Professional Documents

Culture Documents

nwj-s2-ali-jahami

nwj-s2-ali-jahami

Uploaded by

Admin InfiniteCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

nwj-s2-ali-jahami

nwj-s2-ali-jahami

Uploaded by

Admin InfiniteCopyright:

Available Formats

NanoWorld Journal https://doi.org/10.17756/nwj.

2023-s2-015

Research Article Open Access

Effect of Graphene as Additive on the Mechanical

Properties of Concrete

Ali Jahami1, Hussein Mouzanar2, Sarah Mahfouz3, Jamal Khatib3 and Mohammed Sonebi4

1

School of Engineering, Lebanese American University, Byblos, Lebanon

2

Faculty of Engineering, Al Maaref University, Beirut, Lebanon

3

Faculty of Engineering, Beirut Arab University, Beirut, Lebanon

4

School of Natural and Built Environment, Queens University of Belfast, Belfast, UK

Correspondence to:

Abstract

*

Ali Jahami

School of Engineering, Graphene is a smart and relatively new material that has promising appli-

Lebanese American University,

cations in many engineering fields. Recently it was found that graphene can be

Byblos, Lebanon.

E-mail: ahjahamy@hotmail.com produced from burning waste materials which will have an impact on cost and

the wide applications in many engineering fields including construction. The ad-

Received: July 25, 2023

dition of tiny amounts of graphene in concrete mixes can enhance the mechani-

Accepted: September 21, 2023

Published: September 25, 2023 cal and durability properties. This research investigated the effect of graphene as

additive on the mechanical properties of concrete. The addition percentage (by

Citation: Jahami A, Mouzanar H, Mahfouz S,

weight of cement) was 0.02%, 0.035%, and 0.05%. Cubic and cylindrical spec-

Khatib J, Sonebi M. 2023. Effect of Graphene

as Additive on the Mechanical Properties of imens were prepared to assess the compressive strength, flexural strength, and

Concrete. NanoWorld J 9(S2): S87-S92. elasticity modulus of concrete. Results showed that adding graphene to concrete

Copyright: © 2023 Jahami et al. This is an Open

led to an increase in both compressive and flexural strength as well as the modulus

Access article distributed under the terms of the of elasticity. This will help in reducing concrete dimensions in different structural

Creative Commons Attribution 4.0 International members like columns and beams and will contribute towards sustainable devel-

License (CCBY) (http://creativecommons.org/ opment.

licenses/by/4.0/) which permits commercial

use, including reproduction, adaptation, and

distribution of the article provided the original Keywords

author and source are credited.

Graphene, Concrete, Mechanical properties, Additive, Compressive strength,

Published by United Scientific Group Sustainability

Introduction

Because of its unique property of being one of the thinnest but strongest ma-

terials, graphene has developed as one of the most highly promising nanomateri-

als. Several attempts are being undertaken by researchers throughout the world to

investigate the possibilities of employing graphene in various forms in concrete to

improve its properties. A comprehensive study investigated the effect of graphene

dispersed in different dosages 0.5, 0.6, 0.7, 0.8, 0.9, and 1 g/L [1]. The authors

found that graphene inclusion at 1 g/L in concrete increased the flexural, tensile,

and compressive strength by up to 95%, 55%, and 27% respectively. Meanwhile,

an increase in water absorption was observed as well as in shrinkage.

Reddy and Prasad [2] examined the workability, mechanical, durability, and

microstructure features of cement concrete with graphene oxide (GO) additions

of 0.025%, 0.05%, 0.075%, and 0.10%. The test results demonstrated that adding

a little amount of GO to cement concrete significantly increased the strength

qualities yet diminishing the workability. At 28 days, the addition of 0.1% GO

improved compressive, split tensile, and flexural strengths by 38.46%, 14.87%,

and 12.07%, accordingly, as compared to control concrete. However, when the

water absorption of mixes containing GO increased, this shows that GO consid-

erably reduced the volume of pore space.

Jahami et al. S87

Effect of Graphene as Additive on the Mechanical Properties of Concrete Jahami et al.

Zaid et al. [3] carried out a study in which GO was used The results showed that the mechanical and durability charac-

to replace cement at various percentages (0%, 0.03%, 0.06%, teristics of high-strength concrete improved significantly with

0.09%, and 0.12% by cement weight). Steel fibers constituted the addition of GO. As a result, raising the proportion of GO

2% of the binder weight in this study. The findings revealed over 0.075% resulted in a decrease in strength and durability

that combining 0.12% GO with 2% steel fibers increased characteristics.

compressive and split tensile strength by 56% and 37%, cor-

Chen et al. [10] focused on the mechanical properties and

respondingly. As a result, concrete containing GO and steel

shrinkage behavior of concrete containing GO nanosheets.

fibers may be utilized successfully in building applications as a

The author prepared concrete mixtures containing 0.02 wt.%,

sustainable and cost-effective construction material.

