Professional Documents

Culture Documents

PDS_Drydene_GearAll_EP_Series_0322-01

PDS_Drydene_GearAll_EP_Series_0322-01

Uploaded by

txto2881Copyright:

Available Formats

You might also like

- SUZUKI DF4 5 6 Service ManDocument149 pagesSUZUKI DF4 5 6 Service ManJohan Rindmyr100% (4)

- Applied Mechanics: by Dr. H. J. Shah & S. B. JunnarkarDocument4 pagesApplied Mechanics: by Dr. H. J. Shah & S. B. Junnarkarvu minhNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangecarmaNo ratings yet

- Alpha SP Range: DescriptionDocument3 pagesAlpha SP Range: Descriptionvicky kNo ratings yet

- Decathlon Extreme Synthetic Gear OilDocument1 pageDecathlon Extreme Synthetic Gear OilDon HowardNo ratings yet

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoNo ratings yet

- Ficha Tecnica Castrol Optigear BM RangeDocument3 pagesFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- HT Mobilgear 600 Series EngDocument2 pagesHT Mobilgear 600 Series Engmgamal1080No ratings yet

- Mobil Vacuoline 500: Circulating OilsDocument2 pagesMobil Vacuoline 500: Circulating OilstribolasNo ratings yet

- Product Data Sheet: Gulfsea Gear Oil SeriesDocument2 pagesProduct Data Sheet: Gulfsea Gear Oil SeriesObydur RahmanNo ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- TorqGear SeriesDocument1 pageTorqGear SeriesSameh RadwanNo ratings yet

- Omala 220Document2 pagesOmala 220Geviena Pinky Sy SarmientoNo ratings yet

- Cepsa Engranajes HPDocument1 pageCepsa Engranajes HPRamonNo ratings yet

- Ultra Industrial Gear Oil TKDocument2 pagesUltra Industrial Gear Oil TKkievegokoolNo ratings yet

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- GL XX Primetals Gear Oil SeriesDocument3 pagesGL XX Primetals Gear Oil SeriesChérubinNo ratings yet

- Shell Omala Oil 320 Eng M0010Document2 pagesShell Omala Oil 320 Eng M0010Ady MihailaNo ratings yet

- Gulf Gear WT: High Performance Industrial Gear OilDocument1 pageGulf Gear WT: High Performance Industrial Gear Oilatripathi2009No ratings yet

- Agma 5ep Iso 220-Pi SheetDocument2 pagesAgma 5ep Iso 220-Pi SheetESTEBANNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- L-CKD Heavy Duty Industrial Gear OilDocument3 pagesL-CKD Heavy Duty Industrial Gear OilDavidNo ratings yet

- 01-Tds-.Canroyal Full Synthetic Gear Oil Sae 75W-90 Api GL-5Document1 page01-Tds-.Canroyal Full Synthetic Gear Oil Sae 75W-90 Api GL-5catpilar274No ratings yet

- MSDS - Magna-Plate-19263 19264 19265-TDDocument2 pagesMSDS - Magna-Plate-19263 19264 19265-TDMohamad HudhaNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- Polyurea Grease TdsDocument2 pagesPolyurea Grease TdsBanti SidhiwalaNo ratings yet

- Schaeffer # 229Document3 pagesSchaeffer # 229Ingeniero aicNo ratings yet

- Total Azolla ZSDocument1 pageTotal Azolla ZSVelibor KaranovicNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- Technical Data Sheet: Leak Control Gear OilDocument1 pageTechnical Data Sheet: Leak Control Gear OilDon HowardNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- GLXXPrimetals Gear Oil SeriesDocument3 pagesGLXXPrimetals Gear Oil SeriesjadrankostanimirovicNo ratings yet

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangeAlin BAMNo ratings yet

- Hydraulic Oils Pds 0915Document1 pageHydraulic Oils Pds 0915Mohamed FersiNo ratings yet

