Professional Documents

Culture Documents

Badamid-A702-GF25-FR-HF

Badamid-A702-GF25-FR-HF

Uploaded by

maria.goncalvesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Badamid-A702-GF25-FR-HF

Badamid-A702-GF25-FR-HF

Uploaded by

maria.goncalvesCopyright:

Available Formats

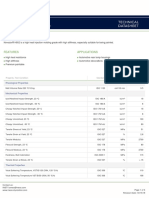

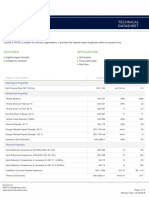

Technical Data Sheet

Badamid® A702 GF25 FR HF

PA66-GF25 FR<52>

Flame retardant (red phosphorus), 25% glass fibre reinforced injection moulding grade

Properties Test Conditions Test Methods Units Dry as conditioned

moulded 23° C, 50% r.H.

Mechanical Properties

Modulus of Elasticity, tensile 23° C, 1 mm/Min ISO 527-1/2 MPa 9200 7200

Yield Stress 1 23° C, 50 mm/Min ISO 527-1/2 MPa * *

Yield Strain 1 23° C, 50 mm/Min ISO 527-1/2 % * *

Nominal Stress at Break 1 23° C, 50 mm/Min ISO 527-1/2 % * *

Stress at Break 1 23° C, 5 mm/Min ISO 527-1/2 MPa 140 105

Strain at Break 1 23° C, 5 mm/Min ISO 527-1/2 % 3 4.5

Bending Strength 2 23° C ISO 178 MPa - -

Charpy Impact Strength, unnotched 2 23° C ISO 179/1eU kJ/m2 60 65

-30° C ISO 179/1eU kJ/m2 60 -

Notched Charpy Impact Strength 2 23° C ISO 179/1eA kJ/m2 12 16

-30° C ISO 179/1eA kJ/m2 - -

Izod notched Impact Strength 2 23° C ISO 180/1A kJ/m2 9 15

-30° C ISO 180/1A kJ/m2 - -

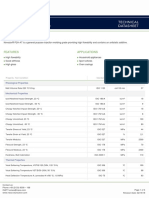

Thermal Properties

Melting Temperature 3 10 K/Min ISO 3146 °C 262 *

Temperature of Deflection under Load 4 0.45 MPa ISO 75-1/2 °C 250 *

1.8 MPa ISO 75-1/2 °C 250 *

Coefficient of Linear Thermal Elongation 5 parallel direction DIN 53752 E-4/K 0.37 *

transverse direction DIN 53752 E-4/K 0.81 *

Maximum Service Temperature some hours - °C 220 *

20 000 h IEC 216 °C 130 *

50 % Decrease in Tensile

Strength or Yield Stress

Flammability 6 0.8 mm UL 94 Class V-0 *

1.6 mm UL 94 Class V-0 *

Glow Wire Test 0.75 mm / 1.6 mm GWIT IEC-60695-2-13 800°C *

0.75 mm / 1.6 mm GWFI IEC-60695-2-12 960°C *

Electric Properties

Relative Permittivity 7 1 MHz IEC 250 - 3,7 5

Dissipation Factor 7 1 MHz IEC 250 E-4 200 1000

Specific Volume Resistivity 7 - IEC 93 Ohm cm 10 15 10 12

Specific Surface Resistivity 7 - IEC 93 Ohm 10 13 10 10

Dielectric Strength 7 - IEC 243-1 kV/mm 33 30

Comparative Tracking Index - IEC 112 V 550 *

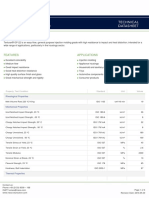

Other data

Water Absorption 23° C. Saturation ISO 62 % 5,7 *

Moisture Absorption 23° C. 50 % r.H. ISO 62 % 1.3 *

Density 23° C ISO 1183 g/ccm 1.44 *

Processing

Melt Temperature - - °C 280 – 300 *

Tool Surface Temperature - - °C 70 – 90 *

Drying Temperature - - °C 80 *

Drying Time - - h 2–4 *

LEGEND:

1

Test Specimen accordng to ISO 3167. Type A * not relevant These data are typical values and represent the state of our

2

Standard bar (80 x 10 x 4) mm - not tested knowledge at issue date. If not otherwise stated, the data is related

3

Compound for moulding NB = No break to uncolored material. They must not be construed as specification

4

Standard bar (110 x 10 x 4) mm limits or as a guarantee for specific properties.

5

Specimen ( ≥ 10 x 10 x 4) mm It is the liability of the processor to test the suitability of the material

6

Standard bar [125 x 13 x 0.8(1.6)] mm for a specific application.

