Professional Documents

Culture Documents

ukcsal001_iss1am02

ukcsal001_iss1am02

Uploaded by

PIERRONCopyright:

Available Formats

You might also like

- Osha StandardsDocument18 pagesOsha Standardsmojback100% (3)

- ukcsts008_iss1am01Document28 pagesukcsts008_iss1am01PIERRONNo ratings yet

- ukcssop012_iss1Document14 pagesukcssop012_iss1PIERRONNo ratings yet

- ukcscsm002_iss1Document66 pagesukcscsm002_iss1PIERRONNo ratings yet

- ukcsts004_iss1am01Document36 pagesukcsts004_iss1am01PIERRONNo ratings yet

- ukcsem003_iss1am01Document56 pagesukcsem003_iss1am01PIERRONNo ratings yet

- ukcssop031_iss1am01Document31 pagesukcssop031_iss1am01PIERRONNo ratings yet

- ukcsts012_iss2Document20 pagesukcsts012_iss2PIERRONNo ratings yet

- ukcsts011_iss1am01Document122 pagesukcsts011_iss1am01PIERRONNo ratings yet

- ukcssop018_iss1Document22 pagesukcssop018_iss1PIERRONNo ratings yet

- ukcsal002_iss1am01Document30 pagesukcsal002_iss1am01PIERRONNo ratings yet

- ukcssop025_iss1am01Document12 pagesukcssop025_iss1am01PIERRONNo ratings yet

- ukcsts014_iss1Document119 pagesukcsts014_iss1PIERRONNo ratings yet

- ukcssop015_iss2Document34 pagesukcssop015_iss2PIERRONNo ratings yet

- ukcsal004_iss1Document13 pagesukcsal004_iss1PIERRONNo ratings yet

- ukcssop007_iss1am01Document13 pagesukcssop007_iss1am01PIERRONNo ratings yet

- ukcsts006_iss1am01Document16 pagesukcsts006_iss1am01PIERRONNo ratings yet

- ukcsts009_iss1am01Document83 pagesukcsts009_iss1am01PIERRONNo ratings yet

- ukcsal005_iss1Document16 pagesukcsal005_iss1PIERRONNo ratings yet

- ukcsts015_iss1am01Document23 pagesukcsts015_iss1am01PIERRONNo ratings yet

- ukcscsm001_iss1Document66 pagesukcscsm001_iss1PIERRONNo ratings yet

- ukcssop023_iss1Document22 pagesukcssop023_iss1PIERRONNo ratings yet

- L4-WI-001f (Rev 6) Engineers Handbook - In Service InspectionsDocument21 pagesL4-WI-001f (Rev 6) Engineers Handbook - In Service InspectionsBrenton MarchukNo ratings yet

- ukcssop030_iss1am01Document12 pagesukcssop030_iss1am01PIERRONNo ratings yet

- ukcssop027_iss1am01Document28 pagesukcssop027_iss1am01PIERRONNo ratings yet

- Case Study Manual (EDU-EMS - LA-CSM) v1.0Document22 pagesCase Study Manual (EDU-EMS - LA-CSM) v1.0sugul sangeethNo ratings yet

- ukcsmal002_iss1Document28 pagesukcsmal002_iss1PIERRONNo ratings yet

- Quality System Manual: Uncontrolled UncontrolledDocument83 pagesQuality System Manual: Uncontrolled UncontrolledEngr Saeed AnwarNo ratings yet

- Barr Quality ManualDocument83 pagesBarr Quality ManualMNo ratings yet

- ukcssop035_iss1Document17 pagesukcssop035_iss1PIERRONNo ratings yet

- ukcsal003_iss1Document12 pagesukcsal003_iss1PIERRONNo ratings yet

- Ukcs Ti GocDocument27 pagesUkcs Ti GocJohn Dry50% (2)

- ukcssop022_iss1Document146 pagesukcssop022_iss1PIERRONNo ratings yet

- ukcssop032_iss2Document23 pagesukcssop032_iss2PIERRONNo ratings yet

- ukcsts003_iss1Document19 pagesukcsts003_iss1PIERRONNo ratings yet

- ukcsts007_iss1am02Document38 pagesukcsts007_iss1am02PIERRONNo ratings yet

- ukcsts013_iss1Document18 pagesukcsts013_iss1PIERRONNo ratings yet

- L2-PIMS-002 - Documentation Control PDFDocument15 pagesL2-PIMS-002 - Documentation Control PDFsam walledNo ratings yet

- ukcsem001_iss1am01Document148 pagesukcsem001_iss1am01PIERRONNo ratings yet

- ukcssop011_iss1Document18 pagesukcssop011_iss1PIERRONNo ratings yet

- Consenting, EIA and HRA Guidance For Marine Renewable Energy Developments in ScotlandDocument39 pagesConsenting, EIA and HRA Guidance For Marine Renewable Energy Developments in ScotlandShamim AkhtarNo ratings yet

- ukcssop005_iss1am04Document92 pagesukcssop005_iss1am04PIERRONNo ratings yet

- ukcssop033_iss1Document24 pagesukcssop033_iss1PIERRONNo ratings yet

- Energy Manual Policy and ProcedureDocument41 pagesEnergy Manual Policy and ProcedureAKHIL SHARMANo ratings yet

- WESM-FASMD-2.0 26 Jun 2021 (EWDO) 1Document11 pagesWESM-FASMD-2.0 26 Jun 2021 (EWDO) 1johncalupasNo ratings yet

- ukcssop029_iss1Document14 pagesukcssop029_iss1PIERRONNo ratings yet

- Audit Question ListDocument38 pagesAudit Question ListelevendotNo ratings yet

- Monitoring, Measurement, Analysis and Evaluation: 1.0 PurposeDocument4 pagesMonitoring, Measurement, Analysis and Evaluation: 1.0 Purposemahsen2000No ratings yet