- Castrol Syngear: Americas DescriptionDocument2 pagesCastrol Syngear: Americas Description80ALLA86iNo ratings yet

- Castrol Hyspin VG Range: DescriptionDocument2 pagesCastrol Hyspin VG Range: DescriptionBruno RussoNo ratings yet

- Oli Energol GR-XPDocument2 pagesOli Energol GR-XPakun leptopNo ratings yet

- Ap Getoel EpDocument1 pageAp Getoel EpSami KahtaniNo ratings yet

- PDS Castrol Trans C 10wDocument2 pagesPDS Castrol Trans C 10wepesanoNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Repsol Maker Super TauroDocument2 pagesRepsol Maker Super Tauroibrahim maulanaNo ratings yet

- Grease PropertiesDocument4 pagesGrease Propertiescarlos sotoNo ratings yet

- Wepp bpzs8fDocument2 pagesWepp bpzs8fArthur Sanda LayukNo ratings yet

- Castrol Magna SW D - 150 PDFDocument2 pagesCastrol Magna SW D - 150 PDFPabloNo ratings yet

- Castrol Aircol SR RangeDocument2 pagesCastrol Aircol SR RangeJeremias UtreraNo ratings yet

- Chevron MeropaDocument4 pagesChevron MeropaKaly7No ratings yet

- (EN) Alpha EP RangeDocument1 page(EN) Alpha EP RangemartinNo ratings yet

- Ultra Hydraulic Oil 1Document2 pagesUltra Hydraulic Oil 1kievegokoolNo ratings yet

- Shell Omala SW 150Document1 pageShell Omala SW 150Anonymous TvZMMT5No ratings yet

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 pagesFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNo ratings yet

- Mak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial GearsDocument2 pagesMak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial Gearschandan sahooNo ratings yet

- Alphasyn GS: DescriptionDocument2 pagesAlphasyn GS: Descriptioncool_ddNo ratings yet

- Equate EMDA 6200Document2 pagesEquate EMDA 6200HichamSalamaNo ratings yet

- Gulf Geartek - Hd-Sept2021 - 20211102102844Document1 pageGulf Geartek - Hd-Sept2021 - 20211102102844magadali7814No ratings yet

- Whitmore GF-Series Synthetic Blend Gear OilDocument1 pageWhitmore GF-Series Synthetic Blend Gear OilDon HowardNo ratings yet

- Repsol Circulation 220Document1 pageRepsol Circulation 220ibrahim maulanaNo ratings yet

- Unigear s3 Industrial Gear Oil SeriesDocument2 pagesUnigear s3 Industrial Gear Oil SeriesAnya J PamungkasNo ratings yet

- AP Industrial Gear Oil (FVA54 Micro-Ptting)Document3 pagesAP Industrial Gear Oil (FVA54 Micro-Ptting)Yoong TanNo ratings yet

- Jax Magna-Plate 1100: High-Performance, Corrosion-Control H2 GreaseDocument2 pagesJax Magna-Plate 1100: High-Performance, Corrosion-Control H2 GreaseEmerson 21400% (1)

- Pakelo TarifsDocument4 pagesPakelo Tarifstxto2881No ratings yet

- Castrol BOT913N 5W-30Document2 pagesCastrol BOT913N 5W-30txto2881No ratings yet

- Описание pentosin chf 202 enDocument3 pagesОписание pentosin chf 202 entxto2881No ratings yet

- Yamaha - X94 - Ebicycle Instrukcja - Serwiowap Multemp AC-N Kyodo YushiDocument82 pagesYamaha - X94 - Ebicycle Instrukcja - Serwiowap Multemp AC-N Kyodo Yushitxto2881No ratings yet

- Multi Functional Synthetic Grease: Test Item Test Method Multemp AcDocument1 pageMulti Functional Synthetic Grease: Test Item Test Method Multemp Actxto2881No ratings yet

- Kyodo Yushi Multemp SRLDocument1 pageKyodo Yushi Multemp SRLtxto2881No ratings yet

