Professional Documents

Culture Documents

Risk Assessment No2 - Gooseneck removal_Ver1

Risk Assessment No2 - Gooseneck removal_Ver1

Uploaded by

PIERRONCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment No2 - Gooseneck removal_Ver1

Risk Assessment No2 - Gooseneck removal_Ver1

Uploaded by

PIERRONCopyright:

Available Formats

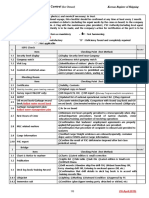

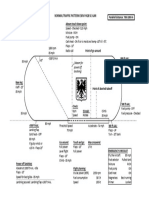

Risk Assessment No. RA-PAR00395-S1.

Status - Stage 1 Draft Page 1

Risk Assessment

Risk Assessment RA-PAR00395-S1 Stage 1 Draft

Gooseneck Removal

Work Site Location / Operation / Project Reference Procedures

Acergy Eagle GI-25 Flexible Jumper Replacement

Approvals

Stage 1 : Denis MOREAU Stage 2 :

Meeting Attendees

Date Name Job Company Name Job Company

06 Oct 2010

General & Project-specific Safety Requirements

01 Appropriate PPE 12 Competent Person 18. CAPP Offshore 21. CNSOPB OSH 22. SIMOPS

11 Tool Box Talks 17. Env Management Training Requirements Procedure / Matrix

Plan Requirements

19. CAPP Offshore

Lifting And Rigging

Guidelines

Risk Assessment Tasks

Num Task Hazard Consequences Risk Level Corrective measures Residual risk

Set Up Vessel On 1) Proximity to FPSO & Damage to subsea E2 = M 1) Permit / authorisation E1 = M

1 Site subsea structures equipment and production for entering 500m zone

2) DP failure lines Use of fan beam ref.

3) Adverse weather Damage to FPSO system (keeping in mind

4) SIMOPS on site (Supply Damage to vessels that FPSO has excusrion)

vessels, other vessels at ROV and integrity surveys

buoy for maintenance, of tower with depths and

Loading and Ofloading of positions of subsea items.

FPSO in tandem mode 2) DP class 2 with manual

with tugs involved, surfers, control backup

...) DP trials performed

5) Vessel blackout outside 500m zone

3) Review weather

conditions prior to start of

work

Vessel Escape route to be

defined (drawing)

4) SIMOPS plan,

Permit to work managed

by Client,

5) Maintenance plan,

regular inspection

Num Task Hazard Consequences Risk Level Corrective measures Residual risk

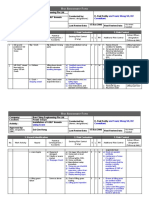

Deployment Of 1) Entanglement of ROV Damage to Sub Sea D3 = M 1) Raise awareness. D2 = M

2 Divers And tether / divers umbilical equipment. Diving bell and ROV TMS

Equipment with surrounding Damage to Vessel to remain above highest

structures. equipment. point on Riser Tower.

2) Dropped objects / Divers injury. Tool box talks.

uncontrolled movements Deck Personnel injury. Good communications.

of lift. Diving supervisor as single

3) Weather conditions point of command.

4) Clash of bell on subsea 2) Good rigging practises.

equipment during normal Good communications.

operation as well as in Certified equipment

case of DP excursion All equipment to be

secured to top of tower

away from edge.

Use lashings / taglines as

required.

Qualified personnel.

11/10/2010 17:47:44 GR - HSEF - 001

Risk Assessment No. RA-PAR00395-S1. Status - Stage 1 Draft Page 2

3) Weather forecast to be

check prior to start of

operation under diving

superivisor decision.

4) Diver bell to be

posiitonned above riser

tower structure.

Num Task Hazard Consequences Risk Level Corrective measures Residual risk

Un-bolting Of 1) Equipment under Injury to divers E3 = H 1) D2 = M

3 Gooseneck pressure (bolt tensioning, Damage to gooseneck, Tool Box talks / Raise

Connections nut splitters) riser & spool flange faces awareness.

2) Presence of methanol in Damage to ROV Equipment familiarity.

the line Secure tools.