- EMS ManualDocument166 pagesEMS ManualCmdr. Adonil Labao50% (2)

- Company Audit ReportDocument10 pagesCompany Audit ReportShakuntala GuptaNo ratings yet

- City of Gastonia Wastewater Treatment DivisionDocument14 pagesCity of Gastonia Wastewater Treatment DivisionLee OngNo ratings yet

- 4VAS QM - Audit-Tech ServicesDocument9 pages4VAS QM - Audit-Tech ServicesSargunan NandagopalNo ratings yet

- FMLF-TNI-007B Rev.01 Audit Plan - SA1 - KAI Commuter Line Rev.01Document9 pagesFMLF-TNI-007B Rev.01 Audit Plan - SA1 - KAI Commuter Line Rev.01danieshusodoNo ratings yet

- Gapl-Qsp-02 Internal AuditDocument2 pagesGapl-Qsp-02 Internal Auditsharif1974No ratings yet

- Eurocontrol Kpi Measurement Monitoring Analysis GuideDocument52 pagesEurocontrol Kpi Measurement Monitoring Analysis Guidemarouane8No ratings yet

- Eurocontrol Kpi Measurement Monitoring Analysis GuideDocument52 pagesEurocontrol Kpi Measurement Monitoring Analysis GuideЕкатерина ДмитриеваNo ratings yet

- IMS Level 1Document64 pagesIMS Level 1Vikrant Salpekar100% (1)

- WESM-MSDM-011 15 June 2017Document218 pagesWESM-MSDM-011 15 June 2017Aldjon Kenneth YapNo ratings yet

- Regal E.ManualDocument24 pagesRegal E.ManualMohammed ZubairNo ratings yet

- Laporan Audit ISO14001-2015 THN 2019Document13 pagesLaporan Audit ISO14001-2015 THN 2019Rick SitumorangNo ratings yet

- ukcssop033_iss1Document24 pagesukcssop033_iss1PIERRONNo ratings yet

- ukcssop022_iss1Document146 pagesukcssop022_iss1PIERRONNo ratings yet

- ukcscsm002_iss1Document66 pagesukcscsm002_iss1PIERRONNo ratings yet

- ukcssop009_iss1am01Document39 pagesukcssop009_iss1am01PIERRONNo ratings yet

- ukcssop015_iss2Document34 pagesukcssop015_iss2PIERRONNo ratings yet

- ukcssop005_iss1am04Document92 pagesukcssop005_iss1am04PIERRONNo ratings yet

- ukcsts011_iss1am01Document122 pagesukcsts011_iss1am01PIERRONNo ratings yet

- ukcssop008_iss1Document13 pagesukcssop008_iss1PIERRONNo ratings yet

- ukcssop007_iss1am01Document13 pagesukcssop007_iss1am01PIERRONNo ratings yet

- ukcsts012_iss2Document20 pagesukcsts012_iss2PIERRONNo ratings yet

- Risk Assessment No3 - Jumper recovery_Ver1Document3 pagesRisk Assessment No3 - Jumper recovery_Ver1PIERRONNo ratings yet

- NG50-1-CO-SAF-GN-AB-00-0006Document56 pagesNG50-1-CO-SAF-GN-AB-00-0006PIERRONNo ratings yet

- Risk Assessment No2 - Gooseneck removal_Ver1Document3 pagesRisk Assessment No2 - Gooseneck removal_Ver1PIERRONNo ratings yet

- ukcsts015_iss1am01Document23 pagesukcsts015_iss1am01PIERRONNo ratings yet

- NG50-3-214-REQ-RP-AB-89-0095Document24 pagesNG50-3-214-REQ-RP-AB-89-0095PIERRONNo ratings yet

- ukcsts013_iss1Document18 pagesukcsts013_iss1PIERRONNo ratings yet

- Risk Assessment No1 - Mob-demob_Ver2Document3 pagesRisk Assessment No1 - Mob-demob_Ver2PIERRONNo ratings yet

- AWS - Know Your Welding NDTDocument83 pagesAWS - Know Your Welding NDTPIERRONNo ratings yet

- NG50-2-300-SPS-PL-AA-30-0062Document41 pagesNG50-2-300-SPS-PL-AA-30-0062PIERRONNo ratings yet

- NG50-5-500-PRO-TR-AB-00-0013Document56 pagesNG50-5-500-PRO-TR-AB-00-0013PIERRONNo ratings yet

- 1-A6025-PL-051301-0010 Rev 0 Line Pipe Spec 051304-0001 20080320Document12 pages1-A6025-PL-051301-0010 Rev 0 Line Pipe Spec 051304-0001 20080320PIERRONNo ratings yet

- NG50-3-200-ENG-RP-AB-83-6804Document44 pagesNG50-3-200-ENG-RP-AB-83-6804PIERRONNo ratings yet

- Aws B 2.1-84 - STD For PQR & WPQRDocument150 pagesAws B 2.1-84 - STD For PQR & WPQRPIERRONNo ratings yet

- NG50-2-300-SPS-TR-AB-30-0132Document182 pagesNG50-2-300-SPS-TR-AB-30-0132PIERRONNo ratings yet

- Arc Flash Overview BrochureDocument6 pagesArc Flash Overview BrochureSayed NagyNo ratings yet

- Wire Rope Exchange October 2011Document80 pagesWire Rope Exchange October 2011Melissa HoodNo ratings yet