- Pds ZF Ecofluid M enDocument2 pagesPds ZF Ecofluid M entxto2881No ratings yet

- EAL Pressure-Relief-Valve-Pilot-Operated Bosch-RexrothDocument1 pageEAL Pressure-Relief-Valve-Pilot-Operated Bosch-Rexrothtxto2881No ratings yet

- Aral Aralub FDP 00: Semi-Liquid GreaseDocument2 pagesAral Aralub FDP 00: Semi-Liquid Greasetxto2881No ratings yet

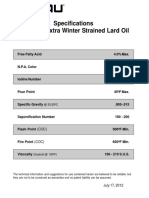

- Specs-Pfau-Peacock-Extra Winter Strained Lard OilDocument1 pageSpecs-Pfau-Peacock-Extra Winter Strained Lard Oiltxto2881No ratings yet

- Vol. II 2017 ISSN Online 1Document118 pagesVol. II 2017 ISSN Online 1txto2881No ratings yet

- Maintenanceandserviceproductspecificationbus enDocument137 pagesMaintenanceandserviceproductspecificationbus entxto2881No ratings yet

- Mobil SHC Aware™ Gear Series: Product DescriptionDocument3 pagesMobil SHC Aware™ Gear Series: Product Descriptiontxto2881No ratings yet

- MAN 341 Typ Z5 - enDocument1 pageMAN 341 Typ Z5 - entxto2881No ratings yet

- Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90Document3 pagesMobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90txto2881No ratings yet

- Asphalt Industry Chain: Laying Down The StandardsDocument8 pagesAsphalt Industry Chain: Laying Down The Standardssheshan_rNo ratings yet

- Kodak Impresora Placas Dryview 8900 - r3 - Service ManualDocument359 pagesKodak Impresora Placas Dryview 8900 - r3 - Service Manualmanolozamora100% (3)

- Determination of Gerotor Pump Theoretical FlowDocument8 pagesDetermination of Gerotor Pump Theoretical FlowBlaza StojanovicNo ratings yet

- D&E MINIATURES 2000 Model Submarine CatalogDocument26 pagesD&E MINIATURES 2000 Model Submarine CatalogDUNCAN0420100% (1)

- OHP GTU Study Material E-Notes Unit-3 28102020032608AMDocument23 pagesOHP GTU Study Material E-Notes Unit-3 28102020032608AMDhaval SonawaneNo ratings yet

- Modern Equipment Ladles Brochure 6 14 PDFDocument20 pagesModern Equipment Ladles Brochure 6 14 PDFCristian Osorio RonquiloNo ratings yet

- Reparación Tuerca Meade Etx70Document13 pagesReparación Tuerca Meade Etx70soplavientosNo ratings yet

- All About Us & Product OverviewDocument30 pagesAll About Us & Product OverviewSuraj ShastriNo ratings yet

- Subframe, Stabilizer Bar, Control ArmDocument42 pagesSubframe, Stabilizer Bar, Control ArmpabloNo ratings yet

- 4X4 MotorDocument31 pages4X4 MotorMisael CaffarelNo ratings yet

- Single Girder Top-Running Components: For Capacities To 5 Tons, and Spans To 36 FeetDocument6 pagesSingle Girder Top-Running Components: For Capacities To 5 Tons, and Spans To 36 FeetJuan RubioNo ratings yet

- Fuel Injection Pump - Install - Type 2 Engines and 7BJ EnginesDocument4 pagesFuel Injection Pump - Install - Type 2 Engines and 7BJ EnginesDaniel AndradeNo ratings yet

- Theoretical Calculation and Simulation Analysis of No-Load Torque of Main ReducerDocument7 pagesTheoretical Calculation and Simulation Analysis of No-Load Torque of Main ReducerChandru VelNo ratings yet

- Understanding TribologyDocument7 pagesUnderstanding Tribologyemad sabriNo ratings yet