3) Uncontrolled movement Testing of equipment prior

of gooseneck / equipment to use.

4) ROV/divers SIMOPS 2)

5) ROV/ structure clash Raise awareness.

6) presence of pressurized Extensive & conservative

gas inside the gooseneck flushing performed &

7) Potential clash during MeOH level measured at

deployement of crane FPSO.

hook/tool basket with Consider pumping 10 m"

subsea asset. of methanol back into the

8) Dropped objects (loose line (from subsea end) to

bolts / pieces when take realistic sample of the

opening flanges) MeOH level in goosneck

(ACTION).

Divers to stand clear

during bolts

tensioning/release.

Hydraulic equipment

activated from surface.

Get back to bell during

flange opening

Once connection is

broken: stand-by period to

let MeOH get out & mix in

water.

ROV to take samples to

check MeOH

concentration at

gooseneck (Total to

confirm accuracy of

measurements / Acergy to

confirm method of

sampling (ACTION) )

Use of disposable

coveralls for divers.

Gas alarms inside diving

bell.

3)

Detailed task plan.

Follow correct

de-tensioning procedure.

Tool Box talks.

Protect flange faces

ASAP.

Good rigging practises and

Certified rigging

Test air bag prior to start of

operation.

4)

Single point of

command/supervision

Good communications and

awareness.

5)

ROV to keep safe distance

during standby periods.

Singhle point of command.

6)

Consider reducing

hydrostatic column

pressure by pumping water

out of jumper inside I-tube

(TBC).

Divers to stand clear

during bolts

tensioning/release.

ROV to inspect connection

before divers return to site.

Contingency = cut through

gooseneck using ROV

grinder to equalise

11/10/2010 17:47:44 GR - HSEF - 001

Risk Assessment No. RA-PAR00395-S1. Status - Stage 1 Draft Page 3

pressure.

7)

Use of mini-beacons on

crane wire.

Pre-installation survey

performed and subsea

structures displayed on

Navipac screen.

ROV to monitor

deployment.

8)

Add lashings to

tooling/falling parts.

Consider placing nut

splitters under flanges.

Num Task Hazard Consequences Risk Level Corrective measures Residual risk

Lifting Gooseneck Off 1) Injury to Divers / personnel D3 = M 1) C2 = L

4 Tower Dropped objects Damage to permanent Certified rigging/equipment

2) equipment Secure tools

Swinging loads. Good communication and

3) supervision.

Entrapment of divers / Single point of command

ROV entanglement ROV monitoring

4) 2)

Use of lift bag. Protect flange faces

Good communication and

supervision.

Single point of command

Use of tag lines / lashings

on gooseneck

Ensure static rigging

correct height to transfer

load safely and within

divers excursion limits

Use of mini-beacon on

crane wire.

Zero crane line meter

when entering splash

zone.

Ensure gooseneck is

rigged to minimise

movements during load

transfer.

3)

Good communication and

supervision.

Single point of command

Raise awareness

Tool box talks

Good tether management

4)

Follow Acergy / IMCA

guide lines on use of lift

bags.

Ensure lift bag is inspected

for leaks before use.

Connection points on

buoyancy tanks inspected

during pre-installation

survey.

11/10/2010 17:47:44 GR - HSEF - 001

You might also like

- HAZID Worksheet FORMDocument16 pagesHAZID Worksheet FORMSrikanth Bammidi100% (3)

- Job Hazard Analysis (HDD)Document7 pagesJob Hazard Analysis (HDD)jay R100% (1)

- JSA For Dewatering PumpDocument1 pageJSA For Dewatering Pumpwahyu nugroho100% (2)

- HAZID Worksheet FORMDocument16 pagesHAZID Worksheet FORMSrikanth Bammidi100% (1)

- Vocabulary Quiz: Marks - 20 5 100Document8 pagesVocabulary Quiz: Marks - 20 5 100Йорданка ГроздановаNo ratings yet

- Lifting Plan For Erection of 2nd To 6th Rev.3Document11 pagesLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNo ratings yet

