Professional Documents

Culture Documents

brochures_ACTI_Sellsheet

brochures_ACTI_Sellsheet

Uploaded by

tane309Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

brochures_ACTI_Sellsheet

brochures_ACTI_Sellsheet

Uploaded by

tane309Copyright:

Available Formats

Aseptic Containment

Isolator (ACTI)

Aseptic Containment Isolator (ACTI)

Intoduction Basic principles

• Esco Aseptic Containment Isolator (ACTI) work in conjunction • Full unidirectional airflow provides superior aseptic work zones.

with advanced material transfer techniques and bio • Safety toughened laminated glass hinges upwards assisted with

decontamination agents providing a 6 log reduction inviable gas springs for batch loading.

contaminants. • Airflow regime runs either in recirculating or full exhaust airflow.

• Esco ACTIs provide standard configurable designs able to adapt full exhaust airflow for fast purging of bio decontamination agent

to various batch sizes and process flows. Through a fully user during aeration period and recirculation option for reduced airflow

selectable operating system, the same Isolator can be setup to taken from the room and exhausted during normal operation and

operate under recirculation or full exhaust airflow and operate during conditioning and decontamination phases

in positive or negative pressure modes, allowing the system • U15 supply and exhaust filters suitable for either toxic or non-

to be multifunctional and cater for all requirements of toxic toxic aseptic materials. Exhaust Filter directly below the isolator

or non-toxic aseptic materials. For toxic materials, the system can be removed & a bypass tube fitted for non-potent material

incorporates safe change filters. applications

Standard Features

• Full unidirectional airflow provides superior aseptic work zones.

• Safety toughened laminated glass hinges upwards assisted with

Airflow Regimes gas springs for batch loading

Room air Filtered air Contaminated air

Exhaust 100% Exhaust 20% Exhaust 0% Exhaust 100%

Room Air 100%

Room Air 20% Room Air 0% Room Air 100%

HPV Return

HPV Supply

Normal Running Normal Running Decontamination Aeration

- Full Exhaust Airflow - Recirculating Airflow - Recirculating Airflow - Full Exhaust Airflow

Aseptic Containment Isolator (ACTI)

General Specifications

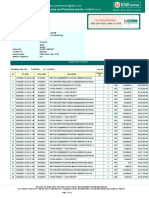

ACTI-2G_ ACTI-3G_ ACTI-4G_

Nominal Size Main 1.2m 1.6m 2.0m

Working Chamber Dimensions 1.2m x 0.75m x 0.85 1.6m x 0.75m x 0.85 2.0m x 0.75m x 0.85

With Adjustable Base Stand (Min) 1.2m x 1.1m x 2.2m 1.6m x 1.1m x 2.2m 2.0m x 1.1m x 2.2m

External Dimensions

(W x D x H)

With Adjustable Base Stand (Max) 1.2m x 0.75m x 2.68m 1.6m x 0.75m x 2.68m 2.0m x 0.75m x 2.68m

Glove Port Height Min 1080 1080 1080

Glove Port Height Max 1360 1360 1360

Chamber Environment ISO Class 5 all Chambers (Grade A)

Filter Type – Isolator Inlet ULPA U15 with Integral mesh guard and knife edge gel seal

Filter Efficiency - Inlet 99.9998% 99.9998% 99.9998%

Filter Type – Isolator Exhaust HEPA H14 with knife edge gel seal

Filter Efficiency - Exhaust 99.997% 99.997% 99.997%

Lighting Level ≥600Lux ≥600Lux ≥600Lux

Sound Level ≤68dBA ≤68dBA ≤68dBA

Chamber 316L 316L 316L

Isolator

Service Housing 316L 316L 316L

Construction

Support Frame 316L 316L 316L

Chamber Internal ≤0.4Ra ≤0.4Ra ≤0.4Ra

Chamber External ≤0.6Ra ≤0.6Ra ≤0.6Ra

Isolator Finish

Service Housing External 0.6Ra 0.6Ra 0.6Ra

Support Frame 1.0Ra 1.0Ra 1.0Ra

220-240V, AC, 50Hz, 1Ø ✓ ✓ ✓

Electrical

Requirements 110-120V, AC, 60Hz, 1Ø ✓ ✓ ✓

(By Client)

