Professional Documents

Culture Documents

physics 13

physics 13

Uploaded by

stoiloff.dimitarCopyright:

Available Formats

You might also like

- Fundamentals of Vehicle Dynamics by Thomas D GillespieDocument99 pagesFundamentals of Vehicle Dynamics by Thomas D GillespieYogesh Chandrawanshi0% (1)

- Resistance and Special WeldingDocument24 pagesResistance and Special WeldingKBSMANITNo ratings yet

- Introduction To WeldingDocument192 pagesIntroduction To WeldingMirtunjay Kumar88% (8)

- PART 166 What Is Spot WeldingDocument4 pagesPART 166 What Is Spot Weldingravindra_jivaniNo ratings yet

- Advanced Welding Process (Welding)Document58 pagesAdvanced Welding Process (Welding)Sk SamsuddinNo ratings yet

- WeldingDocument16 pagesWeldingwhoami7174No ratings yet

- Resistance WeldingDocument18 pagesResistance WeldingAnand JainNo ratings yet

- Tigweld DoneDocument16 pagesTigweld DoneSenthil KumarNo ratings yet

- Electric Resistance WeldingDocument30 pagesElectric Resistance WeldingSenthil KumarNo ratings yet

- Sonargaon University Shop 160 Welding - 2: Prepared by Zayed AhmedDocument19 pagesSonargaon University Shop 160 Welding - 2: Prepared by Zayed Ahmedদুর্জয় দুর্বারNo ratings yet

- Resistance WeldingDocument27 pagesResistance WeldingridaNo ratings yet

- Advanced Welding Process and Inspection: Q Α I R t Q= k I RtDocument22 pagesAdvanced Welding Process and Inspection: Q Α I R t Q= k I RtDarshan SNo ratings yet

- The Importance of Shipboard Welding in Preserving TrimDocument34 pagesThe Importance of Shipboard Welding in Preserving TrimJhudiel Carlo AndoyNo ratings yet

- Unit II - mt1Document24 pagesUnit II - mt1Mareeswaran Maruthamuthu M0% (1)

- WeldingDocument7 pagesWeldingJuanNo ratings yet

- Manufacturing Technology: Tig Welding - Process AnalysisDocument8 pagesManufacturing Technology: Tig Welding - Process AnalysisshubhamNo ratings yet

- ElectrodeDocument29 pagesElectrodecibtc wws rypsNo ratings yet

- Arc Welding Refers To A Group Of: SolderingDocument12 pagesArc Welding Refers To A Group Of: SolderingBhushan VermaNo ratings yet

- Welding ShopDocument5 pagesWelding ShopWaqas Hussain MalikNo ratings yet

- Non-Arc Welding ProcessesDocument30 pagesNon-Arc Welding ProcessesKhalid El MasryNo ratings yet

- "Spot Welding": Mindanao University of Science and Technology C.M. Recto Avenue, Lapasan, Cagayan de Oro CityDocument10 pages"Spot Welding": Mindanao University of Science and Technology C.M. Recto Avenue, Lapasan, Cagayan de Oro CityAcerz VillagraciaNo ratings yet

- Chapter-4 Principle of Selected Joining and Assembling Process A Brief History of WeldingDocument12 pagesChapter-4 Principle of Selected Joining and Assembling Process A Brief History of WeldingFira tubeNo ratings yet

- Experiment No 02: AIM To Study Resistance Welding & Its SetupDocument6 pagesExperiment No 02: AIM To Study Resistance Welding & Its Setuprahul9981759900No ratings yet

- Arc Welding Process PDFDocument12 pagesArc Welding Process PDFBiswanath RoulNo ratings yet

- Electrode Converted Into TextDocument14 pagesElectrode Converted Into TextNeha NimbarkNo ratings yet

- Welding and Joining Process: Basic Concept of WeldingDocument7 pagesWelding and Joining Process: Basic Concept of WeldingNaresh kumarNo ratings yet

