Professional Documents

Culture Documents

MS220VA_MSR220VA_OM_2022-12-12_ZIEHL_EN

MS220VA_MSR220VA_OM_2022-12-12_ZIEHL_EN

Uploaded by

Muhammad Munirul AlamCopyright:

Available Formats

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- Operating Manual MSF220K: - PTC-relay For Dry TransformersDocument8 pagesOperating Manual MSF220K: - PTC-relay For Dry TransformersFoti KarakoukaNo ratings yet

- Operating Manual TR400: - PT 100 Temperature Relay With 2 Analog OutputsDocument12 pagesOperating Manual TR400: - PT 100 Temperature Relay With 2 Analog OutputsOmnhickNo ratings yet

- Ba Msf220vu e PDFDocument8 pagesBa Msf220vu e PDFSyariefNo ratings yet

- 7XV5662!2!5AD10 Manual Ziehl TR600 enDocument10 pages7XV5662!2!5AD10 Manual Ziehl TR600 enEddy Fernando Queca CadizNo ratings yet

- Digital Humidity and Temperature Sensor AM2302Document5 pagesDigital Humidity and Temperature Sensor AM2302rizkypratamaputra58No ratings yet

- Operating Manual TR1200IPDocument20 pagesOperating Manual TR1200IPluisNo ratings yet

- Thermistor Module ModDocument4 pagesThermistor Module ModAdam MikitzelNo ratings yet

- Thomas Liu (Sales Manager)Document5 pagesThomas Liu (Sales Manager)MIN GU KIMNo ratings yet

- IR MelexisDocument52 pagesIR Melexisleomar_bNo ratings yet

- Calibration of Temperature SensorsDocument13 pagesCalibration of Temperature SensorsSubhash KNo ratings yet

- Operating Manual TR1200IPDocument21 pagesOperating Manual TR1200IPFelipe Gallardo CatrilNo ratings yet

- UC8 Troubleshooting Guide v2 0715 2Document18 pagesUC8 Troubleshooting Guide v2 0715 2j.knightNo ratings yet

- For 2-Stage Atmospheric Gas Burners Flame Detection: - Ionisation Probe - Infrared-Flicker Detector IRD 1020 - UV Flame Sensor UVD 971Document6 pagesFor 2-Stage Atmospheric Gas Burners Flame Detection: - Ionisation Probe - Infrared-Flicker Detector IRD 1020 - UV Flame Sensor UVD 971marioalf674150No ratings yet

- Dvi 980 - 982 (En)Document6 pagesDvi 980 - 982 (En)Jozo ĆurčićNo ratings yet

- Installation Instructions 810831-00: Water-Level Limiter / Controller NRS 1-9Document16 pagesInstallation Instructions 810831-00: Water-Level Limiter / Controller NRS 1-9Voicu StaneseNo ratings yet

- ITC-100 - Manual - V1.0 - 6.30Document9 pagesITC-100 - Manual - V1.0 - 6.30mickNo ratings yet

- Honeywell Satronic DKG972Document6 pagesHoneywell Satronic DKG972maccsyNo ratings yet

- ZHRV5Document2 pagesZHRV5thaisubNo ratings yet

- Mlx90614esf-Baa Data SheetDocument40 pagesMlx90614esf-Baa Data Sheetadolfo martinezNo ratings yet

- PTCDocument18 pagesPTCRetno_GNo ratings yet

- 7XV5662-7AD10 Quick Guide TR800 Ziehl 12280-0755-00 enDocument8 pages7XV5662-7AD10 Quick Guide TR800 Ziehl 12280-0755-00 enmansa122No ratings yet

- Manual Hardw eDocument9 pagesManual Hardw eAndreas PeniNo ratings yet

- Manual - PTi 1000 DH - A5 - v1.9 7.2017Document20 pagesManual - PTi 1000 DH - A5 - v1.9 7.2017Zikriya KarnekarNo ratings yet

- MTC2Document4 pagesMTC2ELECTRO-TECHNICAL OFFICERNo ratings yet

- Controlador Zelio RTC48 - Datasheet PDFDocument4 pagesControlador Zelio RTC48 - Datasheet PDFM Daniel HuayancaNo ratings yet

- Satronic BoxDocument6 pagesSatronic BoxbethmongNo ratings yet

- 03p1 03p2 Series GbDocument5 pages03p1 03p2 Series Gbazat OrazowNo ratings yet

- Digicold Digicold Digicold Digicold: SeriesDocument4 pagesDigicold Digicold Digicold Digicold: SeriesdbricchiNo ratings yet

- Electronic Pressure Switch & Transmitter: General SpecificationDocument4 pagesElectronic Pressure Switch & Transmitter: General Specificationhuu thanh nguyenNo ratings yet

- Smoke and Heat Exhaust Control Unit: Technical and Operating Documentation User Instruction ManualDocument13 pagesSmoke and Heat Exhaust Control Unit: Technical and Operating Documentation User Instruction ManualConstantin GubavuNo ratings yet

- Relee Electronice SIEMENSDocument32 pagesRelee Electronice SIEMENSciocioi iancuNo ratings yet

- DKG 972Document6 pagesDKG 972David RamirezNo ratings yet

- Distance SensorDocument5 pagesDistance Sensortuyetden613No ratings yet

- LD-B10-10-catalog Temperature ControllerDocument22 pagesLD-B10-10-catalog Temperature ControllerFareh KhanNo ratings yet

- Sitranst th300 Fi01enDocument7 pagesSitranst th300 Fi01enLuis GuillermoNo ratings yet

- Works Masterspec 230933 (Thermostat)Document5 pagesWorks Masterspec 230933 (Thermostat)DILSHAD AHEMADNo ratings yet

- Adt 7310Document24 pagesAdt 7310nevdullNo ratings yet

- Manual Auraton 2025 RTHDocument36 pagesManual Auraton 2025 RTHBeltzabarbasNo ratings yet

- Adt 7420Document24 pagesAdt 7420Vlad TusanNo ratings yet

- Simirel: Monitors, Interfaces, RelaysDocument32 pagesSimirel: Monitors, Interfaces, RelaysRomel Toledo CalvopiñaNo ratings yet

- Itc-100 Manual v1 1w57Document9 pagesItc-100 Manual v1 1w57mei krismahariyantoNo ratings yet

- Autonics TCN Manual PDFDocument2 pagesAutonics TCN Manual PDFDiego AlanizNo ratings yet

- 118L Digital BulletinDocument4 pages118L Digital Bulletinmbk.2k3No ratings yet

- Series Temperature Controller Instruction Sheet: PrecautionDocument14 pagesSeries Temperature Controller Instruction Sheet: PrecautionBen farah AymenNo ratings yet

