Professional Documents

Culture Documents

Plano Neumatico MD6380_240530_175318

Plano Neumatico MD6380_240530_175318

Uploaded by

ManuAndyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plano Neumatico MD6380_240530_175318

Plano Neumatico MD6380_240530_175318

Uploaded by

ManuAndyCopyright:

Available Formats

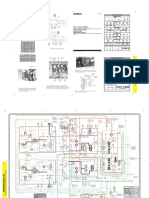

M0108845

January 2021

Component Locations

Schematic Machine

Description

Location Location

Actuator As - Air Inlet F-14 1

Actuator As - Blow Down Valve H-8 2

Actuator As - Drill Air E-8 3

Air Cleaner Gp

Compressor Gp - Air

D-14

F-12

4

5 6

(Dimensions: 48 inches x 35 inches)

Cooling Ar E-10 6

Filter As - Air (Water Separator - Dust Collector) G-1 7

Filter As - Air (Water Separator) G-9 8

Filter As - Hammer Oil Air E-4 9

Filter As - Thread Greaser Air G-4 10

Filter Gp - Oil D-11 11

Glass - Sight E-11 12

Pump Gp - Hammer Oil Air E-5 13

Pump Gp - Thread Greaser Air G-4 14

Sensor As - Inlet Delta Press F-14 15

M0108845

Sensor Gp - Air Filter Inlet Pressure E-14 16

Sensor Gp - Bit Air Pressure E-7 17

Sensor Gp - Compressor Oil Pressure C-12 18

Sensor Gp - Discharge Temp F-11 19

Sensor Gp - Dry Side Oil Pressure D-8 20

Sensor Gp - Temp C-10 21

MD6380 Rotary Blasthole Drill

Sensor Gp - Wet Side Oil Pressure E-8 22

Silencer F-7 23

Strainer As E-11 24

Air System

Switch As - Press E-11 25

Tank - Receiver F-9 26

Valve - Ball (Oil Drain) D-8 27

Valve - Blow Down (N.O) I-8 28

Valve - Oil Stop D-11 29

Valve - Safety Relief F-10 30

RB6381-UP

Valve - Thermal Bypass D-10 31

Valve As - Minimum Pressure

Valve As - Solenoid (Hammer Oil)

F-8

F-3

32

33 29

Valve As - Solenoid (Lube Oil) G-3 34

36 Page,

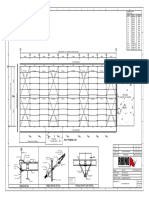

Tap Locations

Pressure, Sampling, and Sensor

Tap Schematic

Description

Number Location

AA Receiver Tank Wet Side Test Port D-9

BB Receiver Tank Dry Side Test Port D-9

CC Drill Air Test Port E-7

DD Blow Down Air Test Port H-9

SOS Sampling Pressure D-12

FWD 34 10 14

PUBLICATIONS.CAT.COM

CHASSIS - LH VIEW

7 33 13 9 5 11 25 FWD

FLUID POWER SYMBOLS

BASIC COMPONENT SYMBOLS

MAIN AUX

VIEW OF AREA “A” PUMP OR MOTOR FLUID CONDITIONER SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION

(FIXED)

PUMP

(2 - SECTION)

PUMP

(VARIABLE & PRESSURE

COMPENSATED)

(ROTATED FOR CLARITY)

16

VARIABILITY SPRING LINE RESTRICTION PRESSURE HYDRAULIC PNEUMATIC LINE RESTRICTION ATTACHMENT

(ADJUSTABLE) (VARIABLE) COMPENSATION ENERGY TRIANGLES (VARIABLE & PRESSURE

COMPENSATED)