220-240V, AC, 60Hz, 1Ø ✓ ✓ ✓

Compressed Air require-

6 Barg Pressure at 5ltr/sec ✓ ✓ ✓

ments (By Client)

Exhaust Duct requirements (By Client) 10” Duct from Isolator to Outside

Pass Chamber ✓ ✓ ✓

Bio-Decontamination Steris ✓ ✓ ✓

Bio-Decontamination Bioquell ✓ ✓ ✓

Non-Viable Air Sampler ✓ ✓ ✓

Viable Air Sampler ✓ ✓ ✓

Sterility Test Pump ✓ ✓ ✓

Options Glove Tester ✓ ✓ ✓

Waste Bag Grommet ✓ ✓ ✓

Sterile Continuous Liner ✓ ✓ ✓ reserves the right to alter its products and specifications without notice. All trademarks and logotypes in this material

Bag-Welder with Table ✓ ✓ ✓

Esco can accept no responsibility for possible errors in catalogues, brochures and other printed materials. Esco

RTP Ø270 - Alpha ✓ ✓ ✓

RTP Ø270 - Beta Canister ✓ ✓ ✓

RTP Ø270 - Beta Liner ✓ ✓ ✓

PLATFORM Esco Pharma Pte Ltd

21 Changi South Street 1 Singapore 486777 • Tel: +65 65420833

SPECIALIST. Fax: +65 65426920 • Email: csis.pharma@escoglobal.com

are the property of Esco and the respective companies.

Esco_Pharma_ACTI_Sellsheet_A4_Feb2016

Esco Technologies, Inc.

1661 Loretta Ave., Feasterville, PA 19053

Tel: 215 322 2155 • Email: eti.pharma@escoglobal.com

Esco Gb Ltd

Unit 9, Century Park Networkcentre, Dearne Lane,

Manvers, Rotherham, South Yorkshire, S63 5DE.

Tel: +44 (0) 1709 761 669 • Email: egb.info@escoglobal.com

escoglobal com

LIVE SUPPORT

. Esco Global Offices: Bahrain | Bangladesh | China | India | Indonesia | Italy | Japan

Malaysia Philippines | Russia | Singapore | South Africa | South Korea | Thailand

PT Esco Bintan Indonesia Esco Micro Pte Ltd PT Esco Bintan Indonesia

United Kingdom | USA Vietnam Cert. No: 651333/E Cert. No: 651076 Cert. No: Q2N130383797001

You might also like

- Ewm Production IntegrationDocument78 pagesEwm Production IntegrationDipak BanerjeeNo ratings yet

- Tirupati Telecom Primary Account Holder Name: Your A/C StatusDocument12 pagesTirupati Telecom Primary Account Holder Name: Your A/C StatusMy PhotosNo ratings yet

- John Carroll University Magazine Spring 2012Document54 pagesJohn Carroll University Magazine Spring 2012johncarrolluniversityNo ratings yet

- New Cytotoxic Drug Safety Cabinets BrochureDocument11 pagesNew Cytotoxic Drug Safety Cabinets BrochureFransiska DewiNo ratings yet

- Basic Principles Airflow Regimes: Weighing and Dispensing Containment Isolators (WDCI) AreDocument2 pagesBasic Principles Airflow Regimes: Weighing and Dispensing Containment Isolators (WDCI) Arejanuar erlanggaNo ratings yet

- Laminar Airflow (Horizontal) PDFDocument2 pagesLaminar Airflow (Horizontal) PDFNeeraj YadavNo ratings yet

- PDFsam - BIOBASE Part 1.1Document68 pagesPDFsam - BIOBASE Part 1.1cuma mencobaNo ratings yet

- Circulaire Filtration Fume Cabinets With VisionaireDocument9 pagesCirculaire Filtration Fume Cabinets With VisionaireAkhmad Rosul RaisNo ratings yet

- Bio-Ecoline Top Air Clase Ii A2 PDFDocument2 pagesBio-Ecoline Top Air Clase Ii A2 PDFIván Riquelme NúñezNo ratings yet