- Gajra GearsDocument17 pagesGajra GearsJuhi Yadav100% (2)

- Qcs 2010 Part 8.05 Valves, Penstocks and AppurtenancesDocument18 pagesQcs 2010 Part 8.05 Valves, Penstocks and AppurtenancesRotsapNayrbNo ratings yet

- Fiat Barchetta: Electrical SystemDocument12 pagesFiat Barchetta: Electrical SystemHallex OliveiraNo ratings yet

- 121E Gear Cutting by Hobbing (20070930)Document51 pages121E Gear Cutting by Hobbing (20070930)Jaskaran SinghNo ratings yet

- Assignment 3 TOM2 YBKDocument2 pagesAssignment 3 TOM2 YBKyogesh_b_kNo ratings yet

- High Speed Printing Machine - 240215 - 044513Document19 pagesHigh Speed Printing Machine - 240215 - 044513Murali AgencyNo ratings yet

- R19 Mechatronics - MITDocument84 pagesR19 Mechatronics - MITScientist SakthivelNo ratings yet

- Unit 2Document1 pageUnit 2Dhileepan KumarasamyNo ratings yet

- Operador Siemens Intercam PDFDocument32 pagesOperador Siemens Intercam PDFCristian Orosco ValverdeNo ratings yet

- Starting Model Year 1986 Serial Number 0A197112 and Up (USA) 09503295 and Up (Belgium)Document308 pagesStarting Model Year 1986 Serial Number 0A197112 and Up (USA) 09503295 and Up (Belgium)James ThompsonNo ratings yet

- CG956G (208) Service Manual PDFDocument76 pagesCG956G (208) Service Manual PDFDanilo Marin100% (2)

- SS 2688 e PDFDocument9 pagesSS 2688 e PDFDaniel Castillo PeñaNo ratings yet

- Design of An Ackermann Type Steering Mechanism: ArticleDocument15 pagesDesign of An Ackermann Type Steering Mechanism: ArticleKaasamHarishKumarNo ratings yet

PDS_Drydene_GearAll_EP_Series_0322-01

PDS_Drydene_GearAll_EP_Series_0322-01

Uploaded by

txto2881Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDS_Drydene_GearAll_EP_Series_0322-01

PDS_Drydene_GearAll_EP_Series_0322-01

Uploaded by

txto2881Copyright:

Available Formats

PRODUCT DATA SHEET

DRYDENE GEARALL® EP GEAR OILS

EXTREME PRESSURE INDUSTRIAL GEAR OIL

PRODUCT DESCRIPTION FEATURES AND BENEFITS

DRYDENE GEARALL® EP GEAR OILS are high-performance extreme DRYDENE GEARALL EP GEAR OILS feature robust additives that deliver

pressure gear oils for all type of enclosed gear drives. They are both protective and efficiency-improving properties in industrial gearbox

recommended for industrial spur, bevel and helical enclosed gears with applications:

circulation or splash lubrication. The special extreme pressure additive

package provides excellent performance for gear sets operating under • Advanced corrosion inhibitors control the formation of harmful

heavy or shock loads at temperatures up to 100 °C. contaminants

PRODUCT APPLICATION • EP additives build a protective layer to reduce friction and wear rates

on metal-on-metal contact points

DRYDENE GEARALL EP GEAR OILS are recommended for use and provide

in a number of enclosed industrial gear applications where AGMA EP gear • Protects gear teeth from micro-pitting wear which helps lower gear

oils are specified: and bearing wear over the life of the fluid

• Spur • Bevel • Excellent water separation promotes extended gear service life

• Helical • Planetary

DRYDENE GEARALL EP GEAR OILS are also suitable for use in bath,

splash, circulating or spray mist applications as applicable to the specified

viscosity grade.