VALVE ENVELOPES VALVES VALVE PORTS

ONE POSITION TWO POSITION THREE POSITION TWO - WAY THREE - WAY FOUR - WAY

CONTROL VALVES CHECK VALVES

AB A B

4 P T P T

BASIC SPRING SHUTTLE PILOT

NORMAL POSITION SHIFTED POSITION INFINITE POSITION

SYMBOL LOADED CONTROLLED

FLUID STORAGE RESERVOIRS

VENTED PRESSURIZED RETURN ABOVE FLUID LEVEL RETURN BELOW FLUID LEVEL

MEASUREMENT ROTATING SHAFTS

PRESSURE TEMPERATURE FLOW UNIDIRECTIONAL BIDIRECTIONAL

A 1

COMBINATION CONTROLS

SOLENOID SOLENOID SOLENOID SOLENOID & SERVO THERMAL DETENT

OR MANUAL & PILOT PILOT OR MANUAL

MANUAL CONTROL SYMBOLS

PUSH - PULL LEVER MANUAL SHUTOFF GENERAL MANUAL PUSH BUTTON PEDAL SPRING

RELEASED PRESSURE PILOT CONTROL SYMBOLS REMOTE SUPPLY PRESSURE

EXTERNAL RETURN INTERNAL RETURN SIMPLIFIED COMPLETE INTERNAL

SUPPLY PRESSURE

ACCUMULATORS CROSSING & JOINING LINES HYDRAULIC & PNEUMATIC CYLINDERS

SPRING LOADED GAS CHARGED LINES CROSSING LINES JOINING SINGLE ACTING DOUBLE ACTING

HYDRAULIC PUMPS HYDRAULIC MOTORS INTERNAL PASSAGEWAYS

23 27 FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

INFINITE

POSITIONING 3 POSITION 2 POSITION

UNIDIRECTIONAL UNIDIRECTIONAL

CC 17 3 32 26 BIDIRECTIONAL BIDIRECTIONAL

FLOW IN ONE

DIRECTION

PARALLEL

FLOW

CROSS

FLOW

FLOW IN

EITHER

DIRECTION

© 2021 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the

CHASSIS - RH VIEW “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not

be used without permission.

ELECTRICAL SYMBOLS TABLE

24 18 SOS BB AA 15 19 HYDRAULIC SYMBOLS (ELECTRICAL)

G

M

TRANSDUCER TRANSDUCER GENERATOR ELECTRIC MOTOR

(FLUID) (GAS / AIR)

PRESSURE SWITCH PRESSURE SWITCH TEMPERATURE ELECTRICAL WIRE

(ADJUSTABLE) SWITCH

WIRE NUMBER IDENTIFICATION CODES

ELECTRICAL SCHEMATIC EXAMPLE HYDRAULIC SCHEMATIC EXAMPLE

CURRENT STANDARD CURRENT STANDARD

HARNESS IDENTIFICATION CODE THIS EXAMPLE

INDICATES WIRE 135 IN HARNESS “AG”

WIRE WIRE

COLOR

CIRCUIT NUMBER

325-AG135 PK-14 IDENTIFICATION WIRE COLOR

CIRCUIT NUMBER WIRE GAUGE*

*Wire gauge is shown in AWG (American Wire Gauge)

IDENTIFICATION but could also be shown in metric denoted with mm 325-PK

PREVIOUS STANDARD

WIRE WIRE COLOR

325-PK-14 B A

CIRCUIT NUMBER WIRE GAUGE* (EXAMPLE VALVE)

IDENTIFICATION *Wire gauge is shown in AWG (American Wire Gauge)

but could also be shown in metric denoted with mm

12 28 DD 2 30 8 22 20 31 21

AIR COMPRESSOR - TOP VIEW

14 13 12 11 10 9 8 7 6 5 4 3 2 1

J J

(Dimensions: 48 inches x 35 inches)

M0108845

I I

(28) VALVE - BLOW DOWN

(N.O)

449-7123

36 Page,

(2) ACTUATOR AS

H BLOW DOWN VALVE H

566-1328

ELECTRONIC

DD CONTROLLED

TEST

PORT

AIR-AUXILIARY

APPLICATION

BLOW DOWN

VALVE

(8) FILTER AS - AIR (7) FILTER AS - AIR

(WATER SEPARATOR) (WATER SEPARATOR)