- Understanding Technological Responses of Industrial Firms To Environmental Problems: Implications For Government PolicyDocument16 pagesUnderstanding Technological Responses of Industrial Firms To Environmental Problems: Implications For Government PolicyMuiz SaddozaiNo ratings yet

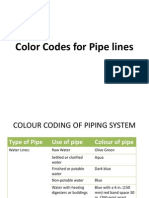

- A Color Codes For Pipe Lines ANSIDocument24 pagesA Color Codes For Pipe Lines ANSIliveconnectionz282No ratings yet

- OSHA Crane Regulations Final Rule PDFDocument273 pagesOSHA Crane Regulations Final Rule PDFMohamed HadjkacemNo ratings yet

- ENGSAFE - EV - Grp.3 (Fire Code, Fire Safety, Industrial Hygiene)Document69 pagesENGSAFE - EV - Grp.3 (Fire Code, Fire Safety, Industrial Hygiene)scaragNo ratings yet

- National Framework For PPE Conformity Assessment - InfraDocument48 pagesNational Framework For PPE Conformity Assessment - Infrashah86zamNo ratings yet

- 0811 Employee Involvement PDFDocument2 pages0811 Employee Involvement PDFFirman Suryadi RahmanNo ratings yet

- Oxy-Acetylene Safety RulesDocument5 pagesOxy-Acetylene Safety RuleschrisNo ratings yet

- Development of Importance Category Factor For Temporary Structures Subject To Seismic and Wind LoadsDocument18 pagesDevelopment of Importance Category Factor For Temporary Structures Subject To Seismic and Wind LoadsJoão Alfredo De LazzariNo ratings yet

- PROFESSIONAL ORGANIZATION NursingDocument37 pagesPROFESSIONAL ORGANIZATION NursingTrupti AghamakarNo ratings yet

- Environmental Health and Safety Guidelines For Construction, Renovation and DemolitionDocument29 pagesEnvironmental Health and Safety Guidelines For Construction, Renovation and Demolitionrizonico100% (1)

- Hemet Fire Services Final ReportDocument0 pagesHemet Fire Services Final ReportCraig ShultzNo ratings yet

- OshDocument11 pagesOshMuhammad KasranNo ratings yet

- H2S PresentationDocument66 pagesH2S Presentationmuhammad mustajabNo ratings yet

- Benching For ExcavationDocument40 pagesBenching For Excavationganganna80% (5)

- Earthmoving Equipment Fatalities in The Construction IndustryDocument8 pagesEarthmoving Equipment Fatalities in The Construction IndustryakayaNo ratings yet

- Sheet: Protecting Workers During A PandemicDocument3 pagesSheet: Protecting Workers During A Pandemicdhoo_babyNo ratings yet

- Clark SM 575 Service ManualDocument20 pagesClark SM 575 Service Manualgerardo100% (58)

- Operation and Maintenance Manual: 1600 Series Industrial EngineDocument92 pagesOperation and Maintenance Manual: 1600 Series Industrial EnginedmitryiNo ratings yet

- OSHA 10 Fact Sheet - Electrical SafetyDocument1 pageOSHA 10 Fact Sheet - Electrical SafetyJuan Carlos Plasencia100% (1)

- Noise (Occupational) : Noise, Radiation, and Other Exposures For ConstructionDocument2 pagesNoise (Occupational) : Noise, Radiation, and Other Exposures For ConstructionSAmyNo ratings yet

- Chemicalengineeringmagzinenov2012 PDFDocument77 pagesChemicalengineeringmagzinenov2012 PDF施君儒No ratings yet

- GLD.012 Health Safety Environment and Community (HSEC) Reporting (v2.1)Document6 pagesGLD.012 Health Safety Environment and Community (HSEC) Reporting (v2.1)JoséNo ratings yet

- Lecture 8.1&2 Process Safety Management Ilearn PDFDocument32 pagesLecture 8.1&2 Process Safety Management Ilearn PDFMuhammad AshmanNo ratings yet

- Process Safety Management (PSM) : Module Two - Overview of The PSM RuleDocument40 pagesProcess Safety Management (PSM) : Module Two - Overview of The PSM Rulebilo1984No ratings yet

- E2C-SMP-002 Safety Management ProcedureDocument24 pagesE2C-SMP-002 Safety Management ProcedureVPN NetworkNo ratings yet

- OSHA 3162 - Screening and SurveillanceDocument40 pagesOSHA 3162 - Screening and SurveillanceWahed Mn ElnasNo ratings yet

- The New Hire: A Pocket Guide For EmployersDocument10 pagesThe New Hire: A Pocket Guide For Employerskenny_jjjj100% (1)

ukcsal001_iss1am02

ukcsal001_iss1am02

Uploaded by

PIERRONCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ukcsal001_iss1am02

ukcsal001_iss1am02

Uploaded by

PIERRONCopyright:

Available Formats

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

Contents

Authorisation for Issue

Amendment Record

Amendment Summary

Distribution List

Preface

List of Abbreviations

Paragraph Page

Uncontrolled

1 Introduction 1

2 Monitoring 1

2.1 Group 1

2.2 Stream 1

2.3 Regional (United Kingdom

Continental Shelf (UKCS) Upstream) 2

2.4 Business Units 2

2.5 Delivery Unit 2

3 Audit of Compliance with Processes

and Procedures 3

4 Reviews 4

March 2001 Issue 1 i/ii

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

Authorisation for Issue

Issue Authority

Name: Dave Ewen

Signature: ________________________________________________

Date: ________________________________________________

Position: Audit Relationship Manager

Uncontrolled

Technical Authority

Name: Bill Cuthbert

Signature: ________________________________________________

Date: ________________________________________________

Position: Audit Relationship Manager, Business Audit, Aberdeen

April 2002 Issue 1/AM02 iii/iv

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

Amendment Record

For Audit Use

Amendment Incorporated By

Checked

Number

Name Signature Date Signature Date

Uncontrolled

AMOSAF.171

March 2001 Issue 1 v/vi

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

Amendment Summary

Issue No Date Description

Issue 1 March 2001 First issue.