0.05 wt.%, and 0.08 wt.% GO. The results show that GO may

Mohammed et al. [4] investigated the behavior of GO enhance the compressive strength, flexural strength, and elas-

at high temperatures in ordinary and high strength concrete. ticity modulus of concrete by 4.04 - 12.65%, 3.8 - 7.38%, and

The experimental results showed that mechanical strength im- 3.92 - 10.97%, respectively, at a concrete age of 28 days. Fur-

proved significantly after 800 °C exposure in both normal and thermore, it was shown that GO enhances the shrinkage strain

high strength specimens with GO. Furthermore, improved of concrete.

resistance to crack formation was reported in GO mixtures,

Based on the previous studies done on graphene, it can

which resulted in the retaining of most of the initial strengths.

be noted that few research was conducted on the effect of

A study was conducted about incorporating GO nanosheets graphene on concrete mechanical properties, and the topic is

in concrete [5]. This study outlines an experimental study of still considered new. Therefore, this article aimed to evaluate

the slump and physical properties of concrete reinforced with the mechanical properties of concrete containing graphene as

GO nanosheets at additions ranging from 0.00% to 0.08% additive. Moreover, new equations relating different mechani-

by weight of cement. The results revealed that increasing the cal properties were derived and compared to the ones provided

level of GO nanosheets from 0.02% to 0.08% increased the by the ACI code for normal concrete. The expected outputs

compressive strength of the concrete. Meanwhile, the slump of of this work include density, elasticity modulus, compressive

concrete containing GO nanosheets falls from 0.02% to 0.80% strength, and flexure strength. Some recommendations for fu-

with the addition of GO nanosheets. The flexural strength val- ture research and practicing engineers were introduced at the

ues improved with the addition of GO nanosheets, ranging end of the article.

from 2.77% to 15.60% at 28 days when the GO nanosheet

concentration increased from 0.02% to 0.08%. The results also Materials and Method

show that 0.03% is the best GO nanosheet dose for increasing

the split tensile strength of concrete. The cement utilized is CEM1 complied with ASTM

C192. The fine aggregate used was 5 mm sand with a density

Bellum et al. [6] explored the effects of GO addition on of 2650 kg/m3, while the coarse aggregate utilized was 10 mm

the compressive strength and modulus of elasticity of geo- crushed limestone with a density of 2550 kg/m3. GO shown in

polymer concrete. When 3% GO was added to a 30% ground figure 1 (Multi-walled carbon nanotube) was purchased from

granulated blast-furnace slag replacement, the compressive an online provider. It has a diameter of 5 - 8 nm and a purity

strength and modulus of elasticity increased by 38.51% and of 97%. Table 1 shows the properties of the GO employed.

28%, respectively, while the chloride ion permeability in-

creased by 65.44%, when compared to the control mix. Based on a series of trial mixes, a concrete mix having a

proportion of 1 (cement): 1.65 (fine aggregate): 3.45 (coarse

Yu and Wu [7] conducted a thorough investigation on the aggregate) by weight was selected as the control mix (GO-0)

usage of GO to improve the characteristics of ultra-high-per- with no GO. The water to cement ratio was 0.5. In the other

formance concrete (UHPC) with fine recycled aggregate. The mixes (GO-0.02, GO-0.035, and GO-0.05), 0.02%, 0.035%,

researchers noted that the addition of GO enhanced the com- and 0.05% of GO were added respectively. Details of all con-

pressive strength, tensile strength, flexural strength, and elas- crete mixes are presented in table 2.

tic modulus of UHPC by 2.04% - 16.04%, 7.36% - 30.50%,

5.83% - 23.40%, and 3.62% - 12.95%, respectively. Further-

more, the addition of GO increased the chloride penetration

resistance and the freezing and thawing resistance of UHPC.

Chu et al. [8] studied the use of GO as an addition for im-

proving the characteristics of UHPC made from recycled sand

in this work. The inclusion of GO increased the compressive

strength, flexural strength, splitting tensile strength, and elas-

tic modulus of recycled sand UHPC by 8.24 - 16.83%, 11.26

- 26.62%, 15.63 - 29.54%, and 5.84 - 12.25%, correspondingly.

Shanmuga et al. [9] also conducted research on the re-

inforcing effects of GO on high-strength concrete prepared

with and without rice husk ash. GO was applied in varying

ratios of 0.025, 0.050, 0.075, and 0.1% by weight of cement.

Figure 1: GO.

NanoWorld Journal | Volume 9 Supplement 2, 2023 S88

Effect of Graphene as Additive on the Mechanical Properties of Concrete Jahami et al.

