonNo ratings yet

- BSR Presentation For TOTALDocument16 pagesBSR Presentation For TOTALGharib HashemNo ratings yet

- Jindal Saw - SS Welded and Seamless PipesDocument9 pagesJindal Saw - SS Welded and Seamless PipesRajat ChhabraNo ratings yet

- Stock 18 AgtDocument30 pagesStock 18 AgtSyifaul QulubNo ratings yet

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-040 - Fuel Filter and LinesDocument3 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-040 - Fuel Filter and LinesMANUALES100% (1)

- 220 - Válvula de GloboDocument1 page220 - Válvula de GloboRafael SalazarNo ratings yet

- Filtre PDFDocument18 pagesFiltre PDFCatalin StanNo ratings yet

- Filtros Cuno 3M 70-0201-8754-1Document2 pagesFiltros Cuno 3M 70-0201-8754-1vandoNo ratings yet

- A325 Structural BoltsDocument1 pageA325 Structural Boltsbayu_sukmaperdanaNo ratings yet

- PROCO Flexible JointsDocument4 pagesPROCO Flexible Jointsaverois ibn roisNo ratings yet

- Hamerlug Unions (Anson)Document15 pagesHamerlug Unions (Anson)Leonardo ViannaNo ratings yet

- pipe-clamps-section-from-pipe-hanger-catalogsDocument36 pagespipe-clamps-section-from-pipe-hanger-catalogsAndrew JacksonNo ratings yet

- Numero de Partes de Todos Los YenkosDocument1 pageNumero de Partes de Todos Los YenkosJose Antonio AcostaNo ratings yet

- 491 TechdataDocument11 pages491 Techdatahugo.vicenteNo ratings yet

- Clamps ColorDocument19 pagesClamps ColorGerson SuarezNo ratings yet

- EstiloDocument2 pagesEstiloJosé EnriqueNo ratings yet

- A Guide To The Use of Steel SlagDocument35 pagesA Guide To The Use of Steel SlagGreissy Margory Reynaga CalderonNo ratings yet

- Dresser 38 - 2Document3 pagesDresser 38 - 2Garcia Rodriguez Omar danielNo ratings yet

- WTI UK Screw Thread Inserts and Kits CatalogueDocument16 pagesWTI UK Screw Thread Inserts and Kits CatalogueThor InternationalNo ratings yet

- Turnbuckles: Vanguard Steel LTDDocument9 pagesTurnbuckles: Vanguard Steel LTDJeanne DangNo ratings yet

- Hub Myers de 3-4Document5 pagesHub Myers de 3-4pruebaprueba1No ratings yet

- Engine Mounting 580dDocument2 pagesEngine Mounting 580dJESUS0% (1)

- Helium SLA Disc 7E1 Passport 2017 PDFDocument8 pagesHelium SLA Disc 7E1 Passport 2017 PDFPieter Baobab BoomNo ratings yet

- Build Master PricelistDocument2 pagesBuild Master PricelistAngel TeshiNo ratings yet

- Pipe Schedule and Thickness RevisedDocument4 pagesPipe Schedule and Thickness Revisedrajaram100% (1)

- NEW Electroweld Pricelist - APR 25 2022Document7 pagesNEW Electroweld Pricelist - APR 25 2022ernst gencayaNo ratings yet

- Ca3v 4Document119 pagesCa3v 4Ayub Anwar M-SalihNo ratings yet

- MKT 001 Rev 02 Rotary Shoulder Handbook RS PDFDocument116 pagesMKT 001 Rev 02 Rotary Shoulder Handbook RS PDFKarla Hernandez0% (1)

- Selectrode: 317L Flux Coated TigDocument3 pagesSelectrode: 317L Flux Coated TigUta GilangNo ratings yet

- SVF 522F Data Sheet-2020Document1 pageSVF 522F Data Sheet-2020Karla FordNo ratings yet

- Calculos Catarinas PDFDocument48 pagesCalculos Catarinas PDFHéctor Rodriguez RubioNo ratings yet

- Weald Motorsport Accessories CatalogueDocument11 pagesWeald Motorsport Accessories Catalogueharold.busNo ratings yet

- Tank-Accessories HandholeDocument7 pagesTank-Accessories HandholeAsep DarojatNo ratings yet

- Samsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsFrom EverandSamsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsRating: 1 out of 5 stars1/5 (1)

- Manual Soldadura en CampoDocument32 pagesManual Soldadura en Campoll vvNo ratings yet

