Professional Documents

Culture Documents

S46998-A0006-P981_EN

S46998-A0006-P981_EN

Uploaded by

muhamedshuaibbhaiCopyright:

Available Formats

You might also like

- Weekly Chemistwise Metrics Tracker (2023-24) - April '24Document14 pagesWeekly Chemistwise Metrics Tracker (2023-24) - April '24iammouliNo ratings yet

- MSA ProcedureDocument3 pagesMSA ProcedureAnkur0% (1)

- 3600 Elta Software User GuideDocument0 pages3600 Elta Software User Guidelara610731No ratings yet

- Cisco Advanced IPSec With FlexVPNDocument91 pagesCisco Advanced IPSec With FlexVPNSrdjan MilenkovicNo ratings yet

- 7 Series Chipset PCH DatasheetDocument41 pages7 Series Chipset PCH DatasheetLeonardo Garcia50% (2)

- QuantaDocument41 pagesQuantaJoaoNo ratings yet

- Quanta FH9 DA0FH9MB6C0 - R2aDocument48 pagesQuanta FH9 DA0FH9MB6C0 - R2aYetawa GuaviareNo ratings yet

- Acer Chromebook C740 - Quanta ZHNB DAZHNMB1AD0 RADocument39 pagesAcer Chromebook C740 - Quanta ZHNB DAZHNMB1AD0 RAmike onciucNo ratings yet

- Acer Chromebook C740 - Quanta ZHNB DAZHNMB1AD0 RaDocument39 pagesAcer Chromebook C740 - Quanta ZHNB DAZHNMB1AD0 RaRed de Tecnicos MDQNo ratings yet

- 2023 Catalog LNRXX EngDocument2 pages2023 Catalog LNRXX Engc membrenoNo ratings yet

- 5gen Quanta Fh9 Da0fh9mb6c0 - R2aDocument5 pages5gen Quanta Fh9 Da0fh9mb6c0 - R2arohit.ydv.8368No ratings yet

- Pressure Transmitter 33XDocument2 pagesPressure Transmitter 33XMintatuyNo ratings yet

- CLR07-02-000 - Sondakan RW 15 - MatrixDocument10 pagesCLR07-02-000 - Sondakan RW 15 - MatrixilhamNo ratings yet

- By6 By6d PDFDocument47 pagesBy6 By6d PDFivan SANo ratings yet

- Nddi2 LS - GS - 3ba23173Document27 pagesNddi2 LS - GS - 3ba23173Long Nguyen ThanhNo ratings yet

- Main Distribution Panel Details: Schedule of Loads of A Multi Family Dwelling Unit (Main Distributor Panel)Document1 pageMain Distribution Panel Details: Schedule of Loads of A Multi Family Dwelling Unit (Main Distributor Panel)Mariniel SibugNo ratings yet

- TR-7578-C Wiring DiagramDocument1 pageTR-7578-C Wiring Diagramarupamguria05No ratings yet

- Toshiba Satellite c75d l75d Bd9 Da0bd9mb8e0da0bd9mb8f0 Rev A1a Schematicunlocked 1Document41 pagesToshiba Satellite c75d l75d Bd9 Da0bd9mb8e0da0bd9mb8f0 Rev A1a Schematicunlocked 1Gomez RonaldNo ratings yet

- Datenblatt Serie-21PHB eDocument2 pagesDatenblatt Serie-21PHB eBoody CNo ratings yet

- Planta ZTE OutdoorDocument6 pagesPlanta ZTE OutdoorwidoblNo ratings yet

- Lz4 V4uv0r enDocument14 pagesLz4 V4uv0r enelectronicaNo ratings yet

- SN54ACT16244, 74ACT16244 Datasheet (Rev. B)Document18 pagesSN54ACT16244, 74ACT16244 Datasheet (Rev. B)Ecus ElectronicsNo ratings yet

- EPS Eaton PDFDocument2 pagesEPS Eaton PDFRazvan FagarasNo ratings yet

- Quick Installation Guide: Automatical Solution For EPS FunctionDocument2 pagesQuick Installation Guide: Automatical Solution For EPS FunctionDucNo ratings yet

- Acrosser Technology AR B1673 DatasheetDocument5 pagesAcrosser Technology AR B1673 DatasheetWaleed MareeNo ratings yet

- Asus A8ES Laptop SchematicsDocument94 pagesAsus A8ES Laptop SchematicsftenminNo ratings yet

- H P (0,01%) P T S 33 X S 35 X: Ighly Recise Ressure Ransmitters Eries EriesDocument2 pagesH P (0,01%) P T S 33 X S 35 X: Ighly Recise Ressure Ransmitters Eries Eriess bNo ratings yet

- Description Features: LTC488/LTC489 Quad RS485 Line ReceiverDocument12 pagesDescription Features: LTC488/LTC489 Quad RS485 Line ReceiverCahyo GuntoroNo ratings yet

- Tolerance Notes: VFA12-HD VFA12-HDDocument5 pagesTolerance Notes: VFA12-HD VFA12-HDneil gonzalesNo ratings yet

- FTTH Materials Comparison Rev1Document1 pageFTTH Materials Comparison Rev1Victor EstomoNo ratings yet

- Cisco Switch ApplicationsDocument10 pagesCisco Switch ApplicationsAllan CazéNo ratings yet

- Pioneer Deh-1280mp Crt4230 Car AudioDocument35 pagesPioneer Deh-1280mp Crt4230 Car AudioSomde TrombetaNo ratings yet

- Nha Anh BonDocument34 pagesNha Anh BonMaker PhạmNo ratings yet

- A en 05802 00Document32 pagesA en 05802 00jose florNo ratings yet

- Rab MV Panel Pix12 GiDocument1 pageRab MV Panel Pix12 GiHariyantoNo ratings yet

- Single Line Diagram: Doloriel, Charlemaigne Josef Prequencia, Glenn Paulo EE-5ADocument1 pageSingle Line Diagram: Doloriel, Charlemaigne Josef Prequencia, Glenn Paulo EE-5ACharlemaigne Josef Cuartero DolorielNo ratings yet