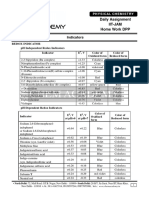

Table 1: Properties of GO. modulus tests, and beam molds with dimensions 100 x 100

x 400 mm for flexural strength test at 7- and 28-days (Fig-

Properties Value ure 4). After that, all specimens were crushed to eliminate the

Name Multi-walled carbon nanotubes trapped air. The specimens were then air-cured in their molds

Purity 97% for 24 hours, then de-molded and moist cured at room tem-

Quantity 20 g perature for 28 days. The cured specimens were then placed in

Diameter 5 - 8 nm an environmental room at 20 °C.

Length 3 - 12 μm

Specific surface area > 233 m²/g

The concrete density of specimens was measured as per

Bulk density 0.15 g/cm3 ASTM C188 [12] requirements. As for elasticity modulus,

Resistivity 1412 μΩm specimens were tested according to ASTM C469 [13] re-

Water content < 1.5% quirements. The compressive strength test was conducted as

per ASTM C109 [14] requirement for cubic specimens and as

Table 2: Details of concrete mixes.

Weight (kg/m3)

Mix Cement Sand Water Gravel GO

GO-0 450 743 225 1543 0

GO-0.02 450 743 225 1543 0.02%

GO-0.035 450 743 225 1543 0.035%

GO-0.05 450 743 225 1543 0.05%

The concrete mix design adopted throughout this study

was in accordance with procedure specified by ASTM C192

[11]. The dry components (Figure 2) were blended for 2 min- Figure 4: Casting concrete.

utes at a moderate speed as shown in figure 3 before the wet

components were poured and well mixed. The Slump test was

conducted for all mixes. The degree of workability was close per ASTM C39 [15] requirements for cylindrical specimens.

for all mixes (15 ± 3 mm). The fresh mixture was poured in 100 Regarding flexure strength, ASTM C78 [16] requirements

mm cubic molds and cylindrical molds with 150 mm diameter were applied for the beam specimens.

and 300 mm height for compressive strength and elasticity

Results and Discussion

Density and elasticity modulus

Figure 5 displays the density results of the different mixes.

The density was 2300, 2303, 2310, and 2340 Kg/m3 for GO-0,

GO-0.02, GO-0.035, and GO-0.05, respectively. The results

showed no significant effect of graphene addition on con-

crete density. Figure 6 shows the average elasticity modulus

for the control mix GO-0 and the mixes with GO (GO-0.02,

GO-0.035, and GO-0.05). The modulus of elasticity ranged

between 20308 MPa and 23354 MPa. Figure 6 depicts the

elasticity modulus improvement of 2.42%, 5%, and 15% re-

spectively for GO-0.02, GO-0.035, and GO-0.05 compared

Figure 2: Concrete components.

Figure 3: Concrete mixing. Figure 5: Density for concrete mixes.

NanoWorld Journal | Volume 9 Supplement 2, 2023 S89

Effect of Graphene as Additive on the Mechanical Properties of Concrete Jahami et al.

to the control mix. As reported by Chen et al. [10], composites GO-0. Figure 8 displays the compressive strength of concrete

made of graphene-based cement show that adding graphene mixes at 7 and 28 days. The 28 days compressive strength was

increases their elastic modulus at low concentration of GO. enhanced by 6.32%, 13%, and 19.25% when adding 0.02%,

According to Ismail et al. [17], graphene at 0.02%, 0.05%, and 0.035%, and 0.05% GO at early age and later ages. The con-

0.10% demonstrated a modulus of elasticity improvement of crete sample GO-0.05 had the maximum enhancement in

21.70%, 1.87%, and 3.48%, respectively, over the reference strength. A similar trend was observed by Ismail et al. [17],

sample. showing an increase in compressive strength of 20.82, 8.41,

and 9.48% compared to the reference specimen by adding

According to ACI code, there is a relation between the

0.02, 0.05, and 0.10% GO nanoplates. The concrete sample

elasticity modulus and both concrete density and compressive

GO-0.05 had the maximum enhancement in strength. Con-

strength. The relation is as follows:

versely, Ismail et al. [17] showed that adding 0.02% graphene

represents the higher strength at different ages. With an in-

crease in GO content in the concrete mixtures, a progressive

rise in strength may be seen.

Figure 9 illustrates the cubic compressive strength and

cylindrical compressive strength of the four different mixes

(GO-0, GO-0.02, GO-0.035, and GO-0.05). The ratio of

compressive strength between cubical and cylindrical speci-

men ranged between 0.73 and 0.8 which is acceptable.

Figure 6: Elasticity modulus for concrete mixes.

