Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewstraining-plan-for-jdvp-automotive (1)

training-plan-for-jdvp-automotive (1)

Uploaded by

Subleon GuerreroTraining plan for jdvp

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Joint Industry Standard: Solderability Tests For Printed BoardsDocument16 pagesJoint Industry Standard: Solderability Tests For Printed BoardsKishor JadhavNo ratings yet

- Cat III Inspection Mud 2021Document56 pagesCat III Inspection Mud 2021Fāōū ZīNo ratings yet

- DC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELDocument32 pagesDC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELBRAIYAM ALEXANDER MORENO VARGAS100% (1)

- Vitamins SpreadsheetDocument6 pagesVitamins SpreadsheetB-Rock Daniels100% (1)

- (Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFDocument337 pages(Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFAlex Sustaita100% (1)

- AUTOMOTIVE SERVICING NC-I (Training Plan)Document9 pagesAUTOMOTIVE SERVICING NC-I (Training Plan)Amor BayawaNo ratings yet

- JPK Pemetaan Cu3Document12 pagesJPK Pemetaan Cu3zulkhairi.maarofNo ratings yet

- Checklist For RatingsDocument4 pagesChecklist For RatingsOILER GABRIOLA, MARK GREGORY IIINo ratings yet

- TD-01-USsd-UK-BEARING INSPECTION IMPLEMENTATION COURSE REV002Document23 pagesTD-01-USsd-UK-BEARING INSPECTION IMPLEMENTATION COURSE REV002saifNo ratings yet

- Ok Task A - Steering, Suspension and Brake SystemsDocument13 pagesOk Task A - Steering, Suspension and Brake SystemsMarvin Sarmiento TalimonganNo ratings yet

- Force InductionDocument17 pagesForce InductionMuhammad Aznan ZakariaNo ratings yet

- Trent 1000 Borescope InspectionDocument148 pagesTrent 1000 Borescope InspectionSumrauy SontongNo ratings yet

- CD AutomobileDocument12 pagesCD AutomobileDarshan AwhadNo ratings yet

- Evidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be CollectedDocument2 pagesEvidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be Collectedhussain DiamlaNo ratings yet

- Evidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be CollectedDocument2 pagesEvidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be Collectedhussain DiamlaNo ratings yet

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- 7T04 CS Kma PR ND 0005Document12 pages7T04 CS Kma PR ND 0005Hatem Ragab100% (1)

- TLA Original 11/10/2018: Kristhian Andres Bermúdez Prieto 1033 805 066 2BNDocument5 pagesTLA Original 11/10/2018: Kristhian Andres Bermúdez Prieto 1033 805 066 2BNanon_5261876No ratings yet

- Smog Check ManualDocument47 pagesSmog Check ManualJLNo ratings yet

- 03 - Revised MOS - AIR BALANCINGDocument8 pages03 - Revised MOS - AIR BALANCINGEditor EditorNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- Section C - Preparation and Coating Audit TemplateDocument7 pagesSection C - Preparation and Coating Audit TemplateAnnNo ratings yet

- D. Brake SystemDocument6 pagesD. Brake Systemanang waskitoNo ratings yet

- MFS15c Assembly DisassemblyDocument51 pagesMFS15c Assembly Disassemblykmc10No ratings yet

- 5 KJ 4 e 75 YsabetrvrfDocument2 pages5 KJ 4 e 75 YsabetrvrfMohamed SelimNo ratings yet

- Evap Tester KentmooreDocument56 pagesEvap Tester KentmooreluisNo ratings yet

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- Introduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownDocument51 pagesIntroduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownKenneth John BrownNo ratings yet

- MMH Dan StoringDocument13 pagesMMH Dan Storingfilza100% (1)

- Wi-Tm01-004 03-060622Document11 pagesWi-Tm01-004 03-060622พสธร สอนทองNo ratings yet