- Notes-22 7Document20 pagesNotes-22 7Dan JonNo ratings yet

- Work Shop Pratice - MyDocument8 pagesWork Shop Pratice - MyTaran TulaNo ratings yet

- TIG Presentation.Document31 pagesTIG Presentation.Md Anamul HoqueNo ratings yet

- 304 SsDocument54 pages304 Ssshakir ramzanNo ratings yet

- Chapter 3-Electric WeldingDocument32 pagesChapter 3-Electric WeldingAMAR CHAND MEENANo ratings yet

- Welding: Al-Hussein Bin Talal UniversityDocument8 pagesWelding: Al-Hussein Bin Talal UniversityJaber AbdallahNo ratings yet

- WeldingDocument28 pagesWeldingShahdan DahlanNo ratings yet

- Welding and Cutting ProcessDocument60 pagesWelding and Cutting Processquiron2010100% (1)

- Welding Types of Welding Gas Welding (Oxy-Acetylene) Arc Welding (Metal Arc) Merits & Limitations of Welding Process Application ConclusionDocument14 pagesWelding Types of Welding Gas Welding (Oxy-Acetylene) Arc Welding (Metal Arc) Merits & Limitations of Welding Process Application ConclusionAjinkya MoreNo ratings yet

- Welding Details Slide - 1Document32 pagesWelding Details Slide - 1Azmain IktedarNo ratings yet

- Welding: Dr. Sunil JhaDocument21 pagesWelding: Dr. Sunil JharassdriverNo ratings yet

- Principle of Arc WeldingDocument60 pagesPrinciple of Arc Weldingsamurai7_7786% (7)

- Electric Welding: Some of The Advantages of Welding AreDocument11 pagesElectric Welding: Some of The Advantages of Welding ArePriyadarshi MNo ratings yet

- 6 Electric WeldingDocument19 pages6 Electric WeldingSujan MajiNo ratings yet

- WeldingDocument169 pagesWeldingamarparimi100% (1)

- Resistance WeldingDocument21 pagesResistance WeldingAyush KumarNo ratings yet

- Welding WorkshopDocument29 pagesWelding WorkshopAnonymous h5OeGoX3MTNo ratings yet

- 2 WeldingDocument24 pages2 WeldingpriyanshuvraoNo ratings yet

- WELDINGDocument8 pagesWELDINGManibhusan MohapatroNo ratings yet

- Welding: Edge PreparationsDocument8 pagesWelding: Edge PreparationsManibhusanNo ratings yet

- Welding Rods Welding Rods: Manual Metal Arc Welding (MMA)Document6 pagesWelding Rods Welding Rods: Manual Metal Arc Welding (MMA)CT0011No ratings yet

- 87 Technical Sheet - Tig WeldingDocument1 page87 Technical Sheet - Tig WeldingZeu AressNo ratings yet

- Resistance WeldingDocument13 pagesResistance WeldingAashishSethiNo ratings yet

- Electric Welding: Unit-IiDocument41 pagesElectric Welding: Unit-IiKUMAR SNo ratings yet

- Miyachi Fundamentals Resistance WeldingDocument8 pagesMiyachi Fundamentals Resistance Weldinghlgc63No ratings yet

- MT - 2Document15 pagesMT - 2Arnav PandeyNo ratings yet

- About Welding Process 46Document1 pageAbout Welding Process 46XerexNo ratings yet

- Welding TechnologyDocument218 pagesWelding Technologywbl_200789% (9)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Welding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsFrom EverandWelding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsNo ratings yet

- Effect_of_microstructure_on_the_impact_toughness_aDocument13 pagesEffect_of_microstructure_on_the_impact_toughness_astoiloff.dimitarNo ratings yet

- physics 18Document1 pagephysics 18stoiloff.dimitarNo ratings yet

- physics 14Document1 pagephysics 14stoiloff.dimitarNo ratings yet

- physics 15Document1 pagephysics 15stoiloff.dimitarNo ratings yet

- physics 16Document1 pagephysics 16stoiloff.dimitarNo ratings yet

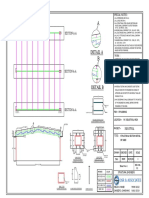

- Building Construction 4 Types of Trusses: King Post Queen Post Multiple King PostDocument4 pagesBuilding Construction 4 Types of Trusses: King Post Queen Post Multiple King PostKunal NaskarNo ratings yet