E = 0.043w1.5 f 'c (1)

Where, “E” is the elasticity modulus in MPa, “w” is the

density in MPa, and f ’c is the concrete compressive strength

in MPa. Based on the experimental findings, a trend line is

plotted as shown in figure 7. According to this figure, concrete Figure 8: Compressive strength for concrete mixes.

with GO can have the following trend line equation:

Flexural strength

1.5

E = 0.049w f 'c (2) Figure 10 shows the flexural strength of concrete samples

with varying content of GO. The flexural strength results were

4.65, 4.71, 5.05, and 5.51 MPa for GO-0, GO-0.02, GO-

A slight change in the constant is realized in the presence 0.035, and GO-0.05 respectively. The increase in GO percent-

of GO in concrete. The “R2” of this equation was around 0.99. ages up to 0.05% contributed to the improvement in flexural

Compressive strength strength which confirms the results of previous studies. Max-

imum flexural strength was obtained on addition of 0.05% of

The compressive strength of the concrete samples was as-

sessed after curing for 7 and 28 days. The sample with GO has

improved compressive strength compared to the control mix

Figure 7: Elasticity modulus trend line according to the experimental

work and ACI code. Figure 9: Cubic and cylindrical compressive strength of concrete mixes.

NanoWorld Journal | Volume 9 Supplement 2, 2023 S90

Effect of Graphene as Additive on the Mechanical Properties of Concrete Jahami et al.

GO. The results also outlined that the flexural strength in- • Based on the experimental findings, a slight change in the

creased by 1.3%, 8.6%, and 18.5% respectively for GO-0, GO- constant was observed in the presence of GO in concrete

0.02, and GO-0.035. As noted by Shanmuga et al. [9], the regarding the relation between the elasticity modulus and

flexural strength increased by 26.81% at the end of 28 days, on both concrete density and compressive strength.

adding 0.075% of GO. The flexural results in figure 10 confirm • Adding 0.05% GO resulted in the maximum

the findings of the previous research. enhancement of compressive strength (19.25%). The

A trend curve was plotted for the experimental results strength of the concrete mixes gradually increased as the

relating both compressive strength and flexure strength. The GO content was increased.

curve has a formula of: • The flexural strength results showed a progressive

enhancement with the increase of GO percentages.

f r = 0.3541f 'c 0.8816 (3) Based on the experimental findings, a different equation

was adopted in the presence of GO in concrete regarding

Where, “fr” is the flexure strength in MPa and “f ’c” is the the relation between compressive strength and flexural

compressive strength in MPa. This is different from the rela- strength. The trend line showed a higher flexural strength

tion adopted by the ACI code that relates the same parameters at a determined compressive strength for GO mixes. This

for conventional concrete which is defined as follows: indicates that GO mixes achieved higher tensile strength

and ductility than the control mix.

f r = 0.625f 'c 0.5 (4)

• In general, the introduction of 0.05% GO resulted in

higher compressive strength, more ductility, and tensile

strength compared to the control mix.

Acknowledgments

None.

Conflict of Interest

All authors declare that they have no conflicts of interest.

References

1. Dalal SP, Dalal P. 2021. Experimental investigation on strength and du-

rability of graphene nanoengineered concrete. Constr Build Mater 276:

Figure 10: Flexural strength of concrete mixes. 122236. https://doi.org/10.1016/j.conbuildmat.2020.122236

2. Reddy PV, Prasad RD. 2023. Graphene oxide reinforced cement con-

Figure 11 shows the plot of both relations. For the same crete–a study on mechanical, durability and microstructure characteris-

compressive strength, concrete with GO has higher flexure tics. Fuller Nanotub Carbon Nanostruct 31(3): 255-265. https://doi.org/

10.1080/1536383X.2022.2141231

strength than conventional concrete. This means better tensile

strength and ductility for GO concrete is achieved compared 3. Zaid O, Hashmi SR, Aslam F, Abedin ZU, Ullah A. 2022. Experi-

mental study on the properties improvement of hybrid graphene oxide

to conventional concrete.

fiber-reinforced composite concrete. Diam Relat Mater 124: 108883.

https://doi.org/10.1016/j.diamond.2022.108883

4. Mohammed A, Sanjayan JG, Nazari A, Al-Saadi NT. 2017. Effects of

graphene oxide in enhancing the performance of concrete exposed to

high-temperature. Aust J Civil Eng 15(1): 61-71. https://doi.org/10.10

80/14488353.2017.1372849

5. Wu YY, Que L, Cui Z, Lambert P. 2019. Physical properties of concrete

containing graphene oxide nanosheets. Materials 12(10): 1707. https://

doi.org/10.3390/ma12101707

6. Bellum RR, Muniraj K, Indukuri CS, Madduru SR. 2020. Investigation

on performance enhancement of fly ash-GGBFS based graphene geo-

polymer concrete. J Build Eng 32: 101659. https://doi.org/10.1016/j.

Figure 11: Relation between compressive strength and flexural strength. jobe.2020.101659

7. Yu L, Wu R. 2020. Using graphene oxide to improve the properties

Conclusions of ultra-high-performance concrete with fine recycled aggregate.

