Professional Documents

Culture Documents

روولور 2

روولور 2

Uploaded by

abbasnjjarkhatirkolai57Copyright:

Available Formats

You might also like

- US5421114 DerringerDocument12 pagesUS5421114 Derringeruntersberg92% (12)

- Browning BLR Pre 81 Field Service ManualDocument11 pagesBrowning BLR Pre 81 Field Service ManualEric ReedNo ratings yet

- Hydraulic System of DozerDocument5 pagesHydraulic System of DozerYe' Naing0% (1)

- Yarn ManufacturerersDocument31 pagesYarn ManufacturerersMarufNo ratings yet

- Konecranes SMV37 52 GC Top Lift Container Handler BrochureDocument24 pagesKonecranes SMV37 52 GC Top Lift Container Handler BrochureCardoso MalacaoNo ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- United States Patent (19) : HoenigDocument5 pagesUnited States Patent (19) : HoenigminiselNo ratings yet

- United States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashDocument7 pagesUnited States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashSandeep SNo ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

- Rat Hole DiggerDocument4 pagesRat Hole DiggerDarshan MakwanaNo ratings yet

- Us 2345069Document4 pagesUs 234506916f628aNo ratings yet

- 24% Zevery A. Aeger.: H. F. Wheeler Patented June 17, 1890Document4 pages24% Zevery A. Aeger.: H. F. Wheeler Patented June 17, 1890Слэйтер Строительная компанияNo ratings yet

- Us804694 PDFDocument9 pagesUs804694 PDFZelenyNo ratings yet

- Dec. 1, 1953 C, B, Spase 2,661,086: Friction Clutch With Lever Fulcrum Ring AssemblyDocument4 pagesDec. 1, 1953 C, B, Spase 2,661,086: Friction Clutch With Lever Fulcrum Ring AssemblyPrihastya WishnutamaNo ratings yet

- US36505Document5 pagesUS36505ReggieNo ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- United States Patent (19) : ReinschreiberDocument6 pagesUnited States Patent (19) : ReinschreiberBarmak CheraghiNo ratings yet

- Mannlicher Us975256Document3 pagesMannlicher Us975256cll1968No ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- Us 3722358Document9 pagesUs 3722358awe234No ratings yet

- US712730Document5 pagesUS712730director.note.okNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- Remington Rolling Block Patent US2962016Document5 pagesRemington Rolling Block Patent US2962016Marcelo Pizzuti PesNo ratings yet

- United States Patent (16) Patent N6. US 6,564,491 B2Document5 pagesUnited States Patent (16) Patent N6. US 6,564,491 B2edef345No ratings yet

- Patented May 29, 1894.: A, BurgessDocument5 pagesPatented May 29, 1894.: A, BurgessСлэйтер Строительная компанияNo ratings yet

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Document7 pages??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- Pistol Nickl Us1427966Document11 pagesPistol Nickl Us1427966cll1968No ratings yet

- J. M. Browning.: No. 580,924, Patented Apr. 20, 1897Document9 pagesJ. M. Browning.: No. 580,924, Patented Apr. 20, 1897Слэйтер Строительная компанияNo ratings yet

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- Us 4689908Document6 pagesUs 4689908djsfNo ratings yet

- United States Patent (191: Sanford (45) Dec. 25, 1973Document13 pagesUnited States Patent (191: Sanford (45) Dec. 25, 1973vadimNo ratings yet

- WU. W I M : July 2, 1946-F. Sampson Ei'Al I 2,403,306Document4 pagesWU. W I M : July 2, 1946-F. Sampson Ei'Al I 2,403,306KurtNo ratings yet

- Benelli B76 US3893369Document4 pagesBenelli B76 US3893369apoorva singhNo ratings yet

- 1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieDocument3 pages1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieVincent Grangé-PradérasNo ratings yet

- Firing Mechanism For A RevolverDocument9 pagesFiring Mechanism For A RevolverjonybravominiNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Cetme: Special Purpose Assault MACHINEGUN 5.56x45Document24 pagesCetme: Special Purpose Assault MACHINEGUN 5.56x45Jon MorenoNo ratings yet

- Us 1454454Document3 pagesUs 1454454dfdfsdNo ratings yet

- Brief Description of The: Semi-Automatic RifleDocument53 pagesBrief Description of The: Semi-Automatic Riflejustin_j_gaudet100% (1)