- Promag 3000Document112 pagesPromag 3000Olivério TeixeiraNo ratings yet

- NXT4 Bia e 1Document24 pagesNXT4 Bia e 1Felipe AchurraNo ratings yet

- Nolden5000 UsermanualDocument55 pagesNolden5000 Usermanualnagy_istván_zoltánNo ratings yet

- SW32V Operating Manual e ZIEHL 2017-05-03Document22 pagesSW32V Operating Manual e ZIEHL 2017-05-03Jatupol PongsirisartNo ratings yet

- Detailed Manual: Toho Electronics Inc. Multi-Channel Board ControllerDocument35 pagesDetailed Manual: Toho Electronics Inc. Multi-Channel Board ControllerArchie MaguillanoNo ratings yet

- MSF220V MSF220VU Datasheet e ZIEHL 2017-02-21Document1 pageMSF220V MSF220VU Datasheet e ZIEHL 2017-02-21hector CarreraNo ratings yet

- Datasheet For LM45Document9 pagesDatasheet For LM45Bhimsen BudhathokiNo ratings yet

- Pulsteknik Appleton ATX Cont CSF DDocument17 pagesPulsteknik Appleton ATX Cont CSF Drocket-vtNo ratings yet

- Instructions and Advices To Use The Electronic Controller Logik 9Document27 pagesInstructions and Advices To Use The Electronic Controller Logik 9Muhammad Zeeshan Saeed100% (1)

- Honeywell Mmi 813.1 Mod 23Document5 pagesHoneywell Mmi 813.1 Mod 23nestor_moNo ratings yet

- Manual Full (English) HE-HT01 v1.1Document35 pagesManual Full (English) HE-HT01 v1.1Sarkis KaprelianNo ratings yet

- MULTICAL 603 - Data Sheet - EnglishDocument12 pagesMULTICAL 603 - Data Sheet - EnglishDan ChiriacNo ratings yet

- Air motors trainingDocument50 pagesAir motors trainingMuhammad Munirul AlamNo ratings yet

- Types of UV LED LightDocument3 pagesTypes of UV LED LightMuhammad Munirul AlamNo ratings yet

- Transformer - Inspection ChecklistDocument2 pagesTransformer - Inspection ChecklistMuhammad Munirul AlamNo ratings yet

- What Is The Spinning Procedure of Transforming Fiber Into YarnDocument5 pagesWhat Is The Spinning Procedure of Transforming Fiber Into YarnMuhammad Munirul AlamNo ratings yet

- How Many KG of CO2 in 1 KWHDocument6 pagesHow Many KG of CO2 in 1 KWHMuhammad Munirul AlamNo ratings yet

- Pasteurized VsDocument55 pagesPasteurized VsMuhammad Munirul AlamNo ratings yet

- Overrun CalculationsDocument4 pagesOverrun CalculationsMuhammad Munirul AlamNo ratings yet

- Electrical Hazards & Safety TrainingDocument45 pagesElectrical Hazards & Safety TrainingMuhammad Munirul AlamNo ratings yet

- ALP Model Paper 3Document12 pagesALP Model Paper 3Swabya Sachi DasNo ratings yet

- Manual de Repuestos LG500 NuevoDocument108 pagesManual de Repuestos LG500 NuevoPaola Gómez GuzmánNo ratings yet

- Tutorial Week 11 - Non-Isothermal CSTR - System ABDocument25 pagesTutorial Week 11 - Non-Isothermal CSTR - System ABsiti azilaNo ratings yet

- Examen Inglés de La Comunidad de Madrid (Ordinaria de 2022) (WWW - Examenesdepau.com)Document8 pagesExamen Inglés de La Comunidad de Madrid (Ordinaria de 2022) (WWW - Examenesdepau.com)Lil CiamiNo ratings yet

- Altivar Process Ride Through Time - IE04Document3 pagesAltivar Process Ride Through Time - IE04Goran MladenovicNo ratings yet

- 2012 Stimulaton VesselsDocument2 pages2012 Stimulaton VesselsmajdirossrossNo ratings yet

- The Journal of Energy and DevelopmentDocument26 pagesThe Journal of Energy and DevelopmentThe International Research Center for Energy and Economic Development (ICEED)No ratings yet

- Interview Questions MS WordDocument20 pagesInterview Questions MS Wordhassan iftikhar100% (1)

- REF - NO.PSE/P 2603-1 List: HBL Power Systems LTDDocument24 pagesREF - NO.PSE/P 2603-1 List: HBL Power Systems LTDmukesh_kht1No ratings yet

- 980E-4 Hoist System Components, Operation, AdjustmentDocument30 pages980E-4 Hoist System Components, Operation, AdjustmentRonny Leido Rodriguez Bernabe100% (1)

- Markscheme: International Baccalaureate Baccalauréat International Bachillerato InternacionalDocument7 pagesMarkscheme: International Baccalaureate Baccalauréat International Bachillerato InternacionalEdgarNo ratings yet

- Summary of Progress of Work-2023.02.04Document111 pagesSummary of Progress of Work-2023.02.04Zahidul zahidNo ratings yet

- Commander SK Technical Manual DataDocument122 pagesCommander SK Technical Manual DataBlelebNo ratings yet

- Nailor Catalog UFADCombinedDocument136 pagesNailor Catalog UFADCombinedDavid RivardNo ratings yet

- Effect of Water Content On Solid Biofuel Pellets Produced From Rice StrawDocument6 pagesEffect of Water Content On Solid Biofuel Pellets Produced From Rice Strawrikayolanda23No ratings yet

- Chris - Electrician CVDocument1 pageChris - Electrician CVchris_dalzellNo ratings yet

- 2021 - 2022 - 2023 امتحانات الثانوية العامة اللغه الانجليزيهDocument28 pages2021 - 2022 - 2023 امتحانات الثانوية العامة اللغه الانجليزيهamira0mahmoud00No ratings yet

- Heating Curve WRKSHT v2Document2 pagesHeating Curve WRKSHT v2Samuel PaulNo ratings yet

- PV CalculatorDocument2 pagesPV CalculatorChad RingströmNo ratings yet

- Modulo Monocristalino 144 Células 535W - Bel EnergyDocument2 pagesModulo Monocristalino 144 Células 535W - Bel EnergyRoswel Piovezani FerreiraNo ratings yet

- D3e802f8707!1!9l Pumpe Duse Tdi Bew and BRMDocument24 pagesD3e802f8707!1!9l Pumpe Duse Tdi Bew and BRMJan HavelNo ratings yet

- Thermo Lab ReportDocument11 pagesThermo Lab Reportceojoe65No ratings yet

- AC Plus: O N FR EQDocument40 pagesAC Plus: O N FR EQIgnacioNo ratings yet

- 3-0-105f EXHAUST SYSTEM PURGE CRANK TIMES TO PREVENT POTENTIALDocument11 pages3-0-105f EXHAUST SYSTEM PURGE CRANK TIMES TO PREVENT POTENTIALMohamed HussinNo ratings yet