469-3542 469-3542

TO AUX OPTIONS

G G

DUST COLLECTOR

PURGE

ORIFICE

(34) VALVE AS

SOLENOID (LUBE OIL)

(14) PUMP GP 507-8806

THREAD GREASER AIR (10) FILTER AS

8X-2317 THREAD GREASER AIR

469-9282

(15) SENSOR AS (23) SILENCER

INLET DELTA PRESS (30) VALVE 560-3332

(26) TANK - RECEIVER (32) VALVE AS

385-1173

SAFETY RELIEF 541-0334 EXH

MINIMUM PRESSURE

549-2163

510-4166

F (19) SENSOR GP MUFFLER F

DISCHARGE TEMP

(5) COMPRESSOR GP - AIR THREAD GREASER

238-0112

571-0557 SPRAY SOLENOID

ELECTRIC DRY SIDE

ACTUATOR

(1) ACTUATOR AS PRIMARY FILTER

AIR INLET DISCHARGE

SECONDARY

378-1020 CHECK VALVE

FILTER (33) VALVE AS

(16) SENSOR GP - AIR FILTER (3) ACTUATOR AS (17) SENSOR GP - BIT AIR (13) PUMP GP SOLENOID (HAMMER OIL)

DRILL AIR PRESSURE (9) FILTER AS

INLET PRESSURE BUTTERFLY

AIR/OIL HAMMER OIL AIR 443-3932

320-3063 533-4008 320-3065 513-1772 HAMMER OIL AIR

INLET VALVE 469-9282

ELECTRONIC

AIR COMPRESSOR

CONTROLLED CC

TO DRILL AIR

AIR/OIL (24) STRAINER AS EXH

E E

485-1106 TEST

AIR/OIL PORT

(12) GLASS - SIGHT

488-0605 DRILL AIR

SCAVENGE BIT AIR VALVE

AIR/OIL

LINES

(25) SWITCH AS - PRESS (6) COOLING AR WET SIDE (22) SENSOR GP - WET SIDE

116-9933 541-0165 OIL PRESSURE

320-3065

(20) SENSOR GP - DRY SIDE AIR-AUXILIARY APPLICATION

SEE NOTE 1 OIL PRESSURE

OIL 320-3065

OIL OIL

OIL OIL WET SIDE DRY SIDE

TEST PORT TEST PORT

D (4) AIR CLEANER GP D

397-9300

AA BB

OIL

SEE NOTE 2

(31) VALVE - THERMAL BYPASS

572-4582 FROM MAIN SYSTEM AIR CIRCUIT

(27) VALVE - BALL (OIL DRAIN)

AIR PRECLEANER SOS (29) VALVE - OIL STOP

(11) FILTER GP - OIL 537-6058

489-6366

491-3180

(21) SENSOR GP - TEMP

238-0112

AIR INTAKE

(18) SENSOR GP - COMPRESSOR

OIL PRESSURE

C 320-3065 C

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

AIR COMPRESSOR OUTPUT

SCAVENGE LINES

COOLING LINES

AIR INTAKE LINES

DRAIN / RETURN LINE

LINE PATTERNS

Pressure Line

Pilot / Load Sensing Pressure

Drain / Return Lines

Air Line

B Component Group B

CALLOUTS

YY Taps (Pressure, Sampling, Sensor - by letter)

DL DL D Connectors (By letter)

Callout Number Component

(Machine Location from (52) VALVE GP - CONTROL Name

Component LocationsTable)

138-1234 Part Number

Do not operate or work on this product unless you have

read and understood the instruction and warnings in the

relevant Operation and Maintenance Manuals and

relevant service literature. Failure to follow the instruc-

NOTE: tions or heed the warnings could result in injury or

death. Proper care is your responsibility.

1. MULTIPLE OIL LINES THAT ORIGINATE

A FROM MANIFOLD TO LUBRICATE A

COMPRESSOR BEARINGS ARE NOT SHOWN.