- Mce - Project Risk RegisterDocument24 pagesMce - Project Risk Registeryono DaryonoNo ratings yet

- Template Hazid WorksheetDocument43 pagesTemplate Hazid WorksheetJagan Bose100% (3)

- ERSA Book PDFDocument24 pagesERSA Book PDFdhatasofkaNo ratings yet

- Khuda Aur Mohabbat Novel in EnglishDocument179 pagesKhuda Aur Mohabbat Novel in EnglishRahima Haq83% (23)

- Risk Assessment No5 - Gooseneck installation_Ver1Document2 pagesRisk Assessment No5 - Gooseneck installation_Ver1PIERRONNo ratings yet

- Risk Assessment No4 - Jumper installation_Ver1Document3 pagesRisk Assessment No4 - Jumper installation_Ver1PIERRONNo ratings yet

- Risk Assessment No3 - Jumper recovery_Ver1Document3 pagesRisk Assessment No3 - Jumper recovery_Ver1PIERRONNo ratings yet

- Risk Assessment No1 - Mob-demob_Ver2Document3 pagesRisk Assessment No1 - Mob-demob_Ver2PIERRONNo ratings yet

- RADocument2 pagesRAalisheeraz0302No ratings yet

- DKO04-Small Craft Alongside - Incl Bunker Barge, Slop BargeDocument2 pagesDKO04-Small Craft Alongside - Incl Bunker Barge, Slop BargeNang D. VuNo ratings yet

- JSA For Dewatering PumpDocument1 pageJSA For Dewatering Pumpwahyu nugrohoNo ratings yet

- JSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadDocument1 pageJSA 003 Hacking of Damaged Thickening at Underdeck - Jetty HeadRyanNo ratings yet

- Job 3ODocument5 pagesJob 3OZakaria AnsorNo ratings yet

- RA - Maceio Terminal (MOORING AT OPEN TERMINAL)Document7 pagesRA - Maceio Terminal (MOORING AT OPEN TERMINAL)latish salianNo ratings yet

- BATC Briefing Guide 1 FEB 2022Document1 pageBATC Briefing Guide 1 FEB 2022Yi Vop100% (1)

- FMECG2SOP13 Rev3.04Document5 pagesFMECG2SOP13 Rev3.04deepaknaydu443No ratings yet

- Transportation and Fixing of Fencing, Underground Cables, Pipes Etc For Establishing Temp FacilitiesDocument8 pagesTransportation and Fixing of Fencing, Underground Cables, Pipes Etc For Establishing Temp FacilitiesazerNo ratings yet

- NFP0011A - Ground Disturbance ProcedureDocument40 pagesNFP0011A - Ground Disturbance ProcedureWajdi MansourNo ratings yet

- Checklist For Port State Control: - ISPS CheckDocument5 pagesChecklist For Port State Control: - ISPS CheckTan DatNo ratings yet

- Jsa For Dewatering PumpDocument1 pageJsa For Dewatering PumpMobin Thomas Abraham100% (3)

- Risk Assessment - Vessel InstallationDocument5 pagesRisk Assessment - Vessel InstallationKono Nor AtanNo ratings yet

- BriefingDocument4 pagesBriefingTural HasanovNo ratings yet

- Safety and Environmental Management System Job Hazard Analysis WorksheetDocument2 pagesSafety and Environmental Management System Job Hazard Analysis Worksheetmaspul lamuruprintNo ratings yet

- Preparation For Arrival/Departure in PortDocument6 pagesPreparation For Arrival/Departure in PortSiddharth Hada100% (1)

- Demolitipon of Parapet Wall Risk Assessment (0075) - Rev-00Document5 pagesDemolitipon of Parapet Wall Risk Assessment (0075) - Rev-00Muhammad OsamaNo ratings yet

- SOP - SOP - OPS40 - Cyclone Procedure - 2020-21 - DraftDocument42 pagesSOP - SOP - OPS40 - Cyclone Procedure - 2020-21 - Draftc0d3athNo ratings yet

- TRG-2103-A18 Major Flooding in Machinery Space - Drill Template Skillgrader - Clean - May24Document5 pagesTRG-2103-A18 Major Flooding in Machinery Space - Drill Template Skillgrader - Clean - May24nicuprivateinternetNo ratings yet