- ASUS GL703GE 1.0 Schematic0 - 15 - 0 PDFDocument59 pagesASUS GL703GE 1.0 Schematic0 - 15 - 0 PDFEnder özveriNo ratings yet

- Gl503ge Rev1.0 - LSF PDFDocument59 pagesGl503ge Rev1.0 - LSF PDFToni SetyawanNo ratings yet

- Data Sheet For Ultrasonic FlareDocument2 pagesData Sheet For Ultrasonic FlareBABILIN VNo ratings yet

- X1 AC Installation GuideDocument2 pagesX1 AC Installation GuideMEL ANGELESNo ratings yet

- DAX1PDMB8E0Document51 pagesDAX1PDMB8E0Jose lopez RosalesNo ratings yet

- Clevo W370SS W35XSSQ - 6-71-W3S50-D02ADocument61 pagesClevo W370SS W35XSSQ - 6-71-W3S50-D02Amobaway2017No ratings yet

- Compal LA-1731Document46 pagesCompal LA-1731ever aguilarNo ratings yet

- Technical Publication: Installation Guidelines - HELIAX 12 RRU Assembly Solution: Pendant ConfigurationDocument20 pagesTechnical Publication: Installation Guidelines - HELIAX 12 RRU Assembly Solution: Pendant Configurationchristophe TrachezNo ratings yet

- Test and Calibration - 007Document10 pagesTest and Calibration - 007Mario AsselNo ratings yet

- Raychem - RSTI InstalaciónDocument6 pagesRaychem - RSTI Instalaciónfredy telloNo ratings yet

- T.D.A 10021HTDocument16 pagesT.D.A 10021HTJose M PeresNo ratings yet

- P T S 21 R S 21 SR / MR: Iezoresistive Ransmitters / Eries EriesDocument2 pagesP T S 21 R S 21 SR / MR: Iezoresistive Ransmitters / Eries EriesBinh Thai HYNo ratings yet

- Matrox Meteor II Multi ChannelDocument3 pagesMatrox Meteor II Multi ChannelyumekiNo ratings yet

- Broadband VIIDocument54 pagesBroadband VIIGicuNo ratings yet

- NatSemiFetDatabook1977 TextDocument278 pagesNatSemiFetDatabook1977 TextmonicaNo ratings yet

- JST Product Overview - JD09 PDFDocument35 pagesJST Product Overview - JD09 PDFm31d1No ratings yet

- CLEVO Tigerhill-Pineview System Block DiagramDocument26 pagesCLEVO Tigerhill-Pineview System Block DiagramChico SouzaNo ratings yet

- CLEVO M1100-D01 1204 DecryptedDocument26 pagesCLEVO M1100-D01 1204 DecryptedMatias MareNo ratings yet

- 79 LXX RegDocument6 pages79 LXX RegSo Was RedNo ratings yet

- UENR82990001Document8 pagesUENR82990001Guido Emanuel SteinbachNo ratings yet

- Topologi The Park - KendariDocument1 pageTopologi The Park - KendariAnsar SaniNo ratings yet

- Military Aerospace RF ConnectorsDocument128 pagesMilitary Aerospace RF Connectorsjosh_nesbittNo ratings yet

- Wiring Diagram: Minas A Servo Driver CN Ser Mini DIN 8-Pin, Male PC Sub-D 9-Pin, FemaleDocument1 pageWiring Diagram: Minas A Servo Driver CN Ser Mini DIN 8-Pin, Male PC Sub-D 9-Pin, Femaleserege75% (4)

- H P (0,01%) P T S 33 X S 35 X: Ighly Recise Ressure Ransmitters Eries EriesDocument2 pagesH P (0,01%) P T S 33 X S 35 X: Ighly Recise Ressure Ransmitters Eries EriesUTOPIA TECHNOLOGYNo ratings yet

- Tda 8505Document27 pagesTda 8505Miszcsi MiszcsiNo ratings yet

- Paa21sr/80444.3 - 1 Paa21sr/80444.3 - 14-20ma Paa21sr/80444.3 - 2.5 PR21S/80549.3-2. 5 4-20ma PR21SR/80444.3-2.5Document5 pagesPaa21sr/80444.3 - 1 Paa21sr/80444.3 - 14-20ma Paa21sr/80444.3 - 2.5 PR21S/80549.3-2. 5 4-20ma PR21SR/80444.3-2.5Jose MadrizNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- VMSDocument100 pagesVMSmuhamedshuaibbhaiNo ratings yet

- Create A Composition of 1920px X 1080px in Adobe After EffectsDocument1 pageCreate A Composition of 1920px X 1080px in Adobe After EffectsmuhamedshuaibbhaiNo ratings yet

- EN50575 DoP EuroClass Dca s1a d1 a2 (English)Document1 pageEN50575 DoP EuroClass Dca s1a d1 a2 (English)muhamedshuaibbhaiNo ratings yet

- Product Description (2019) : Netcol5000-C (030, 032, 065) In-Row Chilled Water Smart Cooling ProductDocument30 pagesProduct Description (2019) : Netcol5000-C (030, 032, 065) In-Row Chilled Water Smart Cooling ProductmuhamedshuaibbhaiNo ratings yet

- Cisco MDS 9000 Family Release Notes For Cisco MDS SAN-OS Release 2.1 (2b)Document22 pagesCisco MDS 9000 Family Release Notes For Cisco MDS SAN-OS Release 2.1 (2b)muhamedshuaibbhaiNo ratings yet

- Cisco MDS 9000 Family Release Notes For Cisco MDS SAN-OS Release 2.1Document30 pagesCisco MDS 9000 Family Release Notes For Cisco MDS SAN-OS Release 2.1muhamedshuaibbhaiNo ratings yet