SPECIFICATIONS

AGMA EP 9005-E02

Cincinnati Lamb P-63 (ISO 68), P-76 (ISO 100), P-77 (ISO 150)

Cincinnati Lamb P-74 (ISO 220), P-59 (ISO 320), P-35 (ISO 460)

David Brown S1.53 101 (Type M, A, E)

DIN 51517 Part 3, CLP

ISO 12925-1 CKC/CKD

SEB 181226

US Steel 224

TYPICAL TECHNICAL PROPERTIES

PROPERTY TEST METHOD ISO 68 ISO 100 ISO 150 ISO 220 ISO 320 ISO 460

Viscosity @ 40°C, cSt ASTM D445 68 100 150 220 320 460

Viscosity @ 100°C, cSt ASTM D445 8.9 11.3 14.8 19.4 24.3 30.8

Viscosity Index ASTM D2270 104 99 98 100 97 97

Pour Point, °C/°F ASTM D97 -25/-13 -24/-11 -24/-11 -24/-11 -23/-9 -16/3

Rust Prevention ASTM D665B Pass Pass Pass Pass Pass Pass

FZG gear test, stages ASTM D5182 12 12 12 12 12 12

FZG Micropitting, Fail stage FVA 54 10 10 10 10 10 10

Four- Ball Weld Load, kgf ASTM D2783 200 200 250 250 250 250

Timken OK Load, lbs. ASTM D2782 65 65 65 65 65 65

Water Seperation ASTM D2711 Pass Pass Pass Pass Pass Pass

Oxidation Test ASTM 2893 Pass Pass Pass Pass Pass Pass

This product is not expected to have any adverse health implications when used for its intended purposes. Always wear protective gloves when handling used oil and dispose of properly. Avoid contact with

skin and wash immediately with soap and water should any contact occur. Always follow manufacturers recommendations for fluid viscosity and service category. RelaDyne assumes no responsibility for

product misuse or improper application. For a copy of this product's Safety Data Sheet (SDS), visit www.DRYDENE.com Rev (0322-01)

RelaDyne, LLC. | 8280 Montgomery Road, Suite 1 | Cincinnati, OH 45236 | 1-888-830-3156 | WWW.RELADYNE.COM

You might also like

- SUZUKI DF4 5 6 Service ManDocument149 pagesSUZUKI DF4 5 6 Service ManJohan Rindmyr100% (4)

- Applied Mechanics: by Dr. H. J. Shah & S. B. JunnarkarDocument4 pagesApplied Mechanics: by Dr. H. J. Shah & S. B. Junnarkarvu minhNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangecarmaNo ratings yet

- Alpha SP Range: DescriptionDocument3 pagesAlpha SP Range: Descriptionvicky kNo ratings yet

- Decathlon Extreme Synthetic Gear OilDocument1 pageDecathlon Extreme Synthetic Gear OilDon HowardNo ratings yet

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoNo ratings yet

- Ficha Tecnica Castrol Optigear BM RangeDocument3 pagesFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- HT Mobilgear 600 Series EngDocument2 pagesHT Mobilgear 600 Series Engmgamal1080No ratings yet

- Mobil Vacuoline 500: Circulating OilsDocument2 pagesMobil Vacuoline 500: Circulating OilstribolasNo ratings yet

- Product Data Sheet: Gulfsea Gear Oil SeriesDocument2 pagesProduct Data Sheet: Gulfsea Gear Oil SeriesObydur RahmanNo ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- TorqGear SeriesDocument1 pageTorqGear SeriesSameh RadwanNo ratings yet

- Omala 220Document2 pagesOmala 220Geviena Pinky Sy SarmientoNo ratings yet

- Cepsa Engranajes HPDocument1 pageCepsa Engranajes HPRamonNo ratings yet

- Ultra Industrial Gear Oil TKDocument2 pagesUltra Industrial Gear Oil TKkievegokoolNo ratings yet

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- GL XX Primetals Gear Oil SeriesDocument3 pagesGL XX Primetals Gear Oil SeriesChérubinNo ratings yet