Issue 1/AM01 March 2002 Change of Technical Authority. Distribution List

updated.

Table 1 revised to update persons responsible for

ensuring audit is done.

Issue 1/AM02 April 2002 Issue Authority changed from Greg Owen to

Uncontrolled

Dave Ewen. Distribution List updated.

April 2002 Issue 1/AM02 vii/viii

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

Distribution List

Holders of Controlled Hard Copy

Copy Copyholder Location

01 Data Control Centre (DCC) ODL, Aberdeen

Virtual Copyholders

Copy Copyholder

Uncontrolled

01 Document Issue Authority (Dave Ewen)

02 Document Technical Authority (Bill Cuthbert)

03 LTO Manager, Wytch Farm (Eamon Naughton)

04 EoS Document Controller (Dave Taylor)

05 EoS Operations Excellence HSE Consultant (David Egan)

06 OIM, Magnus

07 OIM, North West Hutton

08 OIM, Thistle

09 HSE/Compliance Manager, EoS

10 BSG SMS Co-ordinator (Peter Malcolm)

11 MNS SMS Co-ordinator (Peter Faulkner)

12 MNS SMS Co-ordinator (Peter Thompson)

13 MNS SMS Co-ordinator (Carl Thomessen)

14 MNS SMS Co-ordinator (Justin Haigh)

15 BU SMS Co-ordinator, CNS (Jim Blacklaws)

16 NBU SMS Co-ordinator (David Robertson)

17 NBU EPU SMS Co-ordinator (David Egan)

18 NBU SMS Co-ordinator (John Beaumont)

19 NSI SMS Co-ordinator (Ann Rosbrook)

20 SBU SMS Co-ordinator (Malcolm Watson)

21 SBU SMS Co-ordinator (Simon Robinson)

22 MNS SMS Co-ordinator (Bruce Morrison)

April 2002 Issue 1/AM02 ix/x

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

Preface

Purpose

The purpose of this document is to describe the process used within BP for reviewing the

performance of the Safety Management System (SMS).

This document details the frequency and responsibility, at each management level, for carrying

out safety management monitoring and auditing.

Review and Update

Uncontrolled

This document will be subject to 12-monthly review and update, when document holders will

have the opportunity to express opinions and suggest improvements.

However, the document control system allows for continuous update of this document.

As such, any user may at any time identify an error or suggest an improvement using an

Amendment Proposal proforma which is available electronically on the UKCS SMS website,

from the Data Control Centre (DCC) Supervisor or from the Technical Authority.

All holders of this document are registered so that they can be sent updates and be kept

informed of changes or reviews.

Responsibility of Copyholders

It is the responsibility of the registered copyholder of controlled hard copy versions to

maintain the accuracy of the document by ensuring that all updates are promptly

incorporated and acknowledged.

Furthermore, the registered copyholder of controlled hard copy versions must at all times

maintain custody of this document unless prior approval is given by the relevant

Technical Authority.

The roles and responsibilities of copyholders and ‘virtual’ copyholders are detailed in Section 1

of the Document Control Procedure (UKCS-DCM-001).

March 2001 Issue 1 xi/xii

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

List of Abbreviations

ASA Advanced Safety Audit

BU Business Unit

BUL Business Unit Leader

CO2 Carbon Dioxide

DAFWC Days Away From Work Case

DU Delivery Unit

GHSER Getting HSE Right

Uncontrolled

GVP Group Vice President

HSE Health, Safety and Environment

OIM Offshore Installation Manager

OSHA Occupational Safety and Health Administration

RWI Restricted Work Injuries

SCE Safety Critical Element

SMS Safety Management System

STOP Safety Training Observation Programme

UKCS United Kingdom Continental Shelf

UTG Upstream Technology Group

WoS West of Shetland

March 2001 Issue 1 xiii/xiv

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

1 Introduction

Health, Safety and Environment (HSE) performance within BP is managed through the

setting of Group expectations in Getting HSE Right (GHSER) and the setting of

performance targets at Group, stream, regional, Business Unit (BU) and Delivery

Unit (DU) levels. The Safety Management System (SMS) processes and procedures are

put in place to enable the meeting of these expectations and the delivery of the

performance targets.

Progress towards meeting the expectations and performance targets is

monitored through a set of performance indicators, usually collected together on a

performance scorecard.

Assurance that the processes and procedures are working as intended is provided

through regular audits of compliance of the processes and procedures.

Uncontrolled

The effectiveness of the processes and procedures in meeting the expectations and

delivering the performance targets is achieved through a management review.

This is the distinctive difference between reviews and compliance audits.

The following paragraphs specify the minimum requirements for performance indicators,

compliance audits and reviews, and should be supplemented by further audits and

reviews as indicated by the individual BU or DU risk management processes.

In a very limited number of circumstances (eg BUR, Upstream Technology Group (UTG),

Terminals) some of the audits and reviews will not apply (eg well activity management).

2 Monitoring

HSE performance monitoring is carried at Group, stream, regional, BU and DU levels.

2.1 Group

Group data is a high level aggregation of the stream ‘Output data’ detailed below.