- My 03 Practice3Document1 pageMy 03 Practice3muhamedshuaibbhaiNo ratings yet

- My 07 Practice2Document1 pageMy 07 Practice2muhamedshuaibbhaiNo ratings yet

- My 07 Practice1Document1 pageMy 07 Practice1muhamedshuaibbhaiNo ratings yet

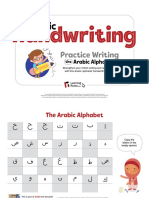

- Arabic Handwriting v3Document14 pagesArabic Handwriting v3muhamedshuaibbhaiNo ratings yet

- Imagine Cup 2023 - Pakistan Finals GuidanceDocument2 pagesImagine Cup 2023 - Pakistan Finals GuidancemuhamedshuaibbhaiNo ratings yet

- My 06 PracticeDocument1 pageMy 06 PracticemuhamedshuaibbhaiNo ratings yet

- Anokha SakhiDocument30 pagesAnokha SakhimuhamedshuaibbhaiNo ratings yet

- My 02 Practice3Document2 pagesMy 02 Practice3muhamedshuaibbhaiNo ratings yet

- My 04 PracticeDocument1 pageMy 04 PracticemuhamedshuaibbhaiNo ratings yet

- My 05 Practice1Document1 pageMy 05 Practice1muhamedshuaibbhaiNo ratings yet

- Achievements of Muslim Women in The Religious and Scholarly Fields PDFDocument57 pagesAchievements of Muslim Women in The Religious and Scholarly Fields PDFmuhamedshuaibbhaiNo ratings yet

- My 02 Practice2Document3 pagesMy 02 Practice2muhamedshuaibbhaiNo ratings yet

- Warehouse ProposedDocument2 pagesWarehouse ProposedmuhamedshuaibbhaiNo ratings yet

- IC23 Pakistan Official Rules and RegulationDocument16 pagesIC23 Pakistan Official Rules and RegulationmuhamedshuaibbhaiNo ratings yet

- List of Computer Sindh Board of Technical EducationDocument17 pagesList of Computer Sindh Board of Technical Educationmuhamedshuaibbhai50% (2)

- Islamic History - Classes XI-XII - NC 2002 - June 2012Document47 pagesIslamic History - Classes XI-XII - NC 2002 - June 2012muhamedshuaibbhai100% (1)

- Introduction (Recovered)Document37 pagesIntroduction (Recovered)muhamedshuaibbhaiNo ratings yet

- SLB Field ManulaDocument145 pagesSLB Field ManulaRaed fouadNo ratings yet

- D200 UserManual Preliminary EnglishDocument46 pagesD200 UserManual Preliminary EnglishIzaias Soares Silva100% (2)

- H. SPESIFIKASI IPAL PUSK NANGA TAYAP PDFDocument2 pagesH. SPESIFIKASI IPAL PUSK NANGA TAYAP PDFfajrul 2222No ratings yet

- Chapter 5 Pictorial DrawingsDocument44 pagesChapter 5 Pictorial DrawingsVisan NaiduNo ratings yet

- Berthold WorkshopDocument71 pagesBerthold WorkshopAgustantoNo ratings yet

- Design of Pier For Minor Bridge at Ch. 11+120Document69 pagesDesign of Pier For Minor Bridge at Ch. 11+120siddharth yadavNo ratings yet

- Evaluation of Blended Learning in Higher Education A Case StudyDocument9 pagesEvaluation of Blended Learning in Higher Education A Case StudyGlobal Research and Development ServicesNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezNo ratings yet

- Reflection PaperDocument1 pageReflection PaperHarold LandichoNo ratings yet

- Gr2 Wk10 Many Ways To MeasureDocument2 pagesGr2 Wk10 Many Ways To MeasureyeezeeNo ratings yet

- URAL 2017 - Owners - Manual - EnglishDocument86 pagesURAL 2017 - Owners - Manual - EnglishPerformNo ratings yet

- Flat Belt DriveDocument25 pagesFlat Belt DriveMurugesan RameshNo ratings yet

- TG-24 Battery Charger System TG-24 Battery Charger System TG-24 Battery Charger System TG-25 Battery Charger SystemDocument11 pagesTG-24 Battery Charger System TG-24 Battery Charger System TG-24 Battery Charger System TG-25 Battery Charger SystemBHUVANESH MNo ratings yet

- Astm D1752-18Document3 pagesAstm D1752-18zaid100% (1)

- Test Series - Forestry: Test Number Date Topic Syllabus Reading Materials 02-11-2020 Paper-1 Section-ADocument4 pagesTest Series - Forestry: Test Number Date Topic Syllabus Reading Materials 02-11-2020 Paper-1 Section-ANikhil AgrawalNo ratings yet

- Logistics Supervisor - Mine Risk Education - Cover-LetterDocument1 pageLogistics Supervisor - Mine Risk Education - Cover-Letteryazeed naiban0% (1)

- MIDAS Gen DescriptionDocument43 pagesMIDAS Gen Descriptionrponnan100% (1)

- DACTS705 English PDFDocument21 pagesDACTS705 English PDFgiapy0000No ratings yet

- Kerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDocument5 pagesKerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDr.Thrivikramji.K.P.No ratings yet

- Quantification Methodology For The Use of Sulphur Concrete in Precast Applications (First Assessment Version) - 0Document33 pagesQuantification Methodology For The Use of Sulphur Concrete in Precast Applications (First Assessment Version) - 0Verma NverNo ratings yet

- Tandler Angle GearsDocument2 pagesTandler Angle GearsEmerson IpialesNo ratings yet

- Narrowing The Gap: The Effects of Steady Traffic Growth & Evolution of Scope ClausesDocument64 pagesNarrowing The Gap: The Effects of Steady Traffic Growth & Evolution of Scope Clausesrobertas negudinasNo ratings yet

- ZR22 Detector TroubleshootingDocument3 pagesZR22 Detector TroubleshootingControl InstrumentationNo ratings yet

- Sidewinder PartsDocument4 pagesSidewinder PartsKhalidNo ratings yet

- Laporan Penjualan Ban TypeDocument18 pagesLaporan Penjualan Ban Typedataari0201No ratings yet

- 50-Applicable Codes and StandardsDocument48 pages50-Applicable Codes and StandardsmohsenNo ratings yet

S46998-A0006-P981_EN

S46998-A0006-P981_EN

Uploaded by

muhamedshuaibbhaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S46998-A0006-P981_EN

S46998-A0006-P981_EN

Uploaded by

muhamedshuaibbhaiCopyright:

Available Formats

Installation instruction

Issue 5, October 2022

LAN fiber housing 1U

S46998-A0006-P981

These installation instructions should be used as a guide by the trained fitter performing the installation.