- D4529-Standard Test Method For Estimation of Net Heat of Combustion of Aviation FuelsDocument4 pagesD4529-Standard Test Method For Estimation of Net Heat of Combustion of Aviation FuelsrezaNo ratings yet

- VersaJet Series Manual 06-13 WebDocument36 pagesVersaJet Series Manual 06-13 WebJOSE LUIS HERNANDEZ CHAVEZNo ratings yet

- Design of Pneumatic CircuitsDocument81 pagesDesign of Pneumatic CircuitsNikhil PandharpatteNo ratings yet

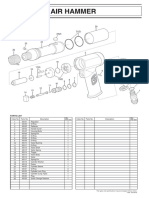

- SP 1400 Parts ListDocument1 pageSP 1400 Parts ListVirajpujariNo ratings yet

- Sharekhan Morning Tiger - 22th April 2022Document7 pagesSharekhan Morning Tiger - 22th April 2022Deepak BhattNo ratings yet

- TM-3WMJ-SL-IDA2 (FTV-CXV14 Series R-32 - DAMA)Document36 pagesTM-3WMJ-SL-IDA2 (FTV-CXV14 Series R-32 - DAMA)HANDOYO RNo ratings yet

MS220VA_MSR220VA_OM_2022-12-12_ZIEHL_EN

MS220VA_MSR220VA_OM_2022-12-12_ZIEHL_EN

Uploaded by

Muhammad Munirul AlamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS220VA_MSR220VA_OM_2022-12-12_ZIEHL_EN

MS220VA_MSR220VA_OM_2022-12-12_ZIEHL_EN

Uploaded by

Muhammad Munirul AlamCopyright:

Available Formats

ZIEHL industrie – elektronik GmbH + Co KG

Daimlerstr.13, 74523 Schwäbisch Hall, Germany

+ 49 791 504-0, info@ziehl.de, www.ziehl.de

Temperature Relays and MINIKA® Mains Monitoring Digital Panelmeters MINIPAN® Switching Relays and Controls Measuring Transducers Grid- and Plant Protection

updated: 2022-12-12 / nm

Operating Manual MS220VA and MSR220VA

PTC thermistor relay with short-circuit detection

0102 8507

Marking see type plate on the device EU type examination certificate PTB 12 ATEX 3006 Issue 2

UK type examination certificate EPS 22 UKEX 1024

MS220VA and MSR220VA 11660-0701-05 Seite 1 / 12 www.ziehl.de

Table of contents

1 General Notes ...................................................................................................................................... 3

2 Display- and control elements ............................................................................................................ 3

3 Pre-Adjustment .................................................................................................................................... 3

4 Application and brief description ....................................................................................................... 4

5 Summary of features ........................................................................................................................... 4

6 Connecting diagram ............................................................................................................................ 4

7 Function diagram ................................................................................................................................ 5

8 Important notes ................................................................................................................................... 5

9 Installation ........................................................................................................................................... 5

10 Commissioning.................................................................................................................................. 6

11 Operating instructions ...................................................................................................................... 6

12 Troubleshooting and remedies ........................................................................................................ 6

13 Technical data ................................................................................................................................... 6

14 Dimensions - Design V2 .................................................................................................................... 8

15 Safety instructions and references for putting into operation ....................................................... 8

15.1 Explosive atmospheres ..............................................................................................................8

15.2 Special remarks for explosive gas atmospheres areas (Zone 0, 1 and 2) ..................................8

15.3 Special remarks for use in the presence of combustible dust (Zone 20, 21 and 22) ...................8

15.4 Safety characteristics of the safety device (EN 50495/VDE 0171-18) ........................................9

15.5 Category and Performance-Level (EN ISO 13849-1) .................................................................9

15.6 Application of the safety device used with equipment category (EN 50495/VDE 0171-18).........9

15.7 Wiring ........................................................................................................................................9

15.8 Safe separation........................................................................................................................ 10

15.9 Stop function............................................................................................................................ 10

15.10 Start and restart ..................................................................................................................... 10

15.11 Manual reset .......................................................................................................................... 10

16 Proof testing of the safety functions .............................................................................................. 10

17 Maintenance and repair................................................................................................................... 11

18 Disposal ........................................................................................................................................... 11

19 EU / UK -Declaration of conformity ................................................................................................ 12

MS220VA and MSR220VA 11660-0701-05 Seite 2 / 12 www.ziehl.de

1 General Notes

Compliance with the following instructions is mandatory to ensure the functionality and safety of the

product. If the following instructions given especially but not limited for general safety, transport, storage,

mounting, operating conditions, start-up, maintenance, repair, cleaning and disposal / recycling are not

observed, the product may not operate safely and may cause a hazard to the life and limb of users and

third parties.

Deviations from the following requirements may therefore lead both to the loss of the statutory material

defect liability rights and to the liability of the buyer for the product that has become unsafe due to the

deviation from the specifications.

2 Display- and control elements

1. LED red „ALARM“

2. LED green „Power ON“

3. Button “Reset”

3 Pre-Adjustment

No settings have to be made. The tripping temperature is determined solely by the response temperature

of the connected thermistors.

Depending on the number of thermistors the following tripping temperatures and reset temperatures arise

related to TNF (detector operating temperature):

Attention!

Only 3 or 6 thermistors in series are allowed for usage in explosive atmospheres.

Tripping temperature Reset temperature

1 thermistor TNF + 15 K TNF + 5 K

3 thermistors in series TNF + 5 K TNF – 5 K

6 thermistors in series TNF TNF – 20 K

MS220VA and MSR220VA 11660-0701-05 Seite 3 / 12 www.ziehl.de

4 Application and brief description

The device protects electrical equipment against excessive warming and thermal overload. Used in com-

bination with respective thermistors tripping temperatures from 60 °C up to 180 °C can be realized.

The device is conform to EN 60947-8. Thermistors according to DIN VDE V 0898-1-401 (ATEX) or

equivalent detail specification (UKEX) shall be connected. The thermistors are suitable for installation

into windings of electrical machines or transformers, bearings and heatsinks as well as to monitor the

temperature of liquid media, airflow and gases. With ATEX approval, equipment in explosive gas atmos-

pheres Zone 1 and 2 (marking G: gas) or in areas with combustible dust Zone 21 and 22 (marking D:

dust) can be protected. All functions of the device serve to protect non-explosive-protected equipment

and explosive-protected equipment in regular operation and in case of failure

5 Summary of features

• 1 thermistor circuit for 1 (not allowed for explosive atmospheres) 3 or 6 PTC thermistors.

• Short-circuit detection within the thermistor circuit.

• Output relay with 1 change-over contact (co).

• Operating status display.

