Professional Documents

Culture Documents

TDS-COPO313-EN-Rev1-TJP

TDS-COPO313-EN-Rev1-TJP

Uploaded by

QC DYACopyright:

Available Formats

You might also like

- Supplement Chapter 5 DT AnswersDocument11 pagesSupplement Chapter 5 DT AnswersJea BalagtasNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- TDS-PP2131-EN-Rev1015-MBAPA[1]Document2 pagesTDS-PP2131-EN-Rev1015-MBAPA[1]QC DYANo ratings yet

- TDS-GRADE_1-EN-Rev1-TJPDocument2 pagesTDS-GRADE_1-EN-Rev1-TJPQC DYANo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- ARYA_SASOL_LIM1922[2]Document3 pagesARYA_SASOL_LIM1922[2]Murat DalgicNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- Tecacomp Peek 450 Natural 1015088Document1 pageTecacomp Peek 450 Natural 1015088Kumaar RanjanNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- Plastdepo Tpe 30an TDSDocument1 pagePlastdepo Tpe 30an TDSnisannnNo ratings yet

- Trimma FM6341HFDocument2 pagesTrimma FM6341HFJUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- Petra 130 SpecsDocument2 pagesPetra 130 SpecssdecarlogaNo ratings yet

- Styrolution TDS300600621530Document2 pagesStyrolution TDS300600621530seguridadehigieneseguridadehigNo ratings yet

- Total 3645Document1 pageTotal 3645M. Kürşad ArslanNo ratings yet

- Technical Data Sheet - TheRMOFIL PP F820R00 Natural-Sumika Polymer Compounds Ltd. (2017)Document2 pagesTechnical Data Sheet - TheRMOFIL PP F820R00 Natural-Sumika Polymer Compounds Ltd. (2017)Priyalakshmi NarasimhanNo ratings yet

- PP h4120 TdsDocument2 pagesPP h4120 TdsengrmfawadazharNo ratings yet

- Ecopond PBATDocument3 pagesEcopond PBATsoniud14No ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- POM KEPITAL F30-03 enDocument2 pagesPOM KEPITAL F30-03 enAthonioMourinhoNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- Abp-2030 Tds-Iso-EngDocument2 pagesAbp-2030 Tds-Iso-Engkatolokchok100% (2)

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Celstran® PA66-GF50-07Document1 pageCelstran® PA66-GF50-07Ankur PanwarNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- Kepital F20 - 03Document2 pagesKepital F20 - 03Kumaar RanjanNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- LOXILENE-PP-Talc 20%Document2 pagesLOXILENE-PP-Talc 20%pava16230.meNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- TDS - Megalon® 150GHSLDocument1 pageTDS - Megalon® 150GHSLshawnNo ratings yet

- 70g33gra BK350Document2 pages70g33gra BK350Ranjan GnanaoliNo ratings yet

- Name: Name: Name: Name: ABS710 ABS710 ABS710 ABS710Document2 pagesName: Name: Name: Name: ABS710 ABS710 ABS710 ABS710DiegoTierradentroNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- Pla - FC 32230 - ErtDocument2 pagesPla - FC 32230 - ErtfernandoincesaNo ratings yet

- Datasheet Cawiton PR13665 - 002 PDFDocument1 pageDatasheet Cawiton PR13665 - 002 PDFFred HahnNo ratings yet

- Hopelex Pc-1100uDocument2 pagesHopelex Pc-1100uChu ChuNo ratings yet

- Tds Heraform r900 Nat EngDocument2 pagesTds Heraform r900 Nat EngSenophoeNo ratings yet

- Datasheet Cawiton PR13650 - 004 PDFDocument1 pageDatasheet Cawiton PR13650 - 004 PDFFred HahnNo ratings yet

- POM - KEPITAL F20-03 - Standard GradeDocument2 pagesPOM - KEPITAL F20-03 - Standard GradeMadhav RajpurohitNo ratings yet

- Norsodyne H 16239 enDocument1 pageNorsodyne H 16239 enFachrurraziNo ratings yet