STANDARD RECOMMENDED PROCEDURE S46998-A0006-P9817 | ISSUE 1 | DECEMBER 2022 | PAGE 1 OF 15

General information

Warning!

Possible laser/LED radiation in the non-visible spectrum!

Never look into open fiber ends if the level of risk from laser/LED radiation is not known.

Important:

The assignment of the risk level must be specified definitively by the site technician/operator responsible for the

communications facility and must be indicated accordingly (e.g. by attaching standard-compliant warning signs as per the

current edition of DIN EN/IEC 60825-1, and in accordance with the current edition of BGV B2 “Laser radiation”).

If there is any change in the technical data relating to the risk level, the warnings must be adapted accordingly and

occupational safety precautions must be taken if required, see also e.g. the current edition of DIN EN/IEC 60825-2.

Cleaning:

Cleaning agents based on alcohol (e.g. isopropyl alcohol) or water (e.g. De.sol.it 2000 or 3000, Ecoclean 2000)

should be used for cleaning cables and modules.

Kit content

2x

4x 4x Quantity depends

on configuration

M6x16

1x10cm 4x

ONLY ADTP VERSION

ONLY PGTL VERSION

1x

M20

Splice bridge kit

1x 2x 8x

Required tools

PH3

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 2 OF 15

1a 1b Splice pack version

2 3 Standard cassette option

4x 4x M6x16

4 Standard cassette option 5 MFT cassette

option

Loose tube cable 75cm 1,5m

70cm 1,5m

Loose tube cable

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 3 OF 15

6

4

3

2

1

Adapters 19-24

Cassette 4

Adapters 13-18

Cassette 3

Adapters 7-12

Cassette 2

Adapters 37-48

Adapters 1-6 Cassette 4

Cassette 1

LC-D Adapters 25-36

Cassette 3

Adapters 13-24

Cassette 2

SC Adapters 1-12

Cassette 1

4

3

2

1

Adapters 43-48

Cassette 4

Adapters 37-42

Cassette 3

Adapters 31-36

Cassette 2

Adapters 25-30

Cassette 1

Adapters 19-24

Cassette 4

Adapters 13-18

Adapters 7-12 Cassette 3

Adapters 1-6 Cassette 2

Cassette 1

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 4 OF 15

8a Unicam option

Loose tube cable:

2cm 1m

Tight buffer cable:

1m 4cm

8b

Loose tube cable:

2cm 1m

Tight buffer cable:

1m 4cm

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 5 OF 15

9 BRDG option 10

Loose tube cable:

2cm 1m

Tight buffer cable:

1m 4cm 4x

11

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 6 OF 15

12a BRDG cabel option

Loose tube cable:

2cm 1m

Tight buffer cable:

1m 4cm

Bare fiber

12b Loose tube cable:

2cm 1m

Tight buffer cable:

1m 4cm

Bare fiber

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 7 OF 15

13 MFT CASSETTE INSTALLATION AND FIBER SPLICING

Splice tray

Technical data

Capacity of the Trays

Pigtails

Type Ribbon Shrink Splice Crimp-Splice Fiberlok Coupler 900 µ Fibers

Ø 3mm

1 4 (12 fiber) - - - - - -

2/3 - 24 - - - - -

2/3 - - 24 - - - -

2/3 - 12 - - 1 - -

2/3 - - 12 - 1 - -

2/3 - 16 - 2 - - -

2/3 - - 14 2 - - -

2/3 - - - - - 12 -

2/3 - - - - - - 12

Tray type 2 or 3 can be optionally ordered with pigtail adapter or hinged adapter.

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 8 OF 15

14 Tray description

Variable splice protection holder (5)

Cover mounting (2) Buffer tube / fiber entrance (8)

Fiber hold-down (6)

Guide (4)

Locking element (1) Hinge mounting (7)

Slack storage

mininimum bend radius

Hinge ( 3) 25 mm (9)

Housing for

mounting element (20) Strain-relief

for buffer tubes (10)

Locking element for

fiber entrance (11)

Hinge point (12)

Strain-relief with

cable tie (18)

Mounting element (17) Hole for securing screw (16)

Cover locking catch (19) Fiber guide channel (14)

Pockets for locking and

mounting elements (13)

Hole for O-Pack (15)

1. Locking element: For locking the trays together.

2. Cover mounting: For fastening the covers on the trays

3. Hinge: For linking the trays together

4. Guide: For routing fibers to another tray

5. Variable splice protector holder: For storing splices

6. Fiber hold-down: For routing the fibers

7. Hinge mounting: Mounting point for item 3

8. Buffer tube / fiber entrance: For inserting fibers or buffer tubes

9. Slack storage: For storing slack

10. Strain-relief: For securing buffer tubes

11. Locking element: For securing the silicone protection on fiber entry

12. Hinging point: For hinging the tray on an O-Pack

13. Pockets for locking or mounting element: For mounting item 1 or item 17

14. Fiber guide channel: For guiding the fibers

15. Hole for central pin: For mounting the tray on the O-Pack

16. Hole for securing screw: For mounting with a screw

17. Mounting element: For mounting (hooking) in tray holders or enclosures

18. Strain-relief with cable tie: For mounting the cable ties

19. Cover locking catch: For locking the cover

20. Housing for mounting element: For mounting the tray on an enclosure

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 9 OF 15

Isolierband

Mounting Buffer Tubes, 900-µm Pigtails, Pigtail and Ribbon/ Insulating tape

Single Fibers in the Tray

Buffer tubes: Remove strain-relief for buffer tubes (10) from

the tray with a knife.