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- US4648190 Single Shot Falling Block ActionDocument6 pagesUS4648190 Single Shot Falling Block ActionE MakinenNo ratings yet

- ' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sDocument4 pages' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sЮрий РуденкоNo ratings yet

- US Patent 3884090Document5 pagesUS Patent 3884090sthollanderNo ratings yet

- Ruger Mark IDocument7 pagesRuger Mark IAdam OrionNo ratings yet

- United States Patent (19) : Hood Et Al.Document5 pagesUnited States Patent (19) : Hood Et Al.8787No ratings yet

- Us 5540394Document10 pagesUs 5540394estramilsolutionNo ratings yet

- Us 3045556Document7 pagesUs 3045556director.note.okNo ratings yet

- United States Patent (19) : VicardDocument4 pagesUnited States Patent (19) : Vicard155100% (1)

- First: United States PatentDocument7 pagesFirst: United States Patentyraju88No ratings yet

- Patented Dec. I7, I90".: ' WH NesseszDocument3 pagesPatented Dec. I7, I90".: ' WH NesseszPayal MinochaNo ratings yet

- SU Carburatores - LandRoverDocument24 pagesSU Carburatores - LandRoverChevronelleNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- The Auburndale Watch Company: First American Attempt Toward the Dollar WatchFrom EverandThe Auburndale Watch Company: First American Attempt Toward the Dollar WatchNo ratings yet

- B2 Listening 11Document1 pageB2 Listening 11Juan MiguelNo ratings yet

- Training-Coating Machine OperationDocument12 pagesTraining-Coating Machine Operationraju1559405No ratings yet

- Tips and Tricks Motivation LetterDocument5 pagesTips and Tricks Motivation LetterTousif RahmanNo ratings yet

- Polymers 15 01581Document24 pagesPolymers 15 01581Tehreem IshtiaqNo ratings yet

- VaughanDocument16 pagesVaughanMalik RizwanNo ratings yet

- 2010 Lighting and Electrical CatalogDocument90 pages2010 Lighting and Electrical CatalogTravis Erwin100% (1)

- Sri VidyameditationDocument24 pagesSri VidyameditationClaudia ShanNo ratings yet

- CMC Development Project Management in Boston MA Resume Gary LavineDocument4 pagesCMC Development Project Management in Boston MA Resume Gary LavineGaryLavine2No ratings yet

- CDU BIOCHEMISTRY Structure of Triacylglycerols WorksheetDocument2 pagesCDU BIOCHEMISTRY Structure of Triacylglycerols WorksheetKrisha Mae VillanuevaNo ratings yet

- Christian SongsDocument12 pagesChristian Songsmarie crisNo ratings yet

- Engine Control Toyota Cuiser 2007 - 1GR - FeDocument6 pagesEngine Control Toyota Cuiser 2007 - 1GR - Fe35.Hoàng Xuân TânNo ratings yet

- PUMA 11 e ManualDocument10 pagesPUMA 11 e ManualJarlath2010No ratings yet

- 6.775 Midterm Project 65nm CMOS Op Amp Design: Monroe@mit - EduDocument21 pages6.775 Midterm Project 65nm CMOS Op Amp Design: Monroe@mit - EduAc Logic GP1No ratings yet

- Analog Circuits II Lab ManualDocument47 pagesAnalog Circuits II Lab ManualParesh SawantNo ratings yet

- Copy of Tabel Excel CaloriiDocument185 pagesCopy of Tabel Excel CaloriibogziNo ratings yet

- The Wedding Dance 2Document16 pagesThe Wedding Dance 2JojhelNo ratings yet

- Wild Magic Extended ListDocument6 pagesWild Magic Extended ListbeepboopbotNo ratings yet

- Staining Techniques in Biological StudiesDocument52 pagesStaining Techniques in Biological StudiesRamyaAbhishekShenoyNo ratings yet

- Sis - SSM Price List Yarn For The Month of Feb 2024 Upto 15.02.2024Document1 pageSis - SSM Price List Yarn For The Month of Feb 2024 Upto 15.02.2024GOWRIJEYASHANKAR S KNo ratings yet

- Timber Code Check Theory Enu PDFDocument34 pagesTimber Code Check Theory Enu PDFjcvalenciaNo ratings yet