2.2 Stream

‘Output data’ on accidents, incidents, illnesses and spills is collected for upstream level

via the Operate 1 and Operate 2 spreadsheets. ‘Input data’ is collected on the following:

• Advanced Safety Audits (ASAs)

• Safety observations

• Safety training

• Closure of actions/findings

The input and output data is used to generate an upstream safety profile matrix featuring

all the upstream BUs. The distribution of this data is extensive and includes Group Vice

Presidents (GVPs), Business Unit Leaders (BULs) and BU HSE Team Leaders.

The responsibility for collation of this data is with the upstream HSE function.

March 2001 Issue 1 1

UKCS-AL-001 Policy for Monitoring/Audit/Review of SMS Performance

2.3 Regional (United Kingdom Continental Shelf

(UKCS) Upstream)

Safety performance is reported monthly to the Regional President, Regional Leadership

Team and Safety Governance Board. This includes accident and incident data, incident

severity potential, and near miss to accident ratio. The responsibility for collating the data

lies with the West of Shetland (WoS) HSE Team Leader (part of the devolved

Federal responsibilities).

Environmental performance is reported quarterly to the Environmental Governance

Board. Any significant environmental performance issues are taken to the Regional

Leadership Team by the Governance Board Chairman. The responsibility for collating this

data is with the Central Environmental Team.

2.4 Business Units

Uncontrolled

Each BU produces a performance scorecard, updated at least monthly. The HSE

elements of the scorecard include, as a minimum (except where not applicable):

• Days Away From Work Cases (DAFWCs)

• Restricted Work Injuries (RWIs)

• Occupational Safety and Health Administration (OSHA) recordables

• Near miss to accident ratio

• Hydrocarbon leaks

• Dropped objects

• CO2 emissions

• Total hydrocarbon emissions

The data is reviewed monthly by the BU Management Team.

The responsibility for collation of the data lies with the BU HSE Team Leader.

2.5 Delivery Unit

Each DU produces a performance scorecard, updated at least monthly.

The HSE elements of the DU scorecard include, as a minimum (except where not

applicable), the metrics defined above for the BU scorecard, and data on ASAs and their

Safety Observation Programme (eg Safety Training Observation Programme (STOP)).

This data is reviewed monthly by the DU Management Team. The responsibility for

collating the data lies with the DU HSE Adviser.

’No leaks’ campaign data is collected monthly as per a standard performance scorecard.

This data is reviewed monthly by the DU Management Team. The responsibility for

collating the data lies with the DU ‘No Leaks’ Co-ordinator.

2 March 2001 Issue 1

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

Each DU will have a set of integrity-related measures. This will include

(where applicable):

• Safety Critical Element (SCE) performance standard anomalies (offshore BUs only)

• Overdue safety category maintenance

• Process upsets

• Normal maintenance backlog

• Overdue periodic inspections

• Corrosion control and monitoring

This data is to be reviewed monthly by each DU Management Team.

The responsibility for collating the data lies with the DU HSE Adviser.

Uncontrolled

3 Audit of Compliance with Processes and Procedures

Audits of compliance are carried out to provide assurance that the processes and

procedures are working as intended. In some cases, the audits are a requirement of an

external accreditation, eg ISO 14001.

Table 1 defines the minimum mandatory audit requirements for ‘normal operations’ in

BUs which are part of the upstream UKCS region. Additional audits and/or increased

frequency should be applied when there is major organisational, procedural or structural

change within the BU.

Compliance Audit Minimum Frequency Responsibility for Ensuring

Audit is Done

Emergency Procedures Quarterly OIM, Terminal Manager or PUL

Operating Procedures Quarterly OIM, Terminal Manager or PUL

Maintenance Procedures Quarterly OIM, Terminal Manager or PUL

Competence Assurance Annually OIM, Terminal Manager or PUL

Permit to Work Weekly OIM, Terminal Manager or PUL

Appointment of Area and Quarterly OIM, Terminal Manager or PUL

Isolating Authorities

Management of Alarms Monthly OIM, Terminal Manager or PUL

and Trips, and Control

of Overrides

Management of Quarterly OIM, Terminal Manager or PUL

Long-term Isolations

Table 1 Minimum Mandatory Requirements for ‘Normal Operations’ in BUs

March 2002 Issue 1/AM01 3

UKCS-AL-001 Policy for Monitoring/Audit/Review of SMS Performance

Compliance Audit Minimum Frequency Responsibility for Ensuring

Audit is Done

Locked Valve Register Quarterly OIM, Terminal Manager or PUL

Management

Control of Lifting Equipment Quarterly OIM, Terminal Manager or PUL

and Lifting Operations

Control of Pressure Hoses Quarterly OIM, Terminal Manager or PUL

Storage and Control of Quarterly OIM, Terminal Manager or PUL

Explosives, Radioactive and

Hazardous Substances

Third-party and Quarterly OIM, Terminal Manager or PUL

Uncontrolled

Hired Equipment

Site/Platform Quarterly OIM, Terminal Manager or PUL

Induction Process

Well Activity Management Quarterly OIM, Terminal Manager or PUL

Process for the Segregation, Quarterly OIM, Terminal Manager or PUL

Recycling and Management

of Waste

Management of Action Quarterly OIM, Terminal Manager or PUL

Tracking and Closeout

Table 1 Minimum Mandatory Requirements for ‘Normal Operations’ in BUs (cont’d)

4 Reviews

Reviews are carried out with the prime objective of determining the effectiveness of the

processes and procedures in meeting the expectations and delivering the performance

targets. This is distinctly different from compliance audits, which provide assurance that

the processes and procedures are working as intended.

Whilst the ultimate review is the comparison of actual performance against targets,

it is important that some key processes are reviewed individually. Table 2 defines the

minimum mandatory review requirements for BUs in the upstream UKCS region.

The term ‘internal’ means a review carried out by the BU or DU management,

but with outside help if necessary.