- R A 24 Off Loading & Loading of Equipment With A CraneDocument3 pagesR A 24 Off Loading & Loading of Equipment With A CraneSoufian BahmadNo ratings yet

- BULLDOZER - C52JSA-044 - Using Bulldozer Ripper - 25-Feb-15Document5 pagesBULLDOZER - C52JSA-044 - Using Bulldozer Ripper - 25-Feb-15hechame TamerhouletNo ratings yet

- 033 Risk Assessment For Construction of Chilled Water ChamberDocument13 pages033 Risk Assessment For Construction of Chilled Water ChamberVIRUPAKSHA KOOLINo ratings yet

- JSA Fuel Transfer From Tug Boat To BargeDocument2 pagesJSA Fuel Transfer From Tug Boat To BargeRyanNo ratings yet

- 5 Navigation at Offshore Locations PDFDocument11 pages5 Navigation at Offshore Locations PDFAmit100% (1)

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- SOP - ForkliftDocument4 pagesSOP - ForkliftGyanendra Narayan Nayak100% (1)

- Activity 5 - Simulator Trainees Copy Exercise - Deck - TijamDocument3 pagesActivity 5 - Simulator Trainees Copy Exercise - Deck - TijamJohn Dennis TijamNo ratings yet

- HIRA ExerciseDocument7 pagesHIRA ExerciseTrầnNgọcPhươngThảoNo ratings yet

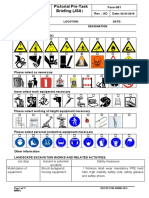

- Landscape Form-051-Pictorial Pre-Task Briefing (JSA) 19 Oct 2019 - FinalDocument17 pagesLandscape Form-051-Pictorial Pre-Task Briefing (JSA) 19 Oct 2019 - FinalJohn Vincent Macatangay Cleofe100% (1)

- Doc5.hirard PilingDocument3 pagesDoc5.hirard PilingJames JoviNo ratings yet

- 733.learner No - IG2. 20.08.2020.OBE, DL, SaudiArabiaDocument11 pages733.learner No - IG2. 20.08.2020.OBE, DL, SaudiArabiaMominul hoqueNo ratings yet

- Subjek Area Simulator TrainingDocument9 pagesSubjek Area Simulator Trainingkhairunnisa2205No ratings yet

- 1.initial Risk Identification Evalu-CS 18116246 - (DAYUNG-3)Document2 pages1.initial Risk Identification Evalu-CS 18116246 - (DAYUNG-3)synyster92xNo ratings yet

- HIRA Exercise Phase 2Document7 pagesHIRA Exercise Phase 2TrầnNgọcPhươngThảoNo ratings yet

- Tsa-001 - Rev 0 - ExcavationDocument2 pagesTsa-001 - Rev 0 - ExcavationMusadiq HussainNo ratings yet

- HIRA Exercise - 1Document8 pagesHIRA Exercise - 1TrầnNgọcPhươngThảoNo ratings yet

- Convair Traveler Vol - Xvii 1965-66Document92 pagesConvair Traveler Vol - Xvii 1965-66TateNo ratings yet

- Working Aloft Risk AssessmentDocument2 pagesWorking Aloft Risk Assessmentsidadams2100% (1)

- DWK322 Eplan5Document3 pagesDWK322 Eplan5Francisco Samuel Iohann M.No ratings yet

- Mip17-Hse-Jsa-Rtt-003 For Soil Improvement & Stone Column WorkDocument4 pagesMip17-Hse-Jsa-Rtt-003 For Soil Improvement & Stone Column WorkAmeerHamzaWarraichNo ratings yet

- ERP-20-Structure FailureDocument5 pagesERP-20-Structure FailureChRistian KingsNo ratings yet

- Job Hazard Analysis Site InspectionDocument12 pagesJob Hazard Analysis Site InspectionNonsoufo eze100% (1)

- Knowledge Sharing - Drone - Adi GunawanDocument33 pagesKnowledge Sharing - Drone - Adi Gunawanmiftahus siddiqNo ratings yet

