Professional Documents

Culture Documents

NORYL GTX™ Resin_GTX820_Americas_Technical_Data_Sheet

NORYL GTX™ Resin_GTX820_Americas_Technical_Data_Sheet

Uploaded by

maria.goncalvesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NORYL GTX™ Resin_GTX820_Americas_Technical_Data_Sheet

NORYL GTX™ Resin_GTX820_Americas_Technical_Data_Sheet

Uploaded by

maria.goncalvesCopyright:

Available Formats

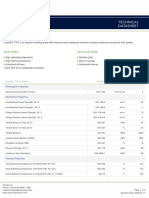

™

NORYL GTX RESIN GTX820

REGION AMERICAS

DESCRIPTION

™

NORYL GTX 820 resin is a 20% glass reinforced alloy of Polyphenylene Ether (PPE) + Polyamide (PA). This injection moldable grade has high stiffness

(flexural modulus 4000 MPa), excellent chemical resistance, and high heat resistance. NORYL GTX GTX830 resin is an excellent candidate for a wide variety

of applications including valves for water management.

TYPICAL PROPERTY VALUES Revision 20190925

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

MECHANICAL

Tensile Stress, break, 5 mm/min 139 MPa ISO 527

Tensile Strain, break, 5 mm/min 3.6 % ISO 527

Tensile Modulus, 1 mm/min @ 120°C 6400 MPa ISO 527

Flexural Modulus, 2 mm/min 5960 MPa ISO 178

Flexural Stress, break, 2 mm/min 217 MPa ISO 178

Tensile Modulus, 5 mm/min 6350 MPa ASTM D 638

Tensile Strain, brk, Type I, 5 mm/min 3.6 % ASTM D 638

Tensile Stress, brk, Type I, 5 mm/min 133 MPa ASTM D 638

Flexural Modulus, 1.3 mm/min, 50 mm span 6030 MPa ASTM D 790

Flexural Stress, brk, 1.3 mm/min, 50 mm span 210 MPa ASTM D 790

Flexural Stress, yld, 2.6 mm/min, 100 mm span 194 MPa ASTM D 790

Flexural Modulus, 2.6 mm/min, 100 mm span 5960 MPa ASTM D 790

Hardness, Rockwell R 119 - ASTM D 785

IMPACT

Izod Impact, notched 80*10*4 +23°C 8.8 kJ/m² ISO 180/1A

Izod Impact, unnotched 80*10*4 +23°C 86 kJ/m² ISO 180/1U

Izod Impact, notched, 23°C 80 J/m ASTM D 256

Izod Impact, notched, -30°C 53 J/m ASTM D 256

Izod Impact, unnotched, 23°C 900 J/m ASTM D 4812

Charpy 23°C, V-notch Edgew 80*10*4 sp=62mm 8.7 kJ/m² ISO 179/1eA

Charpy 23°C, Unnotch Edgew 80*10*4 sp=62mm 62 kJ/m² ISO 179/1eU

THERMAL

Vicat Softening Temp, Rate A/50 252 °C ISO 306

Vicat Softening Temp, Rate B/50 229 °C ISO 306

Vicat Softening Temp, Rate B/50 248 °C ASTM D 1525

HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm 211 °C ISO 75/Af

HDT/Bf, 0.45 MPa Flatw 80*10*4 sp=64mm 248 °C ISO 75/Bf

HDT, 0.45 MPa, 6.4 mm, unannealed 254 °C ASTM D 648

HDT, 1.82 MPa, 6.4 mm, unannealed 232 °C ASTM D 648

CTE, 23°C to 60°C, flow 2.7E-05 1/°C ISO 11359-2

CTE, 23°C to 60°C, xflow 7.8E-05 1/°C ISO 11359-2

CTE, 23°C to 80°C, flow 2.7E-05 1/°C ASTM E 831

CTE, 23°C to 80°C, xflow 8.7E-05 1/°C ASTM E 831

CTE, -20°C to 150°C, flow 0.0000306 – 0.0000396 1/°C ASTM E 831

© 2019 Copyright by SABIC. All rights reserved

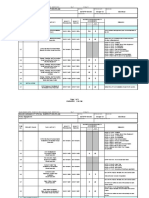

PHYSICAL

Specific Gravity 1.24 - ASTM D 792

Density 1.245 g/cm³ ASTM D 792

Density 1.25 g/cm³ ISO 1183

Moisture Absorption, 50% RH, 24 hrs 0.17 % ASTM D 570

Charpy 23°C, Unnotch Edgew 80*10*4 sp=62mm 62 kJ/m² ISO 179/1eU

THERMAL

Vicat Softening Temp, Rate A/50 252 °C ISO 306