7

Bar (80 x 80 x 1) mm

8

Specimen ( ≥ 15 x 15 x 4) mm Issue date: 2016-10-25

Bada AG · Untere Strut 1 · D-77815 Bühl/Baden · Fon: +49 (0) 72 23-940 77-0 · Fax: +49 (0) 72 23-940 77-77 · info@bada.de · www.bada.de

You might also like

- AMBROSE, James TRIPENY, Patrick. Simplified Design of Wood Structures. John Wiley & Sons. 1994.Document376 pagesAMBROSE, James TRIPENY, Patrick. Simplified Design of Wood Structures. John Wiley & Sons. 1994.Kesya R Reis100% (2)

- Ultrasonic TestingDocument21 pagesUltrasonic TestingHÉCTOR EDUARDO PONCE HERNÁNDEZ100% (1)

- Pa 12Document1 pagePa 12pava16230.meNo ratings yet

- B70 S Natural S1: Badamid®Document2 pagesB70 S Natural S1: Badamid®hocineNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Makrolon SF800 - en - 56979992 00009671 17283484Document3 pagesMakrolon SF800 - en - 56979992 00009671 17283484Shinichi SuzukiNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Makrolon LED2245 - en - 81038415 00003726 19218403Document4 pagesMakrolon LED2245 - en - 81038415 00003726 19218403dave judayaNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- PBT - Lanxess Pocan B3235 000000Document3 pagesPBT - Lanxess Pocan B3235 000000armandoNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Flow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Document4 pagesFlow Elem. Makrolon 2467 - en - 56977450 00003066 15285551Guilherme Dos Santos SouzaNo ratings yet

- Styrolution TDS302200150418Document3 pagesStyrolution TDS302200150418erayNo ratings yet

- LANXESS Durethan BKV35H2.0 901510 ISO ENDocument3 pagesLANXESS Durethan BKV35H2.0 901510 ISO ENcristinamss33No ratings yet

- LANXESS Durethan A30SFN31 000000 ISO ENDocument3 pagesLANXESS Durethan A30SFN31 000000 ISO ENNguyen Dinh VinhNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- Makrolon Rx3440 - en - 87242367 05124840 21462211Document3 pagesMakrolon Rx3440 - en - 87242367 05124840 21462211MamdouhNo ratings yet

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- TDS - TS002 - Durethan AKV30H3.0Document3 pagesTDS - TS002 - Durethan AKV30H3.0oberta.andrzejNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Lanxess Durethan Bkv130h2.0 901510 Iso enDocument3 pagesLanxess Durethan Bkv130h2.0 901510 Iso enRICARDONo ratings yet

- Lanxess - Pocan B7425Document3 pagesLanxess - Pocan B7425rihabNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Durethan B30S 000000 ISO enDocument3 pagesDurethan B30S 000000 ISO enjujuplasticNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Durethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030Document3 pagesDurethan B30S 000000: PA 6, Non-Reinforced, Injection Molding ISO Shortname: ISO 1874-PA 6, GR, 14-030zoranNo ratings yet

- Makrolon 2407 - en - 56977361 00009645 19213223Document4 pagesMakrolon 2407 - en - 56977361 00009645 19213223vaibhav ShindeNo ratings yet

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 pagesBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNo ratings yet

- YEE70G30HSLNCDocument2 pagesYEE70G30HSLNCRanjan GnanaoliNo ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- Zytel® 73G15L NC010-gbDocument12 pagesZytel® 73G15L NC010-gbzoxxxnNo ratings yet

- Kynar Flex® 2800-20 ResinDocument5 pagesKynar Flex® 2800-20 ResinmohammedNo ratings yet

- Makrolon 6265 X - en - 83439336 05122261 16125443Document4 pagesMakrolon 6265 X - en - 83439336 05122261 16125443solar4meNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Makrolon AL2447 - en - 56978848 00009654 19215151 2Document4 pagesMakrolon AL2447 - en - 56978848 00009654 19215151 2optoyhamelNo ratings yet

- Makrolon 6485 - en - 56978635 00009652 18539090Document4 pagesMakrolon 6485 - en - 56978635 00009652 18539090Lin DanNo ratings yet

- Tds Carbon enDocument1 pageTds Carbon engegacolucNo ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- TDS - Lexan 141R (141R-701)Document2 pagesTDS - Lexan 141R (141R-701)It WittayaNo ratings yet

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocument2 pagesPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNo ratings yet

- 000273-TECHNYL-C-102-NCDocument3 pages000273-TECHNYL-C-102-NCGiampietro PiccoliNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- Nylon 6-BAYER DURATHAN BKV130-901510Document3 pagesNylon 6-BAYER DURATHAN BKV130-901510dcrypto2022No ratings yet

- Makrolon 6557 - TDSDocument4 pagesMakrolon 6557 - TDSCassianNo ratings yet

- Bayblend FR1514 - en - 56967951 05122960 20070851Document3 pagesBayblend FR1514 - en - 56967951 05122960 20070851phairyNo ratings yet