Constr Build Mater 259: 120657. https://doi.org/10.1016/j.conbuild-

The main findings of this study are as follows: mat.2020.120657

8. Chu H, Zhang Y, Wang F, Feng T, Wang L, et al. 2020. Effect

• The addition of GO to the concrete mix resulted in an

of graphene oxide on mechanical properties and durability of ul-

increase in the elasticity modulus. The addition of 0.05% tra-high-performance concrete prepared from recycled sand. Nanoma-

graphene in concrete showed a 15% improvement in terials 10(9): 1718. https://doi.org/10.3390/nano10091718

elasticity modulus results.

NanoWorld Journal | Volume 9 Supplement 2, 2023 S91

Effect of Graphene as Additive on the Mechanical Properties of Concrete Jahami et al.

9. Priya ST, Mehra A, Jain S, Kakria K. 2021. Effect of graphene oxide 14. ASTM C109/C109M-21. Standard Test Method for Compressive

on high-strength concrete induced with rice husk ash: mechanical and Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube

durability performance. Innov Infrastruct Solut 6: 1-16. https://doi. Specimens). [https://www.astm.org/c0109_c0109m-21.html] [Ac-

org/10.1007/s41062-020-00378-9 cessed September 25, 2023]

10. Chen Z, Xu Y, Hua J, Wang X, Huang L, et al. 2020. Mechanical prop- 15. ASTM C39/C39M-21. Standard Test Method for Compressive

erties and shrinkage behavior of concrete-containing graphene-oxide Strength of Cylindrical Concrete Specimens. [https://www.astm.org/

nanosheets. Materials 13(3): 590. https://doi.org/10.3390/ma13030590 c0039_c0039m-21.html] [Accessed September 25, 2023]

11. ASTM C192/C192M-19. Standard Practice For Making and Curing 16. ASTM C78-09. Standard Test Method for Flexural Strength of Con-

Concrete Test Specimens in the Laboratory. [https://webstore.ansi.org/ crete (Using Simple Beam with Third-Point Loading). [https://www.

standards/astm/astmc192c192m19] [Accessed September 25, 2023] astm.org/standards/c78] [Accessed September 25, 2023]

12. ASTM C188-95(2003). Standard Test Method for Density of Hy- 17. Ismail FI, Shafiq N, Abbas YM, Zahid M, Bheel N, et al. 2023. The

draulic Cement. [https://www.astm.org/c0188-95r03.html] [Accessed behavior of graphene-nanoplatelets-based high-performance concrete

September 25, 2023] under ambient curing. Structures 47: 694-708. https://doi.org/10.1016/j.

istruc.2022.11.086

13. ASTM C469/C469M-14. Standard Test Method for Static Modulus

of Elasticity and Poisson’s Ratio of Concrete in Compression. [https://

www.astm.org/c0469_c0469m-14.html] [Accessed September 25,

2023]

NanoWorld Journal | Volume 9 Supplement 2, 2023 S92

You might also like

- A Final Link in The Global Hydrogen Supply Chain: "Spera Overcomes Many of TheDocument1 pageA Final Link in The Global Hydrogen Supply Chain: "Spera Overcomes Many of TheFlogamagNo ratings yet

- Modified CementsDocument6 pagesModified CementsThisari MunmullaNo ratings yet

- Graphene-Iron Ore Tailings-Based Cementitious Composites With High Early Flexural StrengthDocument17 pagesGraphene-Iron Ore Tailings-Based Cementitious Composites With High Early Flexural StrengthchinnaswamygopalamNo ratings yet

- 12 - Experimental Investigations On The Impact of Graphene-Based Oxides in ConcreteDocument6 pages12 - Experimental Investigations On The Impact of Graphene-Based Oxides in ConcreteIsmael Eliú Rodas MontoyaNo ratings yet

- Journal of Building Engineering: S.C. Devi, R.A. KhanDocument12 pagesJournal of Building Engineering: S.C. Devi, R.A. Khanshri ramNo ratings yet

- Electrochemically Produced Graphene With Ultra Large Particles Enhances Mechanical Properties of Portland Cement MortarDocument15 pagesElectrochemically Produced Graphene With Ultra Large Particles Enhances Mechanical Properties of Portland Cement MortarJefferson Prof. Engenharia CivilNo ratings yet

- 3.improving Mechanics Behavior of Hot Mix Asphalt Using Graphene-OxideDocument8 pages3.improving Mechanics Behavior of Hot Mix Asphalt Using Graphene-OxideDharmendraMahtoNo ratings yet

- 10 1016@j Conbuildmat 2020 121093Document17 pages10 1016@j Conbuildmat 2020 121093Noor Ul Amin AwanNo ratings yet

