Professional Documents

Culture Documents

proforma_spec_Pre-insulated_Pipes_AC

proforma_spec_Pre-insulated_Pipes_AC

Uploaded by

kylechan.hwCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

proforma_spec_Pre-insulated_Pipes_AC

proforma_spec_Pre-insulated_Pipes_AC

Uploaded by

kylechan.hwCopyright:

Available Formats

[PROFORMA]

PARTICULAR SPECIFICATION for

Pre-insulated Pipes in Air Conditioning and Refrigeration Installation

(Brief title description of work in brackets to be inserted, if necessary)

for

[Project Title ]

1. Scope and Specification of Works

1.1 Installation/ System

1.1.1 All pre-insulated pipe shall be pre-fabricated and pre-insulated in off-site factory.

All pre-insulated pipe shall consist of (i) carrier pipe/ service pipe, (ii) thermal

insulation and (iii) external jacket/ cladding. The pre-fabrication and pre-

insulation system shall include pipe fittings.

1.1.2 Pre-fabricated and pre-insulated pipe section shall be used and provided for the

following installations for all areas including riser pipes, headers and pipes in

plant rooms, unless otherwise approved by the Supervising Officer:

[Note: The items listed below are for consideration to suit the project and if any

item is not applicable in this contract, the item shall be retained with “Not

Used” to be remarked. This proforma specification is a general guidance and is

not exhaustive, Project Officer should exercise his/ her professional judgment to

specify the requirements to meet the project specific needs. Project Officer

should consider the suitability and cost benefit of using pre-insulated pipe for

various installations, especially those of small pipe size and with many elbow/

branching.]

1.1.2.1 Chilled water pipe

1.1.2.2 Hot water pipe

1.1.2.3 Refrigerant pipe

[Note: Project Officer shall add specific installations which are not included in

the items above to suit the project design requirement.]

1.1.3 Unless otherwise indicated, pre-fabrication and pre-insulation shall include but not

limit to pipework, valve, flanges, fittings and all accessories.

Building Services Branch, ArchSD Page 1 of 3 File code: 771118230.docx

Annex to BSB Circular No. 20 of 2015 KCM/PCC/mcc

Issue Date: 26 October 2015

1.2 Installation Requirements

1.2.1 The pre-insulated pipes shall be delivered to site with 100mm exposed ends to

facilitate field joining. All joints shall be insulated by the same material using

foam injection method on site. All foam-in-situ (on site foaming) shall be limited

to pipe length below 1 meter. All pipework longer than 1 meter requiring

insulation shall be pre-insulated, no on site foaming is allowed except for pipe

joints and other piping accessories approved by the Supervising Officer. The

insulation shall be applied following the contour of pipework and adhere tightly

and evenly with the pipework surface.

1.2.2 The Contractor shall follow the approved manufacturer’s method statement on

installation of pre-insulated pipes and in-situ foaming of pipe joints. Details shall

be submitted to the Supervising Officer for approval.

1.2.3 The Contractor shall provide approved pipe sleeves and pipe collars, and approved

fire rated pipe sleeves, collars or barriers where necessary and applicable, or the

pre-insulated pipes itself having a fire penetration time not less than the structure

through which it passes when tested in accordance with BS 476 – 20:1987 for all

pre-insulated pipes passing through compartments, walls, floors and any structural

openings in compliance with relevant regulations and code of practices. The fire

barriers shall have the same fire resisting rating as the structure through which the

pre-insulated pipe passes.

1.2.4 The Contractor shall engage pre-insulated pipe supplier to provide training by

recognized trainer to the Supervising Officer’s representatives, project installers

and inspectors to enable them to understand and familiarize with the installation

and to ensure the pre-insulated piping system will be properly installed.

1.3 Technical Requirements

1.3.1 Where specified the Contractor shall supply and install pre-insulated pipes, the

foam insulation used shall be CFC, HCFC and HFC free.

1.3.2 The thermal conductivity (k value) of the foam insulation shall not be more than

0.026 W/moC at a mean temperature of 20oC. Density shall not be less than 35

kg/m3.

Building Services Branch, ArchSD Page 2 of 3 File code: 771118230.docx

Annex to BSB Circular No. 20 of 2015 KCM/PCC/mcc

Issue Date: 26 October 2015

1.3.3 Fire performance of the complete pre-insulated pipe assembly for different

applications shall be Class O as stipulated in BS 5422: 2009. The definition of

Class O (national class) shall be referred to Annex E of BS 5422:2009. A class O

(national class) material is one which:

- has a Class 1 surface spread of flame rating in accordance with BS 476-

7:1997 and has a fire propagation index (I) of not more than 12.0 and a sub-

index (i1) of not more than 6.0 in accordance with BS 476-6:1989+A1:2009;

or

- is of limited combustibility in accordance with “Materials of limited

combustibility” (E.2 of Annex E, BS 5422:2009); or

- is non-combustible in accordance with Non-combustible materials (E.1 of

Annex E, BS 5422:2009).

Test reports to substantiate the fire properties of the insulation material shall be

issued by laboratories accredited by HOKLAS or other laboratory accreditation

bodies recognized by HOKLAS.

1.3.4 Galvanised Steel/ Aluminum/ Stainless Steel/ Other Material* (please

specify)____________sheet shall be applied as external jacket/ cladding of the

pre-insulated pipe. Treatment, such as epoxy coating, shall be applied to jacket/

cladding to protect against rusting if necessary when use in outdoor areas.