- Manufacturing Processes I - Machining ProcessesDocument57 pagesManufacturing Processes I - Machining ProcessesImtiajur Rahman AyonNo ratings yet

- Failure of Titanic PDFDocument26 pagesFailure of Titanic PDFAkshay BhaleraoNo ratings yet

- Course Update: Ceramic MaterialsDocument7 pagesCourse Update: Ceramic Materialssayhigaurav07No ratings yet

- C83600 (Red Brass) PDFDocument2 pagesC83600 (Red Brass) PDFshawntsungNo ratings yet

- Science: Quarter 2, WK 4 - Module 4Document36 pagesScience: Quarter 2, WK 4 - Module 4Ericha Solomon83% (6)

- GlassDocument23 pagesGlasssamatha100% (1)

- MakuriDocument11 pagesMakuriJhoncastilloNo ratings yet

- Astm A668Document2 pagesAstm A668ErickNo ratings yet

- Main CatalogDocument151 pagesMain CatalogНикита МельниковNo ratings yet

- Bergner Plano FINALDocument11 pagesBergner Plano FINALRakesh KumarNo ratings yet

- SuhnerBollardsHandrailsTubeCatalogue FINALDocument20 pagesSuhnerBollardsHandrailsTubeCatalogue FINALLee NagleNo ratings yet

- Hydraulic & Manual Tools: Flexible Busbar and Copper Busbar Manipulation and Transformation SolutionsDocument28 pagesHydraulic & Manual Tools: Flexible Busbar and Copper Busbar Manipulation and Transformation SolutionschellaliNo ratings yet

- 344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel StructureDocument327 pages344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel Structurej f100% (1)

- Lecture 12 (Alluminium and Its Alloy)Document16 pagesLecture 12 (Alluminium and Its Alloy)Nhihonium oxideNo ratings yet

- Not For Production Use (For Reference Only) : ASTM A778-01Document1 pageNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefNo ratings yet

- Specification Sheet: 2205: (UNS S32205/S31803)Document2 pagesSpecification Sheet: 2205: (UNS S32205/S31803)Haytham MohamedNo ratings yet

- Pneumatic Heavy-Duty Quarter Turn ActautorDocument14 pagesPneumatic Heavy-Duty Quarter Turn ActautorPriyanka rajpurohitNo ratings yet

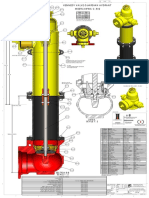

- Kennedy Valve Guardian Hydrant Meets Awwa C-502: Detail Scale 1: 2Document1 pageKennedy Valve Guardian Hydrant Meets Awwa C-502: Detail Scale 1: 2Amjed HNo ratings yet

- Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements ForDocument31 pagesSteel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements Foralucard375100% (1)

- Senior Welding Inspection, Steels - WIS 10: Question Paper (MSR-SWI-3)Document5 pagesSenior Welding Inspection, Steels - WIS 10: Question Paper (MSR-SWI-3)Chandra MohanNo ratings yet

- RRW 410 FDocument90 pagesRRW 410 FvNo ratings yet

- D2 Data SheetDocument9 pagesD2 Data SheetJim ToddNo ratings yet

- NIST Standard Reference Materials® 2021 CatalogDocument118 pagesNIST Standard Reference Materials® 2021 CatalogMetal deptNo ratings yet

- Sachde Prints 30.09.20Document1 pageSachde Prints 30.09.20tejas nandaniNo ratings yet

- Manufacturing ProcessDocument6 pagesManufacturing Processbro nawalibmatNo ratings yet

- Progress in Materials Science: Lenka Kunc Ická, Radim Kocich, Terry C. LoweDocument49 pagesProgress in Materials Science: Lenka Kunc Ická, Radim Kocich, Terry C. LoweDaniel FridmanNo ratings yet