- Shell Omala Oil 320 Eng M0010Document2 pagesShell Omala Oil 320 Eng M0010Ady MihailaNo ratings yet

- Gulf Gear WT: High Performance Industrial Gear OilDocument1 pageGulf Gear WT: High Performance Industrial Gear Oilatripathi2009No ratings yet

- Agma 5ep Iso 220-Pi SheetDocument2 pagesAgma 5ep Iso 220-Pi SheetESTEBANNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- L-CKD Heavy Duty Industrial Gear OilDocument3 pagesL-CKD Heavy Duty Industrial Gear OilDavidNo ratings yet

- 01-Tds-.Canroyal Full Synthetic Gear Oil Sae 75W-90 Api GL-5Document1 page01-Tds-.Canroyal Full Synthetic Gear Oil Sae 75W-90 Api GL-5catpilar274No ratings yet

- MSDS - Magna-Plate-19263 19264 19265-TDDocument2 pagesMSDS - Magna-Plate-19263 19264 19265-TDMohamad HudhaNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- Polyurea Grease TdsDocument2 pagesPolyurea Grease TdsBanti SidhiwalaNo ratings yet

- Schaeffer # 229Document3 pagesSchaeffer # 229Ingeniero aicNo ratings yet

- Total Azolla ZSDocument1 pageTotal Azolla ZSVelibor KaranovicNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- Technical Data Sheet: Leak Control Gear OilDocument1 pageTechnical Data Sheet: Leak Control Gear OilDon HowardNo ratings yet

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaNo ratings yet

- GLXXPrimetals Gear Oil SeriesDocument3 pagesGLXXPrimetals Gear Oil SeriesjadrankostanimirovicNo ratings yet

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangeAlin BAMNo ratings yet

- Hydraulic Oils Pds 0915Document1 pageHydraulic Oils Pds 0915Mohamed FersiNo ratings yet

- Castrol Syngear: Americas DescriptionDocument2 pagesCastrol Syngear: Americas Description80ALLA86iNo ratings yet

- Castrol Hyspin VG Range: DescriptionDocument2 pagesCastrol Hyspin VG Range: DescriptionBruno RussoNo ratings yet

- Oli Energol GR-XPDocument2 pagesOli Energol GR-XPakun leptopNo ratings yet

- Ap Getoel EpDocument1 pageAp Getoel EpSami KahtaniNo ratings yet

- PDS Castrol Trans C 10wDocument2 pagesPDS Castrol Trans C 10wepesanoNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Repsol Maker Super TauroDocument2 pagesRepsol Maker Super Tauroibrahim maulanaNo ratings yet

- Grease PropertiesDocument4 pagesGrease Propertiescarlos sotoNo ratings yet

- Wepp bpzs8fDocument2 pagesWepp bpzs8fArthur Sanda LayukNo ratings yet

- Castrol Magna SW D - 150 PDFDocument2 pagesCastrol Magna SW D - 150 PDFPabloNo ratings yet

- Castrol Aircol SR RangeDocument2 pagesCastrol Aircol SR RangeJeremias UtreraNo ratings yet

- Chevron MeropaDocument4 pagesChevron MeropaKaly7No ratings yet

- (EN) Alpha EP RangeDocument1 page(EN) Alpha EP RangemartinNo ratings yet

- Ultra Hydraulic Oil 1Document2 pagesUltra Hydraulic Oil 1kievegokoolNo ratings yet

- Shell Omala SW 150Document1 pageShell Omala SW 150Anonymous TvZMMT5No ratings yet

- Ficha Tecnica Castrol Hyspin AWS RangeDocument2 pagesFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNo ratings yet

- Mak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial GearsDocument2 pagesMak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial Gearschandan sahooNo ratings yet

- Alphasyn GS: DescriptionDocument2 pagesAlphasyn GS: Descriptioncool_ddNo ratings yet