- Catalogo Posicionadores de Soldadura Koike ArnsonDocument40 pagesCatalogo Posicionadores de Soldadura Koike Arnsonll vvNo ratings yet

- MSA Example WorkbookDocument41 pagesMSA Example Workbookll vvNo ratings yet

- MSA-Attribute GR R FORMATDocument17 pagesMSA-Attribute GR R FORMATll vvNo ratings yet

- LinearityDocument4 pagesLinearityll vvNo ratings yet

- Sigma Calc GRAPHICS DMPODocument2 pagesSigma Calc GRAPHICS DMPOll vvNo ratings yet

- Thread Turning ToolsDocument22 pagesThread Turning ToolsАндрейNo ratings yet

- General Hss End Mills Yg1Document60 pagesGeneral Hss End Mills Yg1bayuwiroNo ratings yet

- Stainless Steel International StandardsDocument3 pagesStainless Steel International StandardsAmir MusaibNo ratings yet

- Mar 18 AvlDocument1 pageMar 18 AvlBala KrishnanNo ratings yet

- Titan Ys-61Document2 pagesTitan Ys-61JUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Pipe Material ASTM CodesDocument2 pagesPipe Material ASTM CodesShreekanthKannathNo ratings yet

- Ferrous Alloys Stainless SteelsDocument41 pagesFerrous Alloys Stainless SteelsSumedh SinghNo ratings yet

- List of Copper Alloys - WikipediaDocument1 pageList of Copper Alloys - WikipediaMarcel KuhneNo ratings yet

- Classification of Different Welding Processes With PDFDocument4 pagesClassification of Different Welding Processes With PDFMadhu NNo ratings yet

- Rab Rehab Kantor Agama KonutDocument14 pagesRab Rehab Kantor Agama KonutLa Ode Muhamad SalehNo ratings yet

- 6063 Aluminium Alloy - WikipediaDocument3 pages6063 Aluminium Alloy - WikipediaNinad PawarNo ratings yet

- Visual Report For PF POSITIONDocument33 pagesVisual Report For PF POSITIONKyNo ratings yet

- Phase Transformation 12Document20 pagesPhase Transformation 12Guilherme Dos Santos MoreiraNo ratings yet

- ASTMDocument23 pagesASTMchiragpatel6650% (1)

- Steelgrades 2Document6 pagesSteelgrades 2dexterisNo ratings yet

- Materials Selection Assignment. LiveDocument10 pagesMaterials Selection Assignment. Liverichward5No ratings yet

- Yc Inox Co., LTD.: Inspection CertificateDocument1 pageYc Inox Co., LTD.: Inspection CertificateMuneer KonajeNo ratings yet

- Welding Consumables For Cast SteelDocument4 pagesWelding Consumables For Cast Steelmehul20110% (1)

- Material Groups PDFDocument3 pagesMaterial Groups PDFAnonymous B1AOOsmRMiNo ratings yet

- Eglin SteelDocument3 pagesEglin SteelShaun LeeNo ratings yet

- Material With Electrode SelectionDocument3 pagesMaterial With Electrode SelectionpmkarNo ratings yet

- Astm A530Document2 pagesAstm A530Thiruvengadam75% (4)

- Prevention of Vibration With Irregular Helix Flutes.: B133E VFMHV VFMHVRB VFJHV Vf6Mhv Vf6MhvrbDocument12 pagesPrevention of Vibration With Irregular Helix Flutes.: B133E VFMHV VFMHVRB VFJHV Vf6Mhv Vf6MhvrbNAHRUDIN KOLIĆNo ratings yet

- Pengelasan - 2 - Materials - 1Document82 pagesPengelasan - 2 - Materials - 1Reza Rachman DarmawanNo ratings yet

- AESW016Document10 pagesAESW016aslam.ambNo ratings yet

- Valve Material TypesDocument3 pagesValve Material TypesimanadbNo ratings yet

- Material Spec Chart 1Document1 pageMaterial Spec Chart 1mr.dennis73No ratings yet

- ASTM F568M (General Engineering Application)Document1 pageASTM F568M (General Engineering Application)Stephen Rey CaldeaNo ratings yet

- Monel Alloy 400 UNS N04400 Round Bar Stockiest, Suppliers & Exporters in IndiaDocument3 pagesMonel Alloy 400 UNS N04400 Round Bar Stockiest, Suppliers & Exporters in IndiaOZAIRTRADELINKNo ratings yet

- ElectrodosDocument14 pagesElectrodosanon-635614100% (6)