- Sv/Filter-Cg: Air Purifying Units With Uvc Germicidal ChamberDocument6 pagesSv/Filter-Cg: Air Purifying Units With Uvc Germicidal ChamberНиколай ШипочкиNo ratings yet

- Sen Fan Unit 01Document2 pagesSen Fan Unit 01Israel ArceoNo ratings yet

- Sci 4N2 S PDFDocument3 pagesSci 4N2 S PDFArchie PérezNo ratings yet

- Aero Mouse Ivc Green LineDocument4 pagesAero Mouse Ivc Green Lineromaniabulgaria19No ratings yet

- Ourair SQ 1750 Brochure enDocument4 pagesOurair SQ 1750 Brochure enFELIX DOSSNo ratings yet

- Cabinas Flujo Laminar Nüve LN90 LN120Document4 pagesCabinas Flujo Laminar Nüve LN90 LN120hexapodo2No ratings yet

- Built For The Year 2000 and Beyond: Marketing PotentialDocument2 pagesBuilt For The Year 2000 and Beyond: Marketing PotentialAwadhNo ratings yet

- Polypropylene Horizontal PRO Laminar Clean Bench: Advanced Operation SystemDocument2 pagesPolypropylene Horizontal PRO Laminar Clean Bench: Advanced Operation SystemAshiqNo ratings yet

- CABINA Telstar CYTO ULTRADocument4 pagesCABINA Telstar CYTO ULTRAJ VkNo ratings yet

- Data-Sheet PDFDocument4 pagesData-Sheet PDFCarlos ChisanNo ratings yet

- AstroPure 550C Catalogue Rev 1Document3 pagesAstroPure 550C Catalogue Rev 1m.indrajayaNo ratings yet

- Biological Safety Cabinet AC3 Brochure A4 VF LR (ESCO-Isolator)Document4 pagesBiological Safety Cabinet AC3 Brochure A4 VF LR (ESCO-Isolator)hannac20211025No ratings yet

- BSC 1100iia2 X - 4004 37Document7 pagesBSC 1100iia2 X - 4004 37NDNo ratings yet

- Alf Horisontal 2Document4 pagesAlf Horisontal 2Sri Wahyuni HandayaniNo ratings yet

- CatalogueDocument6 pagesCatalogueRakesh RanjanNo ratings yet

- Electrostatic Precipitator: The Principle of Electrostatic PrecipitatorsDocument2 pagesElectrostatic Precipitator: The Principle of Electrostatic PrecipitatorsKumar SauravNo ratings yet

- Cleaning SystemDocument12 pagesCleaning SystemThe GamingspyNo ratings yet

- Compounding Equipment CYT Pharma Brochure A4 VD LRDocument8 pagesCompounding Equipment CYT Pharma Brochure A4 VD LRsukrid.iceNo ratings yet

- Ip Transducers Series 500FCDocument2 pagesIp Transducers Series 500FCRajesh SirsathNo ratings yet

- V Oracle Iq 5876Document4 pagesV Oracle Iq 5876dfNo ratings yet

- Gammacell 1000 SpecsDocument4 pagesGammacell 1000 Specsozama16No ratings yet

- Eco V (HRV)Document8 pagesEco V (HRV)Jake ClooneyNo ratings yet

- Blood Cell Labelling Datasheet ADS1082bDocument2 pagesBlood Cell Labelling Datasheet ADS1082bSHIBIN JAYAKRISHNANNo ratings yet

- Suction AmbulanDocument4 pagesSuction AmbulanariefNo ratings yet

- Laminar Vertical Cabinet: Basic CharacteristicsDocument2 pagesLaminar Vertical Cabinet: Basic CharacteristicsBoris KozjanNo ratings yet

- Fumehood Efa Brochure A4 VC LRDocument12 pagesFumehood Efa Brochure A4 VC LRYusmi NoernithdaNo ratings yet

- AAF Leaflet BioCel VXL AstroCel VXLDocument2 pagesAAF Leaflet BioCel VXL AstroCel VXLsoumya saswatNo ratings yet

- Biological Safety Cabinet - AC2-G3 - Brochure - A4 - VG - LRDocument8 pagesBiological Safety Cabinet - AC2-G3 - Brochure - A4 - VG - LRhüseyin vururNo ratings yet