2. NO. OF PRECLEANER/AIRCLEANER UNITS THIS SCHEMATIC IS FOR THE MD6380 ROTARY BLASTHOLE DRILL AIR SYSTEM

VARIES BASED ON COMPRESSORS. MEDIA NUMBER: M0108845

ALL OPTIONS SHOWN REFLECT ARE AVAILABLE SCHEMATIC PART NUMBER: 538-4982, CHANGE: 02, VERSION: -

Components are shown installed on a fully operable machine with the key and engine off, transmission shifter

BUT NOT PRESENT ON EVERY MACHINE. in neutral and with parking brake set.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations.

Refer to the Parts Manual using a specific serial number prefix in SIS before ordering parts from this schematic.

14 13 12 11 10 9 8 7 6 5 4 3 2 1

You might also like

- 2002 System Wiring Diagrams Toyota CorollaDocument41 pages2002 System Wiring Diagrams Toyota Corollakabanek75% (4)

- Unlock Your Macro Types - Training PlansDocument21 pagesUnlock Your Macro Types - Training Plansrfzfwn8nf4No ratings yet

- R1150RT IABS Electric Diagram V1.0Document3 pagesR1150RT IABS Electric Diagram V1.0Zeljko Tanasic50% (2)

- Hydr 725 & 730 Serie AltaDocument2 pagesHydr 725 & 730 Serie Altasebastian jaramillo trujilloNo ratings yet

- 793D Off-Highway Truck Hydraulic System PDFDocument2 pages793D Off-Highway Truck Hydraulic System PDFHéctorHernándezDíazNo ratings yet

- 246C, 256C, 262C, 262C2 and 272C 277C, 277C2, 287C, 287C2 and 297C Skid Steer LoaderDocument4 pages246C, 256C, 262C, 262C2 and 272C 277C, 277C2, 287C, 287C2 and 297C Skid Steer LoaderVictor Rodrigo Cortes Yañez100% (2)

- 988H Hydraulic System PDFDocument2 pages988H Hydraulic System PDFtom souza100% (1)

- Machine - Top Boom and Stick Control: Hydraulic System - Attachment 320 GC, 320 and 323 ExcavatorDocument2 pagesMachine - Top Boom and Stick Control: Hydraulic System - Attachment 320 GC, 320 and 323 ExcavatorLeandro BustamanteNo ratings yet

- App2 Architect RFP Response Evaluation FormDocument4 pagesApp2 Architect RFP Response Evaluation FormElliot MunNo ratings yet

- Free Clip ArtDocument153 pagesFree Clip ArtALIMAR50% (2)

- 2 PH Camión 793 F PDFDocument2 pages2 PH Camión 793 F PDFAnonymous HhjNxRCS6ANo ratings yet

- 950H and 962H Wheel Loader Electrical System IT62H Integrated ToolcarrierDocument4 pages950H and 962H Wheel Loader Electrical System IT62H Integrated ToolcarrierVillalba LuisNo ratings yet

- 793F and 793F WTR OEM Hydraulic System Off-Highway Truck: Traction ControlDocument2 pages793F and 793F WTR OEM Hydraulic System Off-Highway Truck: Traction Controlpercy de la cruzNo ratings yet

- Main Control View Backhoe Coupler: Hydraulic System 420 and 430 Backhoe LoaderDocument2 pagesMain Control View Backhoe Coupler: Hydraulic System 420 and 430 Backhoe Loaderedwin gutierrez lNo ratings yet

- Plano Hidraulico HEX CAT 336Document2 pagesPlano Hidraulico HEX CAT 336Anonymous I3rbKZrx7G100% (1)

- 120NG Greader HydDocument2 pages120NG Greader HydGideon PaongananNo ratings yet