- 310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 02Document5 pages310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 02Vinay MishraNo ratings yet

- Shezi Final ProjectDocument8 pagesShezi Final ProjectwahajNo ratings yet

- Element 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetDocument14 pagesElement 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetGurumoorthy Rajavijayan100% (2)

- International Regulations for Preventing Collisions at SeaFrom EverandInternational Regulations for Preventing Collisions at SeaNo ratings yet

- ukcssop033_iss1Document24 pagesukcssop033_iss1PIERRONNo ratings yet

- ukcscsm002_iss1Document66 pagesukcscsm002_iss1PIERRONNo ratings yet

- ukcssop022_iss1Document146 pagesukcssop022_iss1PIERRONNo ratings yet

- ukcssop005_iss1am04Document92 pagesukcssop005_iss1am04PIERRONNo ratings yet

- ukcssop015_iss2Document34 pagesukcssop015_iss2PIERRONNo ratings yet

- ukcssop009_iss1am01Document39 pagesukcssop009_iss1am01PIERRONNo ratings yet

- ukcsts011_iss1am01Document122 pagesukcsts011_iss1am01PIERRONNo ratings yet

- ukcssop008_iss1Document13 pagesukcssop008_iss1PIERRONNo ratings yet

- ukcssop007_iss1am01Document13 pagesukcssop007_iss1am01PIERRONNo ratings yet

- ukcsts015_iss1am01Document23 pagesukcsts015_iss1am01PIERRONNo ratings yet

- Risk Assessment No3 - Jumper recovery_Ver1Document3 pagesRisk Assessment No3 - Jumper recovery_Ver1PIERRONNo ratings yet

- NG50-2-300-SPS-PL-AA-30-0062Document41 pagesNG50-2-300-SPS-PL-AA-30-0062PIERRONNo ratings yet

- NG50-5-500-PRO-TR-AB-00-0013Document56 pagesNG50-5-500-PRO-TR-AB-00-0013PIERRONNo ratings yet

- ukcsts012_iss2Document20 pagesukcsts012_iss2PIERRONNo ratings yet

- NG50-1-CO-SAF-GN-AB-00-0006Document56 pagesNG50-1-CO-SAF-GN-AB-00-0006PIERRONNo ratings yet

- ukcsts013_iss1Document18 pagesukcsts013_iss1PIERRONNo ratings yet

- Risk Assessment No1 - Mob-demob_Ver2Document3 pagesRisk Assessment No1 - Mob-demob_Ver2PIERRONNo ratings yet

- AWS - Know Your Welding NDTDocument83 pagesAWS - Know Your Welding NDTPIERRONNo ratings yet

- NG50-3-200-ENG-RP-AB-83-6804Document44 pagesNG50-3-200-ENG-RP-AB-83-6804PIERRONNo ratings yet

- NG50-3-214-REQ-RP-AB-89-0095Document24 pagesNG50-3-214-REQ-RP-AB-89-0095PIERRONNo ratings yet

- Aws B 2.1-84 - STD For PQR & WPQRDocument150 pagesAws B 2.1-84 - STD For PQR & WPQRPIERRONNo ratings yet

- NG50-2-300-SPS-TR-AB-30-0132Document182 pagesNG50-2-300-SPS-TR-AB-30-0132PIERRONNo ratings yet

- 1-A6025-PL-051301-0010 Rev 0 Line Pipe Spec 051304-0001 20080320Document12 pages1-A6025-PL-051301-0010 Rev 0 Line Pipe Spec 051304-0001 20080320PIERRONNo ratings yet

- GCED Climate ChangeDocument8 pagesGCED Climate ChangekazrolNo ratings yet

- Windshear Avoidance and Recovery (JT ID IW)Document20 pagesWindshear Avoidance and Recovery (JT ID IW)Qushay Al IdrusNo ratings yet

- Trafikvarv ENG ESKV, PA28 SE-GAN, MPHDocument1 pageTrafikvarv ENG ESKV, PA28 SE-GAN, MPHarik.rubinsteinNo ratings yet