- Shovel ChecklistDocument2 pagesShovel Checklistjamal motaNo ratings yet

- Injection Pump Maintenance ChecklistDocument2 pagesInjection Pump Maintenance ChecklisthaythamNo ratings yet

- WODocument1 pageWOAriNo ratings yet

- WODocument1 pageWOAriNo ratings yet

- Process Plant CommissioningDocument2 pagesProcess Plant CommissioningHatem Hussein100% (4)

- 5-Day Combined Mechanical Seals & Dry Gas Seals Course 2015Document4 pages5-Day Combined Mechanical Seals & Dry Gas Seals Course 2015Tayyab ZubairNo ratings yet

- 2017 Smog Check ManualDocument55 pages2017 Smog Check ManualJustin DowlerNo ratings yet

- StartupDocument1 pageStartupbundajoseph148No ratings yet

- Competency Based Curriculum NC3 AutomotiveDocument10 pagesCompetency Based Curriculum NC3 AutomotiveGilbert MendozaNo ratings yet

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (2)

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- 4th-Yr Cblm-AutomotiveDocument218 pages4th-Yr Cblm-Automotiveapi-24026514885% (20)

- 2.2L Basic TestingDocument12 pages2.2L Basic TestingAndres Florentin Pizarro LazarteNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Evaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition EngineDocument48 pagesEvaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition Engineasma hamzaNo ratings yet

- Calibration Certificate FormDocument1 pageCalibration Certificate Formel_sharkawy2011100% (2)

- D 6894 - 03 - Rdy4otqDocument13 pagesD 6894 - 03 - Rdy4otqNguyễn Bằng NộiNo ratings yet

- Inspection Sheet - For Light VehicleDocument6 pagesInspection Sheet - For Light VehicleSigit SugionoNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument13 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- 02961E00 - Eni Guidelines On Risk-Based InspectionsDocument54 pages02961E00 - Eni Guidelines On Risk-Based InspectionsMauro MLR100% (4)

- D6891 - 21 Standard Test Method For Evaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition EngineDocument46 pagesD6891 - 21 Standard Test Method For Evaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition EngineProvocateur SamaraNo ratings yet

- RollerDocument2 pagesRollerengr.haseebbalochNo ratings yet

- Vehicle Wheel ServiceDocument12 pagesVehicle Wheel ServiceNadhirah JohaNo ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test ReportGOSP3 QC MechanicalNo ratings yet

- Lks 2018 - A-Tune Up EfiDocument6 pagesLks 2018 - A-Tune Up EfiahmadbandrexNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Lubmarine_Um serviço rápido de análise de óleoDocument16 pagesLubmarine_Um serviço rápido de análise de óleoFelipe MNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Model-Based Testing Essentials - Guide to the ISTQB Certified Model-Based Tester: Foundation LevelFrom EverandModel-Based Testing Essentials - Guide to the ISTQB Certified Model-Based Tester: Foundation LevelNo ratings yet

- Delhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsDocument3 pagesDelhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsAnishikaNo ratings yet

- Basic Presentation SkillsDocument20 pagesBasic Presentation Skills11Rula SabithaTB100% (1)

- Operation Reasrech On IglooDocument18 pagesOperation Reasrech On IglooMd Yeasin ArafatNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- Geometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALDocument67 pagesGeometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALdrssagrawalNo ratings yet

- Quatre Agro Enterprise Private LimitedDocument25 pagesQuatre Agro Enterprise Private Limitedp23pallavNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- Behaviour of Hollow Core Slabs Under Point LoadsDocument17 pagesBehaviour of Hollow Core Slabs Under Point LoadsVálter LúcioNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- Louis I KahnDocument27 pagesLouis I KahnKiran BasuNo ratings yet

- Everlast INTERVAL TRAINING ROUND TIMER PDFDocument1 pageEverlast INTERVAL TRAINING ROUND TIMER PDFanniaanniaNo ratings yet

- OHara PDFDocument17 pagesOHara PDFTomás HidalgoNo ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- HP Deskjet D1600 Printer SeriesDocument13 pagesHP Deskjet D1600 Printer SeriesRizki JuliadiNo ratings yet

