Professional Documents

Culture Documents

Shell Omala S5 Wind 320

Shell Omala S5 Wind 320

Uploaded by

txto2881Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell Omala S5 Wind 320

Shell Omala S5 Wind 320

Uploaded by

txto2881Copyright:

Available Formats

Technical Data Sheet

• LONG LIFE

• EXTRA PROTECTION

•

Shell Omala S5 Wind 320 ENHANCED SYSTEM

EFFICIENCY

Advanced Synthetic Wind Turbine Gear Oil

Shell Omala S5 Wind advanced fully synthetic wind turbine gear oil offers exceptional lubrication performance,

even under severe operating conditions.

The innovative formulation is developed to protect your wind turbine gears and bearings by minimizing wear,

protecting against micro-pitting, maintaining effective fluidity at extremes of low temperature and minimizing foam

formation.

Performance, Features & Benefits · Cleanliness

· Long oil life – Maintenance saving High levels of fluid cleanliness are maintained throughout

manufacture, offering the levels required by stringent leading

Shell Omala S5 Wind is designed with an innovative

additive technology blended in a new generation, very high Wind Turbine and gearbox Original Equipment

performance metallocene Poly-Alpha-Olefin (mPAO) base Manufacturers (OEM).

fluid that delivers an outstanding resistance to degradation Shell Omala S5 Wind exceeds the requirements of relevant

throughout the maintenance interval. It will defend against filtration equipment manufacturers for the wind turbine

deposit formation to prolong oil and gearbox life. Shell industry.

Omala S5 Wind offers the potential to significantly extend

Main Applications

service intervals when compared to conventional mineral

industrial gear oils and has been developed to reduce · Wind turbines main gearboxes

Shell Omala S5 Wind is specifically designed to provide

bearing surface stresses.

· Excellent wear & corrosion protection

optimum performance and long service life. It is designed to

lubricate and protect wind turbine main gearboxes, even

Shell Omala S5 Wind provides high levels of load carrying

under the very harsh conditions found in cold climate and

capacity, high micro-pitting performance and scuffing

humid regions, including offshore locations.

resistance in a wide range of operating temperatures, even

under low speed / high torque loading conditions. These · Yaw and pitch drive gearboxes

Shell Omala S5 Wind is also suitable for use in wind turbine

features provide significant benefits to promote long term

auxiliary gearboxes such as yaw and pitch drives where an

gear and bearing life.

ISO 320 mm2s-1 viscosity, PAO or mineral oil is specified.

Shell Omala S5 Wind demonstrates excellent rust and

corrosion resistance, even in the presence of seawater.

· Enhanced system efficiency

Shell Omala S5 Wind is developed to maintain and

enhance the efficiency of wind turbine gearboxes through

improved low temperature fluidity, rapid air release,

resistance to foam formation, and excellent water

separation properties.

Page 1 of 3 Omala S5 Wind 320, v 1.8 06.03.2023.14.44

Specifications, Approvals & Recommendations · GE

Meets or exceeds the following industry standards · Vestas

· ISO 12925-1 Type CKD Meets or exceeds the following OEM component requirements

· ANSI/AGMA 9005-E02 (EP) of

· IEC 61400-4 · SKF

· DIN 51517-3 (CLP) · Schaeffler

· GB/T 33540.3-2017 · Timken

Designed to meet or exceed the OEM requirements of · Hydac

· Suzlon · CC Jensen

Approved by · Mintai

· NGC

· Freudenberg

· Winergy For a full listing of equipment approvals and

· ZF Wind recommendations, please consult your local Shell Technical

· Moventas Helpdesk.

· Eickhoff Compatibility & Miscibility

· Bonfiglioli Shell Omala S5 Wind is compatible with seals, sealants and

· Dalian Huarui Heavy Industries (DHHI) paints used by major wind turbine gearbox OEMs.

· SANY Heavy Energy Machinery Changing to Shell Omala S5 Wind

· Tianjin TEEK Transmission

Shell Omala S5 Wind is compatible with other Shell PAO

· Taiyuan Heavy Industry (TYHI)

gearbox oils. To realise the full performance benefits of Shell

·

Omala S5 Wind, it is recommended to completely drain the

Envision

gearbox, flush and fill with Shell Omala S5 Wind.

