Professional Documents

Culture Documents

TDS_F18030

TDS_F18030

Uploaded by

ShashankShethCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS_F18030

TDS_F18030

Uploaded by

ShashankShethCopyright:

Available Formats

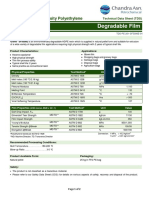

LINEAR LOW DENSITY POLYETHYLENE

F18030 FILM EXTRUSION GRADE

Relene F18030 is a butene based Linear Low Density Polyethylene grade with Optimum level of Antioxidants & without Slip

& Anti block and is designed for good processing on Cast Film lines with balanced mechanical & optical properties

Typical Characteristics*

Property Test Method Unit Typical Value**

Melt Flow Index (190O C / 2.16 Kg) ASTM D 1238 g/10 min. 3.0

Density (23O C) ASTM D 792 g/cm3 0.920

Film Properties

Tensile Strength at Yield (MD / TD) ASTM D 882 MPa 12 / 10

Tensile Strength at Break (MD/TD) ASTM D 882 MPa 30 / 20

Elongation at Break (MD / TD) ASTM D 882 % 450 / 650

Tear Strength (MD / TD) ASTM D 1922 g/µm 2.5 / 11.0

Dart Impact Strength, F50 ASTM D 1709A g/ µm 2.3

(38 mm dart, 66 cm height)

Haze ASTM D 1003 % 2.0

Gloss @ 60 O ASTM D 2457 95

* Typical characteristics and not to be taken as specifications

** Typical values of 25 µ cast film made with following parameters: Cast line output – 20 kg/hr, Melt Temperature - 270°C, Die Length – 600

mm, Die Gap – 0.8 mm, Chill Roll temp – 18˚C, Line speed – 15 mpm

APPLICATIONS:

Co ex Films, Stretch & Cling Films, Hygiene Films, Personal Care, General Purpose packaging.

Regulatory Information

• Meets the requirements stipulated in standard IS: I0146 on "Specification for Polyethylene for safe use in contact with foodstuffs,

pharmaceuticals, and drinking water". It also conforms to IS 16738:2018 “Positive List of Constituents for Polypropylene,

Polyethylene and their Copolymers for its Safe Use in Contact with Foodstuffs and Pharmaceuticals”

• The grade and the additives incorporated in it also comply with the FDA: CFR Title 21,177.1520, Olefin polymers.

• F18030 is not intended for use in medical and pharmaceutical applications.

Storage Recommendations

• Bags should be stored in dry/closed conditions at temperatures below 50°C and protected from UV / direct sunlight.

Reliance Industries Limited, Product Application & Research Centre (PARC)

Reliance Industries Limited, Baroda Complex, P.O.Petrochemicals, District Vadodara: Pin 391346, Gujarat, India

E-mail: polymer_patsupport@ril.com Website: www.ril.com

Updated as of Mar 2019

DISCLAIMER

The information contained herein may include typical properties and processing parameters of the

grade or its typical performances when used in respective applications. The values given above

are based on analysis of representative samples and not the actual product supplied. It is the

customer’s responsibility to inspect and test our grades in order to satisfy itself as to the suitability

of the products for customers’ particular application. The customer is solely responsible for all

determinations regarding any use of material or product and any process in its area of interest.

RIL assumes no obligation or liability for any loss, damage or injury directly or indirectly suffered

or incurred as a result of using any of the information or product given in this document. The

information and data presented herein is true and accurate to the best of our knowledge. No

warranty or guarantee expressed or implied, is made regarding performance or otherwise. This

information and data may not be considered as a suggestion to use our products without taking

into account existing patents, or legal provisions or regulations, whether national or international.

The user of any information and/or data is advised to obtain the latest details from any of the

offices of the company or its authorized agents, as the information and/or data is subject to change

based on the research and development work undertaken by the company.

Reliance Industries Limited, Product Application & Research Centre (PARC)

Reliance Industries Limited, Baroda Complex, P.O.Petrochemicals, District Vadodara: Pin 391346, Gujarat, India

E-mail: polymer_patsupport@ril.com Website: www.ril.com

Updated as of Mar 2019

You might also like

- Ace Strategy InfoDocument1 pageAce Strategy Infoapi-292206241No ratings yet

- Guingguing v. PeopleDocument2 pagesGuingguing v. PeopleRenesméNo ratings yet

- Linear Low Density Polyethylene: Film Extrusion GradeDocument2 pagesLinear Low Density Polyethylene: Film Extrusion GradeAnugya RastogiNo ratings yet

- TDS F4600Document2 pagesTDS F4600tech.omNo ratings yet

- Reliance Ldpe Heavy Duty Non Slip 0 5 Mfi J22fa002eDocument2 pagesReliance Ldpe Heavy Duty Non Slip 0 5 Mfi J22fa002eakshayNo ratings yet