The term ‘external’ means a review (sometimes called an audit) carried out by personnel

from outside of the BU, but not necessarily outwith BP.

4 March 2002 Issue 1/AM01

Policy for Monitoring/Audit/Review of SMS Performance UKCS-AL-001

Reviews Internal or Minimum Responsibility

External for Delivery

GHSER Annual Internal Annually HSE Team Leader

Self-assessment

Management and Internal Quarterly HSE Adviser

Closeout of

Actions

Safe System Internal Annually HSE Adviser

of Work

Emergency Internal Annually HSE Adviser

Exercise

Programme

Uncontrolled

SMS Compliance Internal Annually HSE Adviser

Legislative Internal Annually HSE Adviser

Compliance

Management of Internal Annually Integrity Leader

Change

Technical Integrity Internal Annually Integrity Leader

Performance

Standards

Lessons Learned Internal Quarterly HSE Adviser

Health Plan Internal Annually HSE Adviser

Getting HSE Right External 3 yearly HSE Team Leader

External

ISO 14001 External As per HSE Team Leader

accreditation

Occupational External 3 yearly HSE Team Leader

Health

Occupational External 3 yearly HSE Team Leader

Hygiene

First Aid Needs External 2 yearly HSE Team Leader

Assessment

Table 2 Minimum Mandatory Review Requirements for

BUs in the Upstream UKCS Region

March 2001 Issue 1 5/6

You might also like

- Osha StandardsDocument18 pagesOsha Standardsmojback100% (3)

- ukcsts008_iss1am01Document28 pagesukcsts008_iss1am01PIERRONNo ratings yet

- ukcssop012_iss1Document14 pagesukcssop012_iss1PIERRONNo ratings yet

- ukcscsm002_iss1Document66 pagesukcscsm002_iss1PIERRONNo ratings yet

- ukcsts004_iss1am01Document36 pagesukcsts004_iss1am01PIERRONNo ratings yet

- ukcsem003_iss1am01Document56 pagesukcsem003_iss1am01PIERRONNo ratings yet

- ukcssop031_iss1am01Document31 pagesukcssop031_iss1am01PIERRONNo ratings yet

- ukcsts012_iss2Document20 pagesukcsts012_iss2PIERRONNo ratings yet

- ukcsts011_iss1am01Document122 pagesukcsts011_iss1am01PIERRONNo ratings yet

- ukcssop018_iss1Document22 pagesukcssop018_iss1PIERRONNo ratings yet

- ukcsal002_iss1am01Document30 pagesukcsal002_iss1am01PIERRONNo ratings yet

- ukcssop025_iss1am01Document12 pagesukcssop025_iss1am01PIERRONNo ratings yet

- ukcsts014_iss1Document119 pagesukcsts014_iss1PIERRONNo ratings yet

- ukcssop015_iss2Document34 pagesukcssop015_iss2PIERRONNo ratings yet

- ukcsal004_iss1Document13 pagesukcsal004_iss1PIERRONNo ratings yet

- ukcssop007_iss1am01Document13 pagesukcssop007_iss1am01PIERRONNo ratings yet

- ukcsts006_iss1am01Document16 pagesukcsts006_iss1am01PIERRONNo ratings yet

- ukcsts009_iss1am01Document83 pagesukcsts009_iss1am01PIERRONNo ratings yet

- ukcsal005_iss1Document16 pagesukcsal005_iss1PIERRONNo ratings yet

- ukcsts015_iss1am01Document23 pagesukcsts015_iss1am01PIERRONNo ratings yet

- ukcscsm001_iss1Document66 pagesukcscsm001_iss1PIERRONNo ratings yet

- ukcssop023_iss1Document22 pagesukcssop023_iss1PIERRONNo ratings yet

- L4-WI-001f (Rev 6) Engineers Handbook - In Service InspectionsDocument21 pagesL4-WI-001f (Rev 6) Engineers Handbook - In Service InspectionsBrenton MarchukNo ratings yet

- ukcssop030_iss1am01Document12 pagesukcssop030_iss1am01PIERRONNo ratings yet

- ukcssop027_iss1am01Document28 pagesukcssop027_iss1am01PIERRONNo ratings yet

- Case Study Manual (EDU-EMS - LA-CSM) v1.0Document22 pagesCase Study Manual (EDU-EMS - LA-CSM) v1.0sugul sangeethNo ratings yet

- ukcsmal002_iss1Document28 pagesukcsmal002_iss1PIERRONNo ratings yet

- Quality System Manual: Uncontrolled UncontrolledDocument83 pagesQuality System Manual: Uncontrolled UncontrolledEngr Saeed AnwarNo ratings yet

- Barr Quality ManualDocument83 pagesBarr Quality ManualMNo ratings yet

- ukcssop035_iss1Document17 pagesukcssop035_iss1PIERRONNo ratings yet

- ukcsal003_iss1Document12 pagesukcsal003_iss1PIERRONNo ratings yet

- Ukcs Ti GocDocument27 pagesUkcs Ti GocJohn Dry50% (2)

- ukcssop022_iss1Document146 pagesukcssop022_iss1PIERRONNo ratings yet

- ukcssop032_iss2Document23 pagesukcssop032_iss2PIERRONNo ratings yet

- ukcsts003_iss1Document19 pagesukcsts003_iss1PIERRONNo ratings yet

- ukcsts007_iss1am02Document38 pagesukcsts007_iss1am02PIERRONNo ratings yet

- ukcsts013_iss1Document18 pagesukcsts013_iss1PIERRONNo ratings yet

- L2-PIMS-002 - Documentation Control PDFDocument15 pagesL2-PIMS-002 - Documentation Control PDFsam walledNo ratings yet