· Nordex Acciona

· Siemens Gamesa

Typical Physical Characteristics

Properties Method Shell Omala S5 Wind 320

Kinematic Viscosity @400C mm2/s ISO 3104 320

Kinematic Viscosity @1000C mm2/s ISO 3104 39

Viscosity Index ISO 2909 170

Flash Point (COC) 0

C ISO 2592 240

Pour Point 0

C ISO 3016 -48

Density @15 C 0

kg/m 3 ISO 12185 862

Rust Protection, Sea Water (24 hours) ASTM D665B Pass

Bearing Corrosion Protection, Sea Water Rating SKF EMCOR 0-0

Foaming Characteristics Sequences I,II,III mL/mL ASTM D892 5/0, 0/0, 5/0

Tendency/Stability

Flender Foam

Neat Volume Increase, after 1 minute @25ºC % maximum ISO 12152 5

Air-Oil Dispersion, after 5 minutes @25ºC % maximum ISO 12152 5

FZG Scuffing

Standard Test (A20/8.3/90) failure load stage ISO 14635-1 (mod) 14

minimum DIN 51534 (mod)

Double Speed (A20/16.6/90) failure load stage 14

minimum

Page 2 of 3 Omala S5 Wind 320, v 1.8 06.03.2023.14.44

Properties Method Shell Omala S5 Wind 320

Low Temperature (A20/8.3/60) failure load stage 12

minimum

FVA Micro-pitting

Fail Load Stage minimum FVA Proc. No. 54 10

GFT-Class FVA Proc. No. 54 High

FAG FE-8 Bearing Test Stages 1 - 4 DIN 51819 Pass

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,

variations in these characteristics may occur.

Health, Safety & Environment

· Health and Safety

Shell Omala S5 Wind is unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on Health and Safety is available on the appropriate Safety Data Sheet, which can be obtained from

https://www.epc.shell.com

· Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

· Advice

Advice on applications not covered here may be obtained from your Shell representative.

Page 3 of 3 Omala S5 Wind 320, v 1.8 06.03.2023.14.44

You might also like

- Omala 460Document4 pagesOmala 460Asad InaamNo ratings yet

- Large-Eddy Simulations of Turbulence - Lesieur Et AlDocument233 pagesLarge-Eddy Simulations of Turbulence - Lesieur Et AlEdis KuznierNo ratings yet

- Exam 1 Study Guide Problems PDFDocument32 pagesExam 1 Study Guide Problems PDFS. GreenNo ratings yet

- PersonalCare CL F0032 (AP) Low PH Exfoliating Facial Cleanser With AHADocument1 pagePersonalCare CL F0032 (AP) Low PH Exfoliating Facial Cleanser With AHAsrpoo13No ratings yet

- S2 G 100 - TDS PDFDocument3 pagesS2 G 100 - TDS PDFWawanDarmawanNo ratings yet

- Omala S2 G 100Document3 pagesOmala S2 G 100AMITNo ratings yet

- Omala S2 G 460Document3 pagesOmala S2 G 460Petrus MalailakNo ratings yet

- S2 G 460 - TDS PDFDocument3 pagesS2 G 460 - TDS PDFWawanDarmawanNo ratings yet

- Omala S2 GX 460Document2 pagesOmala S2 GX 460Kieran MañalacNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsMohd FaidzalNo ratings yet

- Omala S2 GX 320 NewDocument2 pagesOmala S2 GX 320 NewAhmed FathyNo ratings yet

- Shell Omala S2 GX 1000 - TDSDocument2 pagesShell Omala S2 GX 1000 - TDSbiron rumangunNo ratings yet

- Shell Omala S2 G 220 DatasheetDocument5 pagesShell Omala S2 G 220 DatasheetSergio OrdoviniNo ratings yet

- Shell Omala S2 GX 680 TDSDocument2 pagesShell Omala S2 GX 680 TDSEdgar Leonel CortésNo ratings yet