- Udaipur WikiDocument19 pagesUdaipur Wikipiyush jainNo ratings yet

- Cummins C25 C30 C35 C40 Spec SheetDocument5 pagesCummins C25 C30 C35 C40 Spec Sheetkillers201493No ratings yet

- BMS Sequence of Operation SOO For HVAC SystemDocument4 pagesBMS Sequence of Operation SOO For HVAC SystemDong VanraNo ratings yet

- Man As A Geologic Agent - Sherlock - 1922Document404 pagesMan As A Geologic Agent - Sherlock - 1922geoecologistNo ratings yet

- Equipment Maintenance Log Template 03Document2 pagesEquipment Maintenance Log Template 03Thoni LacknerNo ratings yet

- PDF Automatic Transmissions and Transaxles 7Th Edition James D Halderman Ebook Full ChapterDocument53 pagesPDF Automatic Transmissions and Transaxles 7Th Edition James D Halderman Ebook Full Chapterevon.gaskins482100% (3)

- Manual Reductor SumitomoDocument11 pagesManual Reductor SumitomoPhilip WalkerNo ratings yet

- OSHA 1926 Subpart M App C - Personal Fall Arrest Systems - Non-Mandatory Guidelines For Complying With 1926.502 (D)Document8 pagesOSHA 1926 Subpart M App C - Personal Fall Arrest Systems - Non-Mandatory Guidelines For Complying With 1926.502 (D)Gunnie PandherNo ratings yet

روولور 2

روولور 2

Uploaded by

abbasnjjarkhatirkolai57Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

روولور 2

روولور 2

Uploaded by

abbasnjjarkhatirkolai57Copyright:

Available Formats

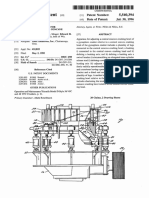

United States Patent [191 [11] 4,024,663

Baker [45] May 24, 1977

[54] CYLINDER LOCK FOR REVOLVERS [57] ‘ ABSTRACT

[76] Inventor: Wayne B. Baker, PO. Box 188, A cylinder lock for a revolver adapted to be positioned

Freedom, Idaho 83120 - entirely within the body of the revolver to release the

cylinder during cocking of the revolver hammer and to

[22] Filed: Aug. 18, 1975 lock the cylinder against turning during ?ring of the

[21] Appl. No.: 605,669 revolver and when the hammer is in a forward position.

A locking bar has a cylinder engaging lug on one end

[52] US. Cl. ................................................. .. 42/67 and is pivotally connected adjacent its other end to the

[51] Int. Cl.2 ......................................... .. F41C 1/00 frame handle of the revolver. A spring loaded pin car

[58] Field of Search ................................ .. 42/67, 65 ried by the hammer moves the locking bar such that the

[56] References Cited lug is moved out of a notch provided therefor in the

cylinder to allow rotation of the cylinder and the pin is

UNITED STATES PATENTS then moved into an enlarged notch on the locking bar

161,615 4/1875 Hood ................................... .. 42/67 and is cammed into the hammer to allow the lug of the

336,894 3/1886 Cilley .... _. 42/67 bar to be biased by a spring at the other end of the bar

650,931 6/1900 Ehbets et al. . ..... .. 42/67 into position in a new notch of the cylinder. After the

2,733,529 2/1956 Ruger .......... ._... . . . . .. 42/67 trigger is pulled the pin is biased from the hammer to

3,187,454 6/1965 Geber ..... .. 42/67 again be in position to move the locking bar.

3,831,305 8/1974 Casull .................................. .. 42/67

Primary Examiner—Charles T. Jordan

Attorney, Agent, or Firm—B. Deon Criddle 5 Claims, 6 Drawing Figures

US. atent May 24, 1977 4,024,63

1

4,024,663 2

CYLINDER LOCK FOR REVOLVERS THE DRAWING

In the drawings:

FIELD OF THE INVENTION FIG. 1 is a perspective view of a small revolver incor

This invention relates to ?rearms and more 'particu- 5 poratin'g the cylinder lock of the invention;

larly to revolvers and means for locking and releasing FIG. 2, a side elevation view of the revolver of FIG.

the rotating cylinders of such revolvers. I, with a side plate removed to show interior compo

PRIOR ART .

nents;