- Grivory GVX 5h Nat - Mds - enDocument5 pagesGrivory GVX 5h Nat - Mds - enJohn KingNo ratings yet

- Styro Lution Tds 401200140448Document3 pagesStyro Lution Tds 401200140448scribdNo ratings yet

- Evonik Corporation Vestamid X7293 Plasticized Nylon 12Document3 pagesEvonik Corporation Vestamid X7293 Plasticized Nylon 12Prabhu MohanNo ratings yet

- Emerge™ Pc/Abs 7740: Technical InformationDocument3 pagesEmerge™ Pc/Abs 7740: Technical InformationbobNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- 202-Covestro Makrolon RX1805 Technical Data Sheet 03-12-2018Document3 pages202-Covestro Makrolon RX1805 Technical Data Sheet 03-12-2018obeckoneNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- Makrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityDocument4 pagesMakrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityagungNo ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Apeejay School, Saket First Terminal Examination - 2016: Class Xii (Physics) General InstructionsDocument4 pagesApeejay School, Saket First Terminal Examination - 2016: Class Xii (Physics) General InstructionsabhilashagoelNo ratings yet

- How Far Can We See Analysis of The Measurement Range of Long-Range LiDAR Data For Wind Power ForecastingDocument4 pagesHow Far Can We See Analysis of The Measurement Range of Long-Range LiDAR Data For Wind Power ForecastingRafael AmaralNo ratings yet

- Air-Cooled Heat Exchanger Type ZBWDocument8 pagesAir-Cooled Heat Exchanger Type ZBWraja raniNo ratings yet

- Particular Specification For StormDocument11 pagesParticular Specification For StormManju NaikNo ratings yet

- Shear Strength of SoilsDocument63 pagesShear Strength of SoilsEbrahem saeedNo ratings yet

- Thermodynamic Properties of R-134a Saturated R-134aDocument6 pagesThermodynamic Properties of R-134a Saturated R-134aGvbo rA9No ratings yet

- GT TableDocument62 pagesGT Tableeuric82No ratings yet

- Energy Audit InstrumentsDocument74 pagesEnergy Audit InstrumentsANIL KUMARNo ratings yet

- Tndt-frm-ndt-007 Magnetic Particle Inspection ReportDocument2 pagesTndt-frm-ndt-007 Magnetic Particle Inspection ReportKhalid Hidayatullah100% (1)

- 7SD80xx Manual A1 V040003 Us PDFDocument416 pages7SD80xx Manual A1 V040003 Us PDFKarthik SelvamNo ratings yet

- Ref Bessel Mto ImportanteDocument5 pagesRef Bessel Mto ImportanteMartin PanicioNo ratings yet

- Jordan 2005 PDFDocument20 pagesJordan 2005 PDFcimasukNo ratings yet

- JEE Mains 2024 29 Jan Shift 1 Paper With Solutions (PDF)Document17 pagesJEE Mains 2024 29 Jan Shift 1 Paper With Solutions (PDF)rnvermaNo ratings yet

- RP SpiralDocument48 pagesRP SpiralLakshit NagarNo ratings yet

- Risk Based Inspections (RBI)Document13 pagesRisk Based Inspections (RBI)Richard Koehler100% (1)

- Eng SS 114-2157 GDocument14 pagesEng SS 114-2157 Gsav33No ratings yet

- 07 DiagnosticsDocument132 pages07 DiagnosticsJosué Soldera100% (2)

- 1Document3 pages1Anwaraime RadzakNo ratings yet

- SVET Overview: Add To Quote RequestDocument3 pagesSVET Overview: Add To Quote RequestthuronNo ratings yet

- Homework 2.5Document11 pagesHomework 2.5GalimoNo ratings yet

- Mathematics in The Modern World IM 1Document20 pagesMathematics in The Modern World IM 1Angelica Wyne AlisboNo ratings yet

- Guidance Note NDT 001, Feb 04Document11 pagesGuidance Note NDT 001, Feb 04Stephen LewellenNo ratings yet

- 2005 Deer KrommenhoekDocument28 pages2005 Deer KrommenhoekMuhammad Irfan MaulanaNo ratings yet

- Inconel 600 Technical Data: Type AnalysisDocument3 pagesInconel 600 Technical Data: Type Analysisorangelanaya-1No ratings yet

- Final W11 Math239Document12 pagesFinal W11 Math239Sheethala SwaminathanNo ratings yet

- What Is Biomechanics?: Basic Biomechanics, 6 Edition by Susan J. Hall, PH.DDocument19 pagesWhat Is Biomechanics?: Basic Biomechanics, 6 Edition by Susan J. Hall, PH.DMandar patil100% (1)

- Analog & Digital Control SystemsDocument3 pagesAnalog & Digital Control SystemsAyush PurohitNo ratings yet

- Future-Proofing Fenders WhitepaperDocument9 pagesFuture-Proofing Fenders WhitepaperShannel VendiolaNo ratings yet