- Hex Bolt (Din 933) PDFDocument1 pageHex Bolt (Din 933) PDFKABIR CHOPRANo ratings yet

- Experience Innovation Quality: Applications of Macalloy 650 StainlessDocument2 pagesExperience Innovation Quality: Applications of Macalloy 650 StainlessMaitrabarun KarjeeNo ratings yet

- TI Tools - Lip Seal - Main Shaft Bushing Tool 2908-0150-80Document1 pageTI Tools - Lip Seal - Main Shaft Bushing Tool 2908-0150-80parabellum871No ratings yet

physics 13

physics 13

Uploaded by

stoiloff.dimitarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

physics 13

physics 13

Uploaded by

stoiloff.dimitarCopyright:

Available Formats

113. For welding what metals is welding in a protected gas environment used?

At e.d.z. in shielding gas environments, the welding arc and electrode are protected by a gas that

protects the molten metal from its interaction with the surrounding air. It is used for welding carbon,

low-alloyed and high-alloyed steels of aluminum, magnesium, nickel, copper, titanium, zirconium.

Welding can be performed both in a still gas environment and by supplying the shielding gas in the

form of a jet with the help of a special torch.

114. Is it possible to weld sheet steel with a thickness of more than 5 mm using a gas flame. welding?

Yes, it is possible with right-hand welding (the torch moves from left to right and in front of the filler

rod. In this case, the flame is directly directed at the metal tub, so it is better protected from the air

and receives a greater amount of heat of the flame compared to the left welding. In addition, the

flame is able to cover the root of the seam more fully and melt the welded ends. Therefore, with

thicknesses of the welded parts > 3 mm.)

115. What determines the quality of the welding flame in a gas torch? Depending on the ratio of

acetylene and oxygen C2H2:O2 = t, flames of different chemical nature can be set:

116. What are the advantages and disadvantages of electric beam welding? Advantages: Precise,

almost distortion-free welding of thin (> 0.1 mm} to thick-walled (< 150.-.200 mm) products. In many

cases, it can be applied as a final technology, without the need for additional machining. Typical case

is the welding of finished gears in gear boxes. ; Welding of both common structural steels and

reactive metals that are sensitive to ambient gases and have a high melting point and/or high

thermal conductivity - titanium, nickel, molybdenum, etc. Production of responsible products for the

space and aircraft industry (turbines, fuel tanks, etc.) Disadvantages of EL welding ( as a production

method) are reduced to: high investment costs for welding equipment; longer auxiliary times - on

average from 1 to 5 hours to reach the required vacuum in the working chamber; necessity of very

accurate mechanical preparation of the surfaces to be joined.

117. Where is laser welding used? It is mainly used as a precise method for joining details of steel

and non-ferrous metals with a thickness of 0.01 to 10 mm in the various fields of engineering:

equipment construction, electrical engineering, chemical, energy and general mechanical

engineering, etc.

118. What is the principle of electrical resistance? welding? Electric resistance welding (ESW for

short) is the most widely applied pressure welding method. It additionally uses heat, which is

released when an electric current passes through the connection point as a result of its contact

resistance. The principle of the conductive ECZ can be traced most easily in the case of a point

connection: In point electrofusion welding, two or more parts are joined by overlapping, being

pressed by two electrodes connected to the secondary circuit of a welding current source

(transformer). As a result of the local heating, part of the metal of the two parts, located immediately

under the electrodes, melts and forms an elliptical weld pool. Under the continuous pressure of the

electrodes, the crystallizing metal of the bath and the dough-like metal located around it deform

plastically and form the so-called welding point.