A current monitors continuously the resistance of the thermistor circuit. In cold state, the resistance is ≤

250 Ω per thermistor (thermistor circuit ≤ 1.5 kΩ). The device is switched on and relay contacts 11, 14 are

closed. The resistance of the thermistor rises rapidly at detector operating temperature TNF. The device

switches off at a resistance of 3…4 kΩ and the relay contacts 11, 14 close. The device also switches off

in the case of detector or line short-circuit (< approx. 20Ω) or detector or line interruption. Device type MS

switches on automatically when the temperature has cooled down. Device type MSR remains switched off

until the build in or an external reset button is pushed. Power-on is recognized as reset. With bridged

terminals Y1, Y2, the reclosing lock function is disabled and a device type MSR works like a device type

MS.

6 Connecting diagram

PTC PTC thermistor

Us Supply voltage

S1 Off switch

S2 Push button on

S3 Remote reset

H1 Indicator lamp fault

F1 – F4 Fuses

K1 Contactor

*1 external interlock

See chapter 15.11

*2 Manual reset

Only MSR

MS220VA and MSR220VA 11660-0701-05 Seite 4 / 12 www.ziehl.de

7 Function diagram

MS220VA (automatic reset)

MSR220VA (reclosing lock)

1)

Detector or line short-circuit

2)

Caution! The relay switches on automatically after a supply voltage dip.

With a bridge at the reset input (Y1/Y2) the reclosing lock is out of operation. The

device switches back automatically, when the temperature of the thermistor circuit

has fallen below the switchback value.

8 Important notes

Attention!

Observe safety rules and standards. Notice safety remarks!

Attention!

Hazardous voltage!

May cause electric shock and burns.

Before commencing work on the system, the power must be disconnected.

9 Installation

• The applicant must observe safety rules and standards.

• The device can be mounted on 35 mm rail according EN 60715 or with screws M4 (Option)

• The device must be installed in an enclosure of international protection class IP 5X or better.

• Terminals maximum tightening torque 0,5 Nm

When installing the device into the switchgear cabinet, please observe the max. admissible tem-

perature. Care for both, sufficient clearance to other devices or sources of heat or enough forced

draught. If cooling is made more difficult, e.g. close devices with increased surface temperature

or by handicap of airflow cooling, the permissible ambient temperature reduces.

MS220VA and MSR220VA 11660-0701-05 Seite 5 / 12 www.ziehl.de

10 Commissioning

Attention!

Before switching on the mains voltage make sure that it matches the specification

on the type plate.

Attention!

Observe chapter 15.8 Safe separation.

• After the supply voltage is switched on and when the thermistors are correctly connected the green

LED „ON“ must light-up and the relay contacts 11,14 must close.

• The correct function of the tripping device must be checked by resistance simulation at terminals T1

and T2 according to chapter 16 Proof testing of the safety functions. This check must be repeated after

changes to the installation.

11 Operating instructions

The device type MSR must be manually reset after a fault signal (red = alarm). For this purpose, the

built-in reset button or an external button (remote reset terminals Y1, Y2) can be used.

12 Troubleshooting and remedies

Relay contacts 11, 14 do not close:

• Check the supply voltage Us at terminals A1, A2 (green LED lights-up).

• Check the thermistors at terminals T1, T2. In case of a fault the red LED lights-up.

• The resistance of the thermistor circuit must be 50 Ω < R < 1500 Ω. The terminal voltage T1, T2 must

be < 2.5 VDC with connected thermistors and temperature below TNF.

• For device type MSR push the button “Reset”. A fault signal can be reset at R < 1.65 kΩ. The status

LED changes from red to green. Alternatively, a reset can be done with closing an external contact at

terminals Y1, Y2 or with voltage recovery.

Relay contacts 11, 14 do not open:

• With no connection at terminals T1, T2 the device must indicate a fault and the relay contacts 11, 14

must open. The terminal voltage T1, T2 must be approximately 8 VDC.

In case of any other malfunctions, replace the device. Please add a description of the occurred malfunction

when sending back for repair.

13 Technical data

Power supply (A1, A2)

Power supply Us AC 220-240 V

(see type plate) AC / DC 24 V (without galvanic isolation)

Voltage tolerance AC 0,9 Us …1,1 Us

DC 21 ... 30 V

Frequency 50 / 60 Hz

Frequency tolerance 45 Hz … 65 Hz

Power consumption <2W

Voltage dip buffer time max. 20 ms

PTC thermistor input (T1, T2) according to DIN VDE V 0898-1-401 or equivalent

Number 1 (not allowed for explosive atmospheres) 3 or 6 thermistors

Rated response temperature TFS 60 °C … 180 °C

Response tolerance ±6 °C

Collective resistance cold thermistor ≤ 1.65 kΩ

Terminal voltage (PTC thermistor) ≤ 2.5 VDC at R ≤ 3.65 kΩ, ≤ 2 V at R ≤ 1.65 kΩ

Open-circuit voltage ≤ 9 VDC at R =

MS220VA and MSR220VA 11660-0701-05 Seite 6 / 12 www.ziehl.de

Terminal current (PTC thermistor) ≤ 1 mA

Power consumption ≤ 2 mW

Line capacity max. 0.2 µF

Temperature monitor cut-out-point 3.3 kΩ …3.65 kΩ …3.85 kΩ

Temperature monitor reclosing point 1.7 kΩ …1.8 kΩ …1.95 kΩ

Short circuit monitor cut-out-point ≤ 20 Ω

Short circuit monitor reclosing point ≤ 40 Ω

Reset input (Y1, Y2) Potential free contact (no)

Current 1 mA

Voltage < 30 VDC

Relay output (11,12,14) EN 60947-5-1

Contacts 1 change-over contact (co)

Switching voltage max. AC 400 V

Switch-on current (NO) AC 15 A 4s 10% ED

min. voltage / current 12 V 10 mA

Conventional thermal current Ith max. 5 A

Switching power max. AC cos φ = 1 2000 VA

Switching power max. DC (ohm) 0.25 A 300 V; 0.35 A 150 V; 1 A 60 V; 8 A 30 V

Contact life electrical cos φ = 1 2 x 105 operating cycles at 250 V / 2 A

1 x 105 operating cycles at 250 V / 5 A

Contact life mechanical 3 x 107 operating cycles

Recommended fuse (NO) 4 A time-lag or miniature circuit-breaker MCB B4

Recommended fuse (NC) 3,15 A time-lag

AC-15 Ie = 3 A Ue = 250 V

Utilization category

DC-13 Ie = 2 A Ue = 24 V

Rated operational current

DC-13 Ie = 0.4 A Ue = 120 V

Rated operational voltage

DC-13 Ie = 0.2 A Ue = 250 V

UL electrical ratings 250 VAC, 3 A, general use

C300

Test conditions IEC/EN 60947-8

Rated impulse voltage 4000 V

Overvoltage category III

Pollution degree 2

Rated insulation voltage Ui 320V

Transformer EN 61558-2-6 (VDE 0570)

Proof Test Voltage 2500 VAC 50 Hz

EMC - Immunity EN 61000-6-2

EMC - Emission n.a., fmainosc < 9kHz

On-period 100 %

Ambient conditions

Fitting position any

Rated ambient temperature -20 °C ... +55 °C

Rated storage Temperature -20 °C …+70 °C (1K21 EN 60721-3-1)

Altitude ≤ 2000 m above sea level.