- Module 1 What Is Geography and TourismDocument22 pagesModule 1 What Is Geography and TourismLeanne Abegail EstabilloNo ratings yet

- Gear Trains: 8.1. Angular Velocity RatioDocument16 pagesGear Trains: 8.1. Angular Velocity RatioaddisudagneNo ratings yet

- UntitledDocument14 pagesUntitlednaresh kumarNo ratings yet

- Coal Ash Dewatering SolutionDocument23 pagesCoal Ash Dewatering Solution류태하No ratings yet

- Make List SLTD-J-1401-L-6-00003-02Document4 pagesMake List SLTD-J-1401-L-6-00003-02tribhuvan ShankarNo ratings yet

- Contoh Form Rko Obat PRB Per ApotekDocument19 pagesContoh Form Rko Obat PRB Per ApoteksaddamNo ratings yet

- Technical Data: Digital Color Progressive Scan Camera DÜRR TXG06c-K22 - Gigabit EthernetDocument20 pagesTechnical Data: Digital Color Progressive Scan Camera DÜRR TXG06c-K22 - Gigabit EthernetDiogo FiaesNo ratings yet

- DC Jow Ga Beginner CurriculumDocument2 pagesDC Jow Ga Beginner CurriculumKevinNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- IllithidDocument5 pagesIllithidMattia La RosaNo ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- Soal PAS K13 Kelas 9 Ganjil Tp. 2019-2020Document5 pagesSoal PAS K13 Kelas 9 Ganjil Tp. 2019-2020Fairuz AbadiNo ratings yet

- Battles Fought On The Great Wall of China Qin DynastyDocument2 pagesBattles Fought On The Great Wall of China Qin DynastySachin NagmotiNo ratings yet

training-plan-for-jdvp-automotive (1)

training-plan-for-jdvp-automotive (1)

Uploaded by

Subleon Guerrero0 ratings0% found this document useful (0 votes)

1 views8 pagesTraining plan for jdvp

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTraining plan for jdvp

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views8 pagestraining-plan-for-jdvp-automotive (1)

training-plan-for-jdvp-automotive (1)

Uploaded by

Subleon GuerreroTraining plan for jdvp

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 8

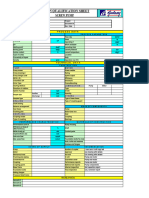

Annex A

Course: AUTOMOTIVE SERVICING NC I

Unit of competency: PERFORM DIESEL ENGINE TUNE-UP

Module title: PERFORMING DIESEL ENGINE TUNE-UP

Modality: check which modality will be applied. Multi-modal is allowed.

( ) Full-online ( √ ) Blended online ( √ ) Distance Learning ( √ ) Face-to-Face

Learning Outcomes Contents Learning Resources

LO#1. SET AND Procedures in Vehicle (running

INSTALL INJECTION installing injection condition)

PUMP TO ENGINE pump Injection pump

Fuel injection timing Cleaning materials

marks location SST

interpretation and Diesel engine

application Training

Use of special service manuals/competency-

tool (SST) in installing based learning

injection pump material (CBLM)/auto

Positive work values books/service

Type and classification manuals

of gasket and sealant Progress chart

CD/VHS

Fender/grill cover

Sealant/gasket

LO#2. INSPECT Procedures in injection Vehicle (running

INJECTION TIMING timing. condition)

Timing marks Injection pump

interpretation and Cleaning materials

application. SST

Use of SST Diesel engine

Positive work values. Training manuals

Fuel injection marks Progress chart

Timing CD/VHS

result/reference table Timing device

Table of timing result

LO#3. BLEED Procedures in Vehicle (running

INJECTION SYSTEM bleeding injection condition)