- Present Perfect Simple or Past SimpleDocument1 pagePresent Perfect Simple or Past SimplePaulina ŁucjaNo ratings yet

- Drilling Operation PresentationDocument52 pagesDrilling Operation PresentationIbrahim DewaliNo ratings yet

- AO-2020-003 Final ReportDocument56 pagesAO-2020-003 Final ReportJose A. HerreraNo ratings yet

- ABEN 55 2 Weather and HydrologyDocument81 pagesABEN 55 2 Weather and HydrologyPEARL ANGELIE UMBANo ratings yet

- ICSE Natural Vegetations Year QuestionsDocument16 pagesICSE Natural Vegetations Year QuestionsAdrit DasNo ratings yet

- 2021-036 Fleetwide Sharing - Safe Mooring and Winch Brake Rendering Test - CompressedDocument14 pages2021-036 Fleetwide Sharing - Safe Mooring and Winch Brake Rendering Test - CompressedAbhilashNo ratings yet

- Trabajo Práctico 1 InglésDocument3 pagesTrabajo Práctico 1 InglésRenzo CassellaNo ratings yet

- D1006 Standard Practice For Conducting Exterior Exposure Tests of Paints On WoodDocument7 pagesD1006 Standard Practice For Conducting Exterior Exposure Tests of Paints On WoodGiovanni OsorioNo ratings yet

- Webinaret 3 Metric Allen Et Al Metric Sebal (P)Document18 pagesWebinaret 3 Metric Allen Et Al Metric Sebal (P)Waqas Kareem AwanNo ratings yet

- Quiz Sostaz PDFDocument10 pagesQuiz Sostaz PDFjanemulimba05No ratings yet

- English Grammar: College of Languages English Department First Stage Instructor: Jiyar OthmanDocument87 pagesEnglish Grammar: College of Languages English Department First Stage Instructor: Jiyar Othmanaeman kingNo ratings yet

- Weathering, Erosion, and Deposition: Broken Down Moved Deposited, or DroppedDocument10 pagesWeathering, Erosion, and Deposition: Broken Down Moved Deposited, or DroppedbrbarnesNo ratings yet

- (12A) GS201 C1U2 VocabDocument2 pages(12A) GS201 C1U2 VocabLy Sing2No ratings yet

- PAS Inggris KL XI Sem. Gasal 2020Document14 pagesPAS Inggris KL XI Sem. Gasal 2020Muhammad Ageng SNo ratings yet

- A Detailed Lesson Plan in Science IV - EDITED PDocument2 pagesA Detailed Lesson Plan in Science IV - EDITED Prengelyngonzaga446No ratings yet

- Wadsworth Guide To Research 2nd Edition Miller Cochran Solutions ManualDocument36 pagesWadsworth Guide To Research 2nd Edition Miller Cochran Solutions Manualbisterkeelvat.ydma3q100% (34)

- Razvan 4 AcoperisDocument1 pageRazvan 4 AcoperisMaria MateiNo ratings yet

- Tugas B.inggrisDocument7 pagesTugas B.inggris10Muhammad Wildan M.No ratings yet

- Lifting and Hoisting Work: MajorDocument2 pagesLifting and Hoisting Work: MajorSalahuddin ChNo ratings yet

- Climate-Change PPT1Document42 pagesClimate-Change PPT1Raida AdimNo ratings yet

- Daily Star (2021.06.07)Document48 pagesDaily Star (2021.06.07)Gavril BogdanNo ratings yet

- Chapter One GeographicDocument3 pagesChapter One GeographicAbaas MuuseNo ratings yet

- Gold Preliminary Unit 7 Test: 1 Underline The Correct AlternativeDocument2 pagesGold Preliminary Unit 7 Test: 1 Underline The Correct Alternativeeuge pasNo ratings yet

- Q2W4 EngDocument30 pagesQ2W4 EngCandz candzNo ratings yet

- T2 E 1782 Term 3 Year 4 Reading Assessment BookletDocument8 pagesT2 E 1782 Term 3 Year 4 Reading Assessment BookletHossam DaifNo ratings yet