Climatic conditions 5-85 % rel. F., no condensation (3K22 EN60721-3-3)

Vibration DIN EN 60068-2-6 2…25 Hz ±1.6 mm 25 ... 150 Hz 5 g

Vibration DIN EN 60947-8 2 … 13.2 Hz ± 1 mm 13.2 ... 100 Hz ± 0.7 g

Vibration DIN EN 60947-8 2 … 13.2 Hz ± 1 mm 13.2 ... 100 Hz ± 0.7 g

Shock DIN EN 60947-8 half sine, 10 g, 11 ms

Housing Design V2

Dimensions (W x H x D) mm 35 x 90 x 58 mm

Width 2M

Plastic material PA66

Fire protection class UL 94 V-2

Protection class housing EN 60529 IP 30

Mounting EN 60715 Snap mounting on 35 mm standard rail EN60715

Optional: Screw mounting M4 screws (additional bar not included)

Weight approx. 117 g

Terminal connection Screw mounting M3

MS220VA and MSR220VA 11660-0701-05 Seite 7 / 12 www.ziehl.de

Protection class terminals EN 60529 IP 20

Line connection solid wire 1 x 0.5 ... 2.5 mm2 (AWG 22 - 14)

Stranded wire with insulated ferrules 1 x 0.14 …1.5 mm2 (AWG 28 - 16)

Insulation strip length min 8 mm

Tightening torque 0.5 Nm

Subject to technical modifications

14 Dimensions - Design V2

58 35

48

16,5 Option

Maße in mm

1) Top piece

2) Bottom piece

5 3) Mounting bar

61,8

4) Seal mounting link

(90)

45

98

116

5) Front plate element

6) Characteristic for bottom

4 7) Extensible bolt for wall fas-

tening with screws. Bolt bore

Ø 4.2 mm

6

3

1 2 3

15 Safety instructions and references for putting into operation

Attention!

Safety Instructions and references

please read carefully!

15.1 Explosive atmospheres

• The increased danger within explosive atmospheres (gas or dust) requires the careful attention of the

safety instructions and references for putting into operation. Observe the national safety rules and

regulations for prevention of accidents as well as the standard EN 60079-14 / VDE 0165-1. All work

for the connection, for putting into operation and maintenance is to be implemented by qualified, re-

sponsible technical personnel. Inappropriate behaviour can cause heavy personal damage and dam-

ages to property.

• The response of device must directly switch off the motor, also when used together with inverters. This

must be implemented with circuitry.

15.2 Special remarks for explosive gas atmospheres areas (Zone 0, 1 and 2)

• The device must be installed outside potentially explosive gas atmospheres unless the device is pro-

tected by a suitable ignition protection type (for example a flameproof enclosure).

15.3 Special remarks for use in the presence of combustible dust (Zone 20, 21 and 22)

• The device must be installed outside potentially explosive dust atmospheres unless the device is pro-

tected by a suitable enclosure for dust atmospheres.

MS220VA and MSR220VA 11660-0701-05 Seite 8 / 12 www.ziehl.de

15.4 Safety characteristics of the safety device (EN 50495 / VDE 0170-18)

Safety Integrity Level (EN 61508) and safety related parameters

Operating mode Hardware architecture HFT Safety Integrity Level

low demand mode 1oo1 0 SIL 1

Type MTBF PFH SFF SD SU DD DU

MS220VA 54 years 4.07E-07 55% 4.44E-07 5.55E-08 0 4.07E-07

MSR220VA 52 years 4.26E-07 55 % 4.52E-07 6.10E-08 0 4.26E-07

Type Proof test inter- 1year 3 years 5 years 10 years

val T1

MS220VA PFDavg 1.78E-03 5.35E-03 8.91E-03 1.78E-02

MSR220VA PFDavg 1.87E-03 5.60E-03 9.33E-03 1.87E-02

Observe proof test interval according EN 60079-17 for electrical equipment ≤ 3 years.

15.5 Category and Performance-Level (EN ISO 13849-1)

The device fulfils the requirements of category 1 and PL = c. MTTFd = 100 years.

The data of the functional safety stated above are valid for an ambient temperature of 40 °C. Data for

additional ambient temperatures can be obtained on request.

15.6 Application of the safety device used with equipment category (EN 50495 / VDE 0170-18)

This standard describes the minimum requirements of safety integrity level and fault tolerance of a safety

device in the application together with the category of the Equipment Ander Control (EUC).

EUC Safety device

no safety device SIL 1 SIL 2

Category 2

Zone 1, Zone 21 Zone 0, Zone 20 Zone 0, Zone 20

(2G, 2D) EPL = Gb, Db

Category 3

Zone 2, Zone 22 Zone 1, Zone 21 Zone 0, Zone 20

(3G, 3D) EPL = Gc, Dc

The device thus is suitable as safety device for Equipment Under Control (EUC) with HFT = 0 category 3

in Zone 1 and Zone 21. The combined equipment shall comply with the relevant standards EN 60079-0

according to the categories to match.

15.7 Wiring

• The lines of the thermistor circuit must be routed as separate control lines. Using lines of the supply

cable or other mains voltage lines is not permissible. If extreme inductive or capacitive stray effects

are to be expected by parallel cables of the power installation, shielded control lines should be used.

• The terminals Y1, Y2 may be attached parallel to a common resetting mechanism. Thermistor lines

must not be connected.

• The line resistance within the thermistor circuit may not exceed a value of 20 Ω to ensure short circuit

detection.

• Maximum of permissible length for thermistor circuit lines:

Wire length 2 x 1000 m 2 x 800 m 2 x 500 m 2 x 300 m 2 x 250 m

Wire cross section 2.5 mm2 1.5 mm2 1.0 mm2 0.75 mm2 0.5 mm2

• With commissioning and after modification of the plant the thermistor resistance must be checked with

a suitable measuring instrument. With a resistance < 50 Ω the sensor circuit is to be examined for

short-circuit.

Attention!

Check PTC’s only with measuring voltages of < 2.5 V.

MS220VA and MSR220VA 11660-0701-05 Seite 9 / 12 www.ziehl.de

15.8 Safe separation

• Line circuits (A1, A2) and (11, 12, 14) have a safe separation to low-voltage electric circuits (T1, T2)

and (Y1, Y2).

• Devices with a combined supply voltage DC/AC 24 V have no galvanic isolation and must be used with

a power supply according to EN 61558-2-6 (safety isolating transformer or battery grid) and with pro-

tected wiring.