- 773 and 773E Off-Highway Truck Air System 460-6701-00, (For Serial Numbers DJS1-UP FKT1-UP PRB1-UP) (UENR6748)Document4 pages773 and 773E Off-Highway Truck Air System 460-6701-00, (For Serial Numbers DJS1-UP FKT1-UP PRB1-UP) (UENR6748)hadian 5mNo ratings yet

- Plano Hidraulico 336 Next GenDocument4 pagesPlano Hidraulico 336 Next GenIr Ram Mo0% (1)

- 797F - Kenr8379-02Document6 pages797F - Kenr8379-02Marco Antonio Pampa CondoriNo ratings yet

- Electrical System 120H and 135H Motor Grader: Machine Harness Connector and Component LocationsDocument2 pagesElectrical System 120H and 135H Motor Grader: Machine Harness Connector and Component LocationsCicero MeloNo ratings yet

- Stick Lowering Control Valve Bucket CylinderDocument2 pagesStick Lowering Control Valve Bucket CylinderDaniela HuancoNo ratings yet

- HIDRAULICO Cat 772Document2 pagesHIDRAULICO Cat 772Tom SouzaNo ratings yet

- UENR3603-10 October 2016Document23 pagesUENR3603-10 October 2016CADAHINo ratings yet

- Uenr3603uenr3603-10 SisDocument2 pagesUenr3603uenr3603-10 Sisevan100% (2)

- N-0900-P-03-01 - H2S Stripper (C-0903) : Z-0901 D-0915X E-0913 D-0909Document9 pagesN-0900-P-03-01 - H2S Stripper (C-0903) : Z-0901 D-0915X E-0913 D-0909Darrel Espino AranasNo ratings yet

- 345B L Excavator Electrical System (SENR1937-01)Document2 pages345B L Excavator Electrical System (SENR1937-01)sughieantoNo ratings yet

- 966H and 972H Wheel Loader Electrical System With Steel MillDocument6 pages966H and 972H Wheel Loader Electrical System With Steel MillVictor Rodrigo Cortes Yañez100% (1)

- Cat 973Document2 pagesCat 973luxmanproacNo ratings yet

- Schematic 3500B Engine For Electric Power Generation (EPG) With Switchgear Conversion 132-8095Document2 pagesSchematic 3500B Engine For Electric Power Generation (EPG) With Switchgear Conversion 132-8095Hugo ArturoNo ratings yet

- Diagrama Electrico PM200 PerfiladoraDocument2 pagesDiagrama Electrico PM200 PerfiladoraPlstina Rams100% (2)

- N-0900-P-02-01 - PGH 2nd Stage Reactor (R-0902)Document11 pagesN-0900-P-02-01 - PGH 2nd Stage Reactor (R-0902)Darrel Espino AranasNo ratings yet

- 143H and 163H Motor Grader Hydraulic System Ripper AttachmentDocument2 pages143H and 163H Motor Grader Hydraulic System Ripper AttachmentMohamed Harb100% (1)

- Cat336D2GJA ElectricalDocument8 pagesCat336D2GJA ElectricalViet XuanNo ratings yet

- 311563-311564 - Crown Iron Works-CuracaoDocument33 pages311563-311564 - Crown Iron Works-CuracaoRicardoNo ratings yet

- Kenr8666-08 Plano Electrico 246CDocument4 pagesKenr8666-08 Plano Electrico 246CFrank Mc Gyver100% (1)

- Hydraulic 992G - Azx PDFDocument2 pagesHydraulic 992G - Azx PDFGuztiNo ratings yet

- 25.30.33L-7A Electrical SchematicsDocument26 pages25.30.33L-7A Electrical SchematicsGeoff HancockNo ratings yet

- IndraDocument2 pagesIndravsv mnaNo ratings yet

- 323D Excavator Hydraulic System: Machine Component LocationsDocument2 pages323D Excavator Hydraulic System: Machine Component LocationsKJDNKJZEF100% (1)