Wrap buffer tubes with insulating tape for improved grip

and place them in the tray.

Latch strain-relief onto outer edge of tray over the buffer Zugabfangung

tube. Strain-relief

The buffer tubes can also be secured with a cable tie if

required.

Note: Appropriate cable ties have to be used.

Locking tooth of the cable tie

Caution: The locking tooth of the cable tie must be placed

within the MFT splice tray (as shown in the picture), so that

it is possible to assemble and lock several splice

trays without problems

Cable

Insulating tape

Examples of Splicing and Installing Fibers in the Trays

Strip cables to a length in accordance with the regional specifications and the closure or rack installation instruc-

tions. Add at least 1200 mm for storing the fibers in the tray. Arrange the stored fibers in the tray to maximize the

bend radius.

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 10 OF 15

Mounting and Locking Several Trays Together.

Remove hinges (3) from the tray with a knife.

To interlink the required number of trays, always latch the hinges to the hinge mountings (7) so that they are

offset .

Hinge

Hinge mounting

The trays can then be hinged up as required.

To lock several trays, remove the locking element (1) from the tray with a knife. Insert the locking elements in the

locking element pockets (13) so that they are always offset. Place the cover on the last tray and latch it onto the

cover locking catch (19).

Cover

Locking element

Cover locking catch

Close the tray with the cover.

The cover must be latched onto the cover mounting for

the purpose. Cover mounting

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 11 OF 15

15 STANDARD CASSETTE INSTALLATION AND FIBER SPLICING

Components

1. Splice cassette

2. Cable tie, approx. 2,4 x 92 mm

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 12 OF 15

Technical data

The capacity of the splice cassette depends on the splice type and can be taken from the following table.

Capacity per

Designation Ordering No. Explanation

Cassette Splicing organizer

2 - Splicing organizer for 12x crimp C46197-A7-A69 Pack. à 10 St

splice protector

- 12 C45057-Z1-H590 Pack. à 150 St

Crimp splice protector

2 - Splicing organizer for 6x heat-shrink S46999-Z12-A1 Pack. à 10 St

splice protector for singel fibers

- 6 Heat-shrink splice protector for single S46999-A16-A1 Pack. à 10 St

fibers

2 - Splicing organizer for 5x attenuation S46998-A4-R1 Pack. à 10 St

splice or CamSplice

- 5 Heat-shrink splice protector for S46999-A16-A8 Pack. à 5 St

attenuation splices

- 5 CamSplice S46999-M17-C10 Pack. à 6 St

- 5 CamSplice ATC S46998-Z1-A31 Pack. à 6 St

Preparing the cassette and fiber buffers

- Press the splicing organizer into the splice cassette at the required position.

- Secure the splice cassette in the holder of the thermal fusion splicer (except with CamSplice).

Splicing organizer

Free space for 2nd

splicing organizer

Snap lock

- Cut back the cable to a length corresponding to regional specifications and the closure or rack installation

instructions. At least 1200 mm must be added on for the purpose of securing the fibers.

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 13 OF 15

- Clean the fiber buffers (use white spirit)

- Cut back the fiber buffers (min 1200 mm)

- Clean the optical fibers (use cleaning cloth with isopropyl alcohol if necessary).

Wrap woven tape around the fibers in the cassette insertion area and fit marking strips if necessary.

Secure fiber buffers to the cassette using cable tie and tighten the latter by hand. The fiber buffers must not be

deformed.

Cable tie Cassette

Marking strip

Fiber buffer Fibers

- Insert the fiber reserve into the cassette with the largest possible bending radius.

Splicing the fibers

Cut the left-hand fiber unit at the right-hand marking web and the right-hand unit at the left-hand web. Re-

move the fibers from the cassette.

Marking strip

Left-hand Right-hand

fiber unit fiber unit

When using a heat-shrink splice protector, slip the protector onto one of the fibers to be connected before

performing splicing.

Clean, cut back and splice the fibers in accordance with the relevant specifications.

Slip the heat-shrink splice protector over the splice point and heat-shrink in the heater.

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 14 OF 15

When using crimp splice protector, splice the fibers as per point 5.2.

Lay the crimp splice protector in the crimping device, insert the spliced fibers and crimp.

When performing a mechanical splice with CamSplice, the installation instructions including in the packag-

ing must be observed.

Securing the fibers

Insert the spare length of the spliced fibers into the cassette and engage the splice protector.

When splicing without a protector, carefully secure the fiber splicing point onto the center of the splicing

organizer. Press the fibers gently onto the adhesive edges on the sides of the organizer. After splicing all the

fibers, pour splice protection compound over the splicing organizer.

Important!

Secure the fibers with the largest possible bending radius and outside the marked area.

Note minimum bending radius 30 mm

Secure no fibers in the splice compartment for the second splicing

organizer.

Place the ready spliced cassette in the closure or rack.

Important! Use the largest possible bending radius for the fibers.

Corning Optical Communications GmbH & Co. KG • Leipziger Strasse 121 • 10117 Berlin, GERMANY

+00 800 2676 4641 • FAX: +49 30 5303 2335 • www.corning.com/opcomm/emea

Corning Optical Communications reserves the right to improve, enhance, and modify the features and specifications

of Corning Optical Communications products without prior notification. A complete listing of the trademarks of Corning

Optical Communications is available at www.corning.com/opcomm/trademarks. All other trademarks are the properties of

their respective owners. Corning Optical Communications is ISO 9001 certified. © 2021 Corning Optical Communications.

All rights reserved.