- Equate EMDA 6200Document2 pagesEquate EMDA 6200HichamSalamaNo ratings yet

- Gulf Geartek - Hd-Sept2021 - 20211102102844Document1 pageGulf Geartek - Hd-Sept2021 - 20211102102844magadali7814No ratings yet

- Whitmore GF-Series Synthetic Blend Gear OilDocument1 pageWhitmore GF-Series Synthetic Blend Gear OilDon HowardNo ratings yet

- Repsol Circulation 220Document1 pageRepsol Circulation 220ibrahim maulanaNo ratings yet

- Unigear s3 Industrial Gear Oil SeriesDocument2 pagesUnigear s3 Industrial Gear Oil SeriesAnya J PamungkasNo ratings yet

- AP Industrial Gear Oil (FVA54 Micro-Ptting)Document3 pagesAP Industrial Gear Oil (FVA54 Micro-Ptting)Yoong TanNo ratings yet

- Jax Magna-Plate 1100: High-Performance, Corrosion-Control H2 GreaseDocument2 pagesJax Magna-Plate 1100: High-Performance, Corrosion-Control H2 GreaseEmerson 21400% (1)

- Pakelo TarifsDocument4 pagesPakelo Tarifstxto2881No ratings yet

- Castrol BOT913N 5W-30Document2 pagesCastrol BOT913N 5W-30txto2881No ratings yet

- Описание pentosin chf 202 enDocument3 pagesОписание pentosin chf 202 entxto2881No ratings yet

- Yamaha - X94 - Ebicycle Instrukcja - Serwiowap Multemp AC-N Kyodo YushiDocument82 pagesYamaha - X94 - Ebicycle Instrukcja - Serwiowap Multemp AC-N Kyodo Yushitxto2881No ratings yet

- Multi Functional Synthetic Grease: Test Item Test Method Multemp AcDocument1 pageMulti Functional Synthetic Grease: Test Item Test Method Multemp Actxto2881No ratings yet

- Kyodo Yushi Multemp SRLDocument1 pageKyodo Yushi Multemp SRLtxto2881No ratings yet

- Pds ZF Ecofluid M enDocument2 pagesPds ZF Ecofluid M entxto2881No ratings yet

- EAL Pressure-Relief-Valve-Pilot-Operated Bosch-RexrothDocument1 pageEAL Pressure-Relief-Valve-Pilot-Operated Bosch-Rexrothtxto2881No ratings yet

- Aral Aralub FDP 00: Semi-Liquid GreaseDocument2 pagesAral Aralub FDP 00: Semi-Liquid Greasetxto2881No ratings yet

- Specs-Pfau-Peacock-Extra Winter Strained Lard OilDocument1 pageSpecs-Pfau-Peacock-Extra Winter Strained Lard Oiltxto2881No ratings yet

- Vol. II 2017 ISSN Online 1Document118 pagesVol. II 2017 ISSN Online 1txto2881No ratings yet

- Maintenanceandserviceproductspecificationbus enDocument137 pagesMaintenanceandserviceproductspecificationbus entxto2881No ratings yet

- Mobil SHC Aware™ Gear Series: Product DescriptionDocument3 pagesMobil SHC Aware™ Gear Series: Product Descriptiontxto2881No ratings yet

- MAN 341 Typ Z5 - enDocument1 pageMAN 341 Typ Z5 - entxto2881No ratings yet

- Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90Document3 pagesMobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90 Mobilube™ 1 SHC 75W-90txto2881No ratings yet

- Asphalt Industry Chain: Laying Down The StandardsDocument8 pagesAsphalt Industry Chain: Laying Down The Standardssheshan_rNo ratings yet

- Kodak Impresora Placas Dryview 8900 - r3 - Service ManualDocument359 pagesKodak Impresora Placas Dryview 8900 - r3 - Service Manualmanolozamora100% (3)

- Determination of Gerotor Pump Theoretical FlowDocument8 pagesDetermination of Gerotor Pump Theoretical FlowBlaza StojanovicNo ratings yet