You might also like

- Fundamentals of Vehicle Dynamics by Thomas D GillespieDocument99 pagesFundamentals of Vehicle Dynamics by Thomas D GillespieYogesh Chandrawanshi0% (1)

- Resistance and Special WeldingDocument24 pagesResistance and Special WeldingKBSMANITNo ratings yet

- Introduction To WeldingDocument192 pagesIntroduction To WeldingMirtunjay Kumar88% (8)

- PART 166 What Is Spot WeldingDocument4 pagesPART 166 What Is Spot Weldingravindra_jivaniNo ratings yet

- Advanced Welding Process (Welding)Document58 pagesAdvanced Welding Process (Welding)Sk SamsuddinNo ratings yet

- WeldingDocument16 pagesWeldingwhoami7174No ratings yet

- Resistance WeldingDocument18 pagesResistance WeldingAnand JainNo ratings yet

- Tigweld DoneDocument16 pagesTigweld DoneSenthil KumarNo ratings yet

- Electric Resistance WeldingDocument30 pagesElectric Resistance WeldingSenthil KumarNo ratings yet

- Sonargaon University Shop 160 Welding - 2: Prepared by Zayed AhmedDocument19 pagesSonargaon University Shop 160 Welding - 2: Prepared by Zayed Ahmedদুর্জয় দুর্বারNo ratings yet

- Resistance WeldingDocument27 pagesResistance WeldingridaNo ratings yet

- Advanced Welding Process and Inspection: Q Α I R t Q= k I RtDocument22 pagesAdvanced Welding Process and Inspection: Q Α I R t Q= k I RtDarshan SNo ratings yet

- The Importance of Shipboard Welding in Preserving TrimDocument34 pagesThe Importance of Shipboard Welding in Preserving TrimJhudiel Carlo AndoyNo ratings yet

- Unit II - mt1Document24 pagesUnit II - mt1Mareeswaran Maruthamuthu M0% (1)

- WeldingDocument7 pagesWeldingJuanNo ratings yet

- Manufacturing Technology: Tig Welding - Process AnalysisDocument8 pagesManufacturing Technology: Tig Welding - Process AnalysisshubhamNo ratings yet

- ElectrodeDocument29 pagesElectrodecibtc wws rypsNo ratings yet

- Arc Welding Refers To A Group Of: SolderingDocument12 pagesArc Welding Refers To A Group Of: SolderingBhushan VermaNo ratings yet

- Welding ShopDocument5 pagesWelding ShopWaqas Hussain MalikNo ratings yet

- Non-Arc Welding ProcessesDocument30 pagesNon-Arc Welding ProcessesKhalid El MasryNo ratings yet

- "Spot Welding": Mindanao University of Science and Technology C.M. Recto Avenue, Lapasan, Cagayan de Oro CityDocument10 pages"Spot Welding": Mindanao University of Science and Technology C.M. Recto Avenue, Lapasan, Cagayan de Oro CityAcerz VillagraciaNo ratings yet

- Chapter-4 Principle of Selected Joining and Assembling Process A Brief History of WeldingDocument12 pagesChapter-4 Principle of Selected Joining and Assembling Process A Brief History of WeldingFira tubeNo ratings yet

- Experiment No 02: AIM To Study Resistance Welding & Its SetupDocument6 pagesExperiment No 02: AIM To Study Resistance Welding & Its Setuprahul9981759900No ratings yet

- Arc Welding Process PDFDocument12 pagesArc Welding Process PDFBiswanath RoulNo ratings yet

- Electrode Converted Into TextDocument14 pagesElectrode Converted Into TextNeha NimbarkNo ratings yet

- Welding and Joining Process: Basic Concept of WeldingDocument7 pagesWelding and Joining Process: Basic Concept of WeldingNaresh kumarNo ratings yet

- Notes-22 7Document20 pagesNotes-22 7Dan JonNo ratings yet

- Work Shop Pratice - MyDocument8 pagesWork Shop Pratice - MyTaran TulaNo ratings yet

- TIG Presentation.Document31 pagesTIG Presentation.Md Anamul HoqueNo ratings yet

- 304 SsDocument54 pages304 Ssshakir ramzanNo ratings yet

- Chapter 3-Electric WeldingDocument32 pagesChapter 3-Electric WeldingAMAR CHAND MEENANo ratings yet