STANDARD RECOMENDED PROCEDURE S46998-A0006-P981 | ISSUE 1 | DECEMBER 2022 | PAGE 15 OF 15

You might also like

- Weekly Chemistwise Metrics Tracker (2023-24) - April '24Document14 pagesWeekly Chemistwise Metrics Tracker (2023-24) - April '24iammouliNo ratings yet

- MSA ProcedureDocument3 pagesMSA ProcedureAnkur0% (1)

- 3600 Elta Software User GuideDocument0 pages3600 Elta Software User Guidelara610731No ratings yet

- Cisco Advanced IPSec With FlexVPNDocument91 pagesCisco Advanced IPSec With FlexVPNSrdjan MilenkovicNo ratings yet

- 7 Series Chipset PCH DatasheetDocument41 pages7 Series Chipset PCH DatasheetLeonardo Garcia50% (2)

- QuantaDocument41 pagesQuantaJoaoNo ratings yet

- Quanta FH9 DA0FH9MB6C0 - R2aDocument48 pagesQuanta FH9 DA0FH9MB6C0 - R2aYetawa GuaviareNo ratings yet

- Acer Chromebook C740 - Quanta ZHNB DAZHNMB1AD0 RADocument39 pagesAcer Chromebook C740 - Quanta ZHNB DAZHNMB1AD0 RAmike onciucNo ratings yet

- Acer Chromebook C740 - Quanta ZHNB DAZHNMB1AD0 RaDocument39 pagesAcer Chromebook C740 - Quanta ZHNB DAZHNMB1AD0 RaRed de Tecnicos MDQNo ratings yet

- 2023 Catalog LNRXX EngDocument2 pages2023 Catalog LNRXX Engc membrenoNo ratings yet

- 5gen Quanta Fh9 Da0fh9mb6c0 - R2aDocument5 pages5gen Quanta Fh9 Da0fh9mb6c0 - R2arohit.ydv.8368No ratings yet

- Pressure Transmitter 33XDocument2 pagesPressure Transmitter 33XMintatuyNo ratings yet

- CLR07-02-000 - Sondakan RW 15 - MatrixDocument10 pagesCLR07-02-000 - Sondakan RW 15 - MatrixilhamNo ratings yet

- By6 By6d PDFDocument47 pagesBy6 By6d PDFivan SANo ratings yet

- Nddi2 LS - GS - 3ba23173Document27 pagesNddi2 LS - GS - 3ba23173Long Nguyen ThanhNo ratings yet

- Main Distribution Panel Details: Schedule of Loads of A Multi Family Dwelling Unit (Main Distributor Panel)Document1 pageMain Distribution Panel Details: Schedule of Loads of A Multi Family Dwelling Unit (Main Distributor Panel)Mariniel SibugNo ratings yet

- TR-7578-C Wiring DiagramDocument1 pageTR-7578-C Wiring Diagramarupamguria05No ratings yet

- Toshiba Satellite c75d l75d Bd9 Da0bd9mb8e0da0bd9mb8f0 Rev A1a Schematicunlocked 1Document41 pagesToshiba Satellite c75d l75d Bd9 Da0bd9mb8e0da0bd9mb8f0 Rev A1a Schematicunlocked 1Gomez RonaldNo ratings yet

- Datenblatt Serie-21PHB eDocument2 pagesDatenblatt Serie-21PHB eBoody CNo ratings yet

- Planta ZTE OutdoorDocument6 pagesPlanta ZTE OutdoorwidoblNo ratings yet

- Lz4 V4uv0r enDocument14 pagesLz4 V4uv0r enelectronicaNo ratings yet

- SN54ACT16244, 74ACT16244 Datasheet (Rev. B)Document18 pagesSN54ACT16244, 74ACT16244 Datasheet (Rev. B)Ecus ElectronicsNo ratings yet

- EPS Eaton PDFDocument2 pagesEPS Eaton PDFRazvan FagarasNo ratings yet

- Quick Installation Guide: Automatical Solution For EPS FunctionDocument2 pagesQuick Installation Guide: Automatical Solution For EPS FunctionDucNo ratings yet

- Acrosser Technology AR B1673 DatasheetDocument5 pagesAcrosser Technology AR B1673 DatasheetWaleed MareeNo ratings yet

- Asus A8ES Laptop SchematicsDocument94 pagesAsus A8ES Laptop SchematicsftenminNo ratings yet

- H P (0,01%) P T S 33 X S 35 X: Ighly Recise Ressure Ransmitters Eries EriesDocument2 pagesH P (0,01%) P T S 33 X S 35 X: Ighly Recise Ressure Ransmitters Eries Eriess bNo ratings yet

- Description Features: LTC488/LTC489 Quad RS485 Line ReceiverDocument12 pagesDescription Features: LTC488/LTC489 Quad RS485 Line ReceiverCahyo GuntoroNo ratings yet

- Tolerance Notes: VFA12-HD VFA12-HDDocument5 pagesTolerance Notes: VFA12-HD VFA12-HDneil gonzalesNo ratings yet

- FTTH Materials Comparison Rev1Document1 pageFTTH Materials Comparison Rev1Victor EstomoNo ratings yet

- Cisco Switch ApplicationsDocument10 pagesCisco Switch ApplicationsAllan CazéNo ratings yet

- Pioneer Deh-1280mp Crt4230 Car AudioDocument35 pagesPioneer Deh-1280mp Crt4230 Car AudioSomde TrombetaNo ratings yet

- Nha Anh BonDocument34 pagesNha Anh BonMaker PhạmNo ratings yet

- A en 05802 00Document32 pagesA en 05802 00jose florNo ratings yet

- Rab MV Panel Pix12 GiDocument1 pageRab MV Panel Pix12 GiHariyantoNo ratings yet

- Single Line Diagram: Doloriel, Charlemaigne Josef Prequencia, Glenn Paulo EE-5ADocument1 pageSingle Line Diagram: Doloriel, Charlemaigne Josef Prequencia, Glenn Paulo EE-5ACharlemaigne Josef Cuartero DolorielNo ratings yet