- ukcsem001_iss1am01Document148 pagesukcsem001_iss1am01PIERRONNo ratings yet

- ukcssop011_iss1Document18 pagesukcssop011_iss1PIERRONNo ratings yet

- Consenting, EIA and HRA Guidance For Marine Renewable Energy Developments in ScotlandDocument39 pagesConsenting, EIA and HRA Guidance For Marine Renewable Energy Developments in ScotlandShamim AkhtarNo ratings yet

- ukcssop005_iss1am04Document92 pagesukcssop005_iss1am04PIERRONNo ratings yet

- ukcssop033_iss1Document24 pagesukcssop033_iss1PIERRONNo ratings yet

- Energy Manual Policy and ProcedureDocument41 pagesEnergy Manual Policy and ProcedureAKHIL SHARMANo ratings yet

- WESM-FASMD-2.0 26 Jun 2021 (EWDO) 1Document11 pagesWESM-FASMD-2.0 26 Jun 2021 (EWDO) 1johncalupasNo ratings yet

- ukcssop029_iss1Document14 pagesukcssop029_iss1PIERRONNo ratings yet

- Audit Question ListDocument38 pagesAudit Question ListelevendotNo ratings yet

- Monitoring, Measurement, Analysis and Evaluation: 1.0 PurposeDocument4 pagesMonitoring, Measurement, Analysis and Evaluation: 1.0 Purposemahsen2000No ratings yet

- EMS ManualDocument166 pagesEMS ManualCmdr. Adonil Labao50% (2)

- Company Audit ReportDocument10 pagesCompany Audit ReportShakuntala GuptaNo ratings yet

- City of Gastonia Wastewater Treatment DivisionDocument14 pagesCity of Gastonia Wastewater Treatment DivisionLee OngNo ratings yet

- 4VAS QM - Audit-Tech ServicesDocument9 pages4VAS QM - Audit-Tech ServicesSargunan NandagopalNo ratings yet

- FMLF-TNI-007B Rev.01 Audit Plan - SA1 - KAI Commuter Line Rev.01Document9 pagesFMLF-TNI-007B Rev.01 Audit Plan - SA1 - KAI Commuter Line Rev.01danieshusodoNo ratings yet

- Gapl-Qsp-02 Internal AuditDocument2 pagesGapl-Qsp-02 Internal Auditsharif1974No ratings yet

- Eurocontrol Kpi Measurement Monitoring Analysis GuideDocument52 pagesEurocontrol Kpi Measurement Monitoring Analysis Guidemarouane8No ratings yet

- Eurocontrol Kpi Measurement Monitoring Analysis GuideDocument52 pagesEurocontrol Kpi Measurement Monitoring Analysis GuideЕкатерина ДмитриеваNo ratings yet

- IMS Level 1Document64 pagesIMS Level 1Vikrant Salpekar100% (1)

- WESM-MSDM-011 15 June 2017Document218 pagesWESM-MSDM-011 15 June 2017Aldjon Kenneth YapNo ratings yet

- Regal E.ManualDocument24 pagesRegal E.ManualMohammed ZubairNo ratings yet

- Laporan Audit ISO14001-2015 THN 2019Document13 pagesLaporan Audit ISO14001-2015 THN 2019Rick SitumorangNo ratings yet

- ukcssop033_iss1Document24 pagesukcssop033_iss1PIERRONNo ratings yet

- ukcssop022_iss1Document146 pagesukcssop022_iss1PIERRONNo ratings yet

- ukcscsm002_iss1Document66 pagesukcscsm002_iss1PIERRONNo ratings yet

- ukcssop009_iss1am01Document39 pagesukcssop009_iss1am01PIERRONNo ratings yet

- ukcssop015_iss2Document34 pagesukcssop015_iss2PIERRONNo ratings yet

- ukcssop005_iss1am04Document92 pagesukcssop005_iss1am04PIERRONNo ratings yet

- ukcsts011_iss1am01Document122 pagesukcsts011_iss1am01PIERRONNo ratings yet

- ukcssop008_iss1Document13 pagesukcssop008_iss1PIERRONNo ratings yet

- ukcssop007_iss1am01Document13 pagesukcssop007_iss1am01PIERRONNo ratings yet

- ukcsts012_iss2Document20 pagesukcsts012_iss2PIERRONNo ratings yet

- Risk Assessment No3 - Jumper recovery_Ver1Document3 pagesRisk Assessment No3 - Jumper recovery_Ver1PIERRONNo ratings yet

- NG50-1-CO-SAF-GN-AB-00-0006Document56 pagesNG50-1-CO-SAF-GN-AB-00-0006PIERRONNo ratings yet

- Risk Assessment No2 - Gooseneck removal_Ver1Document3 pagesRisk Assessment No2 - Gooseneck removal_Ver1PIERRONNo ratings yet

- ukcsts015_iss1am01Document23 pagesukcsts015_iss1am01PIERRONNo ratings yet

- NG50-3-214-REQ-RP-AB-89-0095Document24 pagesNG50-3-214-REQ-RP-AB-89-0095PIERRONNo ratings yet

- ukcsts013_iss1Document18 pagesukcsts013_iss1PIERRONNo ratings yet

- Risk Assessment No1 - Mob-demob_Ver2Document3 pagesRisk Assessment No1 - Mob-demob_Ver2PIERRONNo ratings yet

- AWS - Know Your Welding NDTDocument83 pagesAWS - Know Your Welding NDTPIERRONNo ratings yet

- NG50-2-300-SPS-PL-AA-30-0062Document41 pagesNG50-2-300-SPS-PL-AA-30-0062PIERRONNo ratings yet