Vicat Softening Temp, Rate B/50 229 °C ISO 306

Vicat Softening Temp, Rate B/50 248 °C ASTM D 1525

HDT/Af, 1.8 MPa Flatw 80*10*4 sp=64mm 211 °C ISO 75/Af

HDT/Bf, 0.45 MPa Flatw 80*10*4 sp=64mm 248 °C ISO 75/Bf

HDT, 0.45 MPa, 6.4 mm, unannealed 254 °C ASTM D 648

HDT, 1.82 MPa, 6.4 mm, unannealed 232 °C ASTM D 648

CTE, 23°C to 60°C, flow 2.7E-05 1/°C ISO 11359-2

CTE, 23°C to 60°C, xflow 7.8E-05 1/°C ISO 11359-2

CTE, 23°C to 80°C, flow 2.7E-05 1/°C ASTM E 831

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

CTE, 23°C to 80°C, xflow 8.7E-05 1/°C ASTM E 831

CTE, -20°C to 150°C, flow 0.0000306 – 0.0000396 1/°C ASTM E 831

PHYSICAL

Specific Gravity 1.24 - ASTM D 792

Density 1.245 g/cm³ ASTM D 792

Density 1.25 g/cm³ ISO 1183

Moisture Absorption, 50% RH, 24 hrs 0.17 % ASTM D 570

Water Absorption, 24 hours 0.5 % ASTM D 570

Moisture Absorption (23°C / 50% RH) 0.49 % ISO 62

Water Absorption, (23°C/sat) 1.88 % ISO 62

Mold Shrinkage, flow, 24 hrs 0.27 % ISO 294

Mold Shrinkage, xflow, 24 hrs 0.93 % ISO 294

Mold Shrinkage, flow, 24 hrs 0.27 % ASTM D 955

Mold Shrinkage, xflow, 24 hrs 0.93 % ASTM D 955

Mold Shrinkage, flow, 3.2 mm 0.4 – 0.6 % SABIC method

Mold Shrinkage, xflow, 3.2 mm 0.65 – 0.85 % SABIC method

Melt Volume Rate, MVR at 280°C/5.0 kg 7.1 cm³/10 min ISO 1133

Melt Flow Rate, 280°C/5.0 kgf 7.0 g/10 min ASTM D 1238

INJECTION MOLDING

Drying Temperature 95 – 105 °C

Drying Time 3–4 hrs

Drying Time (Cumulative) 8 hrs

Maximum Moisture Content 0.07 %

Minimum Moisture Content 0.02 %

Melt Temperature 280 – 305 °C

Nozzle Temperature 280 – 305 °C

Front - Zone 3 Temperature 275 – 305 °C

Middle - Zone 2 Temperature 270 – 305 °C

Rear - Zone 1 Temperature 265 – 305 °C

Mold Temperature 75 – 120 °C

Back Pressure 0.3 – 1.4 MPa

Screw Speed 20 – 100 rpm

Shot to Cylinder Size 30 – 50 %

Vent Depth 0.013 – 0.038 mm

DISCLAIMER

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed

otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED,

INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE

PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller

materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is

intended, or should be construed, to grant any license under any patent or other intellectual property right.

© 2019 Copyright by SABIC. All rights reserved

You might also like

- 588-Water Cooler Cum HeaterDocument6 pages588-Water Cooler Cum Heatersanu222100% (3)

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloNo ratings yet

- CYCOLOY+FR+Resin CX7211 Europe Technical Data Sheet (1)Document3 pagesCYCOLOY+FR+Resin CX7211 Europe Technical Data Sheet (1)riegel94No ratings yet

- Sabic 1004RDocument3 pagesSabic 1004Rlcesaksham23No ratings yet

- Sabic PC 10 Mfi pc1003rDocument3 pagesSabic PC 10 Mfi pc1003rChu ChuNo ratings yet

- CYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetAthiwat TriwattanapornNo ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- ULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetDocument2 pagesULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetKishore Gowda A SNo ratings yet