- TDS PEEK Filament PDFDocument2 pagesTDS PEEK Filament PDFRui MatiasNo ratings yet

- TDS PEEK Filament 1Document2 pagesTDS PEEK Filament 1Krzysztof KardachNo ratings yet

- Desmopan 3059D - en - 00898365 00000542 20011347Document2 pagesDesmopan 3059D - en - 00898365 00000542 20011347sosal salvadosNo ratings yet

- TDS PBT 5829F-105Document2 pagesTDS PBT 5829F-105TRUONGNo ratings yet

- Datasheet Cawiton PR13675 - 002Document1 pageDatasheet Cawiton PR13675 - 002Fred HahnNo ratings yet

- Styrolution 3 G55Document3 pagesStyrolution 3 G55John EduardoNo ratings yet

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoNo ratings yet

- Material-Datasheet MT41VG ISODocument2 pagesMaterial-Datasheet MT41VG ISOPrashanth RNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Teldene®: Technical Data SheetDocument2 pagesTeldene®: Technical Data SheetLFCV5No ratings yet

- Ejemplo Hoja Caracteristicas Granza PPDocument1 pageEjemplo Hoja Caracteristicas Granza PPalfredorozalenNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- Ultramid_sup_®__sup_+A3WGM53+BLACK+20560 (4)Document2 pagesUltramid_sup_®__sup_+A3WGM53+BLACK+20560 (4)Vikas Rao CheetiNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Ultramid A205fDocument3 pagesUltramid A205fSATHISH KUMAR SNo ratings yet

- BNO Thermo Oil-32 (Mineral Based) : Product Data SheetDocument2 pagesBNO Thermo Oil-32 (Mineral Based) : Product Data SheetAyon HossenNo ratings yet

- Datasheet-Ultra Hh-4115-Hi-IsoDocument3 pagesDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Chang Chun Plastics CO., LTDDocument2 pagesChang Chun Plastics CO., LTDChunYenHuangNo ratings yet

- Ruralstar Site Tower Construction SOP V3.0Document48 pagesRuralstar Site Tower Construction SOP V3.0goytomhayle8126No ratings yet

- Financial MathDocument50 pagesFinancial Mathfabricioace1978No ratings yet

- 1 March Practice PDF - 09Document22 pages1 March Practice PDF - 09arpitNo ratings yet

- Sag DRG-1Document6 pagesSag DRG-1rupesh417No ratings yet

- Allahabad Bank Annual Report 2014 15Document242 pagesAllahabad Bank Annual Report 2014 15SanaNo ratings yet

- Economic Theories of The Firm - Past, Present, and Future PDFDocument16 pagesEconomic Theories of The Firm - Past, Present, and Future PDFJeremiahOmwoyoNo ratings yet

- Economic Analysis For BusinessDocument2 pagesEconomic Analysis For BusinessMohan BaralNo ratings yet

- BDO BF Homes Aguirre - CostingDocument29 pagesBDO BF Homes Aguirre - CostingPaula SicatNo ratings yet

- Course Outline Technology EntrepreneurshipDocument3 pagesCourse Outline Technology EntrepreneurshipBisma khanNo ratings yet

- Economics Quiz 3Document3 pagesEconomics Quiz 3Pao EspiNo ratings yet

- Supply Chain Management ReportsDocument19 pagesSupply Chain Management ReportsSazeeth SinghNo ratings yet

- SSC MTS 2023 Tier 1 Sept 5 Shift 1Document32 pagesSSC MTS 2023 Tier 1 Sept 5 Shift 1Mina MeenaNo ratings yet

- First-Utility-bill-for-114-77-NIEPEL PIERRE ROBINDocument1 pageFirst-Utility-bill-for-114-77-NIEPEL PIERRE ROBINelaamlyNo ratings yet

- Sales Quiz 1Document3 pagesSales Quiz 1Roldan Cejuela CañadaNo ratings yet

- Indian FinalDocument65 pagesIndian Final04 Sourabh BaraleNo ratings yet

- PT Menolak Rugi Jurnal ZeovDocument68 pagesPT Menolak Rugi Jurnal Zeovtarakannnn364No ratings yet