- 9a662cdb-2db3-49ea-a13d-5fc7b9d76aefDocument2 pages9a662cdb-2db3-49ea-a13d-5fc7b9d76aefricicla1No ratings yet

- OmalaDocument2 pagesOmalaSunario YapNo ratings yet

- Gpcdoc Gtds Shell Omala s2 G 150 (En) TdsDocument3 pagesGpcdoc Gtds Shell Omala s2 G 150 (En) TdsMuhammad RipandiNo ratings yet

- Shell G 220Document3 pagesShell G 220Tamara GarciaNo ratings yet

- Omala S2 G 220Document3 pagesOmala S2 G 220AMITNo ratings yet

- Shell Omala S2 G 680: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 680: Performance, Features & BenefitsRaden ArdyNo ratings yet

- 22638Document3 pages22638mhNo ratings yet

- Omala S2 GX 150Document2 pagesOmala S2 GX 150Kieran MañalacNo ratings yet

- Omala S2 GX 220Document2 pagesOmala S2 GX 220phucdc095041No ratings yet

- Shell Omala S2 G 1000: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 1000: Performance, Features & BenefitsRaden ArdyNo ratings yet

- Shell Omala S2 GX 320: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 320: Performance, Features & Benefits Main ApplicationsRaden ArdyNo ratings yet

- Shell Omala s2 GX 320 TdsDocument2 pagesShell Omala s2 GX 320 TdsOnie Hammamz OylNo ratings yet

- 13 Omala S4 GX 220 PDFDocument2 pages13 Omala S4 GX 220 PDFthanhhuyenNo ratings yet

- Gpcdoc Local Tds Qatar Shelml Omala s4 We 320 (Ar-Qa) TdsDocument3 pagesGpcdoc Local Tds Qatar Shelml Omala s4 We 320 (Ar-Qa) TdsEhsanNo ratings yet

- Shell Omala S4 WE 220: Performance, Features & BenefitsDocument3 pagesShell Omala S4 WE 220: Performance, Features & BenefitsPro.MechanicNo ratings yet

- Omala S2 GX 100Document2 pagesOmala S2 GX 100Kieran MañalacNo ratings yet

- Shell Omala S2 GX 100 TDSDocument2 pagesShell Omala S2 GX 100 TDSEdgar Leonel CortésNo ratings yet

- Shell Omala S2 G 150: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 150: Performance, Features & BenefitsAzamuddin JasrelNo ratings yet

- Shell Omala S4 GXV 320 - TDSDocument2 pagesShell Omala S4 GXV 320 - TDSDENNY BAYUAJINo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsMudabbir Shan AhmedNo ratings yet

- Shell Omala S2 G 680 (Ar-BH) TDSDocument4 pagesShell Omala S2 G 680 (Ar-BH) TDSJavier GonzalezNo ratings yet

- GPCDOC Local TDS Bahrain Shell Omala S2 G 680 (Ar-BH) TDSDocument4 pagesGPCDOC Local TDS Bahrain Shell Omala S2 G 680 (Ar-BH) TDSAditomo PutrantoNo ratings yet

- Shell Omala S2 GX 150: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 150: Performance, Features & Benefits Main ApplicationsVelibor KaranovicNo ratings yet

- Shell Omala S2 G 320: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 320: Performance, Features & BenefitsVelibor KaranovicNo ratings yet

- Shell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsAliNo ratings yet

- Shell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 100: Performance, Features & Benefits Main ApplicationsRaden ArdyNo ratings yet

- Omala S4 GXV 220Document2 pagesOmala S4 GXV 220Aaron ChanNo ratings yet

- Omala s4 GXV 220Document2 pagesOmala s4 GXV 220Igreja CCMVNo ratings yet

- Omala S2 GX 68Document2 pagesOmala S2 GX 68Kieran MañalacNo ratings yet

- Shell Omala S4 GX 220 (En) TDS v2Document2 pagesShell Omala S4 GX 220 (En) TDS v2Jacques Lopez OrtegaNo ratings yet

- Omala S1 W 460Document2 pagesOmala S1 W 460Adnan QayumNo ratings yet

- Shell Omala S4 GX 220Document3 pagesShell Omala S4 GX 220Anonymous oAbjbl4HNo ratings yet