- ASUS GL703GE 1.0 Schematic0 - 15 - 0 PDFDocument59 pagesASUS GL703GE 1.0 Schematic0 - 15 - 0 PDFEnder özveriNo ratings yet

- Gl503ge Rev1.0 - LSF PDFDocument59 pagesGl503ge Rev1.0 - LSF PDFToni SetyawanNo ratings yet

- Data Sheet For Ultrasonic FlareDocument2 pagesData Sheet For Ultrasonic FlareBABILIN VNo ratings yet

- X1 AC Installation GuideDocument2 pagesX1 AC Installation GuideMEL ANGELESNo ratings yet

- DAX1PDMB8E0Document51 pagesDAX1PDMB8E0Jose lopez RosalesNo ratings yet

- Clevo W370SS W35XSSQ - 6-71-W3S50-D02ADocument61 pagesClevo W370SS W35XSSQ - 6-71-W3S50-D02Amobaway2017No ratings yet

- Compal LA-1731Document46 pagesCompal LA-1731ever aguilarNo ratings yet

- Technical Publication: Installation Guidelines - HELIAX 12 RRU Assembly Solution: Pendant ConfigurationDocument20 pagesTechnical Publication: Installation Guidelines - HELIAX 12 RRU Assembly Solution: Pendant Configurationchristophe TrachezNo ratings yet

- Test and Calibration - 007Document10 pagesTest and Calibration - 007Mario AsselNo ratings yet

- Raychem - RSTI InstalaciónDocument6 pagesRaychem - RSTI Instalaciónfredy telloNo ratings yet

- T.D.A 10021HTDocument16 pagesT.D.A 10021HTJose M PeresNo ratings yet

- P T S 21 R S 21 SR / MR: Iezoresistive Ransmitters / Eries EriesDocument2 pagesP T S 21 R S 21 SR / MR: Iezoresistive Ransmitters / Eries EriesBinh Thai HYNo ratings yet

- Matrox Meteor II Multi ChannelDocument3 pagesMatrox Meteor II Multi ChannelyumekiNo ratings yet

- Broadband VIIDocument54 pagesBroadband VIIGicuNo ratings yet

- NatSemiFetDatabook1977 TextDocument278 pagesNatSemiFetDatabook1977 TextmonicaNo ratings yet

- JST Product Overview - JD09 PDFDocument35 pagesJST Product Overview - JD09 PDFm31d1No ratings yet

- CLEVO Tigerhill-Pineview System Block DiagramDocument26 pagesCLEVO Tigerhill-Pineview System Block DiagramChico SouzaNo ratings yet

- CLEVO M1100-D01 1204 DecryptedDocument26 pagesCLEVO M1100-D01 1204 DecryptedMatias MareNo ratings yet

- 79 LXX RegDocument6 pages79 LXX RegSo Was RedNo ratings yet

- UENR82990001Document8 pagesUENR82990001Guido Emanuel SteinbachNo ratings yet

- Topologi The Park - KendariDocument1 pageTopologi The Park - KendariAnsar SaniNo ratings yet

- Military Aerospace RF ConnectorsDocument128 pagesMilitary Aerospace RF Connectorsjosh_nesbittNo ratings yet

- Wiring Diagram: Minas A Servo Driver CN Ser Mini DIN 8-Pin, Male PC Sub-D 9-Pin, FemaleDocument1 pageWiring Diagram: Minas A Servo Driver CN Ser Mini DIN 8-Pin, Male PC Sub-D 9-Pin, Femaleserege75% (4)

- H P (0,01%) P T S 33 X S 35 X: Ighly Recise Ressure Ransmitters Eries EriesDocument2 pagesH P (0,01%) P T S 33 X S 35 X: Ighly Recise Ressure Ransmitters Eries EriesUTOPIA TECHNOLOGYNo ratings yet

- Tda 8505Document27 pagesTda 8505Miszcsi MiszcsiNo ratings yet

- Paa21sr/80444.3 - 1 Paa21sr/80444.3 - 14-20ma Paa21sr/80444.3 - 2.5 PR21S/80549.3-2. 5 4-20ma PR21SR/80444.3-2.5Document5 pagesPaa21sr/80444.3 - 1 Paa21sr/80444.3 - 14-20ma Paa21sr/80444.3 - 2.5 PR21S/80549.3-2. 5 4-20ma PR21SR/80444.3-2.5Jose MadrizNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- VMSDocument100 pagesVMSmuhamedshuaibbhaiNo ratings yet

- Create A Composition of 1920px X 1080px in Adobe After EffectsDocument1 pageCreate A Composition of 1920px X 1080px in Adobe After EffectsmuhamedshuaibbhaiNo ratings yet

- EN50575 DoP EuroClass Dca s1a d1 a2 (English)Document1 pageEN50575 DoP EuroClass Dca s1a d1 a2 (English)muhamedshuaibbhaiNo ratings yet

- Product Description (2019) : Netcol5000-C (030, 032, 065) In-Row Chilled Water Smart Cooling ProductDocument30 pagesProduct Description (2019) : Netcol5000-C (030, 032, 065) In-Row Chilled Water Smart Cooling ProductmuhamedshuaibbhaiNo ratings yet

- Cisco MDS 9000 Family Release Notes For Cisco MDS SAN-OS Release 2.1 (2b)Document22 pagesCisco MDS 9000 Family Release Notes For Cisco MDS SAN-OS Release 2.1 (2b)muhamedshuaibbhaiNo ratings yet

- Cisco MDS 9000 Family Release Notes For Cisco MDS SAN-OS Release 2.1Document30 pagesCisco MDS 9000 Family Release Notes For Cisco MDS SAN-OS Release 2.1muhamedshuaibbhaiNo ratings yet

- My 03 Practice3Document1 pageMy 03 Practice3muhamedshuaibbhaiNo ratings yet

- My 07 Practice2Document1 pageMy 07 Practice2muhamedshuaibbhaiNo ratings yet

- My 07 Practice1Document1 pageMy 07 Practice1muhamedshuaibbhaiNo ratings yet

- Arabic Handwriting v3Document14 pagesArabic Handwriting v3muhamedshuaibbhaiNo ratings yet