- Influence of Pristine Graphene Particle Sizes On Physicochemical, Microstructural and Mechanical Properties of Portland Cement MortarsDocument12 pagesInfluence of Pristine Graphene Particle Sizes On Physicochemical, Microstructural and Mechanical Properties of Portland Cement MortarsJefferson Prof. Engenharia CivilNo ratings yet

- Articulo 3Document7 pagesArticulo 3gustavo vegaNo ratings yet

- Template SPRINGERDocument12 pagesTemplate SPRINGERCSE R. AISHWARYANo ratings yet

- Fmats 10 1128095Document17 pagesFmats 10 1128095İsmail KalafatNo ratings yet

- Articulo 2Document14 pagesArticulo 2gustavo vegaNo ratings yet

- Materials 16 04457Document17 pagesMaterials 16 04457Mithun KanishkaNo ratings yet

- Sustainability 15 08054 v2Document12 pagesSustainability 15 08054 v2Sam SalahNo ratings yet

- Opolymer Graphene ##Document8 pagesOpolymer Graphene ##fs friedaNo ratings yet

- Insights Into The Mechanism of Graphene Acting On Water and Chloride Ion Permeability of Cement-Based MaterialsDocument18 pagesInsights Into The Mechanism of Graphene Acting On Water and Chloride Ion Permeability of Cement-Based MaterialsJefferson Prof. Engenharia CivilNo ratings yet

- Nanomaterials 12 00833Document15 pagesNanomaterials 12 00833gustavo vegaNo ratings yet

- Characterisation of "One-Part" Ambient Cured Engineered Geopolymer CompositesDocument14 pagesCharacterisation of "One-Part" Ambient Cured Engineered Geopolymer CompositesJee Hock LimNo ratings yet

- Construction and Building Materials: Yu Shang, Dong Zhang, Chao Yang, Yanyun Liu, Yong LiuDocument9 pagesConstruction and Building Materials: Yu Shang, Dong Zhang, Chao Yang, Yanyun Liu, Yong LiuLeonardo LealNo ratings yet

- Effect of Mineral Admixture GGBS On ConcDocument15 pagesEffect of Mineral Admixture GGBS On ConcSumanNo ratings yet

- Various NaOH Molarities (Mukhallad M.AL-mashhadani)Document9 pagesVarious NaOH Molarities (Mukhallad M.AL-mashhadani)ROHIT RANJANNo ratings yet

- Construction and Building MaterialsDocument8 pagesConstruction and Building MaterialsVeronika PrymNo ratings yet

- Study On Compressive Strength of Concrete On Partial Replacement of Cement With Ground Granulated Blast Furnace Slag (GGBS)Document10 pagesStudy On Compressive Strength of Concrete On Partial Replacement of Cement With Ground Granulated Blast Furnace Slag (GGBS)John Carlo CayananNo ratings yet

- 1 s2.0 S1359835X17302804 MainDocument10 pages1 s2.0 S1359835X17302804 MainSiva GuruNo ratings yet

- The Use of Superabsorbent Polymers To Reduce Cracki - 2014 - Cement and ConcreteDocument8 pagesThe Use of Superabsorbent Polymers To Reduce Cracki - 2014 - Cement and ConcreteKatarzyna OsowskaNo ratings yet

- Comparative Study On Tensile Strength and Impact Load Carrying Capacity of Concrete With Rubber and Steel FiberDocument10 pagesComparative Study On Tensile Strength and Impact Load Carrying Capacity of Concrete With Rubber and Steel Fiberjai2009No ratings yet

- materials-14-03073Document15 pagesmaterials-14-03073Ibeh joelNo ratings yet

- Construction and Building Materials: A. Mohammed, J.G. Sanjayan, W.H. Duan, A. NazariDocument7 pagesConstruction and Building Materials: A. Mohammed, J.G. Sanjayan, W.H. Duan, A. NazariahmadNo ratings yet

- 09 - Durability Assessment of High-Performance Concretes Containing Graphene OxideDocument8 pages09 - Durability Assessment of High-Performance Concretes Containing Graphene OxideIsmael Eliú Rodas MontoyaNo ratings yet

- Artículo 6Document7 pagesArtículo 6Paula Camila Arias CaicedoNo ratings yet

- DivyaDocument25 pagesDivyaKingshuk MukherjeeNo ratings yet

- Flysah 1Document8 pagesFlysah 1Ashraff JawahirNo ratings yet

- Influence of Graphene Oxide On The Mechanical Properties, Fracture Toughness, and Microhardness of Recycled ConcreteDocument14 pagesInfluence of Graphene Oxide On The Mechanical Properties, Fracture Toughness, and Microhardness of Recycled ConcreteAdemar GrossNo ratings yet

- Property Assessment of Concretes With Graphene OxideDocument7 pagesProperty Assessment of Concretes With Graphene OxideAlireza AzarioonNo ratings yet