- Pt. Bangun Sarana Graha LestariDocument9 pagesPt. Bangun Sarana Graha Lestariandre comalNo ratings yet

- Chapter-The Age of Industrialisation: Multiple Choice QuestionDocument6 pagesChapter-The Age of Industrialisation: Multiple Choice QuestionAbhilash GSNo ratings yet

- TDI Válvula Relevadora Mca. TDIDocument14 pagesTDI Válvula Relevadora Mca. TDIJorge CalcaneoNo ratings yet

- Family Leadership Succession and Firm Performance: The Moderating Effect of Tacit Idiosyncratic Firm KnowledgeDocument9 pagesFamily Leadership Succession and Firm Performance: The Moderating Effect of Tacit Idiosyncratic Firm KnowledgeJorge Ivan Villada LizarazoNo ratings yet

- Unit 5 Acceptance Sampling Plans: StructureDocument18 pagesUnit 5 Acceptance Sampling Plans: Structurevinay100% (2)

- IMF and World BankDocument2 pagesIMF and World BankMinh HàNo ratings yet

- Prospectus MPL 33rd - National U17 2023Document8 pagesProspectus MPL 33rd - National U17 2023sanchita yadav100% (1)

- Somas ValveGuide EN 2022 Dokumentbank PDFDocument17 pagesSomas ValveGuide EN 2022 Dokumentbank PDFrendymulyadiNo ratings yet

- Raft Slab LayoutDocument1 pageRaft Slab LayoutDINESH M.NNo ratings yet

- New QC MPR Format, Oct.22,09.11.2022Document14 pagesNew QC MPR Format, Oct.22,09.11.2022Devendra SinghNo ratings yet

- Adhoc00000007241758 2000712387Document6 pagesAdhoc00000007241758 2000712387Suman KumarNo ratings yet

- BeautyDocument8 pagesBeautypaolaNo ratings yet

- Vimal Moulders India Pvt. Ltd. First/Last Part Approval Inspection ReportDocument1 pageVimal Moulders India Pvt. Ltd. First/Last Part Approval Inspection ReportartiNo ratings yet

TDS-COPO313-EN-Rev1-TJP

TDS-COPO313-EN-Rev1-TJP

Uploaded by

QC DYACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS-COPO313-EN-Rev1-TJP

TDS-COPO313-EN-Rev1-TJP

Uploaded by

QC DYACopyright:

Available Formats

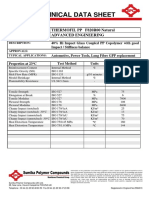

Technical Data Sheet

COPO 313

Description

A post-consumer recycled polypropylene copolymer for general use. Available in

standard black.

Material Properties

Physical Value Unit Test Method

Density 0.92 g/cm3

MBA method

Rheological

Melt Flow Rate (230°C / 2.16 kg) 13 g/10 min ISO 1133

Mechanical

Tensile Modulus (23°C) 1350 MPa ISO 527-2/1

Tensile Stress at Yield (23°C) 24 MPa ISO 527-2/50

Flexural Modulus (23°C) 1500 MPa ISO 178/2

Shrinkage 1,7 % MBA method

Impact

Izod Impact Strength, notched (23°C) 6 kJ/m2 ISO 180/1A

Charpy Impact Strength, notched (23°C) 5.5 kJ/m2 ISO 179/1eA

Thermal

Vicat Softening Temperature 80 °C ISO 306/B50

Note:

The data above is provided in good faith and represents typical properties based on our current knowledge and experience.

The information concerning shrinkage has been received on the dimentions of a specimen bar and not from a final product. We

recommend a separate production on other similar comonents to define the final shrinkage.

Product properties may be changed without notice. These properties are provided as a guide and should not be construed as binding

specification limits or minimum values. This document does not create any liability, warranty or guarantee of product performance. It is

the buyer's responsibility to determine the suitability of TJP products for the intended application.