- Lexan FR Resin 505rDocument3 pagesLexan FR Resin 505rShabi HadashNo ratings yet

- LEXAN FST3403tDocument3 pagesLEXAN FST3403tJose Ramon Florez OrdizNo ratings yet

- LEXAN™ Copolymer - EXL9330 - Americas - Technical - Data - SheetDocument4 pagesLEXAN™ Copolymer - EXL9330 - Americas - Technical - Data - SheetBrent TairaNo ratings yet

- LEXAN™ Copolymer - EXL9330 - Asia - Technical - Data - SheetDocument4 pagesLEXAN™ Copolymer - EXL9330 - Asia - Technical - Data - Sheetkls.thorodinsonNo ratings yet

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetDocument2 pagesLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroNo ratings yet

- A GD VDBDocument3 pagesA GD VDBthehoang12310No ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- ABS Cycolac MG47Document3 pagesABS Cycolac MG47countzeroaslNo ratings yet

- SABIC® PPcompound - G3230A - Americas - Technical - Data - SheetDocument2 pagesSABIC® PPcompound - G3230A - Americas - Technical - Data - SheetAarón González MedinaNo ratings yet

- SABIC PC Resin - PC0703R - Technical - Data - SheetDocument3 pagesSABIC PC Resin - PC0703R - Technical - Data - SheetAryaNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- PBT Valox 420SEO 30%GLDocument3 pagesPBT Valox 420SEO 30%GLcountzeroaslNo ratings yet

- TDS - Lexan 141R (141R-701)Document2 pagesTDS - Lexan 141R (141R-701)It WittayaNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDocument2 pagesPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNo ratings yet

- PC-ABS Cycoloy™ C6600Document2 pagesPC-ABS Cycoloy™ C6600countzeroaslNo ratings yet

- Cycolac MG 47Document3 pagesCycolac MG 47Juan DanielNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- LUPOY EU5002W (Eng) - TDS (ASTM)Document3 pagesLUPOY EU5002W (Eng) - TDS (ASTM)erayNo ratings yet

- SABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)Document3 pagesSABIC Innovative Plastics Lexan® 940 PC: Polymer, Thermoplastic, Polycarbonate (PC)MRC RailNo ratings yet

- LEXAN™ Resin_143R_Europe_Technical_Data_SheetDocument2 pagesLEXAN™ Resin_143R_Europe_Technical_Data_SheetFahri ibişoğluNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- CYCOLOY™ FR Resins - C2950HF - Americas - Technical - Data - Sheet-1Document2 pagesCYCOLOY™ FR Resins - C2950HF - Americas - Technical - Data - Sheet-1Lidiane RibeiroNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- ABSaf 312 ADocument2 pagesABSaf 312 AAdonis BasilioNo ratings yet

- LG Abs - Hi100hDocument2 pagesLG Abs - Hi100hqshakimNo ratings yet

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- CYCOLAC MG47F - TDS (EN)Document3 pagesCYCOLAC MG47F - TDS (EN)rafacastillopNo ratings yet

- XENOY™ Resin - 5220U - Europe - Technical - Data - SheetDocument2 pagesXENOY™ Resin - 5220U - Europe - Technical - Data - SheetEduardo TreviñoNo ratings yet

- ASA LI970: Description ApplicationDocument4 pagesASA LI970: Description ApplicationRonal Deiby Cadavid PinzonNo ratings yet

- LEXAN™ Resin - 141R - Asia - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Asia - Technical - Data - SheetTruc Thao NguyenNo ratings yet

- Hoja Tecnica ASADocument2 pagesHoja Tecnica ASAFernando AngioliniNo ratings yet

- LEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetRamesh KannanNo ratings yet

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Propriedades ABSDocument1 pagePropriedades ABSengmecanica07022013No ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- ROTOLENE-HDHFDocument2 pagesROTOLENE-HDHFFernando BautistaNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- LNP+LUBRILOY+Compound D2000AXH Global Technical Data SheetDocument3 pagesLNP+LUBRILOY+Compound D2000AXH Global Technical Data SheetYEIFRI RODRIGUEZ BTCNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- Badamid-A702-GF25-FR-HFDocument1 pageBadamid-A702-GF25-FR-HFmaria.goncalvesNo ratings yet