COMPONENTS pump. Injection pump/feed

Handling of bleeder pump

screw and pump. Cleaning materials

Handling of equipment SST

such as tester and Engine

pressurized gases. Training manuals

Positive work values. CBLM

Automotive reference

books

Progress chart

CD/VHS

Gasket

Fender cover

LO#4. CONDUCT Procedures in Vehicle (good running

COMPRESSION compression testing. condition)

TESTING Use of compression Injection pump/feed

testing instruments. pump

Use of special service Cleaning materials

tools SST

Positive work values Engine mock-up

Effects of low Training manuals

compression CBLM

Automotive reference

books

Progress chart

CD/VHS

Timing device

Table of timing result

Course: AUTOMOTIVE SERVICING NC I

Unit of competency: PERFORM GAS ENGINE TUNE-UP

Module title: PERFORMING GAS ENGINE TUNE-UP

Modality: check which modality will be applied. Multi-modal is allowed.

( ) Full-online ( √ ) Blended online ( √ ) Distance Learning ( √ ) Face-to-Face

Learning Outcomes Contents Learning Resources

LO#1. Procedure in setting valve Engine mock-up

MEASURE/ tappet clearance. Feeler gauge

ADJUST VALVE Procedure in checking Basic hand tools

TAPPET CLEARANCE

and adjusting valve tappet

clearance.

Safety procedure.

LO#2. Procedures in adjusting Engine mock-up

spark plug clearance. Feeler gauge

TEST SPARK PLUG Procedures in testing Spark plug wrench

spark plug.

Analyzing spark plug

spark.

Safety procedure.

Timing result/reference

table

LO#3. Procedures in replacing Engine mock-up

fuel filter and air cleaner. Fuel filter

CHECK/ Types of filter elements. Basic hand tools

REPLACE FUEL AND

AIR FILTER Air cleaner

LO#4. Procedures in Engine mock-up

inspecting/adjusting/repla Volt-ohm-

TEST AND REPLACE cing contact point gap. milliammeter (VOM)

IGNITION BREAKER

Procedures in testing and Basic hand tools

replacing condenser. Feeler gauge

LO#5. Procedures in adjusting Engine mock-up

dwell angle. Dwell meter

CHECK AND ADJUST Setting ignition timing. Tachometer

DISTRIBUTOR

SETTING

Procedures in ignition Basic hand tools

timing. Timing light

Procedure in checking

advance timing.

LO#6. Procedures in adjusting Engine mock-up

idle engine speed. Tachometer

SET FUEL MIXTURE Adjusting idle fuel Basic hand tools

AND IDLE RPM

mixture.

LO#7. Procedures in Engine mock-up

PERFORM compression testing. Compression gauge

COMPRESSION Safety precaution. Basic hand tools

TESTING

Compression Manufacturer’s

specification. specification

Course: AUTOMOTIVE SERVICING NC I

Unit of competency: SERVICE AUTOMOTIVE BATTERY

Module title: SERVICING AUTOMOTIVE BATTERY

Modality: check which modality will be applied. Multi-modal is allowed.

( ) Full-online ( √ ) Blended online ( √ ) Distance Learning ( √ ) Face-to-Face

Learning Outcomes Contents Learning Resources

LO#1. IDENTIFY Components of batteries Mock-up battery

AND EXPLAIN THE Types of batteries - Maintenance free

OPERATION AND Classification of batteries - Conventional

SAFE HANDLING Charging and discharging Brochures, catalogs,

OF DIFFERENT process manuals, tapes, CDs,

TYPES OF Hazards associated with LEs

BATTERY use of batteries

Safe handling of batteries

LO#2. Different types of battery Battery

DEMONSTRATE testing PPE

THE TESTING OF Procedure in testing Service manual

AN AUTOMOTIVE - Hydrometer Checklist

BATTERY - Cell tester Testing instruments

- Load tester/multi- - Load tester

tester - Specific gravity tester

Testing tools and - Cell voltage tester

equipment - Multi tester

Personal safety in testing

battery

Oral and written

communication

Science and math:

solution, electrolyte, ratio

and proportion,

temperature

LO3. Safety procedure in Vehicle

DEMONSTRATE removing/replacing Battery

THE CORRECT battery is observed Tools and equipment

PROCEDURE FOR Correct tools and (wrenches)

REMOVING AND equipment in PPE

REPLACING removing/replacing Service manual

BATTERIES battery is used. Forms

Hazards in - Job order

removing/replacing - Requisition slip

battery.

