Professional Documents

Culture Documents

Cable XLPE

Cable XLPE

Uploaded by

gradydaniel14Copyright:

Available Formats

You might also like

- PPC McqsDocument43 pagesPPC McqsArbab Ali100% (1)

- Bring-Your-Own-Device ("Byod") Acceptable Use PolicyDocument7 pagesBring-Your-Own-Device ("Byod") Acceptable Use PolicyAmanNo ratings yet

- B.04. Cable XHHW-2 - General CableDocument1 pageB.04. Cable XHHW-2 - General CableBenjamín Benzaquen SalazarNo ratings yet

- XLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeDocument1 pageXLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeLEMAGA GROUPNo ratings yet

- TECK90: XLPE/PVC/AIA/PVC, Control and Power, Armored 1000 V, CSA TECK90, Three ConductorDocument2 pagesTECK90: XLPE/PVC/AIA/PVC, Control and Power, Armored 1000 V, CSA TECK90, Three ConductorjxvichoNo ratings yet

- General Cable VFDDocument2 pagesGeneral Cable VFDFrancisco MartinezNo ratings yet

- R4 CableDocument1 pageR4 CableVijay KarthikeyanNo ratings yet

- IndustrialCatalog PDocument1 pageIndustrialCatalog PEnekoNo ratings yet

- R2 CableDocument1 pageR2 CableKristaNo ratings yet

- Single Conductor 15KV, Shielded, MV-105Document2 pagesSingle Conductor 15KV, Shielded, MV-105henry hernandezNo ratings yet

- FINALDocument38 pagesFINALJasmeen KaurNo ratings yet

- Teck 90Document1 pageTeck 90fernandoNo ratings yet

- CVTC VFD - Flexible Motor Supply Cable: XLPE/PVC, Low-Voltage Power, Al/Polyester/AI + TC Braid ShieldedDocument2 pagesCVTC VFD - Flexible Motor Supply Cable: XLPE/PVC, Low-Voltage Power, Al/Polyester/AI + TC Braid ShieldedIbrahim ElkhatibNo ratings yet

- 358Document2 pages358Christian Camilo Suarez RodriguezNo ratings yet

- GXL CablesDocument1 pageGXL CablesVijay KarthikeyanNo ratings yet

- Siemon-Category6a Futp Cable International Spec-SheetDocument2 pagesSiemon-Category6a Futp Cable International Spec-SheetsrobayocNo ratings yet

- TWP CableDocument1 pageTWP CableKristaNo ratings yet

- FLR4G11Y-FL4G11Y CablesDocument1 pageFLR4G11Y-FL4G11Y CablesVijay KarthikeyanNo ratings yet

- XTEInterface ServletDocument2 pagesXTEInterface ServletRodni EmslieNo ratings yet

- TXL CableDocument1 pageTXL CableVijay KarthikeyanNo ratings yet

- RK CableDocument1 pageRK CableKristaNo ratings yet

- Data Sheet Areamaster Generation 2 Led Luminaire Appleton en Us 7437666Document2 pagesData Sheet Areamaster Generation 2 Led Luminaire Appleton en Us 7437666william Manrique PerezNo ratings yet

- SXL CableDocument1 pageSXL CableVijay KarthikeyanNo ratings yet

- Battery CablesDocument1 pageBattery CablesKristaNo ratings yet

- Application Product Construction Technical Data: 2D ViewDocument1 pageApplication Product Construction Technical Data: 2D ViewseenudesignNo ratings yet

- VDF Apantallado GENERAL CABLEDocument8 pagesVDF Apantallado GENERAL CABLEEduardo SolisNo ratings yet

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيNo ratings yet

- EUPEN Datasheet ALC Airport Pavement Secondary Cable 600V Ed 06 2020-10-12Document1 pageEUPEN Datasheet ALC Airport Pavement Secondary Cable 600V Ed 06 2020-10-12Prem HNo ratings yet

- Flame Retardant, LSHF Cables: 3. Cable Construction D EtailsDocument4 pagesFlame Retardant, LSHF Cables: 3. Cable Construction D EtailsasNo ratings yet

- FLR6Y-B CablesDocument1 pageFLR6Y-B CablesKristaNo ratings yet

- General BICC 279700Document4 pagesGeneral BICC 279700Byron PanchiNo ratings yet