- Injection Molding Grade: Description ApplicationsDocument2 pagesInjection Molding Grade: Description ApplicationsSangharshBhustalimathNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- BFDocument56 pagesBFvikrantsingh2908No ratings yet

- Lik Final PDFDocument30 pagesLik Final PDFkrishna tiwariNo ratings yet

- +vernacular Terms PDFDocument3 pages+vernacular Terms PDFCyril Joy NagrampaNo ratings yet

- Product Data Sheet: DimensionalDocument1 pageProduct Data Sheet: DimensionalIvanNo ratings yet

- Refrigeration and Airconditioning QuizDocument5 pagesRefrigeration and Airconditioning QuizRajesh Kumar R0% (1)

- Volume 1Document429 pagesVolume 1Lincolh Maza ReyesNo ratings yet

- Civil Engineering: Sr. No. Core Areas PercentageDocument9 pagesCivil Engineering: Sr. No. Core Areas PercentageIzo SeremNo ratings yet

- 2008 Catalog LOISIRS2000Document24 pages2008 Catalog LOISIRS20004gen_3No ratings yet

- ArcelorMittal Energy Projects - EN10225-2019 Plates - Feb 2020Document2 pagesArcelorMittal Energy Projects - EN10225-2019 Plates - Feb 2020Vinoth Kumar PothuvudaiNo ratings yet

- List of Paper Publications Journals: InternationalDocument7 pagesList of Paper Publications Journals: InternationalvempadareddyNo ratings yet

- A Comparative Study of Conventional RC Girder Bridge and Integral BridgeDocument20 pagesA Comparative Study of Conventional RC Girder Bridge and Integral Bridgesanket panchalNo ratings yet

- SAE AMS 5524l-2014Document5 pagesSAE AMS 5524l-2014Mehdi MokhtariNo ratings yet

- Mother of Divine Grace Academy: 1 Quarterly EXAMINATION IN General Physics 2 SY: 2022-2023Document2 pagesMother of Divine Grace Academy: 1 Quarterly EXAMINATION IN General Physics 2 SY: 2022-2023Christian G. OñasaNo ratings yet

- A Spherical Pressure Vessel Has An Inside Diameter...Document2 pagesA Spherical Pressure Vessel Has An Inside Diameter...RjNo ratings yet

- CF8M ValvesDocument4 pagesCF8M ValvesPranav PrashantNo ratings yet

- Astm D 4439 00 Standard Terminology For Geosynthetics PDFDocument5 pagesAstm D 4439 00 Standard Terminology For Geosynthetics PDFDeyvi ManriqueNo ratings yet

- Aer Conditionat LGDocument22 pagesAer Conditionat LGcasiloNo ratings yet

- OML751 Testing of MaterialsDocument39 pagesOML751 Testing of MaterialsVikashini GNo ratings yet

- GuidelinesfortheWeldedFabricationofNickelStainlessSteelsforCorrosionResistantService 11007Document52 pagesGuidelinesfortheWeldedFabricationofNickelStainlessSteelsforCorrosionResistantService 11007Jihwan LeeNo ratings yet

- MSM Re-2Document1 pageMSM Re-2Vijay GajeraNo ratings yet

- SATIP-P-104-08 Rev 7 FinalDocument4 pagesSATIP-P-104-08 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- 7 Pyrotek CrossfeederDocument27 pages7 Pyrotek CrossfeederMuhamad Hafidz RyansyahNo ratings yet

- 39CQM Air HandlingDocument32 pages39CQM Air Handlingcarrier SingaporeNo ratings yet

- Kumwell Grounding and Lightning Protection-12Document1 pageKumwell Grounding and Lightning Protection-12TAEWARAT RAKRUANGNo ratings yet

- Castel Check ValveDocument9 pagesCastel Check Valveamin2shahinNo ratings yet

- Eni Dicrea SX 68Document2 pagesEni Dicrea SX 68AMAZING AGNo ratings yet

- Member Stability Bracing: Appendix 6Document8 pagesMember Stability Bracing: Appendix 6mabuhamdNo ratings yet

- APP169Document12 pagesAPP169bungykitNo ratings yet

- G4-Concrete Test Specimens Preparation in LaboratoryDocument4 pagesG4-Concrete Test Specimens Preparation in LaboratoryhatdogNo ratings yet