- Welding: Al-Hussein Bin Talal UniversityDocument8 pagesWelding: Al-Hussein Bin Talal UniversityJaber AbdallahNo ratings yet

- WeldingDocument28 pagesWeldingShahdan DahlanNo ratings yet

- Welding and Cutting ProcessDocument60 pagesWelding and Cutting Processquiron2010100% (1)

- Welding Types of Welding Gas Welding (Oxy-Acetylene) Arc Welding (Metal Arc) Merits & Limitations of Welding Process Application ConclusionDocument14 pagesWelding Types of Welding Gas Welding (Oxy-Acetylene) Arc Welding (Metal Arc) Merits & Limitations of Welding Process Application ConclusionAjinkya MoreNo ratings yet

- Welding Details Slide - 1Document32 pagesWelding Details Slide - 1Azmain IktedarNo ratings yet

- Welding: Dr. Sunil JhaDocument21 pagesWelding: Dr. Sunil JharassdriverNo ratings yet

- Principle of Arc WeldingDocument60 pagesPrinciple of Arc Weldingsamurai7_7786% (7)

- Electric Welding: Some of The Advantages of Welding AreDocument11 pagesElectric Welding: Some of The Advantages of Welding ArePriyadarshi MNo ratings yet

- 6 Electric WeldingDocument19 pages6 Electric WeldingSujan MajiNo ratings yet

- WeldingDocument169 pagesWeldingamarparimi100% (1)

- Resistance WeldingDocument21 pagesResistance WeldingAyush KumarNo ratings yet

- Welding WorkshopDocument29 pagesWelding WorkshopAnonymous h5OeGoX3MTNo ratings yet

- 2 WeldingDocument24 pages2 WeldingpriyanshuvraoNo ratings yet

- WELDINGDocument8 pagesWELDINGManibhusan MohapatroNo ratings yet

- Welding: Edge PreparationsDocument8 pagesWelding: Edge PreparationsManibhusanNo ratings yet

- Welding Rods Welding Rods: Manual Metal Arc Welding (MMA)Document6 pagesWelding Rods Welding Rods: Manual Metal Arc Welding (MMA)CT0011No ratings yet

- 87 Technical Sheet - Tig WeldingDocument1 page87 Technical Sheet - Tig WeldingZeu AressNo ratings yet

- Resistance WeldingDocument13 pagesResistance WeldingAashishSethiNo ratings yet

- Electric Welding: Unit-IiDocument41 pagesElectric Welding: Unit-IiKUMAR SNo ratings yet

- Miyachi Fundamentals Resistance WeldingDocument8 pagesMiyachi Fundamentals Resistance Weldinghlgc63No ratings yet

- MT - 2Document15 pagesMT - 2Arnav PandeyNo ratings yet

- About Welding Process 46Document1 pageAbout Welding Process 46XerexNo ratings yet

- Welding TechnologyDocument218 pagesWelding Technologywbl_200789% (9)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Welding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsFrom EverandWelding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsNo ratings yet

- Effect_of_microstructure_on_the_impact_toughness_aDocument13 pagesEffect_of_microstructure_on_the_impact_toughness_astoiloff.dimitarNo ratings yet

- physics 18Document1 pagephysics 18stoiloff.dimitarNo ratings yet

- physics 14Document1 pagephysics 14stoiloff.dimitarNo ratings yet

- physics 15Document1 pagephysics 15stoiloff.dimitarNo ratings yet

- physics 16Document1 pagephysics 16stoiloff.dimitarNo ratings yet

- Building Construction 4 Types of Trusses: King Post Queen Post Multiple King PostDocument4 pagesBuilding Construction 4 Types of Trusses: King Post Queen Post Multiple King PostKunal NaskarNo ratings yet

- Manufacturing Processes I - Machining ProcessesDocument57 pagesManufacturing Processes I - Machining ProcessesImtiajur Rahman AyonNo ratings yet

- Failure of Titanic PDFDocument26 pagesFailure of Titanic PDFAkshay BhaleraoNo ratings yet