- FLRY11Y CablesDocument1 pageFLRY11Y CablesKristaNo ratings yet

- Low Voltage CablesDocument1 pageLow Voltage CablesKristaNo ratings yet

- FLRYWK CablesDocument1 pageFLRYWK CablesKristaNo ratings yet

- Unishield - Uniblend 5kvDocument2 pagesUnishield - Uniblend 5kvfmillan5018No ratings yet

- SGT CableDocument1 pageSGT CableVijay KarthikeyanNo ratings yet

- Opgw: Optical Cables Optical Ground WireDocument3 pagesOpgw: Optical Cables Optical Ground WireMilagros Mercedes Olmos CervantesNo ratings yet

- Auto 125 CableDocument1 pageAuto 125 CableKristaNo ratings yet

- Technical Specification - Grounding - WP4Document6 pagesTechnical Specification - Grounding - WP4nnNo ratings yet

- 3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Document2 pages3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Yesith AlmanzaNo ratings yet

- Copper Building Wire Type THHNTHWN 21 PDFDocument2 pagesCopper Building Wire Type THHNTHWN 21 PDFEmilySisnerosMenorias100% (1)

- Buildingwires Datasheet COPPER BUILDING WIRE TYPE THHNTHWN 21Document2 pagesBuildingwires Datasheet COPPER BUILDING WIRE TYPE THHNTHWN 21ronnel franzuelaNo ratings yet

- NYFGb YDocument5 pagesNYFGb YMuhammad Adrianto LubisNo ratings yet

- SGX CableDocument1 pageSGX CableVijay KarthikeyanNo ratings yet

- SGX CableDocument1 pageSGX CableKristaNo ratings yet

- Paar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeDocument2 pagesPaar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeKelvin NgumbauNo ratings yet

- 9 - 32" (7.32 MM) Monoconductor 1N29-S77 Corrosion Resistant - Camesa EMCDocument2 pages9 - 32" (7.32 MM) Monoconductor 1N29-S77 Corrosion Resistant - Camesa EMCwaynecruzz29No ratings yet

- Enclosure Type: PL513: PL Series GRP EnclosuresDocument1 pageEnclosure Type: PL513: PL Series GRP EnclosuresOel NaubNo ratings yet

- SC - Low Voltage Catalogue - Aluminium - 2020Document18 pagesSC - Low Voltage Catalogue - Aluminium - 2020ooi.impacNo ratings yet

- XLPE/XL-CPE, Instrumentation, Shielded 300 V, UL Type PLTC, Overall Shielded Pairs/TriadsDocument1 pageXLPE/XL-CPE, Instrumentation, Shielded 300 V, UL Type PLTC, Overall Shielded Pairs/TriadsRey AbarientosNo ratings yet

- Audio Cable D3651Document2 pagesAudio Cable D3651maherNo ratings yet

- Siechem WXC CableDocument1 pageSiechem WXC CableVijay KarthikeyanNo ratings yet

- N2XSY 3 X (1.5-300) MM 0.6/1 KVDocument1 pageN2XSY 3 X (1.5-300) MM 0.6/1 KVhenry_gtNo ratings yet

- 5b47751f0bf85761056929Document3 pages5b47751f0bf85761056929Samy HernándezNo ratings yet

- Tri-Rated Rev005Document2 pagesTri-Rated Rev005Jean Pierre Goossens100% (1)

- PHILFLEX DuplexDocument1 pagePHILFLEX DuplexPrefer Electrical Engineering And SupplyNo ratings yet

- 交联聚乙烯绝缘,钢丝铠装,聚氯乙烯套管电力电缆Document3 pages交联聚乙烯绝缘,钢丝铠装,聚氯乙烯套管电力电缆jiahuanhe2023No ratings yet

- Ficha Técnica CABLE ERP SOUTHWIREDocument3 pagesFicha Técnica CABLE ERP SOUTHWIREGhislaine SousaNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Unit 22Document4 pagesUnit 22Thu ĐàoNo ratings yet

- Mcqs On Indian Evidence Act (With Answers)Document39 pagesMcqs On Indian Evidence Act (With Answers)Akanksha DubeyNo ratings yet

- Terms of Reference of Pta Organization Position Terms of ReferencesDocument3 pagesTerms of Reference of Pta Organization Position Terms of ReferencesCastor Jr JavierNo ratings yet