FIG. 3, a view of the locking bar of the cylinder lock,

Revolvers of various size and shapes have been well turned to show the opposite side of the locking bar and

known for more than a hundred years. In almost all the camming notch;

such weapons there is provided some means for se FIG. 4, an enlarged, fragmentary, sectional view of

quentially locking the rotatable cylinder in which car the pin carried by the hammer and the locking bar, take

tridges are placed such that the cartidges are properly on the line 4-4 of FIG. 2;

positioned to be contacted and fired by a hammer of 15 FIG. 5, a fragmentary view of the revolver frame and

the revolver. With large size hand guns the cylinder handle, with the locking bar removed so that the trigger

lock can be rather easily accommodated and various and hammer can be viewed, with the hammer in a

cams or levers can be used to move it during the times safety position; and .

the cylinder must be free to revolve. In smaller sized FIG. 6, a view like that in FIG. 5, but with the ham

revolvers it is often dif?cult to properly position all of 20 mer in a cocked position.

the actuating components and the component sizes

must often be greatly reduced. This size reduction DETAILED DESCRIPTION

often results in a weakening of compnents and early Referring now to the drawing:

failure of the weapon.

25 In the illustrated preferred embodiment a revolver,

BRIEF DESCRIPTION OF THE INVENTION shown generally at 10 has the usual frame 11, with a

Principal objects of the present invention are to pro barrel 12 and handle 13. A cylinder 14 is mounted in

vide a spring biased cylinder lock that can be used even frame 11 and is held in place by a cylinder lock pin 15

with very small sized revolvers and that will be oper that also serves as an axis about which the cylinder

ated by a single spring biased pin carried by the ham 30 revolves. A trigger 16 is pivotally mounted by a pin 17

mer of the revolver. Another object is to provide a to the frame 11 and a spring 18 that is partially recessed

cylinder lock that can be mounted closely adjacent the in the frame engages the trigger to bias it to a forward

frame of the revolver so that it can be as large as possi position.

ble, thereby having the necessary strength to insure A hammer 19 is pivotally mounted to the frame 11 by

continuing operation and long use. .35 a pivot pin 20. The hammer includes a thumb projec

Still other objects of the invention are to provide a tion 19a to be used in pivoting the hammer to a cocked

biasing means for the locking bar that does not require position, a striker 19b that engages a cartridge placed

space therefor closely adjacent to the cylinder, but that in the cylinder, a notch 190 to engage one end of a ?at

will tend to force the lug into cylinder engagement, and spring 21, the other end of which is anchored in handle

to provide operating means carried by the hammer for 40 13 at 22. A spring engaging ?nger 19d engages spring

moving the lug away from the cylinder and not requir 21 to de?ect it and to insure a rapid and positive for

ing links, levers, etc. in the operation thereof. wardpivoting of the hammer when the hammer is re

Principal features of the invention include a locking leased from its fully cocked position, as shown in FIG.

bar having a locking lug on one end thereof to engage 6. A safety notch 19e and a latch shoulder 19f are

notches provided therefor in usual fashion on the out 45 arranged to be sequentially engaged by a ?nger 16a on

side of a revolver cylinder; a camming notch and a trigger 16 to hold the hammer in a safety position and

pivot connection formed intermediate the length of a fully cocked position, respectively.

the locking bar; and a spring receiving hole in the end A hair spring 23, positioned in a recessed portion 19g

of the locking bar opposite the locking lug. of hammer 19 is tensioned around the pivot pin 20 and

A spring biased pin carried by the revolver hammer 50 has one end anchored in a slot 19h provided therefor in

pivots the locking bar to release the locking lug from the hammer. The other end of the spring 23 engages a

the cylinder notches and moves into the camming pawl 24 that is connected to the hammer by a pivot pin

notch such that the lug can move back into engagement 25. As is well known, the pawl engages radially posi

with a notch on the cylinder when the hammer is fully tioned cams on the cylinder 14 to partially rotate the

cocked. As the pin moves into the camming notch it is 55 cylinder upon cocking of the hammer.

forced into the hammer, against the bias of a spring. _ The mechanism heretofore described, including the

Pulling of the trigger releases the hammer to allow it to I revolver frame, handle, barrel, cylinder, cylinder lock

pivot forward whereupon it will strike and ?re a car ing pin, the means for operating the cylinder in re

tridge properly positioned in the cylinder. Such move sponse to cocking of the hammer, the hammer operat

ment of the hammer is permitted by .the locking bar, 60 ing spring and the trigger assembly are all well known

since the pin carried by the hammer remains in the and do not, per se, constitute part of the present inven

hammer until it can spring out after moving to a posi tion. Similarly, the notches 27 spaced around the cylin

tion above the bar, to thereby be in position to engage der 14 to provide means for locking the cylinder in

the top of the locking bar during a subsequent rearward position as it is sequentially rotated are well known.