- Course Update: Ceramic MaterialsDocument7 pagesCourse Update: Ceramic Materialssayhigaurav07No ratings yet

- C83600 (Red Brass) PDFDocument2 pagesC83600 (Red Brass) PDFshawntsungNo ratings yet

- Science: Quarter 2, WK 4 - Module 4Document36 pagesScience: Quarter 2, WK 4 - Module 4Ericha Solomon83% (6)

- GlassDocument23 pagesGlasssamatha100% (1)

- MakuriDocument11 pagesMakuriJhoncastilloNo ratings yet

- Astm A668Document2 pagesAstm A668ErickNo ratings yet

- Main CatalogDocument151 pagesMain CatalogНикита МельниковNo ratings yet

- Bergner Plano FINALDocument11 pagesBergner Plano FINALRakesh KumarNo ratings yet

- SuhnerBollardsHandrailsTubeCatalogue FINALDocument20 pagesSuhnerBollardsHandrailsTubeCatalogue FINALLee NagleNo ratings yet

- Hydraulic & Manual Tools: Flexible Busbar and Copper Busbar Manipulation and Transformation SolutionsDocument28 pagesHydraulic & Manual Tools: Flexible Busbar and Copper Busbar Manipulation and Transformation SolutionschellaliNo ratings yet

- 344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel StructureDocument327 pages344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel Structurej f100% (1)

- Lecture 12 (Alluminium and Its Alloy)Document16 pagesLecture 12 (Alluminium and Its Alloy)Nhihonium oxideNo ratings yet

- Not For Production Use (For Reference Only) : ASTM A778-01Document1 pageNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefNo ratings yet

- Specification Sheet: 2205: (UNS S32205/S31803)Document2 pagesSpecification Sheet: 2205: (UNS S32205/S31803)Haytham MohamedNo ratings yet

- Pneumatic Heavy-Duty Quarter Turn ActautorDocument14 pagesPneumatic Heavy-Duty Quarter Turn ActautorPriyanka rajpurohitNo ratings yet

- Kennedy Valve Guardian Hydrant Meets Awwa C-502: Detail Scale 1: 2Document1 pageKennedy Valve Guardian Hydrant Meets Awwa C-502: Detail Scale 1: 2Amjed HNo ratings yet

- Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements ForDocument31 pagesSteel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements Foralucard375100% (1)

- Senior Welding Inspection, Steels - WIS 10: Question Paper (MSR-SWI-3)Document5 pagesSenior Welding Inspection, Steels - WIS 10: Question Paper (MSR-SWI-3)Chandra MohanNo ratings yet

- RRW 410 FDocument90 pagesRRW 410 FvNo ratings yet

- D2 Data SheetDocument9 pagesD2 Data SheetJim ToddNo ratings yet

- NIST Standard Reference Materials® 2021 CatalogDocument118 pagesNIST Standard Reference Materials® 2021 CatalogMetal deptNo ratings yet

- Sachde Prints 30.09.20Document1 pageSachde Prints 30.09.20tejas nandaniNo ratings yet

- Manufacturing ProcessDocument6 pagesManufacturing Processbro nawalibmatNo ratings yet

- Progress in Materials Science: Lenka Kunc Ická, Radim Kocich, Terry C. LoweDocument49 pagesProgress in Materials Science: Lenka Kunc Ická, Radim Kocich, Terry C. LoweDaniel FridmanNo ratings yet

- Hex Bolt (Din 933) PDFDocument1 pageHex Bolt (Din 933) PDFKABIR CHOPRANo ratings yet

- Experience Innovation Quality: Applications of Macalloy 650 StainlessDocument2 pagesExperience Innovation Quality: Applications of Macalloy 650 StainlessMaitrabarun KarjeeNo ratings yet

- TI Tools - Lip Seal - Main Shaft Bushing Tool 2908-0150-80Document1 pageTI Tools - Lip Seal - Main Shaft Bushing Tool 2908-0150-80parabellum871No ratings yet