- The Internal Revenue Service, A Private CorporationDocument7 pagesThe Internal Revenue Service, A Private Corporationnakan103No ratings yet

- The Unionist February 2014Document8 pagesThe Unionist February 2014novvotikNo ratings yet

- The Courage To Be Happy - Augusto Boal, Legislative Theatre, and The 7th International (1146376)Document11 pagesThe Courage To Be Happy - Augusto Boal, Legislative Theatre, and The 7th International (1146376)Ashwini JayaramanNo ratings yet

- 41Document2 pages41KennethAnthonyMagdamitNo ratings yet

- Test Bank For Business Ethics Case Studies and Selected Readings 7th EditionDocument13 pagesTest Bank For Business Ethics Case Studies and Selected Readings 7th Editionuntradedfantan3wg75100% (28)

- Government Service Insurance System vs. Apolinario K. Daymiel G.R. No. 218097. March 11, 2019 FactsDocument2 pagesGovernment Service Insurance System vs. Apolinario K. Daymiel G.R. No. 218097. March 11, 2019 FactsJILL SEBALLOSNo ratings yet

- IS-U Device Removal (Billing-Related) - User-Exits and Database Table Entries - Utilities Industry - SCN Wiki PDFDocument19 pagesIS-U Device Removal (Billing-Related) - User-Exits and Database Table Entries - Utilities Industry - SCN Wiki PDFmundeckeNo ratings yet

- La Union ReportDocument10 pagesLa Union Reportrizzvill espina100% (2)

- Citric Acid SDS11350 PDFDocument7 pagesCitric Acid SDS11350 PDFSyafiq Mohd NohNo ratings yet

- Teachers' Rights Mini-Guide: Provide Legal AdviceDocument2 pagesTeachers' Rights Mini-Guide: Provide Legal Adviceblackantelope_ericNo ratings yet

- Auto Debit Form (60801026)Document2 pagesAuto Debit Form (60801026)Hanafi AminNo ratings yet

- Thanks For Your Order!: Billing Information Payment Details Receipt DetailsDocument1 pageThanks For Your Order!: Billing Information Payment Details Receipt Detailschalapathi psNo ratings yet

- Genitive Case FixaçãoDocument4 pagesGenitive Case Fixaçãoryan 01 da EPCArNo ratings yet

- Pyrogel Xt-E MsdsDocument11 pagesPyrogel Xt-E MsdsjitendraNo ratings yet

- EPC Best Practice Guidelines V1.0Document104 pagesEPC Best Practice Guidelines V1.0Thomas Dwi Putra SalimNo ratings yet

- Marcoso v. CADocument2 pagesMarcoso v. CAPrincess Samantha SarcedaNo ratings yet

- Guru Nanak in HistoryDocument358 pagesGuru Nanak in HistoryActiya KhanNo ratings yet

- Eti Base Code EnglishDocument4 pagesEti Base Code EnglishJohn RajeshNo ratings yet

- Philippine Laws On Housing and Human SettlementsDocument8 pagesPhilippine Laws On Housing and Human SettlementsJoJONo ratings yet

- Yogesh P Assignment PDFDocument2 pagesYogesh P Assignment PDFಯೋಗೇಶ್ ಪಿNo ratings yet

- NatwestDocument1 pageNatwestVinay SinghNo ratings yet

- NI Speedy 33Document43 pagesNI Speedy 33sitkastanNo ratings yet

- 1624 1637Document5 pages1624 1637cris50% (2)

- Reed Return of PropertyDocument10 pagesReed Return of PropertyHope StephanNo ratings yet

- Most Popular Newspapers and Magazines in MoldovaDocument2 pagesMost Popular Newspapers and Magazines in MoldovaAdriana AntoniNo ratings yet

Cable XLPE

Cable XLPE

Uploaded by

gradydaniel14Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable XLPE

Cable XLPE

Uploaded by

gradydaniel14Copyright:

Available Formats

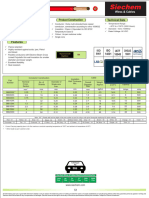

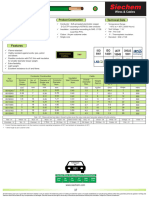

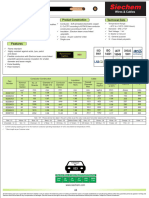

SPEC 5175

January, 2015

XHHW-2 CT High Speed

XLPE, Low-Voltage Power, 600 V

UL Type XHHW-2, CT Rated, Single Conductor, Copper

Product Construction:

Conductor:

• 14 AWG thru 750 kcmil annealed bare copper per

ASTM B3

• Class B stranding per ASTM B8

Insulation:

• Flame-retardant Cross-linked Polyethylene (XLPE)

Print:

• GENERAL CABLE® (PLANT OF MFG) AWG/ Applications: Compliances:

KCMIL LOW FRICTION* TYPE XHHW-2 (UL) 600 V • General purpose building wire for use primarily in Industry Compliances:

SUN RES FOR CT USE** MONTH/YEAR OF MFG conduit or other recognized raceways as specified • National Electric Code (NEC)

SEQUENTIAL FOOTAGE MARK in the National Electrical Code (NEC®) • UL 44 Standard for Rubber Insulated Wire

* Sizes 14 AWG - 10 AWG do not include “LOW FRICTION”

• Industrial environments where superior insulation and Cable

toughness and chemical resistance are required • ICEA S-95-658/NEMA WC70

** Sizes smaller than 1/0 AWG do not include “SUN RES FOR

CT USE” • Maximum operating temperature not to exceed • UL Listed as Type XHHW-2, UL File # E90494

90˚C in dry or wet locations • OSHA Acceptable

Options: • In free air, raceways or cable trays in accordance Flame Test Compliances:

• Tinned copper conductor with NEC • UL 1685, 1/0 AWG and larger

• Full colored insulation Other Compliances:

Features: • EPA 40 CFR, Part 261 for leachable

• Low friction for easy pulling on 8 AWG and larger lead content per TCLP

• “FOR CT USE” on 1/0 AWG and larger • RoHS Compliant

• Sunlight-resistant for 1/0 AWG and larger, all colors

• Rated at 90˚C wet or dry Packaging:

• Smaller cable O.D. • Material cut to length and shipped on

• Excellent electrical, thermal and physical properties non-returnable wood reels

• Excellent resistance to moisture

• Excellent resistance to crush, compression cuts and

heat deformation

COPPER

MINIMUM AVG. WEIGHT NET WEIGHT AMPACITY (1)

NOMINAL COND. INSULATION NOMINAL CABLE

CATALOG COND. SIZE NUMBER DIAMETER THICKNESS DIAMETER LBS/ LBS/

NUMBER (AWG or kcmil) OF WIRES INCHES mm INCHES mm INCHES mm 1000 FT kg/km 1000 FT kg/km 90°C

14 AWG - 750 kcmil CONDUCTORS

391070 14 7 0.07 1.80 0.030 0.76 0.13 3.38 12 18 17 25 25

391080 12 7 0.09 2.26 0.030 0.76 0.15 3.84 20 30 26 39 30

391090 10 7 0.11 2.87 0.030 0.76 0.18 4.57 32 48 38 57 40

5175.008 8 7 0.14 3.56 0.045 1.14 0.24 6.10 51 76 65 97 55

5175.006 6 7 0.18 4.57 0.045 1.14 0.28 7.11 81 121 99 147 75

5175.004 4 7 0.23 5.84 0.045 1.14 0.33 8.38 129 192 152 226 95

5175.002 2 7 0.29 7.37 0.045 1.14 0.39 9.91 205 305 233 347 130

5175.001 1 19 0.32 8.13 0.055 1.40 0.44 11.18 256 381 293 437 145

5175.110 1/0 19 0.36 9.14 0.055 1.40 0.48 12.19 326 485 364 572 170

5175.210 2/0 19 0.41 10.41 0.055 1.40 0.53 13.46 411 612 453 674 195

5175.310 3/0 19 0.46 11.68 0.055 1.40 0.58 14.73 518 772 565 842 225

5175.410 4/0 19 0.51 12.95 0.055 1.40 0.63 16.00 653 972 706 1051 260

5175.250 250 37 0.56 14.22 0.065 1.65 0.70 17.78 722 1074 837 1246 290

5175.350 350 37 0.66 16.76 0.065 1.65 0.80 20.32 1081 1609 1157 1722 350

5175.500 500 37 0.79 20.07 0.065 1.65 0.93 23.62 1544 2298 1634 2432 430

5175.600 600 37 0.87 22.10 0.080 2.03 1.04 26.42 1853 2758 1972 2935 475

5175.750 750 61 0.98 24.89 0.080 2.03 1.15 29.21 2316 3447 2448 3643 535

Dimensions and weights are nominal; subject to industry tolerances.