- Oem 715G3214 (SCH)Document2 pagesOem 715G3214 (SCH)Carlos OdilonNo ratings yet

- 789C 2bw659 A1846 Chasis y CabinaDocument4 pages789C 2bw659 A1846 Chasis y CabinaSergio Velarde romayNo ratings yet

- Re NR 81220001Document4 pagesRe NR 81220001bouheahmedgdalleNo ratings yet

- Planos Electricos 2 CAT C9Document1 pagePlanos Electricos 2 CAT C9Grupo Alber SACNo ratings yet

- HTS3375X - 78 DiagramaDocument10 pagesHTS3375X - 78 DiagramaDario EzequielNo ratings yet

- Design Change Notification: DCN TitleDocument5 pagesDesign Change Notification: DCN TitleThanh HoangNo ratings yet

- Uenr2628uenr2628-02 SisDocument12 pagesUenr2628uenr2628-02 SisNicole SmithNo ratings yet

- Main Control Valve: 345C Excavator Hydraulic SystemDocument2 pagesMain Control Valve: 345C Excavator Hydraulic SystemPablo Luis Pérez PostigoNo ratings yet

- 301 - 5 ExcavatorDocument2 pages301 - 5 ExcavatorLeonardo NunesNo ratings yet

- 962H Electrical DiagramDocument4 pages962H Electrical DiagramMarielis ContrerasNo ratings yet

- Machine - Top: Hydraulic System 320 GC, 320 and 323 ExcavatorDocument2 pagesMachine - Top: Hydraulic System 320 GC, 320 and 323 ExcavatorNovan Yomi Vivanez100% (4)

- 1335CGU DN01 E1RFbDocument1 page1335CGU DN01 E1RFbGodfrey BaitanNo ratings yet

- Philips 715g3214-1 32pfl5604 PsuDocument4 pagesPhilips 715g3214-1 32pfl5604 PsuMarcelo SilvaNo ratings yet

- Al Di Meola - Blackbird Staff OnlyDocument6 pagesAl Di Meola - Blackbird Staff OnlymanuelNo ratings yet

- Trasmittal Nr. HFY-3800-CPECC-PEGVR-T-0205 - HFY-3800-1501-VED-182-MEC-DWG-0001 - 0 - GA DWG For Lean Ami Air Cooler - Code-ADocument4 pagesTrasmittal Nr. HFY-3800-CPECC-PEGVR-T-0205 - HFY-3800-1501-VED-182-MEC-DWG-0001 - 0 - GA DWG For Lean Ami Air Cooler - Code-Ajuuzousama1No ratings yet

- 5-C0003 - Pga1002413340010-02 SH - 1Document2 pages5-C0003 - Pga1002413340010-02 SH - 1Aswindana Ibnu SenaNo ratings yet

- 01A-1 Power Generation XLRTEH4300G033850Document1 page01A-1 Power Generation XLRTEH4300G033850ПавелNo ratings yet

- KENR83130001Document6 pagesKENR83130001letlhogonolo kgwaraeNo ratings yet

- RB A225 Approval Rev 1 - 12 12Document1 pageRB A225 Approval Rev 1 - 12 12TariqMahmoodNo ratings yet

- Machine Component Locations: Hydraulic System 793D Off-Highway TruckDocument2 pagesMachine Component Locations: Hydraulic System 793D Off-Highway TruckJoaquin mejiaNo ratings yet

- KZT40 00 (A) JXDocument1 pageKZT40 00 (A) JXKhaled Mohamed ArayedNo ratings yet

- Sistema Eléctrico FedDocument2 pagesSistema Eléctrico FedAlejandro ReyesNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- Catalogue of Fittings - Orient ChinaDocument83 pagesCatalogue of Fittings - Orient Chinapham thangNo ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- Nso 2012QDocument21 pagesNso 2012QG BabuNo ratings yet

- 9 Social Science sp01Document13 pages9 Social Science sp01Eshan AttarNo ratings yet

- Aem 499 Final Powerpoint Andrewdelili 4-28-2021Document20 pagesAem 499 Final Powerpoint Andrewdelili 4-28-2021api-548751501No ratings yet