Procedures in

removing/replacing

battery

- Conventional

- Electronic control

LO#4. Parts and functions of Battery charger

DEMONSTRATE battery charger Battery charger

Repair/clean and replace manual

THE CORRECT connectors Multi battery connectors

PROCEDURE FOR Topping, filling Cleaning materials

electrolyte/distilled water. - Tap water

SERVICING AND

Procedure in battery - Distilled water

CHARGING charging - Wire brush

- Fast - Soda solution

BATTERIES - Slow Battery cleaner (spray

Manual/automatic type)

Batty cleaning

Proper connection of

battery terminals

PPE/safety practices

LO#5. Jump starting procedure Battery

DEMONSTRATE PPE/safety precaution - Fully charge

THE PROCEDURE Polarity connection - Weak

OF JUMP Jump starting connection Lead/wire connector

STARTING A Battery cable/terminal

BATTERY Booster

Open/close wrenches

Course: AUTOMOTIVE SERVICING NC I

Unit of competency: SERVICE IGNITION SYSTEM

Module title: SERVICING IGNITION SYSTEM

Modality: check which modality will be applied. Multi-modal is allowed.

( ) Full-online ( √ ) Blended online ( √ ) Distance Learning ( √ ) Face-to-Face

Learning Outcomes Contents Learning Resources

LO#1. Engine mock-up

IDENTIFY AND Parts and function of Spark plug

EXPLAIN THE ignition system Contact point

FUNCTION OF components Ignition switch

IGNITION SYSTEM Testing and Battery

COMPONENTS measurement procedures Distributor

Mock-up

Ballast/resistor

VOM

Engine analyzer

LO#2. Procedures in Engine mock-up

CHECK IGNITION disconnecting different Battery

COIL, BALLAST wire terminals. Ignition components

RESISTOR AND Distributor setting Auto wires

HIGH-TENSION procedures

CABLE Spark test procedures

RESISTANCE Spark analysis

Components of ignition

system

Ignition system wiring

diagram

LO#3. Use of tools and Engine mock-up

CHECK equipment in ignition Battery

DISTRIBUTOR timing Ignition components

ASSEMBLY Procedure in ignition Timing light

timing Tachometer

Safety precautions in

ignition timing

Use of measuring

instrument

Dwell angle

measurement

RPM measurement

Course: AUTOMOTIVE SERVICING NC I

Unit of competency: PERFORM UNDERCHASSIS PREVENTIVE MAINTENANCE

Module title: PERFORMING UNDERCHASSIS PREVENTIVE MAINTENANCE

Modality: check which modality will be applied. Multi-modal is allowed.

( ) Full-online ( √ ) Blended online ( √ ) Distance Learning ( √ ) Face-to-Face

Learning Outcomes Contents Learning Resources

LO#1. Clutch/brake fluid levels and Workplace (real

lines. or simulated)

CHECK CLUTCH Clutch/brake line cracks, Vehicle where

AND BRAKE FLUID twists, bends, looseness and the activity can

AND LINES restrictions. be performed.