- NG50-5-500-PRO-TR-AB-00-0013Document56 pagesNG50-5-500-PRO-TR-AB-00-0013PIERRONNo ratings yet

- 1-A6025-PL-051301-0010 Rev 0 Line Pipe Spec 051304-0001 20080320Document12 pages1-A6025-PL-051301-0010 Rev 0 Line Pipe Spec 051304-0001 20080320PIERRONNo ratings yet

- NG50-3-200-ENG-RP-AB-83-6804Document44 pagesNG50-3-200-ENG-RP-AB-83-6804PIERRONNo ratings yet

- Aws B 2.1-84 - STD For PQR & WPQRDocument150 pagesAws B 2.1-84 - STD For PQR & WPQRPIERRONNo ratings yet

- NG50-2-300-SPS-TR-AB-30-0132Document182 pagesNG50-2-300-SPS-TR-AB-30-0132PIERRONNo ratings yet

- Arc Flash Overview BrochureDocument6 pagesArc Flash Overview BrochureSayed NagyNo ratings yet

- Wire Rope Exchange October 2011Document80 pagesWire Rope Exchange October 2011Melissa HoodNo ratings yet

- Understanding Technological Responses of Industrial Firms To Environmental Problems: Implications For Government PolicyDocument16 pagesUnderstanding Technological Responses of Industrial Firms To Environmental Problems: Implications For Government PolicyMuiz SaddozaiNo ratings yet

- A Color Codes For Pipe Lines ANSIDocument24 pagesA Color Codes For Pipe Lines ANSIliveconnectionz282No ratings yet

- OSHA Crane Regulations Final Rule PDFDocument273 pagesOSHA Crane Regulations Final Rule PDFMohamed HadjkacemNo ratings yet

- ENGSAFE - EV - Grp.3 (Fire Code, Fire Safety, Industrial Hygiene)Document69 pagesENGSAFE - EV - Grp.3 (Fire Code, Fire Safety, Industrial Hygiene)scaragNo ratings yet

- National Framework For PPE Conformity Assessment - InfraDocument48 pagesNational Framework For PPE Conformity Assessment - Infrashah86zamNo ratings yet

- 0811 Employee Involvement PDFDocument2 pages0811 Employee Involvement PDFFirman Suryadi RahmanNo ratings yet

- Oxy-Acetylene Safety RulesDocument5 pagesOxy-Acetylene Safety RuleschrisNo ratings yet

- Development of Importance Category Factor For Temporary Structures Subject To Seismic and Wind LoadsDocument18 pagesDevelopment of Importance Category Factor For Temporary Structures Subject To Seismic and Wind LoadsJoão Alfredo De LazzariNo ratings yet

- PROFESSIONAL ORGANIZATION NursingDocument37 pagesPROFESSIONAL ORGANIZATION NursingTrupti AghamakarNo ratings yet

- Environmental Health and Safety Guidelines For Construction, Renovation and DemolitionDocument29 pagesEnvironmental Health and Safety Guidelines For Construction, Renovation and Demolitionrizonico100% (1)

- Hemet Fire Services Final ReportDocument0 pagesHemet Fire Services Final ReportCraig ShultzNo ratings yet

- OshDocument11 pagesOshMuhammad KasranNo ratings yet

- H2S PresentationDocument66 pagesH2S Presentationmuhammad mustajabNo ratings yet

- Benching For ExcavationDocument40 pagesBenching For Excavationganganna80% (5)

- Earthmoving Equipment Fatalities in The Construction IndustryDocument8 pagesEarthmoving Equipment Fatalities in The Construction IndustryakayaNo ratings yet

- Sheet: Protecting Workers During A PandemicDocument3 pagesSheet: Protecting Workers During A Pandemicdhoo_babyNo ratings yet

- Clark SM 575 Service ManualDocument20 pagesClark SM 575 Service Manualgerardo100% (58)

- Operation and Maintenance Manual: 1600 Series Industrial EngineDocument92 pagesOperation and Maintenance Manual: 1600 Series Industrial EnginedmitryiNo ratings yet

- OSHA 10 Fact Sheet - Electrical SafetyDocument1 pageOSHA 10 Fact Sheet - Electrical SafetyJuan Carlos Plasencia100% (1)

- Noise (Occupational) : Noise, Radiation, and Other Exposures For ConstructionDocument2 pagesNoise (Occupational) : Noise, Radiation, and Other Exposures For ConstructionSAmyNo ratings yet

- Chemicalengineeringmagzinenov2012 PDFDocument77 pagesChemicalengineeringmagzinenov2012 PDF施君儒No ratings yet

- GLD.012 Health Safety Environment and Community (HSEC) Reporting (v2.1)Document6 pagesGLD.012 Health Safety Environment and Community (HSEC) Reporting (v2.1)JoséNo ratings yet

- Lecture 8.1&2 Process Safety Management Ilearn PDFDocument32 pagesLecture 8.1&2 Process Safety Management Ilearn PDFMuhammad AshmanNo ratings yet

- Process Safety Management (PSM) : Module Two - Overview of The PSM RuleDocument40 pagesProcess Safety Management (PSM) : Module Two - Overview of The PSM Rulebilo1984No ratings yet

- E2C-SMP-002 Safety Management ProcedureDocument24 pagesE2C-SMP-002 Safety Management ProcedureVPN NetworkNo ratings yet

- OSHA 3162 - Screening and SurveillanceDocument40 pagesOSHA 3162 - Screening and SurveillanceWahed Mn ElnasNo ratings yet

- The New Hire: A Pocket Guide For EmployersDocument10 pagesThe New Hire: A Pocket Guide For Employerskenny_jjjj100% (1)