- Linear Low Density Polyethylene: Blown Film GradeDocument1 pageLinear Low Density Polyethylene: Blown Film GradeChetan BholeNo ratings yet

- Film Grades LL F2001SDocument2 pagesFilm Grades LL F2001SKool LeisureNo ratings yet

- F2001ADocument2 pagesF2001APratik GaikwadNo ratings yet

- JF19010 JF18010: Linear Low Density PolyethyleneDocument1 pageJF19010 JF18010: Linear Low Density PolyethyleneMallikharjuna Reddy GogireddyNo ratings yet

- 24FS040 24FA040: Low Density PolyethyleneDocument1 page24FS040 24FA040: Low Density PolyethyleneMahadi Bachar MahamatNo ratings yet

- TDS H019TGDocument2 pagesTDS H019TGkeyurmangnani2015No ratings yet

- Tds H110maDocument2 pagesTds H110maShibu MohanNo ratings yet

- Linear Low Density Polyethylene: Provisional Technical DatasheetDocument2 pagesLinear Low Density Polyethylene: Provisional Technical DatasheetMohit MohataNo ratings yet

- H030SGDocument2 pagesH030SGLaxman AhirNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Im B120MADocument1 pageIm B120MAPrashant MalikNo ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- Q1018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ1018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Lotrène FE8000 2014 04 16Document2 pagesLotrène FE8000 2014 04 16aman.chaudhary3663No ratings yet

- TDS H020egDocument2 pagesTDS H020egkeyurmangnani2015No ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Qatofin Lotrene Q2018Document2 pagesQatofin Lotrene Q2018HichamSalamaNo ratings yet

- TDS Pe 001 Uf1810Document2 pagesTDS Pe 001 Uf1810asrilNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- TDS J1020xa20Document2 pagesTDS J1020xa20akshayNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- Lotrene LLDPE Datasheet PDFDocument6 pagesLotrene LLDPE Datasheet PDFThụy Thảo LinhNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Product Data Sheet: Typical PropertiesDocument2 pagesProduct Data Sheet: Typical PropertiesManufaktur Sinar JoyoboyoNo ratings yet

- Polypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetMohit MohataNo ratings yet

- Polypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetDocument2 pagesPolypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetMohit MohataNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- FK1828Document3 pagesFK1828dignityymartNo ratings yet

- Low Density Polyethylene: Lamination Film ApplicationsDocument1 pageLow Density Polyethylene: Lamination Film ApplicationsMahadi Bachar MahamatNo ratings yet

- Q2018 Series: Linear Low Density Polyethylene (LLDPE)Document2 pagesQ2018 Series: Linear Low Density Polyethylene (LLDPE)lyesNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsarthymanicNo ratings yet

- TDS Pe 002 Uf1810t 03Document2 pagesTDS Pe 002 Uf1810t 03qc jrpNo ratings yet

- TDS Pe 010 Uf1820t 04Document2 pagesTDS Pe 010 Uf1820t 04Lenggana SukriaNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Mdpe Marlex HHM TR-131Document1 pageMdpe Marlex HHM TR-131Lily LiNo ratings yet

- Product DatasheetDocument1 pageProduct Datasheetأبو أميرNo ratings yet

- Polypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- At-N70 NC006 Tds-En - 071049Document2 pagesAt-N70 NC006 Tds-En - 071049Thunder StromNo ratings yet

- TDS Pe 003 Uf1810s1 03Document2 pagesTDS Pe 003 Uf1810s1 03qc jrpNo ratings yet

- Rlene SpecificationDocument2 pagesRlene SpecificationjaintarunNo ratings yet

- Low Density Polyethylene: Extrusion Coating and Film ApplicationsDocument1 pageLow Density Polyethylene: Extrusion Coating and Film ApplicationsMahadi Bachar MahamatNo ratings yet

- Polypropylene Impact Co Polymer Injection MoldingDocument2 pagesPolypropylene Impact Co Polymer Injection MoldingMohit MohataNo ratings yet

- Bamberger Polymers, Inc. Bapolene® 122B Polyethylene, Linear Low DensityDocument1 pageBamberger Polymers, Inc. Bapolene® 122B Polyethylene, Linear Low DensityDiana SarmientoNo ratings yet

- F20S009Document1 pageF20S009Pratik GaikwadNo ratings yet

- Bamberger Polymers, Inc. Bapolene® 122F Polyethylene, Linear Low DensityDocument1 pageBamberger Polymers, Inc. Bapolene® 122F Polyethylene, Linear Low DensityDiana SarmientoNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsSanjay SharmaNo ratings yet

- POLYMER C150Y - Jan15 - New - Rev1Document2 pagesPOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- TDS HP740T DaelimDocument1 pageTDS HP740T Daelimbrandon abella gutierrezNo ratings yet