pivoting of the hammer. 65 In the present invention, a locking bar, shown gener

Additional objects and features of the invention will ally at 30 has a locking lug 31 projecting from one end

become apparent from the following detailed descrip and adapted to ?t into the notches 27. The locking bar

tion, taken together with the accompanying drawing. is of generally elongate construction, although it may

4,024,663 4

3

have a hump 32 therein to allow it to clear the pivot pin With the cylinder lock shown and described, the

17 for the trigger, and may be curved to conform to the locking bar can be made of relatively large stock, capa

revolver frame con?guration and to provide a boss ble of withstanding long and arduous usage and neither

through which a hole 33 (FIG. 3) may be formed. As the locking bar or its biasing spring take up space

shown in FIG. 2, a pin 34 inserted through frame mem within the frame that is required for other components.

bers and hole 33 serves as a pivot shaft for the locking In addition, the single spring biased pin 39, replaces

bar. A curved spring 35 has one end inserted into the various links, arms and cams common to previously

end of the locking bar opposite to the locking lug and known revolvers.

its other end extending past the spring 21 and abutting Although a preferred embodiment of my invention

the lower inside of the handle 13 of frame 11. So ar has been herein disclosed, it is to be understood that

ranged, the spring acts on the end of the locking bar to the present disclosure is made by way of example and

which it is attached to bias that end down and the look that variations are possible without departing from the

ing lug up into engagement with the cylinder 14. subject matter coming within the scope of the following

A camming notch 36 (FIGS. 3 and 4) is formed on claims, which subject matter I regard as my invention.

the inside of the locking bar 30 and the notch is formed I claim: '

to extend deeply into the locking bar at the top 36a 1. A cylinder lock for revolvers having a frame in

thereof and then is inclined towards the locking lug and cluding a handle and a barrel, a rotatable cylinder piv

out to the inner face of the bar at the bottom 36b otally mounted in the frame, said cylinder having

thereof. spaced notches formed therearound and a spring bi

Hammer 19 has a bore 37 extending therethrough, 20 ased hammer pivotally mounted to the frame, and

and a large counterbore 38 to receive the head of a pin means carried by the hammer and the cylinder,

39 that extends through the bore 37. A spring 40 is whereby the cylinder is partially rotated each time the

positioned witin the counterbore 38 and is held therein hammer is cocked, said cylinder lock comprising

by engagement with the frame 11 when the hammer is a locking bar;

pivotally mounted to the frame. When the hammer is in 25 means for pivotally mounting the locking bar to the

frame; _

its fully forward or ?ring position the pin 39 extends

from the hammer above the locking bar 30. Pivoting of a locking lug carried by said locking bar and adapted

to extend into the notches of the cylinder;

the hammer to a cocked position then slides the pin 39

means biasing the locking bar such that the locking

along the locking bar and forces the locking bar down, 30 lug is biased into said notches; a camming notch

thereby moving the locking lug 31 from a notch 27. At carried by one face of the locking bar; '

the same time, the pivoting of the hammer will rotate pin means including a pin carried by and projecting

the cylinder to place a new chamber beneath the ham from the hammer, said pin pivoting the locking bar

mer when the hammer is ?red. downwardly before moving into the camming

Just before the pivoting hammer reaches its fully 35 > notch and being forced into the hammer upon

cocked position the pin 39 moves into the camming pivoting of the hammer to a cocked position,

notch 36 at which time the locking bar is again biased whereby the locking bar is pivotable upwardly to

up by spring 35. As the locking bar moves up it forces move the locking lug into a cylinder notch; and

the pin 39 (which is in the camming notch) into a re means biasing said pin to project from the hammer

tracted position in the hammer 19, against the bias of 40 and over the locking bar when the hammer is in a

spring 40. The pin 39 is held in this retracted position forward ?ring position.

by its engagement with the inside face of the locking 2. A cylinder lock as in claim 1, wherein the locking

bar and the cylinder is locked by the locking lug carried bar is pivotally mounted to the frame handle.

by the locking bar engaging a notch 27. 3. A cylinder lock as in claim 2, wherein the means