CV. TELAJUNG SELARAS PLASTIK Contact Information : TDS-COPO313-EN

Jl. Raya Setu – Serang, Kp. Telajung RT. 002/004 No. 42-43 Phone : 0813-2396-5961 Rev 1

Kecamatan Cikarang Barat, Kabupaten Bekasi 17520 Phone 2 : 0821-1496-1075 Page 1 of 2

E-mail: officetOmba-polymers.at

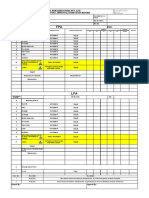

Technical Data Sheet

COPO 313

Processing Information

Value Unit

Preprocessing

80 °C

Drying Temperature

Drying Time 0 hr

Moisture Content <0.05-0.10 %

Injection Molding

Melt Temperature Range 190-220 °C

Recommended Melt Temperature 200 °C

Mold Temperature Range 30-60 °C

Recommended Mold Temperature 40 °C

Recommended Screw Back Pressure 100-150 bar

Extrusion

Melt Temperature Range 180-210 °C

Recommended Melt Temperature 200 °C

Note:

The processing parameters listed above are general guidelines based on our current knowledge and experience. The suitability of the

data for a specific processing method can only be ensured with investigations and tests by the end user.

CV. TELAJUNG SELARAS PLASTIK Contact Information : TDS-COPO313-EN

Jl. Raya Setu – Serang, Kp. Telajung RT. 002/004 No. 42-43 Phone : 0813-2396-5961 Rev 1

Kecamatan Cikarang Barat, Kabupaten Bekasi 17520 Phone 2 : 0821-1496-1075 Page 2 of 2

E-mail: officetOmba-polymers.at

You might also like

- Supplement Chapter 5 DT AnswersDocument11 pagesSupplement Chapter 5 DT AnswersJea BalagtasNo ratings yet

- Mineral Reinforced PP: Features ApplicationsDocument2 pagesMineral Reinforced PP: Features ApplicationskatolokchokNo ratings yet

- TDS-PP2131-EN-Rev1015-MBAPA[1]Document2 pagesTDS-PP2131-EN-Rev1015-MBAPA[1]QC DYANo ratings yet

- TDS-GRADE_1-EN-Rev1-TJPDocument2 pagesTDS-GRADE_1-EN-Rev1-TJPQC DYANo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- ARYA_SASOL_LIM1922[2]Document3 pagesARYA_SASOL_LIM1922[2]Murat DalgicNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- Tecacomp Peek 450 Natural 1015088Document1 pageTecacomp Peek 450 Natural 1015088Kumaar RanjanNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- Plastdepo Tpe 30an TDSDocument1 pagePlastdepo Tpe 30an TDSnisannnNo ratings yet

- Trimma FM6341HFDocument2 pagesTrimma FM6341HFJUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- Petra 130 SpecsDocument2 pagesPetra 130 SpecssdecarlogaNo ratings yet

- Styrolution TDS300600621530Document2 pagesStyrolution TDS300600621530seguridadehigieneseguridadehigNo ratings yet

- Total 3645Document1 pageTotal 3645M. Kürşad ArslanNo ratings yet

- Technical Data Sheet - TheRMOFIL PP F820R00 Natural-Sumika Polymer Compounds Ltd. (2017)Document2 pagesTechnical Data Sheet - TheRMOFIL PP F820R00 Natural-Sumika Polymer Compounds Ltd. (2017)Priyalakshmi NarasimhanNo ratings yet

- PP h4120 TdsDocument2 pagesPP h4120 TdsengrmfawadazharNo ratings yet

- Ecopond PBATDocument3 pagesEcopond PBATsoniud14No ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- POM KEPITAL F30-03 enDocument2 pagesPOM KEPITAL F30-03 enAthonioMourinhoNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- Abp-2030 Tds-Iso-EngDocument2 pagesAbp-2030 Tds-Iso-Engkatolokchok100% (2)

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Celstran® PA66-GF50-07Document1 pageCelstran® PA66-GF50-07Ankur PanwarNo ratings yet