15.9 Stop function

• A stop function triggered by the device must transfer the machine as fast as possible into a safe state.

The stop function must have top priority.

• In case of failure the device switches off the contactor / circuit breaker and prevents an overheating of

the isolation system and / or the surface temperature. The protective function of the device is only

guaranteed if wiring is done directly into the control circuit of the motor in accordance with the connec-

tion diagram. The contacts must be protected, to prevent welding.

15.10 Start and restart

• Only if no dangerous condition is present, a reset is allowed. Device type MS or device type MSR with

bridged terminals Y1, Y2 (auto reset) switches back on after the thermistors cooled down. This function

must not be used in applications where an automatic reset could cause personal injuries or damage to

property.

15.11 Manual reset

• When the device triggers a stop instruction, it must be maintained until the manual reset mechanism

is operated and safe conditions for a renewed start are given. The manual resetting may be only pos-

sible if all safety functions and protection devices are effective.

• Device type MSR have an electronic reclosing lock The stop instruction remains, until a reset is made

by pressing the push-button „Reset“. A start-up is only possible, if no case of failure occurs and the

motor is cooled down to a sufficient value of temperature.

• The device switches on automatically with return of supply voltage. The user must guarantee by exter-

nal interlock (see connection diagram) that the supervised machine does not start again independently.

Attention!

Safety circuits according to EN 60204 / EN 62061. The devices must not be used

alone for functions, where an automatic restart must be prevented.

16 Proof testing of the safety functions

• The safety function must be tested at regular intervals. It is recommended to carry out the proof-test

once a year. Depending on the zone risk, tests should be conducted more frequently. A fault is recog-

nized by the safety test. A fault between safety tests could cause loss of protection.

The following must be tested additionally to recurring examinations with maintenance services:

• The safety function must be tested by interrupt the thermistor circuit wire at terminals T1, T2.

• The short circuit monitoring function must be tested by bridging the thermistor circuit wires at terminals

T1, T2.

• The safety function must be tested by changing the resistance from 1500 Ohm to 4000 Ohm at termi-

nals T1, T2.

• For the device type MSR the function of the electronic interlock must be tested additionally.

• If an error is detected no restart must be induced until the error is cleared.

MS220VA and MSR220VA 11660-0701-05 Seite 10 / 12 www.ziehl.de

17 Maintenance and repair

• The devices are maintenance-free. Only the manufacturer may perform repairs. We recommend test-

ing within the regular maintenance intervals of the plant, where the device is used. EN 60079-17 is to

be observed.

• The guarantee presupposes the observance of these operating instructions (safety and start-up in-

structions).

18 Disposal

Disposal should be carried out properly and in an environmentally friendly manner

in accordance with legal provisions.

ZIEHL is registered with the EAR Foundation under WEEE no.: DE 49 698 543

You will find this and other user manuals written in English under

www.ziehl.com

Sie finden diese und auch weitere Bedienungsanleitungen im Internet unter

www.ziehl.de

ZIEHL industrie – elektronik GmbH + Co KG

Daimlerstr. 13

74523 Schwaebisch Hall

Germany

Fon + 49 791 504-0 info@ziehl.de www.ziehl.de

ZIEHL-ABEGG UK Ltd.

Springfield Business Park

Chelmsford, Essex, CM2 5AS

United Kingdom

Fon + 44 1245 449010 info@ziehl-abegg.co.uk www.ziehl-abegg.com/en-gb

MS220VA and MSR220VA 11660-0701-05 Seite 11 / 12 www.ziehl.de

19 EU / UKCA -Declaration of conformity

EU / UKCA-Konformitätserklärung

EU / UKCA-Declaration of Conformity

Hersteller: ZIEHL industrie-elektronik GmbH + Co KG

Manufacturer:

Anschrift: Daimlerstr. 13

Address: 74523 Schwäbisch Hall

Germany

Produktbezeichnung: Kaltleiter-Relais

Product description: PTC Thermistor Relay

Typ: MS220VA T222415

Type: MSR220VA T222431 T222435

Wir erklären in alleiniger Verantwortung, dass oben 2014/30/EU EMV Richtlinie

bezeichnetes Produkt den grundlegenden Anforderun- SI/2016/1091 EMC Directive

gen entspricht, die in den folgenden Europäischen 2014/34/EU ATEX Richtlinie

Richtlinien und in den UK Rechtsverordnungen festge-SI/2016/1107 ATEX Directive

legt sind. 2014/35/EU Niederspannungsrichtlinie

We declare under our sole responsibility that the above

SI/2016/1101 Low Voltage Directive

designated product meets the basic requirements and 2011/65/EU RoHS Richtlinie

complies with the following directives of the European

2015/863/EU RoHS Directive

Union and the UK Statutory Instruments: SI/2012/3032

Angewandte harmonisierte / designierte Normen und EN 50495:2010

technischen Spezifikationen: EN 60947-8:2003 + A1:2006 + A2:2012

Applied harmonised / designated standards and tech- EN IEC 61000-6-2:2019

nical specifications: EN 61000-6-3:2007 + A1:2011 + AC:2012

EN IEC 63000:2018

Benannte Stelle und Nummer der EU- PTB Physikalisch Technische Bundesanstalt 0102

Baumusterprüfbescheinigung: PTB 12 ATEX 3006 A2

Notified Body and number of the EU-type-examination

certificate:

Zugelassene Stelle und Nummer der UK- Bureau Veritas Consumer Products Services United

Baumusterprüfbescheinigung: Kingdom Limited, approved body No. 8507

Approved Body and number of the UK-type- EPS 22 UKEX 1024

examination certificate

CE-Kennzeichnung / UKCA-Kennzeichnung in: 2012 / 2022

CE marking / UKCA marking since:

Ort, Datum der Ausstellung: Schwäbisch Hall, 25.10.2022

Place, date of issue

ppa.