Master cylinder fluid low level. Brake fluid

Safe handling of hydraulic Eye shield/safety

fluid. goggles

Hazards associated with the Manufacturer’s

use of brake fluid. specifications

manual

Personal

protective

equipment

Fender cover

LO#2. Inspect or change Work area

INSPECT AND transmission gear oil Vehicle

CHANGE Inspect or change differential Reference

TRANSMISSION/DIFF gear oil manual

ERENTIAL GEAR OIL Check leakage of gear oil Gear oil

Refill gear oil Box-end

Observe procedure and safety wrenches

Hydraulic jack or

lifting equipment

Safety shoes

Apron

LO#3. Inspecting power steering Vehicle with

fluid level power steering

INSPECT/REPLACE Replacing power steering fluid system

POWER STEERING Gather technical data Power steering

FLUID Inspect leakage on linkages fluid

Service manual

Basic hand tools

Personal

protective

equipment

Materials

relevant to

activity

Fender guards

LO#4. Automatic transmission fluid Tools/materials

CHECK/REFILL specifications and equipment

AUTOMATIC Automatic transmission fluid required

TRANSMISSION level Service manual

FLUID Hazards and safe handling of Brochure,

automatic transmission fluid catalogs,

(ATF) manual, tape,

Check leakage for automatic CDs, LEs

transmission Volume pump

Refill transmission fluid PPE

Apron

Goggles

Hand gloves

LO#5. Drain/bleed air updates Work place or

Drain/bleed water updates simulated work

INSPECT/BLEED Gather data pertaining to air area

AIR TANK tank Safety goggles

Inspect air tank for moist or Manufacturer’s

leak specification

PPE

Fender cover

Tools required

LO#6. Determine causes of PPE

abnormalities Air tank on

CHECK TIRE AND Check tire and tire pressure wheels

TIRE PRESSURE Check tire studs Tire gauge

Check wheel nuts and bolts Compressor

Inspect tire for solid object Fender cover

struck Manufacturer’s

Inspect tire wear and specification

deformities Gloves

Hand tools

Apron

Safety shoes

Rugs

Torque wrench

LO#7. Check and service body bolts Work place (real

CHECK Check tire studs or simulated)

UNDERCHASSIS Check u-bolts Safety eye

BODY BOLTS AND Check shackle bolts and nuts goggles

NUTS Check tightness on cross Box and open-

member bolts and nuts end wrenches

Check tightness on propeller PPE

shaft bolts and nuts Fender cover

Jack

Support stands

Wheel wedges

Prepared by:

MARK RYAN P. LAAD

AS NC II Trainer

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Joint Industry Standard: Solderability Tests For Printed BoardsDocument16 pagesJoint Industry Standard: Solderability Tests For Printed BoardsKishor JadhavNo ratings yet

- Cat III Inspection Mud 2021Document56 pagesCat III Inspection Mud 2021Fāōū ZīNo ratings yet

- DC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELDocument32 pagesDC9/MD80 PWJT8 Maintenance Practice Training Manual B1 or B1/B2 LEVELBRAIYAM ALEXANDER MORENO VARGAS100% (1)

- Vitamins SpreadsheetDocument6 pagesVitamins SpreadsheetB-Rock Daniels100% (1)

- (Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFDocument337 pages(Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFAlex Sustaita100% (1)

- AUTOMOTIVE SERVICING NC-I (Training Plan)Document9 pagesAUTOMOTIVE SERVICING NC-I (Training Plan)Amor BayawaNo ratings yet

- JPK Pemetaan Cu3Document12 pagesJPK Pemetaan Cu3zulkhairi.maarofNo ratings yet

- Checklist For RatingsDocument4 pagesChecklist For RatingsOILER GABRIOLA, MARK GREGORY IIINo ratings yet

- TD-01-USsd-UK-BEARING INSPECTION IMPLEMENTATION COURSE REV002Document23 pagesTD-01-USsd-UK-BEARING INSPECTION IMPLEMENTATION COURSE REV002saifNo ratings yet

- Ok Task A - Steering, Suspension and Brake SystemsDocument13 pagesOk Task A - Steering, Suspension and Brake SystemsMarvin Sarmiento TalimonganNo ratings yet

- Force InductionDocument17 pagesForce InductionMuhammad Aznan ZakariaNo ratings yet

- Trent 1000 Borescope InspectionDocument148 pagesTrent 1000 Borescope InspectionSumrauy SontongNo ratings yet

- CD AutomobileDocument12 pagesCD AutomobileDarshan AwhadNo ratings yet

- Evidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be CollectedDocument2 pagesEvidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be Collectedhussain DiamlaNo ratings yet

- Evidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be CollectedDocument2 pagesEvidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be Collectedhussain DiamlaNo ratings yet

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- 7T04 CS Kma PR ND 0005Document12 pages7T04 CS Kma PR ND 0005Hatem Ragab100% (1)

- TLA Original 11/10/2018: Kristhian Andres Bermúdez Prieto 1033 805 066 2BNDocument5 pagesTLA Original 11/10/2018: Kristhian Andres Bermúdez Prieto 1033 805 066 2BNanon_5261876No ratings yet

- Smog Check ManualDocument47 pagesSmog Check ManualJLNo ratings yet

- 03 - Revised MOS - AIR BALANCINGDocument8 pages03 - Revised MOS - AIR BALANCINGEditor EditorNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- Section C - Preparation and Coating Audit TemplateDocument7 pagesSection C - Preparation and Coating Audit TemplateAnnNo ratings yet

- D. Brake SystemDocument6 pagesD. Brake Systemanang waskitoNo ratings yet

- MFS15c Assembly DisassemblyDocument51 pagesMFS15c Assembly Disassemblykmc10No ratings yet

- 5 KJ 4 e 75 YsabetrvrfDocument2 pages5 KJ 4 e 75 YsabetrvrfMohamed SelimNo ratings yet

- Evap Tester KentmooreDocument56 pagesEvap Tester KentmooreluisNo ratings yet

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- Introduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownDocument51 pagesIntroduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownKenneth John BrownNo ratings yet

- MMH Dan StoringDocument13 pagesMMH Dan Storingfilza100% (1)

- Wi-Tm01-004 03-060622Document11 pagesWi-Tm01-004 03-060622พสธร สอนทองNo ratings yet

- Shovel ChecklistDocument2 pagesShovel Checklistjamal motaNo ratings yet

- Injection Pump Maintenance ChecklistDocument2 pagesInjection Pump Maintenance ChecklisthaythamNo ratings yet

- WODocument1 pageWOAriNo ratings yet

- WODocument1 pageWOAriNo ratings yet

- Process Plant CommissioningDocument2 pagesProcess Plant CommissioningHatem Hussein100% (4)

- 5-Day Combined Mechanical Seals & Dry Gas Seals Course 2015Document4 pages5-Day Combined Mechanical Seals & Dry Gas Seals Course 2015Tayyab ZubairNo ratings yet

- 2017 Smog Check ManualDocument55 pages2017 Smog Check ManualJustin DowlerNo ratings yet

- StartupDocument1 pageStartupbundajoseph148No ratings yet

- Competency Based Curriculum NC3 AutomotiveDocument10 pagesCompetency Based Curriculum NC3 AutomotiveGilbert MendozaNo ratings yet

- WI-INSP-01 R2 Work Instruction-Pressure Vessel InspDocument8 pagesWI-INSP-01 R2 Work Instruction-Pressure Vessel InspRakesh Mishra100% (2)

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- 4th-Yr Cblm-AutomotiveDocument218 pages4th-Yr Cblm-Automotiveapi-24026514885% (20)

- 2.2L Basic TestingDocument12 pages2.2L Basic TestingAndres Florentin Pizarro LazarteNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Evaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition EngineDocument48 pagesEvaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition Engineasma hamzaNo ratings yet

- Calibration Certificate FormDocument1 pageCalibration Certificate Formel_sharkawy2011100% (2)

- D 6894 - 03 - Rdy4otqDocument13 pagesD 6894 - 03 - Rdy4otqNguyễn Bằng NộiNo ratings yet

- Inspection Sheet - For Light VehicleDocument6 pagesInspection Sheet - For Light VehicleSigit SugionoNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument13 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- 02961E00 - Eni Guidelines On Risk-Based InspectionsDocument54 pages02961E00 - Eni Guidelines On Risk-Based InspectionsMauro MLR100% (4)