- Brochure Isolator 17455Document4 pagesBrochure Isolator 174553LA2No ratings yet

- TDS Sfap-0088 - 200420Document1 pageTDS Sfap-0088 - 200420Mochammad SofyanNo ratings yet

- Deep Pleat HepaDocument1 pageDeep Pleat Hepapulakmandal1No ratings yet

- LABLFHDocument10 pagesLABLFHAnaNo ratings yet

- Heraguard ECO Clean Bench BrochureDocument8 pagesHeraguard ECO Clean Bench BrochureDivisión Laboratorio INo ratings yet

- Class II Biosafety Cabinet Catalog BiolabDocument8 pagesClass II Biosafety Cabinet Catalog BiolabVivek HamseNo ratings yet

- Astrocel I: Better Air Is Our BusinessDocument8 pagesAstrocel I: Better Air Is Our BusinessmohdzamryNo ratings yet

- Terminal Heppa FilterDocument8 pagesTerminal Heppa FiltermpwasaNo ratings yet

- Menred Central Vacuum Cleaner&Ventilation ProductsDocument16 pagesMenred Central Vacuum Cleaner&Ventilation ProductsbjainnNo ratings yet

- Vertical Trilobe BlowerDocument2 pagesVertical Trilobe BlowermanoranjanaclcppNo ratings yet

- CW650 Isolation Room DataSheetDocument4 pagesCW650 Isolation Room DataSheetarafatNo ratings yet

- Etelux Lab2000 IoT Super Purification Glove BoxDocument7 pagesEtelux Lab2000 IoT Super Purification Glove BoxGovernment MULENo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor Filtersвлад камрNo ratings yet

- MX 75-98Document2 pagesMX 75-98Compras WConexNo ratings yet

- AAF Product Leaflet AstroFan FFU EN PDFDocument5 pagesAAF Product Leaflet AstroFan FFU EN PDFAlwin WanNo ratings yet

- Ultrasafe AESDocument7 pagesUltrasafe AEShuyNo ratings yet

- BRO Diluter Control A4 enDocument4 pagesBRO Diluter Control A4 enMaria PopescuNo ratings yet

- 2935 0457 12 - ZL - Brochure - ENDocument24 pages2935 0457 12 - ZL - Brochure - ENjteixNo ratings yet

- Cytotoxic Safety Cabinet: The Premium Solution For Cytotoxic Drug ProcessingDocument8 pagesCytotoxic Safety Cabinet: The Premium Solution For Cytotoxic Drug ProcessingsentermerahNo ratings yet

- OilMistSmoke ODR2000Document2 pagesOilMistSmoke ODR2000Mandrak FantomNo ratings yet

- 1.spec PCRDocument13 pages1.spec PCRanna12071986No ratings yet

- image20IX BrochureDocument4 pagesimage20IX BrochureRobson VianaNo ratings yet

- Visiclear: Surgical Smoke EvacuatorDocument2 pagesVisiclear: Surgical Smoke EvacuatorsayedNo ratings yet

- AD Oracle: The Complete, Global Solution For High-Performance Laser Fume ExtractionDocument4 pagesAD Oracle: The Complete, Global Solution For High-Performance Laser Fume Extractionഎസ്സാർപി ഊരുചുറ്റൽ തുടരുന്നുNo ratings yet

- Adaptive Filter: Enhancing Computer Vision Through Adaptive FilteringFrom EverandAdaptive Filter: Enhancing Computer Vision Through Adaptive FilteringNo ratings yet

- 9010318_ASC Storage Cabinet_Brochure_A4_vD_LR_newDocument12 pages9010318_ASC Storage Cabinet_Brochure_A4_vD_LR_newtane309No ratings yet

- Esco_GPPI Brochure_A4_vA_LR_9010638Document12 pagesEsco_GPPI Brochure_A4_vA_LR_9010638tane309No ratings yet

- DPB-DFLHBrochure A4_vC_LRDocument4 pagesDPB-DFLHBrochure A4_vC_LRtane309No ratings yet

- Biopass_Sellsheet_A4_vA_LR_1590021222Document4 pagesBiopass_Sellsheet_A4_vA_LR_1590021222tane309No ratings yet