Herbert Wahl

Verkaufsleitung

Sales manager

MS220VA and MSR220VA 11660-0701-05 Seite 12 / 12 www.ziehl.de

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- Operating Manual MSF220K: - PTC-relay For Dry TransformersDocument8 pagesOperating Manual MSF220K: - PTC-relay For Dry TransformersFoti KarakoukaNo ratings yet

- Operating Manual TR400: - PT 100 Temperature Relay With 2 Analog OutputsDocument12 pagesOperating Manual TR400: - PT 100 Temperature Relay With 2 Analog OutputsOmnhickNo ratings yet

- Ba Msf220vu e PDFDocument8 pagesBa Msf220vu e PDFSyariefNo ratings yet

- 7XV5662!2!5AD10 Manual Ziehl TR600 enDocument10 pages7XV5662!2!5AD10 Manual Ziehl TR600 enEddy Fernando Queca CadizNo ratings yet

- Digital Humidity and Temperature Sensor AM2302Document5 pagesDigital Humidity and Temperature Sensor AM2302rizkypratamaputra58No ratings yet

- Operating Manual TR1200IPDocument20 pagesOperating Manual TR1200IPluisNo ratings yet

- Thermistor Module ModDocument4 pagesThermistor Module ModAdam MikitzelNo ratings yet

- Thomas Liu (Sales Manager)Document5 pagesThomas Liu (Sales Manager)MIN GU KIMNo ratings yet

- IR MelexisDocument52 pagesIR Melexisleomar_bNo ratings yet

- Calibration of Temperature SensorsDocument13 pagesCalibration of Temperature SensorsSubhash KNo ratings yet

- Operating Manual TR1200IPDocument21 pagesOperating Manual TR1200IPFelipe Gallardo CatrilNo ratings yet

- UC8 Troubleshooting Guide v2 0715 2Document18 pagesUC8 Troubleshooting Guide v2 0715 2j.knightNo ratings yet

- For 2-Stage Atmospheric Gas Burners Flame Detection: - Ionisation Probe - Infrared-Flicker Detector IRD 1020 - UV Flame Sensor UVD 971Document6 pagesFor 2-Stage Atmospheric Gas Burners Flame Detection: - Ionisation Probe - Infrared-Flicker Detector IRD 1020 - UV Flame Sensor UVD 971marioalf674150No ratings yet

- Dvi 980 - 982 (En)Document6 pagesDvi 980 - 982 (En)Jozo ĆurčićNo ratings yet

- Installation Instructions 810831-00: Water-Level Limiter / Controller NRS 1-9Document16 pagesInstallation Instructions 810831-00: Water-Level Limiter / Controller NRS 1-9Voicu StaneseNo ratings yet

- ITC-100 - Manual - V1.0 - 6.30Document9 pagesITC-100 - Manual - V1.0 - 6.30mickNo ratings yet

- Honeywell Satronic DKG972Document6 pagesHoneywell Satronic DKG972maccsyNo ratings yet

- ZHRV5Document2 pagesZHRV5thaisubNo ratings yet

- Mlx90614esf-Baa Data SheetDocument40 pagesMlx90614esf-Baa Data Sheetadolfo martinezNo ratings yet

- PTCDocument18 pagesPTCRetno_GNo ratings yet

- 7XV5662-7AD10 Quick Guide TR800 Ziehl 12280-0755-00 enDocument8 pages7XV5662-7AD10 Quick Guide TR800 Ziehl 12280-0755-00 enmansa122No ratings yet

- Manual Hardw eDocument9 pagesManual Hardw eAndreas PeniNo ratings yet

- Manual - PTi 1000 DH - A5 - v1.9 7.2017Document20 pagesManual - PTi 1000 DH - A5 - v1.9 7.2017Zikriya KarnekarNo ratings yet

- MTC2Document4 pagesMTC2ELECTRO-TECHNICAL OFFICERNo ratings yet

- Controlador Zelio RTC48 - Datasheet PDFDocument4 pagesControlador Zelio RTC48 - Datasheet PDFM Daniel HuayancaNo ratings yet

- Satronic BoxDocument6 pagesSatronic BoxbethmongNo ratings yet

- 03p1 03p2 Series GbDocument5 pages03p1 03p2 Series Gbazat OrazowNo ratings yet

- Digicold Digicold Digicold Digicold: SeriesDocument4 pagesDigicold Digicold Digicold Digicold: SeriesdbricchiNo ratings yet

- Electronic Pressure Switch & Transmitter: General SpecificationDocument4 pagesElectronic Pressure Switch & Transmitter: General Specificationhuu thanh nguyenNo ratings yet

- Smoke and Heat Exhaust Control Unit: Technical and Operating Documentation User Instruction ManualDocument13 pagesSmoke and Heat Exhaust Control Unit: Technical and Operating Documentation User Instruction ManualConstantin GubavuNo ratings yet

- Relee Electronice SIEMENSDocument32 pagesRelee Electronice SIEMENSciocioi iancuNo ratings yet

- DKG 972Document6 pagesDKG 972David RamirezNo ratings yet

- Distance SensorDocument5 pagesDistance Sensortuyetden613No ratings yet

- LD-B10-10-catalog Temperature ControllerDocument22 pagesLD-B10-10-catalog Temperature ControllerFareh KhanNo ratings yet

- Sitranst th300 Fi01enDocument7 pagesSitranst th300 Fi01enLuis GuillermoNo ratings yet

- Works Masterspec 230933 (Thermostat)Document5 pagesWorks Masterspec 230933 (Thermostat)DILSHAD AHEMADNo ratings yet

- Adt 7310Document24 pagesAdt 7310nevdullNo ratings yet

- Manual Auraton 2025 RTHDocument36 pagesManual Auraton 2025 RTHBeltzabarbasNo ratings yet

- Adt 7420Document24 pagesAdt 7420Vlad TusanNo ratings yet

- Simirel: Monitors, Interfaces, RelaysDocument32 pagesSimirel: Monitors, Interfaces, RelaysRomel Toledo CalvopiñaNo ratings yet

- Itc-100 Manual v1 1w57Document9 pagesItc-100 Manual v1 1w57mei krismahariyantoNo ratings yet

- Autonics TCN Manual PDFDocument2 pagesAutonics TCN Manual PDFDiego AlanizNo ratings yet

- 118L Digital BulletinDocument4 pages118L Digital Bulletinmbk.2k3No ratings yet

- Series Temperature Controller Instruction Sheet: PrecautionDocument14 pagesSeries Temperature Controller Instruction Sheet: PrecautionBen farah AymenNo ratings yet

- Promag 3000Document112 pagesPromag 3000Olivério TeixeiraNo ratings yet

- NXT4 Bia e 1Document24 pagesNXT4 Bia e 1Felipe AchurraNo ratings yet

- Nolden5000 UsermanualDocument55 pagesNolden5000 Usermanualnagy_istván_zoltánNo ratings yet

- SW32V Operating Manual e ZIEHL 2017-05-03Document22 pagesSW32V Operating Manual e ZIEHL 2017-05-03Jatupol PongsirisartNo ratings yet

- Detailed Manual: Toho Electronics Inc. Multi-Channel Board ControllerDocument35 pagesDetailed Manual: Toho Electronics Inc. Multi-Channel Board ControllerArchie MaguillanoNo ratings yet

- MSF220V MSF220VU Datasheet e ZIEHL 2017-02-21Document1 pageMSF220V MSF220VU Datasheet e ZIEHL 2017-02-21hector CarreraNo ratings yet

- Datasheet For LM45Document9 pagesDatasheet For LM45Bhimsen BudhathokiNo ratings yet

- Pulsteknik Appleton ATX Cont CSF DDocument17 pagesPulsteknik Appleton ATX Cont CSF Drocket-vtNo ratings yet