(1) Allowable ampacities shown are for general use as specified by the National Electric Code, 2011 Edition, Section 310.15(B)(16). Adjustments and corrections may apply:

90°C – Wet or dry locations. For ampacity derating purposes.

Dwelling – For dwelling units, conductors shall be permitted as listed ampacities at 120/240-volt, 3-wire, single-phase services and feeders.

Phone: 888-593-3355

www.generalcable.com

You might also like

- PPC McqsDocument43 pagesPPC McqsArbab Ali100% (1)

- Bring-Your-Own-Device ("Byod") Acceptable Use PolicyDocument7 pagesBring-Your-Own-Device ("Byod") Acceptable Use PolicyAmanNo ratings yet

- B.04. Cable XHHW-2 - General CableDocument1 pageB.04. Cable XHHW-2 - General CableBenjamín Benzaquen SalazarNo ratings yet

- XLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeDocument1 pageXLPE/PVC, Low-Voltage Power, Unshielded 600 V, UL Type TC-ER - Method 4 Color CodeLEMAGA GROUPNo ratings yet

- TECK90: XLPE/PVC/AIA/PVC, Control and Power, Armored 1000 V, CSA TECK90, Three ConductorDocument2 pagesTECK90: XLPE/PVC/AIA/PVC, Control and Power, Armored 1000 V, CSA TECK90, Three ConductorjxvichoNo ratings yet

- General Cable VFDDocument2 pagesGeneral Cable VFDFrancisco MartinezNo ratings yet

- R4 CableDocument1 pageR4 CableVijay KarthikeyanNo ratings yet

- IndustrialCatalog PDocument1 pageIndustrialCatalog PEnekoNo ratings yet

- R2 CableDocument1 pageR2 CableKristaNo ratings yet

- Single Conductor 15KV, Shielded, MV-105Document2 pagesSingle Conductor 15KV, Shielded, MV-105henry hernandezNo ratings yet

- FINALDocument38 pagesFINALJasmeen KaurNo ratings yet

- Teck 90Document1 pageTeck 90fernandoNo ratings yet

- CVTC VFD - Flexible Motor Supply Cable: XLPE/PVC, Low-Voltage Power, Al/Polyester/AI + TC Braid ShieldedDocument2 pagesCVTC VFD - Flexible Motor Supply Cable: XLPE/PVC, Low-Voltage Power, Al/Polyester/AI + TC Braid ShieldedIbrahim ElkhatibNo ratings yet

- 358Document2 pages358Christian Camilo Suarez RodriguezNo ratings yet

- GXL CablesDocument1 pageGXL CablesVijay KarthikeyanNo ratings yet

- Siemon-Category6a Futp Cable International Spec-SheetDocument2 pagesSiemon-Category6a Futp Cable International Spec-SheetsrobayocNo ratings yet

- TWP CableDocument1 pageTWP CableKristaNo ratings yet

- FLR4G11Y-FL4G11Y CablesDocument1 pageFLR4G11Y-FL4G11Y CablesVijay KarthikeyanNo ratings yet

- XTEInterface ServletDocument2 pagesXTEInterface ServletRodni EmslieNo ratings yet

- TXL CableDocument1 pageTXL CableVijay KarthikeyanNo ratings yet

- RK CableDocument1 pageRK CableKristaNo ratings yet

- Data Sheet Areamaster Generation 2 Led Luminaire Appleton en Us 7437666Document2 pagesData Sheet Areamaster Generation 2 Led Luminaire Appleton en Us 7437666william Manrique PerezNo ratings yet

- SXL CableDocument1 pageSXL CableVijay KarthikeyanNo ratings yet

- Battery CablesDocument1 pageBattery CablesKristaNo ratings yet

- Application Product Construction Technical Data: 2D ViewDocument1 pageApplication Product Construction Technical Data: 2D ViewseenudesignNo ratings yet

- VDF Apantallado GENERAL CABLEDocument8 pagesVDF Apantallado GENERAL CABLEEduardo SolisNo ratings yet