- Shell Omala S2 G 68: Performance, Features & BenefitsDocument3 pagesShell Omala S2 G 68: Performance, Features & BenefitsRaden ArdyNo ratings yet

- How To Use OilDocument3 pagesHow To Use OilMadhusudan SharmaNo ratings yet

- UAE Shell Omala S4 GX 460Document3 pagesUAE Shell Omala S4 GX 460tylerdurdaneNo ratings yet

- Shell Omala S2 G 100: Performance, Features & BenefitsDocument4 pagesShell Omala S2 G 100: Performance, Features & Benefitsرعد العكيليNo ratings yet

- Shell Omala S1 W 460Document2 pagesShell Omala S1 W 460Muhammad SaputraNo ratings yet

- Shell Omala S2 GX 68: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Omala S2 GX 68: Performance, Features & Benefits Main Applicationshoussem houssemNo ratings yet

- Shell Omala S4 WE 320Document3 pagesShell Omala S4 WE 320Muhammad SaputraNo ratings yet

- Shell Omala S4 WE 220Document3 pagesShell Omala S4 WE 220Muhammad SaputraNo ratings yet

- Shell Omala S4 GXV 460 - TDSDocument2 pagesShell Omala S4 GXV 460 - TDSDENNY BAYUAJINo ratings yet

- Shell Omala S2 G150 DatasheetDocument3 pagesShell Omala S2 G150 Datasheetphankhoa83-1No ratings yet

- Omala S1 W 680Document2 pagesOmala S1 W 680Nigel RamkhalawanNo ratings yet

- Shell Omala S1 W 680Document2 pagesShell Omala S1 W 680Muhammad SaputraNo ratings yet

- TDS Shell Omala S4 GXV 220Document2 pagesTDS Shell Omala S4 GXV 220Nokiabhre WijayaNo ratings yet

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleFrom EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleRating: 5 out of 5 stars5/5 (1)

- Описание pentosin chf 202 enDocument3 pagesОписание pentosin chf 202 entxto2881No ratings yet

- Pakelo TarifsDocument4 pagesPakelo Tarifstxto2881No ratings yet

- Castrol BOT913N 5W-30Document2 pagesCastrol BOT913N 5W-30txto2881No ratings yet

- Yamaha - X94 - Ebicycle Instrukcja - Serwiowap Multemp AC-N Kyodo YushiDocument82 pagesYamaha - X94 - Ebicycle Instrukcja - Serwiowap Multemp AC-N Kyodo Yushitxto2881No ratings yet

- Kyodo Yushi Multemp SRLDocument1 pageKyodo Yushi Multemp SRLtxto2881No ratings yet

- Multi Functional Synthetic Grease: Test Item Test Method Multemp AcDocument1 pageMulti Functional Synthetic Grease: Test Item Test Method Multemp Actxto2881No ratings yet

- Aral Aralub FDP 00: Semi-Liquid GreaseDocument2 pagesAral Aralub FDP 00: Semi-Liquid Greasetxto2881No ratings yet

- EAL Pressure-Relief-Valve-Pilot-Operated Bosch-RexrothDocument1 pageEAL Pressure-Relief-Valve-Pilot-Operated Bosch-Rexrothtxto2881No ratings yet

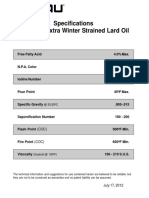

- Specs-Pfau-Peacock-Extra Winter Strained Lard OilDocument1 pageSpecs-Pfau-Peacock-Extra Winter Strained Lard Oiltxto2881No ratings yet

- Maintenanceandserviceproductspecificationbus enDocument137 pagesMaintenanceandserviceproductspecificationbus entxto2881No ratings yet

- MAN 341 Typ Z5 - enDocument1 pageMAN 341 Typ Z5 - entxto2881No ratings yet

- Mobil SHC Aware™ Gear Series: Product DescriptionDocument3 pagesMobil SHC Aware™ Gear Series: Product Descriptiontxto2881No ratings yet

- Vol. II 2017 ISSN Online 1Document118 pagesVol. II 2017 ISSN Online 1txto2881No ratings yet