- Suppliers Assessment ChecklistDocument3 pagesSuppliers Assessment ChecklistRonnel LeanoNo ratings yet

- Schaefer Martin 2018 The Semantic Transparency of English Compound NounsDocument423 pagesSchaefer Martin 2018 The Semantic Transparency of English Compound NounsRania MohammedNo ratings yet

- What Is Pesonet?: Frequently Asked Questions OnDocument4 pagesWhat Is Pesonet?: Frequently Asked Questions OnJackNo ratings yet

- Passage 2 For Grade 6Document3 pagesPassage 2 For Grade 6Irish Joy CachaperoNo ratings yet

- Ysb 8Document2 pagesYsb 8Marek PiznalNo ratings yet

- UNIT I - Introduction To ManagementDocument37 pagesUNIT I - Introduction To ManagementPretentious PMRNo ratings yet

- Checklist of RS WallDocument2 pagesChecklist of RS WallGDRPL NHAINo ratings yet

- Coronel, Kent Kenji B. Sts Final Exam Sat 4-7pmDocument7 pagesCoronel, Kent Kenji B. Sts Final Exam Sat 4-7pmKent CoronelNo ratings yet

- Why The Giant Sleeps So Deeply - Political Consequences of Individual-Level Latino DemographicsDocument23 pagesWhy The Giant Sleeps So Deeply - Political Consequences of Individual-Level Latino DemographicsTyler SmithNo ratings yet

- A Astronom As EsDocument40 pagesA Astronom As EsareianoarNo ratings yet

- Presented By-Anshul Kumbhare Siddhant Mhatre: Boiler AccessoriesDocument10 pagesPresented By-Anshul Kumbhare Siddhant Mhatre: Boiler AccessoriesHarshvardhan Singh ChauhanNo ratings yet

- Radiator - Assemble: Previous ScreenDocument8 pagesRadiator - Assemble: Previous ScreenKusuma JayaNo ratings yet

- Technical Guidelines: Physical Properties of Refrigerants R-410ADocument2 pagesTechnical Guidelines: Physical Properties of Refrigerants R-410AYaxmine Edward StylesNo ratings yet

- A. B. 0.99 M /KG 0.79 M /KG 0.89 M /KG 0.69m /KGDocument143 pagesA. B. 0.99 M /KG 0.79 M /KG 0.89 M /KG 0.69m /KGRyan Togonon100% (1)

- mbm5615 - Experiential Learning With YogaDocument10 pagesmbm5615 - Experiential Learning With Yogaapi-390909861No ratings yet

- Portfolio in My Immersion Work 2.0Document41 pagesPortfolio in My Immersion Work 2.0floreson 16No ratings yet

- Ecology and Distribution of Sea Buck Thorn in Mustang and Manang District, NepalDocument58 pagesEcology and Distribution of Sea Buck Thorn in Mustang and Manang District, NepalSantoshi ShresthaNo ratings yet

- Visto-Resume 26710306Document1 pageVisto-Resume 26710306api-350663722No ratings yet

- What Are The Benefits of An Intensive Outpatient ProgramDocument1 pageWhat Are The Benefits of An Intensive Outpatient ProgramJack williamNo ratings yet

- Competency Enhancing Courses Jan June2023Document2 pagesCompetency Enhancing Courses Jan June2023Yashveer TakooryNo ratings yet

- Paper Format ResearchDocument55 pagesPaper Format ResearchJezryl PelayoNo ratings yet

- Art Meta-Analyses of Experimental Data in An PDFDocument12 pagesArt Meta-Analyses of Experimental Data in An PDFIonela HoteaNo ratings yet

- Practical 2 Data TransferDocument3 pagesPractical 2 Data TransferHet PatelNo ratings yet

- Unit: Storage and MemoryDocument17 pagesUnit: Storage and MemoryMohamed AbubackerNo ratings yet

- Dashboard Digital VoltmeterDocument7 pagesDashboard Digital VoltmetercrashoveriteNo ratings yet

- Flood Control Design2Document51 pagesFlood Control Design2Abo MarvinNo ratings yet

- Boq Ipal Pasar Sukamaju2019Document3 pagesBoq Ipal Pasar Sukamaju2019tiopen5ilhamNo ratings yet