When the hammer is released, by pulling on trigger 45 biasing the locking bar comprises a curved spring hav

16, thereby releasing shoulder 19f of the hammer from ing one end extending into the locking bar at a side of

?nger 16a of the trigger, spring 21 biases the hammer the pivot mounting of the locking bar opposite to the

forward to its ?ring position. Striking of a cartridge in locking lug and the other end in engagement with th

cylinder 14 by striker 19b of the forward moving ham frame handle. ‘

mer will then ?re the cartridge, in well known fashion. 50 4. A cylinder lock as in claim 3, wherein the means

As the hammer moves into its ?ring position the spring biasing the pin to project from the hammer comprises

biased pin 39 moves clear of the locking bar and is a spring positioned in a counterbore of the hammer

biased by spring 40 to its position extending over the and having one end engaging the pin and the other

locking bar. ' end engaging the frame.

As the hammer 19 is pivoted to its fully cocked‘ posi 55 5. A cylinder lock for revolvers having a frame in

tion wherein shoulder 19f is engaged by ?nger 16a of cluding a handle and a barrel, a cylinder rotataby

the trigger it ?rst passes a safety position wherein the mounted in the frame, said cylinder having spaced

notch 19e is engaged by the ?nger 16a. In this safety notches formed therearound and a spring biased ham

position the pin 39 is still above the locking bar, the mer pivotally mounted to the frame, and means carried

locking bar is pivoted downwardly slightly but the lock by the hammer and the cylinder, whereby the cylinder

ing lug has not cleared the notches 27. Because of the is partially rotated each time the hammer is cocked,

depth and angle of safety notch 19e it is necessary that said cylinder lock comprising

the hammer be pivoted to move the notch past ?nger a locking bar having a camming notch in one face

16a and then be reversely pivoted to move the ?nger thereof;

into the notch. When the ?nger is in the notch the 65 means for pivotally mounting the locking bar to the

trigger 16 cannot be pivoted and the gun is in a safe frame handle;

condition. Such a safety arrangement is well known and a locking lug carried by said locking bar and adapted

does not constitute part of the present invention. to extend into the notches of the cylinder;

5

4,024,663 6

a pin carried by and projecting from the hammer,

means biasing the locking bar such that the locking said pin being moved into the camming notch upon

lug is biased into said notches, said means biasing pivoting of the hammer to a cocked position; and

means biasing said pin to project from the hammer

the locking bar comprising a curved spring having and beyond a face of the locking bar when the

one end ?xed to the locking bar opposite at a side

hammer is in a forward ?ring position, said means

biasing said pin comprising a spring positioned in a

of the pivot mounting of the locking bar to the counterbore of the hammer and having one end

engaging the pin and the other end engaging the

locking lug and the other end in engagement with frame.

* * * * *

the frame handle;

15

20

25

30

35

40

50

55

65

You might also like

- US5421114 DerringerDocument12 pagesUS5421114 Derringeruntersberg92% (12)

- Browning BLR Pre 81 Field Service ManualDocument11 pagesBrowning BLR Pre 81 Field Service ManualEric ReedNo ratings yet

- Hydraulic System of DozerDocument5 pagesHydraulic System of DozerYe' Naing0% (1)

- Yarn ManufacturerersDocument31 pagesYarn ManufacturerersMarufNo ratings yet

- Konecranes SMV37 52 GC Top Lift Container Handler BrochureDocument24 pagesKonecranes SMV37 52 GC Top Lift Container Handler BrochureCardoso MalacaoNo ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- United States Patent (19) : HoenigDocument5 pagesUnited States Patent (19) : HoenigminiselNo ratings yet

- United States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashDocument7 pagesUnited States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashSandeep SNo ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

- Rat Hole DiggerDocument4 pagesRat Hole DiggerDarshan MakwanaNo ratings yet

- Us 2345069Document4 pagesUs 234506916f628aNo ratings yet

- 24% Zevery A. Aeger.: H. F. Wheeler Patented June 17, 1890Document4 pages24% Zevery A. Aeger.: H. F. Wheeler Patented June 17, 1890Слэйтер Строительная компанияNo ratings yet

- Us804694 PDFDocument9 pagesUs804694 PDFZelenyNo ratings yet

- Dec. 1, 1953 C, B, Spase 2,661,086: Friction Clutch With Lever Fulcrum Ring AssemblyDocument4 pagesDec. 1, 1953 C, B, Spase 2,661,086: Friction Clutch With Lever Fulcrum Ring AssemblyPrihastya WishnutamaNo ratings yet