- Pds ZF Ecofluid M enDocument2 pagesPds ZF Ecofluid M entxto2881No ratings yet

- Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90Document3 pagesMobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90txto2881No ratings yet

- Lubricant Friction and Wear TestingDocument25 pagesLubricant Friction and Wear TestingRhea TalibNo ratings yet

- Multiple WOW Emulsions-Using The Required HLB For Emulsifier EvaluationDocument7 pagesMultiple WOW Emulsions-Using The Required HLB For Emulsifier EvaluationAngelica RomanNo ratings yet

- sl2019 670 PDFDocument5 pagessl2019 670 PDFNeofytosNo ratings yet

- Horizontal Well PerformanceDocument25 pagesHorizontal Well PerformanceGaurav KunduNo ratings yet

- Metallurgical SlagDocument27 pagesMetallurgical SlagADITYA RAHMANNo ratings yet

- Laboratory Activity 2 Measuring Density and Viscosities of Different FluidsDocument5 pagesLaboratory Activity 2 Measuring Density and Viscosities of Different FluidsJohn Patrick Sanay NunezNo ratings yet

- P2 Series InstallationlManualDocument6 pagesP2 Series InstallationlManualxxshNo ratings yet

- Polyquart Ecoclean: Technical InformationDocument3 pagesPolyquart Ecoclean: Technical InformationSlava75No ratings yet

- Article Careers360 20220827074239Document9 pagesArticle Careers360 20220827074239Md 1728No ratings yet

- Fluid Mechanics White 7th SOL Part1 Part1Document5 pagesFluid Mechanics White 7th SOL Part1 Part1Jose EscobarNo ratings yet

- Week7 (Wed Mar 03-Single Particle in Fluid (Students Notes)Document21 pagesWeek7 (Wed Mar 03-Single Particle in Fluid (Students Notes)Julie Anne CristalesNo ratings yet

- Hargreaves 2007Document15 pagesHargreaves 2007Sam GonçalvesNo ratings yet

- GT18B10M User Manual PDFDocument29 pagesGT18B10M User Manual PDFLuisYFer1No ratings yet

- T9834 in DS 0011 B0 - Orifice Plate and FlangesDocument68 pagesT9834 in DS 0011 B0 - Orifice Plate and FlangesAnonymous ZcrLZQNo ratings yet

- Lab 5 Reynold NumberDocument7 pagesLab 5 Reynold NumberFgj JhgNo ratings yet

- Gesamtkatalog - Dsentechnik 2012 - Englisch PDFDocument194 pagesGesamtkatalog - Dsentechnik 2012 - Englisch PDFjpsingh75No ratings yet

- 2.6 Oseen's Improvement For Slow Flow Past A CylinderDocument6 pages2.6 Oseen's Improvement For Slow Flow Past A CylinderRatovoarisoaNo ratings yet

- Natural Gas Plant OperationDocument212 pagesNatural Gas Plant OperationMuhammad JahanzaibNo ratings yet

- To Find Out The Viscosity of A Given Liquid Using Red Wood ViscometerDocument3 pagesTo Find Out The Viscosity of A Given Liquid Using Red Wood ViscometerApoorva SinghNo ratings yet

- PMP 200Document103 pagesPMP 200milecsaNo ratings yet

- Magnetorheological Fluid PaperDocument15 pagesMagnetorheological Fluid PapershreedharkolekarNo ratings yet

- Boundary Layer TheoryDocument52 pagesBoundary Layer TheoryPratham GargNo ratings yet

- Petroleum Engineering Fluid Properties - Data BookDocument67 pagesPetroleum Engineering Fluid Properties - Data BookMinh Hoàng NguyễnNo ratings yet

- Fuzzy Model (7334-31684-3-PB)Document4 pagesFuzzy Model (7334-31684-3-PB)jbl_No ratings yet

- Reviewer No AnswerDocument27 pagesReviewer No AnswerReydale CachoNo ratings yet

- Road Tunnel Fire CFD Simulation PaperDocument18 pagesRoad Tunnel Fire CFD Simulation PaperNajaf HussainNo ratings yet