- LAXMIDocument15 pagesLAXMIDivya SharmaNo ratings yet

- Short and Long Term Properties of Glass Fiber Reinforced Asphalt Mixtures PDFDocument14 pagesShort and Long Term Properties of Glass Fiber Reinforced Asphalt Mixtures PDFAli YousefNo ratings yet

- A Review Paper On Graphene Modified CementDocument9 pagesA Review Paper On Graphene Modified CementZunnun Bari PialNo ratings yet

- Effects of Graphene Oxide Agglomerates On Workability, Hydration, Microstructure and Compressive Strength of Cement Paste PDFDocument9 pagesEffects of Graphene Oxide Agglomerates On Workability, Hydration, Microstructure and Compressive Strength of Cement Paste PDFAhmed AsemNo ratings yet

- Ref 2Document17 pagesRef 2Julhiño Huamani ChucoNo ratings yet

- 1 s2.0 S1674775521000081 MainDocument14 pages1 s2.0 S1674775521000081 Mainvhb84476No ratings yet

- IRJET-V8I993Document5 pagesIRJET-V8I993nallanagulapadhu29No ratings yet

- Behaviour of High Performance Blended Ternary Concrete Prepared Using Alternative MaterialsDocument9 pagesBehaviour of High Performance Blended Ternary Concrete Prepared Using Alternative MaterialsAnnals of Earth, Environment, and Infrastructure EngineeringNo ratings yet

- 1 s2.0 S2352710219310484 MainDocument15 pages1 s2.0 S2352710219310484 MainjedaNo ratings yet

- Construction and Building MaterialsDocument20 pagesConstruction and Building MaterialsSPK-CIVIL PSG CTNo ratings yet

- Flexural Performance and ToughDocument20 pagesFlexural Performance and ToughDiana Rose B. DatinguinooNo ratings yet

- 1 s2.0 S1018363923000284 MainDocument11 pages1 s2.0 S1018363923000284 MainRidwanNo ratings yet

- Statistical Modeling of Rubberized Concrete Beams Confined by FRP Using RSM TechniqueDocument12 pagesStatistical Modeling of Rubberized Concrete Beams Confined by FRP Using RSM TechniqueSamsouma BkNo ratings yet

- Buildings 12 01554Document18 pagesBuildings 12 01554Ayman ZakariaNo ratings yet

- Durability Characteristics of Steel Fibre Reinforced Geopolymer ConcreteDocument6 pagesDurability Characteristics of Steel Fibre Reinforced Geopolymer ConcreteNanditha Mandava Chowdary100% (1)

- Investigate The Potential of Hypo Sludge and Steel Fiber, Which Can Be Partially Mixed Into The ConcreteDocument4 pagesInvestigate The Potential of Hypo Sludge and Steel Fiber, Which Can Be Partially Mixed Into The ConcreteResearch ParkNo ratings yet

- The Influence of Coarse Aggregate Size and Volume On The Fracture Behavior and Brittleness of Self-Compacting ConcreteDocument16 pagesThe Influence of Coarse Aggregate Size and Volume On The Fracture Behavior and Brittleness of Self-Compacting ConcreteAmou EbiNo ratings yet

- Improvement of Engineering Properties of Fibre Reinforced Self Compacting Concrete With Addition of Granite WasteDocument6 pagesImprovement of Engineering Properties of Fibre Reinforced Self Compacting Concrete With Addition of Granite WasteEditor IJTSRDNo ratings yet

- 1 s2.0 S0010938X16311751 MainDocument15 pages1 s2.0 S0010938X16311751 MainRobson CostaNo ratings yet

- Improving Functional and Environmental Performance of Portland Cement-Based Materials by Graphene NanostructuresDocument8 pagesImproving Functional and Environmental Performance of Portland Cement-Based Materials by Graphene Nanostructuresസഖാവ് ഹരിNo ratings yet

- SynopsisDocument6 pagesSynopsisVijithNo ratings yet

- Experimental Investigation On The Effect of Curing Condition and Admixture On Meso-Structure of Recycled Aggregate Concrete Based On X-Ray CTDocument14 pagesExperimental Investigation On The Effect of Curing Condition and Admixture On Meso-Structure of Recycled Aggregate Concrete Based On X-Ray CTsabariazNo ratings yet

- Research Progress On The Effect of Graphene Oxide On The Properties of Cement-Based CompositesDocument18 pagesResearch Progress On The Effect of Graphene Oxide On The Properties of Cement-Based CompositesMohd Zain KangdaNo ratings yet

- (2021) Effect of Calcium Sulfoaluminate and MgO Expansive Agent On The Mechanical Strength and Crack Resistance of ConcreteDocument10 pages(2021) Effect of Calcium Sulfoaluminate and MgO Expansive Agent On The Mechanical Strength and Crack Resistance of ConcreteRamón RamalhoNo ratings yet