- US36505Document5 pagesUS36505ReggieNo ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- United States Patent (19) : ReinschreiberDocument6 pagesUnited States Patent (19) : ReinschreiberBarmak CheraghiNo ratings yet

- Mannlicher Us975256Document3 pagesMannlicher Us975256cll1968No ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- Us 3722358Document9 pagesUs 3722358awe234No ratings yet

- US712730Document5 pagesUS712730director.note.okNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- United States Patent 1111 3,595,128Document9 pagesUnited States Patent 1111 3,595,128rte678No ratings yet

- Remington Rolling Block Patent US2962016Document5 pagesRemington Rolling Block Patent US2962016Marcelo Pizzuti PesNo ratings yet

- United States Patent (16) Patent N6. US 6,564,491 B2Document5 pagesUnited States Patent (16) Patent N6. US 6,564,491 B2edef345No ratings yet

- Patented May 29, 1894.: A, BurgessDocument5 pagesPatented May 29, 1894.: A, BurgessСлэйтер Строительная компанияNo ratings yet

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Document7 pages??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- Pistol Nickl Us1427966Document11 pagesPistol Nickl Us1427966cll1968No ratings yet

- J. M. Browning.: No. 580,924, Patented Apr. 20, 1897Document9 pagesJ. M. Browning.: No. 580,924, Patented Apr. 20, 1897Слэйтер Строительная компанияNo ratings yet

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- Us 4689908Document6 pagesUs 4689908djsfNo ratings yet

- United States Patent (191: Sanford (45) Dec. 25, 1973Document13 pagesUnited States Patent (191: Sanford (45) Dec. 25, 1973vadimNo ratings yet

- WU. W I M : July 2, 1946-F. Sampson Ei'Al I 2,403,306Document4 pagesWU. W I M : July 2, 1946-F. Sampson Ei'Al I 2,403,306KurtNo ratings yet

- Benelli B76 US3893369Document4 pagesBenelli B76 US3893369apoorva singhNo ratings yet

- 1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieDocument3 pages1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. HorieVincent Grangé-PradérasNo ratings yet

- Firing Mechanism For A RevolverDocument9 pagesFiring Mechanism For A RevolverjonybravominiNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- Us4522106 PDFDocument13 pagesUs4522106 PDFJin Song100% (1)

- Cetme: Special Purpose Assault MACHINEGUN 5.56x45Document24 pagesCetme: Special Purpose Assault MACHINEGUN 5.56x45Jon MorenoNo ratings yet

- Us 1454454Document3 pagesUs 1454454dfdfsdNo ratings yet

- Brief Description of The: Semi-Automatic RifleDocument53 pagesBrief Description of The: Semi-Automatic Riflejustin_j_gaudet100% (1)

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 pagesUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Us965386 PDFDocument6 pagesUs965386 PDFJin SongNo ratings yet

- US4648190 Single Shot Falling Block ActionDocument6 pagesUS4648190 Single Shot Falling Block ActionE MakinenNo ratings yet

- ' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sDocument4 pages' Aug. 5, 1930. B. A. Revelli: Filed April' 22, 192sЮрий РуденкоNo ratings yet

- US Patent 3884090Document5 pagesUS Patent 3884090sthollanderNo ratings yet

- Ruger Mark IDocument7 pagesRuger Mark IAdam OrionNo ratings yet

- United States Patent (19) : Hood Et Al.Document5 pagesUnited States Patent (19) : Hood Et Al.8787No ratings yet

- Us 5540394Document10 pagesUs 5540394estramilsolutionNo ratings yet

- Us 3045556Document7 pagesUs 3045556director.note.okNo ratings yet

- United States Patent (19) : VicardDocument4 pagesUnited States Patent (19) : Vicard155100% (1)

- First: United States PatentDocument7 pagesFirst: United States Patentyraju88No ratings yet

- Patented Dec. I7, I90".: ' WH NesseszDocument3 pagesPatented Dec. I7, I90".: ' WH NesseszPayal MinochaNo ratings yet

- SU Carburatores - LandRoverDocument24 pagesSU Carburatores - LandRoverChevronelleNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- The Auburndale Watch Company: First American Attempt Toward the Dollar WatchFrom EverandThe Auburndale Watch Company: First American Attempt Toward the Dollar WatchNo ratings yet