- TDS Pe 201 Sf5008eDocument2 pagesTDS Pe 201 Sf5008eOktaviandri SaputraNo ratings yet

- 1. Purpose , Benefits & Relationship With Sdgs of Fssc 22000Document13 pages1. Purpose , Benefits & Relationship With Sdgs of Fssc 22000ShashankShethNo ratings yet

- PRO_F18030Document1 pagePRO_F18030ShashankShethNo ratings yet

- Week 2Document46 pagesWeek 2ShashankShethNo ratings yet

- APS Booklet EnglishDocument67 pagesAPS Booklet EnglishShashankShethNo ratings yet

- Before Reading: An Encyclopedia EntryDocument6 pagesBefore Reading: An Encyclopedia EntryĐào Nguyễn Duy TùngNo ratings yet

- Capr-Iii En4115 PDFDocument49 pagesCapr-Iii En4115 PDFYT GAMERSNo ratings yet

- Staircase Lift Design For Elderly at HomeDocument19 pagesStaircase Lift Design For Elderly at Homesabareesh91mechNo ratings yet

- 42) Tan, Et Al. vs. Republic of The Philippines, G.R. No. 193443, April 16, 2012.Document13 pages42) Tan, Et Al. vs. Republic of The Philippines, G.R. No. 193443, April 16, 2012.dondzNo ratings yet

- Leadership in Virtual TeamsDocument13 pagesLeadership in Virtual TeamsBrandon ManuelNo ratings yet

- Account of MR Pybus S Mission To The KinDocument133 pagesAccount of MR Pybus S Mission To The KinHarendraAlwisNo ratings yet

- Ministry of Environment, Forest and Climate Change NotificationDocument12 pagesMinistry of Environment, Forest and Climate Change Notificationaridaman raghuvanshiNo ratings yet

- Barker CH Naish D - Where On Earth Dinosaurs and Other Prehistoric Life The Amazing History of Earth 39 S Most Incredible ADocument162 pagesBarker CH Naish D - Where On Earth Dinosaurs and Other Prehistoric Life The Amazing History of Earth 39 S Most Incredible ARumen Deshkov100% (3)

- Highway Engineering I: Chapter Four Geometrical Design of HighwayDocument39 pagesHighway Engineering I: Chapter Four Geometrical Design of Highwaysirajt300No ratings yet

- Fuller Factory#PricingDocument39 pagesFuller Factory#PricingkkkhattabbbNo ratings yet

- Job Description - CRM Marketing SpecialistDocument1 pageJob Description - CRM Marketing SpecialistMichael-SNo ratings yet

- CWall Ex1Document5 pagesCWall Ex1Virginia gabyella saraunNo ratings yet

- Adetunji CVDocument5 pagesAdetunji CVAdetunji AdegbiteNo ratings yet

- Andheri WestDocument60 pagesAndheri WestNikunj VaghasiyaNo ratings yet

- The Madmullah of Somaliland 1916 1921Document386 pagesThe Madmullah of Somaliland 1916 1921Khadar Hayaan Freelancer100% (1)

- MLR LLRDocument41 pagesMLR LLRKUNNAMPALLIL GEJO JOHNNo ratings yet

- vịt batmanDocument14 pagesvịt batmanTú Lệ100% (1)

- Group2 Non Executive ResultsDocument3 pagesGroup2 Non Executive ResultsGottimukkala MuralikrishnaNo ratings yet

- Oops File-Converted-1 PDFDocument183 pagesOops File-Converted-1 PDFNikhil Yadav67% (6)

- La Bugal V RamosDocument141 pagesLa Bugal V Ramosabo8008No ratings yet

- Martin Luther King Jr. - A True Historical Examination. (N.D.) - Retrieved OctoberDocument5 pagesMartin Luther King Jr. - A True Historical Examination. (N.D.) - Retrieved Octoberapi-336574490No ratings yet

- 2013 848evo DucatiOmahaDocument140 pages2013 848evo DucatiOmahaFabian Alejandro Ramos SandovalNo ratings yet

- Resource AllocationDocument10 pagesResource AllocationZoe NyadziNo ratings yet

- 11th Bio NotesDocument167 pages11th Bio NotesKomalNo ratings yet

- Percakapan 1Document2 pagesPercakapan 1Legend AbadiNo ratings yet

- Arts 7 - Q3 - Mod3 - TheLandofPromiseArtsofMindanao - V1Document28 pagesArts 7 - Q3 - Mod3 - TheLandofPromiseArtsofMindanao - V1DIANE BORROMEO,No ratings yet

- MAN0019215 - TaqPathCOVID-19 - CE-IVD - RT-PCR Kit - IFUDocument27 pagesMAN0019215 - TaqPathCOVID-19 - CE-IVD - RT-PCR Kit - IFUFe LipeNo ratings yet