- Imagine Cup 2023 - Pakistan Finals GuidanceDocument2 pagesImagine Cup 2023 - Pakistan Finals GuidancemuhamedshuaibbhaiNo ratings yet

- My 06 PracticeDocument1 pageMy 06 PracticemuhamedshuaibbhaiNo ratings yet

- Anokha SakhiDocument30 pagesAnokha SakhimuhamedshuaibbhaiNo ratings yet

- My 02 Practice3Document2 pagesMy 02 Practice3muhamedshuaibbhaiNo ratings yet

- My 04 PracticeDocument1 pageMy 04 PracticemuhamedshuaibbhaiNo ratings yet

- My 05 Practice1Document1 pageMy 05 Practice1muhamedshuaibbhaiNo ratings yet

- Achievements of Muslim Women in The Religious and Scholarly Fields PDFDocument57 pagesAchievements of Muslim Women in The Religious and Scholarly Fields PDFmuhamedshuaibbhaiNo ratings yet

- My 02 Practice2Document3 pagesMy 02 Practice2muhamedshuaibbhaiNo ratings yet

- Warehouse ProposedDocument2 pagesWarehouse ProposedmuhamedshuaibbhaiNo ratings yet

- IC23 Pakistan Official Rules and RegulationDocument16 pagesIC23 Pakistan Official Rules and RegulationmuhamedshuaibbhaiNo ratings yet

- List of Computer Sindh Board of Technical EducationDocument17 pagesList of Computer Sindh Board of Technical Educationmuhamedshuaibbhai50% (2)

- Islamic History - Classes XI-XII - NC 2002 - June 2012Document47 pagesIslamic History - Classes XI-XII - NC 2002 - June 2012muhamedshuaibbhai100% (1)

- Introduction (Recovered)Document37 pagesIntroduction (Recovered)muhamedshuaibbhaiNo ratings yet

- SLB Field ManulaDocument145 pagesSLB Field ManulaRaed fouadNo ratings yet

- D200 UserManual Preliminary EnglishDocument46 pagesD200 UserManual Preliminary EnglishIzaias Soares Silva100% (2)

- H. SPESIFIKASI IPAL PUSK NANGA TAYAP PDFDocument2 pagesH. SPESIFIKASI IPAL PUSK NANGA TAYAP PDFfajrul 2222No ratings yet

- Chapter 5 Pictorial DrawingsDocument44 pagesChapter 5 Pictorial DrawingsVisan NaiduNo ratings yet

- Berthold WorkshopDocument71 pagesBerthold WorkshopAgustantoNo ratings yet

- Design of Pier For Minor Bridge at Ch. 11+120Document69 pagesDesign of Pier For Minor Bridge at Ch. 11+120siddharth yadavNo ratings yet

- Evaluation of Blended Learning in Higher Education A Case StudyDocument9 pagesEvaluation of Blended Learning in Higher Education A Case StudyGlobal Research and Development ServicesNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezNo ratings yet

- Reflection PaperDocument1 pageReflection PaperHarold LandichoNo ratings yet

- Gr2 Wk10 Many Ways To MeasureDocument2 pagesGr2 Wk10 Many Ways To MeasureyeezeeNo ratings yet

- URAL 2017 - Owners - Manual - EnglishDocument86 pagesURAL 2017 - Owners - Manual - EnglishPerformNo ratings yet

- Flat Belt DriveDocument25 pagesFlat Belt DriveMurugesan RameshNo ratings yet

- TG-24 Battery Charger System TG-24 Battery Charger System TG-24 Battery Charger System TG-25 Battery Charger SystemDocument11 pagesTG-24 Battery Charger System TG-24 Battery Charger System TG-24 Battery Charger System TG-25 Battery Charger SystemBHUVANESH MNo ratings yet

- Astm D1752-18Document3 pagesAstm D1752-18zaid100% (1)

- Test Series - Forestry: Test Number Date Topic Syllabus Reading Materials 02-11-2020 Paper-1 Section-ADocument4 pagesTest Series - Forestry: Test Number Date Topic Syllabus Reading Materials 02-11-2020 Paper-1 Section-ANikhil AgrawalNo ratings yet

- Logistics Supervisor - Mine Risk Education - Cover-LetterDocument1 pageLogistics Supervisor - Mine Risk Education - Cover-Letteryazeed naiban0% (1)

- MIDAS Gen DescriptionDocument43 pagesMIDAS Gen Descriptionrponnan100% (1)

- DACTS705 English PDFDocument21 pagesDACTS705 English PDFgiapy0000No ratings yet

- Kerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDocument5 pagesKerala's Baby Steps Toward Sanitation - The Vilappilasala PlantDr.Thrivikramji.K.P.No ratings yet

- Quantification Methodology For The Use of Sulphur Concrete in Precast Applications (First Assessment Version) - 0Document33 pagesQuantification Methodology For The Use of Sulphur Concrete in Precast Applications (First Assessment Version) - 0Verma NverNo ratings yet

- Tandler Angle GearsDocument2 pagesTandler Angle GearsEmerson IpialesNo ratings yet

- Narrowing The Gap: The Effects of Steady Traffic Growth & Evolution of Scope ClausesDocument64 pagesNarrowing The Gap: The Effects of Steady Traffic Growth & Evolution of Scope Clausesrobertas negudinasNo ratings yet

- ZR22 Detector TroubleshootingDocument3 pagesZR22 Detector TroubleshootingControl InstrumentationNo ratings yet

- Sidewinder PartsDocument4 pagesSidewinder PartsKhalidNo ratings yet

- Laporan Penjualan Ban TypeDocument18 pagesLaporan Penjualan Ban Typedataari0201No ratings yet

- 50-Applicable Codes and StandardsDocument48 pages50-Applicable Codes and StandardsmohsenNo ratings yet