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيNo ratings yet

- EUPEN Datasheet ALC Airport Pavement Secondary Cable 600V Ed 06 2020-10-12Document1 pageEUPEN Datasheet ALC Airport Pavement Secondary Cable 600V Ed 06 2020-10-12Prem HNo ratings yet

- Flame Retardant, LSHF Cables: 3. Cable Construction D EtailsDocument4 pagesFlame Retardant, LSHF Cables: 3. Cable Construction D EtailsasNo ratings yet

- FLR6Y-B CablesDocument1 pageFLR6Y-B CablesKristaNo ratings yet

- General BICC 279700Document4 pagesGeneral BICC 279700Byron PanchiNo ratings yet

- FLRY11Y CablesDocument1 pageFLRY11Y CablesKristaNo ratings yet

- Low Voltage CablesDocument1 pageLow Voltage CablesKristaNo ratings yet

- FLRYWK CablesDocument1 pageFLRYWK CablesKristaNo ratings yet

- Unishield - Uniblend 5kvDocument2 pagesUnishield - Uniblend 5kvfmillan5018No ratings yet

- SGT CableDocument1 pageSGT CableVijay KarthikeyanNo ratings yet

- Opgw: Optical Cables Optical Ground WireDocument3 pagesOpgw: Optical Cables Optical Ground WireMilagros Mercedes Olmos CervantesNo ratings yet

- Auto 125 CableDocument1 pageAuto 125 CableKristaNo ratings yet

- Technical Specification - Grounding - WP4Document6 pagesTechnical Specification - Grounding - WP4nnNo ratings yet

- 3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Document2 pages3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Yesith AlmanzaNo ratings yet

- Copper Building Wire Type THHNTHWN 21 PDFDocument2 pagesCopper Building Wire Type THHNTHWN 21 PDFEmilySisnerosMenorias100% (1)

- Buildingwires Datasheet COPPER BUILDING WIRE TYPE THHNTHWN 21Document2 pagesBuildingwires Datasheet COPPER BUILDING WIRE TYPE THHNTHWN 21ronnel franzuelaNo ratings yet

- NYFGb YDocument5 pagesNYFGb YMuhammad Adrianto LubisNo ratings yet

- SGX CableDocument1 pageSGX CableVijay KarthikeyanNo ratings yet

- SGX CableDocument1 pageSGX CableKristaNo ratings yet

- Paar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeDocument2 pagesPaar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeKelvin NgumbauNo ratings yet

- 9 - 32" (7.32 MM) Monoconductor 1N29-S77 Corrosion Resistant - Camesa EMCDocument2 pages9 - 32" (7.32 MM) Monoconductor 1N29-S77 Corrosion Resistant - Camesa EMCwaynecruzz29No ratings yet

- Enclosure Type: PL513: PL Series GRP EnclosuresDocument1 pageEnclosure Type: PL513: PL Series GRP EnclosuresOel NaubNo ratings yet

- SC - Low Voltage Catalogue - Aluminium - 2020Document18 pagesSC - Low Voltage Catalogue - Aluminium - 2020ooi.impacNo ratings yet

- XLPE/XL-CPE, Instrumentation, Shielded 300 V, UL Type PLTC, Overall Shielded Pairs/TriadsDocument1 pageXLPE/XL-CPE, Instrumentation, Shielded 300 V, UL Type PLTC, Overall Shielded Pairs/TriadsRey AbarientosNo ratings yet

- Audio Cable D3651Document2 pagesAudio Cable D3651maherNo ratings yet

- Siechem WXC CableDocument1 pageSiechem WXC CableVijay KarthikeyanNo ratings yet

- N2XSY 3 X (1.5-300) MM 0.6/1 KVDocument1 pageN2XSY 3 X (1.5-300) MM 0.6/1 KVhenry_gtNo ratings yet

- 5b47751f0bf85761056929Document3 pages5b47751f0bf85761056929Samy HernándezNo ratings yet

- Tri-Rated Rev005Document2 pagesTri-Rated Rev005Jean Pierre Goossens100% (1)

- PHILFLEX DuplexDocument1 pagePHILFLEX DuplexPrefer Electrical Engineering And SupplyNo ratings yet

- 交联聚乙烯绝缘,钢丝铠装,聚氯乙烯套管电力电缆Document3 pages交联聚乙烯绝缘,钢丝铠装,聚氯乙烯套管电力电缆jiahuanhe2023No ratings yet