- Panda Et Al. - Synthesis and Characterization of One-Part Geopolymers For Extrusion Based 3D Concrete PrintingDocument10 pagesPanda Et Al. - Synthesis and Characterization of One-Part Geopolymers For Extrusion Based 3D Concrete PrintingManu K MohanNo ratings yet

- 2021 Article 5271Document13 pages2021 Article 5271sitinurmilahNo ratings yet

- Masteremaco N 303 TdsDocument2 pagesMasteremaco N 303 TdsChaitanya MehtaNo ratings yet

- Zhang 2019Document18 pagesZhang 2019Aysu UlusalNo ratings yet

- Cuckow 1949Document6 pagesCuckow 1949Thai NghNo ratings yet

- Chem Academy: Daily Assignment Iit-Jam Home Work DPPDocument3 pagesChem Academy: Daily Assignment Iit-Jam Home Work DPPjkc collegeNo ratings yet

- Starch Fatty EsteresDocument6 pagesStarch Fatty EsteresRobertaSouzaNo ratings yet

- Systematic Analysis of Simple Salt S9 - Calcium Carbonate Caco Preliminary TestsDocument4 pagesSystematic Analysis of Simple Salt S9 - Calcium Carbonate Caco Preliminary TestsAnitha SNo ratings yet

- Aldol InstrDocument7 pagesAldol Instrmed jrNo ratings yet

- Cambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationDocument7 pagesCambridge Secondary 1 Checkpoint: Cambridge Assessment International Educationigloo79No ratings yet

- Experiment No. 5: ObjectDocument5 pagesExperiment No. 5: ObjectDarshil GalaiyaNo ratings yet

- Evaporation Rate Esters, Derivatives and Other SolventsDocument2 pagesEvaporation Rate Esters, Derivatives and Other SolventsAminulIslamNo ratings yet

- Mastertop Primer 2 PDFDocument2 pagesMastertop Primer 2 PDFFrancois-No ratings yet

- Mitochondria: Structure and FunctionDocument6 pagesMitochondria: Structure and FunctionHariniNo ratings yet

- LS Carbonate ShortcourseDocument44 pagesLS Carbonate ShortcourseKaharuddin HawingNo ratings yet

- A Thank You From Wikipedia Founder Jimmy Wales: Atoms in MoleculesDocument3 pagesA Thank You From Wikipedia Founder Jimmy Wales: Atoms in MoleculesCA Meenaxi SoniNo ratings yet

- Biochemistry Anabolism of Lipids: Principal Investigator Dr. Sunil Kumar Khare, ProfessorDocument10 pagesBiochemistry Anabolism of Lipids: Principal Investigator Dr. Sunil Kumar Khare, Professorninafatima allamNo ratings yet

- (NON Insulated) Structure Steel, Piping (Up To 120 Q) : Galbon S-HB 100Document11 pages(NON Insulated) Structure Steel, Piping (Up To 120 Q) : Galbon S-HB 100katfy1No ratings yet

- CBSE Class-12 Chemistry Quick Revision Notes Chapter-01: The Solid StateDocument15 pagesCBSE Class-12 Chemistry Quick Revision Notes Chapter-01: The Solid StateRitik Kumar NayakNo ratings yet

- The Evolution of DNA Extraction Methods: Review ArticleDocument7 pagesThe Evolution of DNA Extraction Methods: Review ArticleUmi Aminah Dinda SupardiNo ratings yet

- Melamine FormaldehydeDocument15 pagesMelamine FormaldehydePar Pt YaaniNo ratings yet

- LamanniaDocument13 pagesLamanniaDenis RamosNo ratings yet

- 11 - The P-Block ElementsDocument1 page11 - The P-Block ElementsPuppika DogNo ratings yet

- CHE 026L LAS Mod 2 - Laboratory Apparatus and EquipmentDocument22 pagesCHE 026L LAS Mod 2 - Laboratory Apparatus and EquipmentCyra BantilloNo ratings yet

- Homeostasis Topic 14 A Level Biology Classified Past Papers 2010-2019Document45 pagesHomeostasis Topic 14 A Level Biology Classified Past Papers 2010-2019ADEEL AHMAD100% (1)

- BIO307 Lecture (Protein Structure and Function)Document18 pagesBIO307 Lecture (Protein Structure and Function)Kerstin MarobelaNo ratings yet

- Gen ChemDocument226 pagesGen ChemKemal PujabNo ratings yet

- Gómez Et Al (2018) Physicochemical Evaluation of Low-Fat YoghurtDocument7 pagesGómez Et Al (2018) Physicochemical Evaluation of Low-Fat YoghurtTahir AliNo ratings yet

- Silicone Rubber PropertiesDocument15 pagesSilicone Rubber PropertiesSh.nasirpurNo ratings yet

- 2-Eha PRCS1Document45 pages2-Eha PRCS1MARISSE LYN DORADONo ratings yet