- RGF33NATURALDocument1 pageRGF33NATURALCassianNo ratings yet

- Kepital F20 - 03Document2 pagesKepital F20 - 03Kumaar RanjanNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- LOXILENE-PP-Talc 20%Document2 pagesLOXILENE-PP-Talc 20%pava16230.meNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- TDS - Megalon® 150GHSLDocument1 pageTDS - Megalon® 150GHSLshawnNo ratings yet

- 70g33gra BK350Document2 pages70g33gra BK350Ranjan GnanaoliNo ratings yet

- Name: Name: Name: Name: ABS710 ABS710 ABS710 ABS710Document2 pagesName: Name: Name: Name: ABS710 ABS710 ABS710 ABS710DiegoTierradentroNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- Pla - FC 32230 - ErtDocument2 pagesPla - FC 32230 - ErtfernandoincesaNo ratings yet

- Datasheet Cawiton PR13665 - 002 PDFDocument1 pageDatasheet Cawiton PR13665 - 002 PDFFred HahnNo ratings yet

- Hopelex Pc-1100uDocument2 pagesHopelex Pc-1100uChu ChuNo ratings yet

- Tds Heraform r900 Nat EngDocument2 pagesTds Heraform r900 Nat EngSenophoeNo ratings yet

- Datasheet Cawiton PR13650 - 004 PDFDocument1 pageDatasheet Cawiton PR13650 - 004 PDFFred HahnNo ratings yet

- POM - KEPITAL F20-03 - Standard GradeDocument2 pagesPOM - KEPITAL F20-03 - Standard GradeMadhav RajpurohitNo ratings yet

- Norsodyne H 16239 enDocument1 pageNorsodyne H 16239 enFachrurraziNo ratings yet

- TDS PEEK Filament PDFDocument2 pagesTDS PEEK Filament PDFRui MatiasNo ratings yet

- TDS PEEK Filament 1Document2 pagesTDS PEEK Filament 1Krzysztof KardachNo ratings yet

- Desmopan 3059D - en - 00898365 00000542 20011347Document2 pagesDesmopan 3059D - en - 00898365 00000542 20011347sosal salvadosNo ratings yet

- TDS PBT 5829F-105Document2 pagesTDS PBT 5829F-105TRUONGNo ratings yet

- Datasheet Cawiton PR13675 - 002Document1 pageDatasheet Cawiton PR13675 - 002Fred HahnNo ratings yet

- Styrolution 3 G55Document3 pagesStyrolution 3 G55John EduardoNo ratings yet

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoNo ratings yet

- Material-Datasheet MT41VG ISODocument2 pagesMaterial-Datasheet MT41VG ISOPrashanth RNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Teldene®: Technical Data SheetDocument2 pagesTeldene®: Technical Data SheetLFCV5No ratings yet

- Ejemplo Hoja Caracteristicas Granza PPDocument1 pageEjemplo Hoja Caracteristicas Granza PPalfredorozalenNo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- Ultramid_sup_®__sup_+A3WGM53+BLACK+20560 (4)Document2 pagesUltramid_sup_®__sup_+A3WGM53+BLACK+20560 (4)Vikas Rao CheetiNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Ultramid A205fDocument3 pagesUltramid A205fSATHISH KUMAR SNo ratings yet

- BNO Thermo Oil-32 (Mineral Based) : Product Data SheetDocument2 pagesBNO Thermo Oil-32 (Mineral Based) : Product Data SheetAyon HossenNo ratings yet

- Datasheet-Ultra Hh-4115-Hi-IsoDocument3 pagesDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- Chang Chun Plastics CO., LTDDocument2 pagesChang Chun Plastics CO., LTDChunYenHuangNo ratings yet

- Ruralstar Site Tower Construction SOP V3.0Document48 pagesRuralstar Site Tower Construction SOP V3.0goytomhayle8126No ratings yet

- Financial MathDocument50 pagesFinancial Mathfabricioace1978No ratings yet

- 1 March Practice PDF - 09Document22 pages1 March Practice PDF - 09arpitNo ratings yet

- Sag DRG-1Document6 pagesSag DRG-1rupesh417No ratings yet

- Allahabad Bank Annual Report 2014 15Document242 pagesAllahabad Bank Annual Report 2014 15SanaNo ratings yet