- D&E MINIATURES 2000 Model Submarine CatalogDocument26 pagesD&E MINIATURES 2000 Model Submarine CatalogDUNCAN0420100% (1)

- OHP GTU Study Material E-Notes Unit-3 28102020032608AMDocument23 pagesOHP GTU Study Material E-Notes Unit-3 28102020032608AMDhaval SonawaneNo ratings yet

- Modern Equipment Ladles Brochure 6 14 PDFDocument20 pagesModern Equipment Ladles Brochure 6 14 PDFCristian Osorio RonquiloNo ratings yet

- Reparación Tuerca Meade Etx70Document13 pagesReparación Tuerca Meade Etx70soplavientosNo ratings yet

- All About Us & Product OverviewDocument30 pagesAll About Us & Product OverviewSuraj ShastriNo ratings yet

- Subframe, Stabilizer Bar, Control ArmDocument42 pagesSubframe, Stabilizer Bar, Control ArmpabloNo ratings yet

- 4X4 MotorDocument31 pages4X4 MotorMisael CaffarelNo ratings yet

- Single Girder Top-Running Components: For Capacities To 5 Tons, and Spans To 36 FeetDocument6 pagesSingle Girder Top-Running Components: For Capacities To 5 Tons, and Spans To 36 FeetJuan RubioNo ratings yet

- Fuel Injection Pump - Install - Type 2 Engines and 7BJ EnginesDocument4 pagesFuel Injection Pump - Install - Type 2 Engines and 7BJ EnginesDaniel AndradeNo ratings yet

- Theoretical Calculation and Simulation Analysis of No-Load Torque of Main ReducerDocument7 pagesTheoretical Calculation and Simulation Analysis of No-Load Torque of Main ReducerChandru VelNo ratings yet

- Understanding TribologyDocument7 pagesUnderstanding Tribologyemad sabriNo ratings yet

- Gajra GearsDocument17 pagesGajra GearsJuhi Yadav100% (2)

- Qcs 2010 Part 8.05 Valves, Penstocks and AppurtenancesDocument18 pagesQcs 2010 Part 8.05 Valves, Penstocks and AppurtenancesRotsapNayrbNo ratings yet

- Fiat Barchetta: Electrical SystemDocument12 pagesFiat Barchetta: Electrical SystemHallex OliveiraNo ratings yet

- 121E Gear Cutting by Hobbing (20070930)Document51 pages121E Gear Cutting by Hobbing (20070930)Jaskaran SinghNo ratings yet

- Assignment 3 TOM2 YBKDocument2 pagesAssignment 3 TOM2 YBKyogesh_b_kNo ratings yet

- High Speed Printing Machine - 240215 - 044513Document19 pagesHigh Speed Printing Machine - 240215 - 044513Murali AgencyNo ratings yet

- R19 Mechatronics - MITDocument84 pagesR19 Mechatronics - MITScientist SakthivelNo ratings yet

- Unit 2Document1 pageUnit 2Dhileepan KumarasamyNo ratings yet

- Operador Siemens Intercam PDFDocument32 pagesOperador Siemens Intercam PDFCristian Orosco ValverdeNo ratings yet

- Starting Model Year 1986 Serial Number 0A197112 and Up (USA) 09503295 and Up (Belgium)Document308 pagesStarting Model Year 1986 Serial Number 0A197112 and Up (USA) 09503295 and Up (Belgium)James ThompsonNo ratings yet

- CG956G (208) Service Manual PDFDocument76 pagesCG956G (208) Service Manual PDFDanilo Marin100% (2)

- SS 2688 e PDFDocument9 pagesSS 2688 e PDFDaniel Castillo PeñaNo ratings yet

- Design of An Ackermann Type Steering Mechanism: ArticleDocument15 pagesDesign of An Ackermann Type Steering Mechanism: ArticleKaasamHarishKumarNo ratings yet