- Instructions and Advices To Use The Electronic Controller Logik 9Document27 pagesInstructions and Advices To Use The Electronic Controller Logik 9Muhammad Zeeshan Saeed100% (1)

- Honeywell Mmi 813.1 Mod 23Document5 pagesHoneywell Mmi 813.1 Mod 23nestor_moNo ratings yet

- Manual Full (English) HE-HT01 v1.1Document35 pagesManual Full (English) HE-HT01 v1.1Sarkis KaprelianNo ratings yet

- MULTICAL 603 - Data Sheet - EnglishDocument12 pagesMULTICAL 603 - Data Sheet - EnglishDan ChiriacNo ratings yet

- Air motors trainingDocument50 pagesAir motors trainingMuhammad Munirul AlamNo ratings yet

- Types of UV LED LightDocument3 pagesTypes of UV LED LightMuhammad Munirul AlamNo ratings yet

- Transformer - Inspection ChecklistDocument2 pagesTransformer - Inspection ChecklistMuhammad Munirul AlamNo ratings yet

- What Is The Spinning Procedure of Transforming Fiber Into YarnDocument5 pagesWhat Is The Spinning Procedure of Transforming Fiber Into YarnMuhammad Munirul AlamNo ratings yet

- How Many KG of CO2 in 1 KWHDocument6 pagesHow Many KG of CO2 in 1 KWHMuhammad Munirul AlamNo ratings yet

- Pasteurized VsDocument55 pagesPasteurized VsMuhammad Munirul AlamNo ratings yet

- Overrun CalculationsDocument4 pagesOverrun CalculationsMuhammad Munirul AlamNo ratings yet

- Electrical Hazards & Safety TrainingDocument45 pagesElectrical Hazards & Safety TrainingMuhammad Munirul AlamNo ratings yet

- ALP Model Paper 3Document12 pagesALP Model Paper 3Swabya Sachi DasNo ratings yet

- Manual de Repuestos LG500 NuevoDocument108 pagesManual de Repuestos LG500 NuevoPaola Gómez GuzmánNo ratings yet

- Tutorial Week 11 - Non-Isothermal CSTR - System ABDocument25 pagesTutorial Week 11 - Non-Isothermal CSTR - System ABsiti azilaNo ratings yet

- Examen Inglés de La Comunidad de Madrid (Ordinaria de 2022) (WWW - Examenesdepau.com)Document8 pagesExamen Inglés de La Comunidad de Madrid (Ordinaria de 2022) (WWW - Examenesdepau.com)Lil CiamiNo ratings yet

- Altivar Process Ride Through Time - IE04Document3 pagesAltivar Process Ride Through Time - IE04Goran MladenovicNo ratings yet

- 2012 Stimulaton VesselsDocument2 pages2012 Stimulaton VesselsmajdirossrossNo ratings yet

- The Journal of Energy and DevelopmentDocument26 pagesThe Journal of Energy and DevelopmentThe International Research Center for Energy and Economic Development (ICEED)No ratings yet

- Interview Questions MS WordDocument20 pagesInterview Questions MS Wordhassan iftikhar100% (1)

- REF - NO.PSE/P 2603-1 List: HBL Power Systems LTDDocument24 pagesREF - NO.PSE/P 2603-1 List: HBL Power Systems LTDmukesh_kht1No ratings yet

- 980E-4 Hoist System Components, Operation, AdjustmentDocument30 pages980E-4 Hoist System Components, Operation, AdjustmentRonny Leido Rodriguez Bernabe100% (1)

- Markscheme: International Baccalaureate Baccalauréat International Bachillerato InternacionalDocument7 pagesMarkscheme: International Baccalaureate Baccalauréat International Bachillerato InternacionalEdgarNo ratings yet

- Summary of Progress of Work-2023.02.04Document111 pagesSummary of Progress of Work-2023.02.04Zahidul zahidNo ratings yet

- Commander SK Technical Manual DataDocument122 pagesCommander SK Technical Manual DataBlelebNo ratings yet

- Nailor Catalog UFADCombinedDocument136 pagesNailor Catalog UFADCombinedDavid RivardNo ratings yet

- Effect of Water Content On Solid Biofuel Pellets Produced From Rice StrawDocument6 pagesEffect of Water Content On Solid Biofuel Pellets Produced From Rice Strawrikayolanda23No ratings yet

- Chris - Electrician CVDocument1 pageChris - Electrician CVchris_dalzellNo ratings yet

- 2021 - 2022 - 2023 امتحانات الثانوية العامة اللغه الانجليزيهDocument28 pages2021 - 2022 - 2023 امتحانات الثانوية العامة اللغه الانجليزيهamira0mahmoud00No ratings yet

- Heating Curve WRKSHT v2Document2 pagesHeating Curve WRKSHT v2Samuel PaulNo ratings yet

- PV CalculatorDocument2 pagesPV CalculatorChad RingströmNo ratings yet

- Modulo Monocristalino 144 Células 535W - Bel EnergyDocument2 pagesModulo Monocristalino 144 Células 535W - Bel EnergyRoswel Piovezani FerreiraNo ratings yet

- D3e802f8707!1!9l Pumpe Duse Tdi Bew and BRMDocument24 pagesD3e802f8707!1!9l Pumpe Duse Tdi Bew and BRMJan HavelNo ratings yet

- Thermo Lab ReportDocument11 pagesThermo Lab Reportceojoe65No ratings yet

- AC Plus: O N FR EQDocument40 pagesAC Plus: O N FR EQIgnacioNo ratings yet

- 3-0-105f EXHAUST SYSTEM PURGE CRANK TIMES TO PREVENT POTENTIALDocument11 pages3-0-105f EXHAUST SYSTEM PURGE CRANK TIMES TO PREVENT POTENTIALMohamed HussinNo ratings yet

- D4529-Standard Test Method For Estimation of Net Heat of Combustion of Aviation FuelsDocument4 pagesD4529-Standard Test Method For Estimation of Net Heat of Combustion of Aviation FuelsrezaNo ratings yet

- VersaJet Series Manual 06-13 WebDocument36 pagesVersaJet Series Manual 06-13 WebJOSE LUIS HERNANDEZ CHAVEZNo ratings yet

- Design of Pneumatic CircuitsDocument81 pagesDesign of Pneumatic CircuitsNikhil PandharpatteNo ratings yet

- SP 1400 Parts ListDocument1 pageSP 1400 Parts ListVirajpujariNo ratings yet

- Sharekhan Morning Tiger - 22th April 2022Document7 pagesSharekhan Morning Tiger - 22th April 2022Deepak BhattNo ratings yet

- TM-3WMJ-SL-IDA2 (FTV-CXV14 Series R-32 - DAMA)Document36 pagesTM-3WMJ-SL-IDA2 (FTV-CXV14 Series R-32 - DAMA)HANDOYO RNo ratings yet