- D6891 - 21 Standard Test Method For Evaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition EngineDocument46 pagesD6891 - 21 Standard Test Method For Evaluation of Automotive Engine Oils in The Sequence IVA Spark-Ignition EngineProvocateur SamaraNo ratings yet

- RollerDocument2 pagesRollerengr.haseebbalochNo ratings yet

- Vehicle Wheel ServiceDocument12 pagesVehicle Wheel ServiceNadhirah JohaNo ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test ReportGOSP3 QC MechanicalNo ratings yet

- Lks 2018 - A-Tune Up EfiDocument6 pagesLks 2018 - A-Tune Up EfiahmadbandrexNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- Lubmarine_Um serviço rápido de análise de óleoDocument16 pagesLubmarine_Um serviço rápido de análise de óleoFelipe MNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Model-Based Testing Essentials - Guide to the ISTQB Certified Model-Based Tester: Foundation LevelFrom EverandModel-Based Testing Essentials - Guide to the ISTQB Certified Model-Based Tester: Foundation LevelNo ratings yet

- Delhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsDocument3 pagesDelhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsAnishikaNo ratings yet

- Basic Presentation SkillsDocument20 pagesBasic Presentation Skills11Rula SabithaTB100% (1)

- Operation Reasrech On IglooDocument18 pagesOperation Reasrech On IglooMd Yeasin ArafatNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- Geometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALDocument67 pagesGeometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALdrssagrawalNo ratings yet

- Quatre Agro Enterprise Private LimitedDocument25 pagesQuatre Agro Enterprise Private Limitedp23pallavNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- Behaviour of Hollow Core Slabs Under Point LoadsDocument17 pagesBehaviour of Hollow Core Slabs Under Point LoadsVálter LúcioNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- Louis I KahnDocument27 pagesLouis I KahnKiran BasuNo ratings yet

- Everlast INTERVAL TRAINING ROUND TIMER PDFDocument1 pageEverlast INTERVAL TRAINING ROUND TIMER PDFanniaanniaNo ratings yet

- OHara PDFDocument17 pagesOHara PDFTomás HidalgoNo ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- HP Deskjet D1600 Printer SeriesDocument13 pagesHP Deskjet D1600 Printer SeriesRizki JuliadiNo ratings yet

- Module 1 What Is Geography and TourismDocument22 pagesModule 1 What Is Geography and TourismLeanne Abegail EstabilloNo ratings yet

- Gear Trains: 8.1. Angular Velocity RatioDocument16 pagesGear Trains: 8.1. Angular Velocity RatioaddisudagneNo ratings yet

- UntitledDocument14 pagesUntitlednaresh kumarNo ratings yet

- Coal Ash Dewatering SolutionDocument23 pagesCoal Ash Dewatering Solution류태하No ratings yet

- Make List SLTD-J-1401-L-6-00003-02Document4 pagesMake List SLTD-J-1401-L-6-00003-02tribhuvan ShankarNo ratings yet

- Contoh Form Rko Obat PRB Per ApotekDocument19 pagesContoh Form Rko Obat PRB Per ApoteksaddamNo ratings yet

- Technical Data: Digital Color Progressive Scan Camera DÜRR TXG06c-K22 - Gigabit EthernetDocument20 pagesTechnical Data: Digital Color Progressive Scan Camera DÜRR TXG06c-K22 - Gigabit EthernetDiogo FiaesNo ratings yet

- DC Jow Ga Beginner CurriculumDocument2 pagesDC Jow Ga Beginner CurriculumKevinNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- IllithidDocument5 pagesIllithidMattia La RosaNo ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- Soal PAS K13 Kelas 9 Ganjil Tp. 2019-2020Document5 pagesSoal PAS K13 Kelas 9 Ganjil Tp. 2019-2020Fairuz AbadiNo ratings yet

- Battles Fought On The Great Wall of China Qin DynastyDocument2 pagesBattles Fought On The Great Wall of China Qin DynastySachin NagmotiNo ratings yet