- Economic Theories of The Firm - Past, Present, and Future PDFDocument16 pagesEconomic Theories of The Firm - Past, Present, and Future PDFJeremiahOmwoyoNo ratings yet

- Economic Analysis For BusinessDocument2 pagesEconomic Analysis For BusinessMohan BaralNo ratings yet

- BDO BF Homes Aguirre - CostingDocument29 pagesBDO BF Homes Aguirre - CostingPaula SicatNo ratings yet

- Course Outline Technology EntrepreneurshipDocument3 pagesCourse Outline Technology EntrepreneurshipBisma khanNo ratings yet

- Economics Quiz 3Document3 pagesEconomics Quiz 3Pao EspiNo ratings yet

- Supply Chain Management ReportsDocument19 pagesSupply Chain Management ReportsSazeeth SinghNo ratings yet

- SSC MTS 2023 Tier 1 Sept 5 Shift 1Document32 pagesSSC MTS 2023 Tier 1 Sept 5 Shift 1Mina MeenaNo ratings yet

- First-Utility-bill-for-114-77-NIEPEL PIERRE ROBINDocument1 pageFirst-Utility-bill-for-114-77-NIEPEL PIERRE ROBINelaamlyNo ratings yet

- Sales Quiz 1Document3 pagesSales Quiz 1Roldan Cejuela CañadaNo ratings yet

- Indian FinalDocument65 pagesIndian Final04 Sourabh BaraleNo ratings yet

- PT Menolak Rugi Jurnal ZeovDocument68 pagesPT Menolak Rugi Jurnal Zeovtarakannnn364No ratings yet

- Pt. Bangun Sarana Graha LestariDocument9 pagesPt. Bangun Sarana Graha Lestariandre comalNo ratings yet

- Chapter-The Age of Industrialisation: Multiple Choice QuestionDocument6 pagesChapter-The Age of Industrialisation: Multiple Choice QuestionAbhilash GSNo ratings yet

- TDI Válvula Relevadora Mca. TDIDocument14 pagesTDI Válvula Relevadora Mca. TDIJorge CalcaneoNo ratings yet

- Family Leadership Succession and Firm Performance: The Moderating Effect of Tacit Idiosyncratic Firm KnowledgeDocument9 pagesFamily Leadership Succession and Firm Performance: The Moderating Effect of Tacit Idiosyncratic Firm KnowledgeJorge Ivan Villada LizarazoNo ratings yet

- Unit 5 Acceptance Sampling Plans: StructureDocument18 pagesUnit 5 Acceptance Sampling Plans: Structurevinay100% (2)

- IMF and World BankDocument2 pagesIMF and World BankMinh HàNo ratings yet

- Prospectus MPL 33rd - National U17 2023Document8 pagesProspectus MPL 33rd - National U17 2023sanchita yadav100% (1)

- Somas ValveGuide EN 2022 Dokumentbank PDFDocument17 pagesSomas ValveGuide EN 2022 Dokumentbank PDFrendymulyadiNo ratings yet

- Raft Slab LayoutDocument1 pageRaft Slab LayoutDINESH M.NNo ratings yet

- New QC MPR Format, Oct.22,09.11.2022Document14 pagesNew QC MPR Format, Oct.22,09.11.2022Devendra SinghNo ratings yet

- Adhoc00000007241758 2000712387Document6 pagesAdhoc00000007241758 2000712387Suman KumarNo ratings yet

- BeautyDocument8 pagesBeautypaolaNo ratings yet

- Vimal Moulders India Pvt. Ltd. First/Last Part Approval Inspection ReportDocument1 pageVimal Moulders India Pvt. Ltd. First/Last Part Approval Inspection ReportartiNo ratings yet

![TDS-PP2131-EN-Rev1015-MBAPA[1]](https://imgv2-1-f.scribdassets.com/img/document/748739489/149x198/9e480e1e33/1720421083?v=1)

![ARYA_SASOL_LIM1922[2]](https://imgv2-2-f.scribdassets.com/img/document/749034700/149x198/2086297215/1720509621?v=1)