- Zernack Et Al 2009. Sedimentary Signatures of Cyclic Growth and Destruction of Stratovolcanoes. A Case Study From Mt. Taranaki, New Zealand PDFDocument18 pagesZernack Et Al 2009. Sedimentary Signatures of Cyclic Growth and Destruction of Stratovolcanoes. A Case Study From Mt. Taranaki, New Zealand PDFAndres Almanza SoteloNo ratings yet

- Vasitesa Sygef PVDFDocument380 pagesVasitesa Sygef PVDFIsrael AristaNo ratings yet

- Samri MSc. Thesis FinalDocument125 pagesSamri MSc. Thesis FinalMinilik Tikur SewNo ratings yet

- Note EjiogbeDocument13 pagesNote EjiogbeIfadayo Alabi50% (2)

- Ex No: 1 DateDocument4 pagesEx No: 1 DateVignesh AadhiNo ratings yet

- Degremont WTP MBRDocument29 pagesDegremont WTP MBRCHIN FelleNo ratings yet

- STM29 - Lower Half Martinito, John Patrick Eldwin Recto, Jan Ralph Yanga, Nicole Francine BDocument2 pagesSTM29 - Lower Half Martinito, John Patrick Eldwin Recto, Jan Ralph Yanga, Nicole Francine BJan Ralph RectoNo ratings yet

- Learning About Carbon CycleDocument5 pagesLearning About Carbon CyclegulaikawahNo ratings yet

- 23 Case Studies For Falling From HeightsDocument65 pages23 Case Studies For Falling From HeightsAejaz MujawarNo ratings yet

- STAT1012 Ch4 Continuous Probability DistributionDocument53 pagesSTAT1012 Ch4 Continuous Probability Distributionmakabigail7No ratings yet

- STUCOR - ME8595-TJ (1) - WatermarkDocument14 pagesSTUCOR - ME8595-TJ (1) - WatermarkMr PerfectNo ratings yet

- HALSEY - Bad at Love (Ver. 2) Guitar Chords - Guitar Chords ExplorerDocument5 pagesHALSEY - Bad at Love (Ver. 2) Guitar Chords - Guitar Chords ExplorerManuNo ratings yet

- Low-Loss Power Splitters - Multi-Band 800 - 2500 MHZ 860 10017, 860 10018, 860 10019Document1 pageLow-Loss Power Splitters - Multi-Band 800 - 2500 MHZ 860 10017, 860 10018, 860 10019Zoheir KacimiNo ratings yet

- Seismicity of Odisha (An Eastern State of Indian Peninsula) : A Comprehensive Deterministic Seismic Hazard StudyDocument11 pagesSeismicity of Odisha (An Eastern State of Indian Peninsula) : A Comprehensive Deterministic Seismic Hazard Studysatyabana.dasNo ratings yet

- Behavior and Design of Double Tees With Web OpeningsDocument17 pagesBehavior and Design of Double Tees With Web Openingsunix0123100% (1)

- Test 3 Sem 2Document9 pagesTest 3 Sem 2Ramona Iuliana NeculaNo ratings yet

- Reusable Instrument Line en V8Document12 pagesReusable Instrument Line en V8Agon KarakashiNo ratings yet

- A Grid Tie Inverter For Solar SystemsDocument5 pagesA Grid Tie Inverter For Solar SystemsR-MarufNo ratings yet

- The Story That Must Not Be Told by Kavery NambisanDocument6 pagesThe Story That Must Not Be Told by Kavery Nambisanfreelancer800100% (1)

- Algebra Complete - 1Document120 pagesAlgebra Complete - 1kiran.suresh19No ratings yet

- MAX14871 4.5V To 36V Full-Bridge DC Motor Driver: General Description Benefits and FeaturesDocument15 pagesMAX14871 4.5V To 36V Full-Bridge DC Motor Driver: General Description Benefits and FeaturesUdit AgrawalNo ratings yet