- B2 Listening 11Document1 pageB2 Listening 11Juan MiguelNo ratings yet

- Training-Coating Machine OperationDocument12 pagesTraining-Coating Machine Operationraju1559405No ratings yet

- Tips and Tricks Motivation LetterDocument5 pagesTips and Tricks Motivation LetterTousif RahmanNo ratings yet

- Polymers 15 01581Document24 pagesPolymers 15 01581Tehreem IshtiaqNo ratings yet

- VaughanDocument16 pagesVaughanMalik RizwanNo ratings yet

- 2010 Lighting and Electrical CatalogDocument90 pages2010 Lighting and Electrical CatalogTravis Erwin100% (1)

- Sri VidyameditationDocument24 pagesSri VidyameditationClaudia ShanNo ratings yet

- CMC Development Project Management in Boston MA Resume Gary LavineDocument4 pagesCMC Development Project Management in Boston MA Resume Gary LavineGaryLavine2No ratings yet

- CDU BIOCHEMISTRY Structure of Triacylglycerols WorksheetDocument2 pagesCDU BIOCHEMISTRY Structure of Triacylglycerols WorksheetKrisha Mae VillanuevaNo ratings yet

- Christian SongsDocument12 pagesChristian Songsmarie crisNo ratings yet

- Engine Control Toyota Cuiser 2007 - 1GR - FeDocument6 pagesEngine Control Toyota Cuiser 2007 - 1GR - Fe35.Hoàng Xuân TânNo ratings yet

- PUMA 11 e ManualDocument10 pagesPUMA 11 e ManualJarlath2010No ratings yet

- 6.775 Midterm Project 65nm CMOS Op Amp Design: Monroe@mit - EduDocument21 pages6.775 Midterm Project 65nm CMOS Op Amp Design: Monroe@mit - EduAc Logic GP1No ratings yet

- Analog Circuits II Lab ManualDocument47 pagesAnalog Circuits II Lab ManualParesh SawantNo ratings yet

- Copy of Tabel Excel CaloriiDocument185 pagesCopy of Tabel Excel CaloriibogziNo ratings yet

- The Wedding Dance 2Document16 pagesThe Wedding Dance 2JojhelNo ratings yet

- Wild Magic Extended ListDocument6 pagesWild Magic Extended ListbeepboopbotNo ratings yet

- Staining Techniques in Biological StudiesDocument52 pagesStaining Techniques in Biological StudiesRamyaAbhishekShenoyNo ratings yet

- Sis - SSM Price List Yarn For The Month of Feb 2024 Upto 15.02.2024Document1 pageSis - SSM Price List Yarn For The Month of Feb 2024 Upto 15.02.2024GOWRIJEYASHANKAR S KNo ratings yet

- Timber Code Check Theory Enu PDFDocument34 pagesTimber Code Check Theory Enu PDFjcvalenciaNo ratings yet

- Udaipur WikiDocument19 pagesUdaipur Wikipiyush jainNo ratings yet

- Cummins C25 C30 C35 C40 Spec SheetDocument5 pagesCummins C25 C30 C35 C40 Spec Sheetkillers201493No ratings yet

- BMS Sequence of Operation SOO For HVAC SystemDocument4 pagesBMS Sequence of Operation SOO For HVAC SystemDong VanraNo ratings yet

- Man As A Geologic Agent - Sherlock - 1922Document404 pagesMan As A Geologic Agent - Sherlock - 1922geoecologistNo ratings yet

- Equipment Maintenance Log Template 03Document2 pagesEquipment Maintenance Log Template 03Thoni LacknerNo ratings yet

- PDF Automatic Transmissions and Transaxles 7Th Edition James D Halderman Ebook Full ChapterDocument53 pagesPDF Automatic Transmissions and Transaxles 7Th Edition James D Halderman Ebook Full Chapterevon.gaskins482100% (3)

- Manual Reductor SumitomoDocument11 pagesManual Reductor SumitomoPhilip WalkerNo ratings yet

- OSHA 1926 Subpart M App C - Personal Fall Arrest Systems - Non-Mandatory Guidelines For Complying With 1926.502 (D)Document8 pagesOSHA 1926 Subpart M App C - Personal Fall Arrest Systems - Non-Mandatory Guidelines For Complying With 1926.502 (D)Gunnie PandherNo ratings yet