- Ficha Técnica CABLE ERP SOUTHWIREDocument3 pagesFicha Técnica CABLE ERP SOUTHWIREGhislaine SousaNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Unit 22Document4 pagesUnit 22Thu ĐàoNo ratings yet

- Mcqs On Indian Evidence Act (With Answers)Document39 pagesMcqs On Indian Evidence Act (With Answers)Akanksha DubeyNo ratings yet

- Terms of Reference of Pta Organization Position Terms of ReferencesDocument3 pagesTerms of Reference of Pta Organization Position Terms of ReferencesCastor Jr JavierNo ratings yet

- The Internal Revenue Service, A Private CorporationDocument7 pagesThe Internal Revenue Service, A Private Corporationnakan103No ratings yet

- The Unionist February 2014Document8 pagesThe Unionist February 2014novvotikNo ratings yet

- The Courage To Be Happy - Augusto Boal, Legislative Theatre, and The 7th International (1146376)Document11 pagesThe Courage To Be Happy - Augusto Boal, Legislative Theatre, and The 7th International (1146376)Ashwini JayaramanNo ratings yet

- 41Document2 pages41KennethAnthonyMagdamitNo ratings yet

- Test Bank For Business Ethics Case Studies and Selected Readings 7th EditionDocument13 pagesTest Bank For Business Ethics Case Studies and Selected Readings 7th Editionuntradedfantan3wg75100% (28)

- Government Service Insurance System vs. Apolinario K. Daymiel G.R. No. 218097. March 11, 2019 FactsDocument2 pagesGovernment Service Insurance System vs. Apolinario K. Daymiel G.R. No. 218097. March 11, 2019 FactsJILL SEBALLOSNo ratings yet

- IS-U Device Removal (Billing-Related) - User-Exits and Database Table Entries - Utilities Industry - SCN Wiki PDFDocument19 pagesIS-U Device Removal (Billing-Related) - User-Exits and Database Table Entries - Utilities Industry - SCN Wiki PDFmundeckeNo ratings yet

- La Union ReportDocument10 pagesLa Union Reportrizzvill espina100% (2)

- Citric Acid SDS11350 PDFDocument7 pagesCitric Acid SDS11350 PDFSyafiq Mohd NohNo ratings yet

- Teachers' Rights Mini-Guide: Provide Legal AdviceDocument2 pagesTeachers' Rights Mini-Guide: Provide Legal Adviceblackantelope_ericNo ratings yet

- Auto Debit Form (60801026)Document2 pagesAuto Debit Form (60801026)Hanafi AminNo ratings yet

- Thanks For Your Order!: Billing Information Payment Details Receipt DetailsDocument1 pageThanks For Your Order!: Billing Information Payment Details Receipt Detailschalapathi psNo ratings yet

- Genitive Case FixaçãoDocument4 pagesGenitive Case Fixaçãoryan 01 da EPCArNo ratings yet

- Pyrogel Xt-E MsdsDocument11 pagesPyrogel Xt-E MsdsjitendraNo ratings yet

- EPC Best Practice Guidelines V1.0Document104 pagesEPC Best Practice Guidelines V1.0Thomas Dwi Putra SalimNo ratings yet

- Marcoso v. CADocument2 pagesMarcoso v. CAPrincess Samantha SarcedaNo ratings yet

- Guru Nanak in HistoryDocument358 pagesGuru Nanak in HistoryActiya KhanNo ratings yet

- Eti Base Code EnglishDocument4 pagesEti Base Code EnglishJohn RajeshNo ratings yet

- Philippine Laws On Housing and Human SettlementsDocument8 pagesPhilippine Laws On Housing and Human SettlementsJoJONo ratings yet

- Yogesh P Assignment PDFDocument2 pagesYogesh P Assignment PDFಯೋಗೇಶ್ ಪಿNo ratings yet

- NatwestDocument1 pageNatwestVinay SinghNo ratings yet

- NI Speedy 33Document43 pagesNI Speedy 33sitkastanNo ratings yet

- 1624 1637Document5 pages1624 1637cris50% (2)

- Reed Return of PropertyDocument10 pagesReed Return of PropertyHope StephanNo ratings yet

- Most Popular Newspapers and Magazines in MoldovaDocument2 pagesMost Popular Newspapers and Magazines in MoldovaAdriana AntoniNo ratings yet