[Note: Project Officer shall specify the minimum thickness of the external

jacket/ cladding for various applications to suit the requirements to meet the

project specific needs.]

1.4 Others

[Note: This is a clause allowed for the addition of any particular project information or

supplementary technical requirements, etc., which may not be covered in the above

clauses. In case this clause is not applicable, “Not Used” shall be inserted instead of

deleting this clause.]

Legend:-

* Delete if NOT applicable

Building Services Branch, ArchSD Page 3 of 3 File code: 771118230.docx

Annex to BSB Circular No. 20 of 2015 KCM/PCC/mcc

Issue Date: 26 October 2015

You might also like

- E1300 - Corrosion and CoatingsDocument3 pagesE1300 - Corrosion and Coatingsgerrzen64No ratings yet

- Underground Steam & Condensate Piping PDFDocument26 pagesUnderground Steam & Condensate Piping PDFZacky JoeNo ratings yet

- Shanghai Tower Construction MaterialsDocument25 pagesShanghai Tower Construction Materialskingashish67% (6)

- Calculation of Asphalt Concrete PropertiesDocument8 pagesCalculation of Asphalt Concrete PropertiesEdwin Leon50% (2)

- Quiet DuctDocument4 pagesQuiet DuctacrisostoNo ratings yet

- Project Standard Specification: Duct Insulation 15081 - Page 1/11Document11 pagesProject Standard Specification: Duct Insulation 15081 - Page 1/11adel rihanaNo ratings yet

- SECTION 07 21 23 Loose-Fill InsulationDocument5 pagesSECTION 07 21 23 Loose-Fill InsulationJuanPaoloYbañezNo ratings yet

- Project Standard Specification: Pipe Insulation 15083 - Page 1/15Document15 pagesProject Standard Specification: Pipe Insulation 15083 - Page 1/15adel rihanaNo ratings yet

- 06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkDocument16 pages06/30/22 DESIGN NO. - SECTION 15514 Ductwork Insulation Part 1 - General 1.01 Description of WorkJhoNo ratings yet

- ISOLATEK Intumescent Interior Spec April 2015 2Document6 pagesISOLATEK Intumescent Interior Spec April 2015 2FALwilliamsNo ratings yet

- 23 07 00 General HVAC Insulation RequirementsDocument5 pages23 07 00 General HVAC Insulation RequirementsolivaresjhonNo ratings yet

- Fresh Air Handling Units 39HQMDocument10 pagesFresh Air Handling Units 39HQMAhmadNo ratings yet

- Air Handling Units 39HQMDocument8 pagesAir Handling Units 39HQMAhmadNo ratings yet

- t049 TG 8.1 34 CorrugatedstainlesssteeltubingDocument8 pagest049 TG 8.1 34 Corrugatedstainlesssteeltubingrafael.teixeir.casaisNo ratings yet

- Insulation Tech SpecDocument7 pagesInsulation Tech Specferdinand laiNo ratings yet

- 4294PipingEquip Insulation - Rev3-020107 Conoco PhilipsDocument8 pages4294PipingEquip Insulation - Rev3-020107 Conoco PhilipslsaishankarNo ratings yet

- Code of Practice For The Installation of Cellular Pvc-U (Pvc-Ue) Roofline SystemsDocument14 pagesCode of Practice For The Installation of Cellular Pvc-U (Pvc-Ue) Roofline SystemsmazniseinNo ratings yet

- Building Insulation - MSTDocument7 pagesBuilding Insulation - MSTwafikmh4No ratings yet

- C5000 16 G28 B V04 B02 PDFDocument321 pagesC5000 16 G28 B V04 B02 PDFAhmed OmarNo ratings yet

- Allstate Specification For Astm PDFDocument12 pagesAllstate Specification For Astm PDFZaendals JepitNo ratings yet

- Spec Eng CV010Document13 pagesSpec Eng CV010Evgeniy PalnikovNo ratings yet

- 07 10 00 Damproofing and Waterproofing - OdtDocument16 pages07 10 00 Damproofing and Waterproofing - OdtInah Quiniquini Manalese100% (1)

- Specification Section 07810 Interior Cementitious Spray - Applied FireproofingDocument10 pagesSpecification Section 07810 Interior Cementitious Spray - Applied FireproofingMouayed ZeadanNo ratings yet

- 075216Document15 pages075216Engr KamalNo ratings yet

- Design and Construction Standards: Technical SpecificationDocument8 pagesDesign and Construction Standards: Technical SpecificationolivaresjhonNo ratings yet

- OFS - Plumbing System Specification - 201411Document40 pagesOFS - Plumbing System Specification - 201411netzonetechnical managerNo ratings yet

- Preq - Al Jaber Engineering - Wiltz - TemboDocument292 pagesPreq - Al Jaber Engineering - Wiltz - Tembo721917114 47No ratings yet

- FRP Guide SpecificationDocument9 pagesFRP Guide SpecificationkuhomikzNo ratings yet

- BES-L003 - Spec For FBE CoatingDocument12 pagesBES-L003 - Spec For FBE CoatingRamNo ratings yet

- 22 - Prefabricated Elements in BuildingDocument30 pages22 - Prefabricated Elements in BuildingTemur LomidzeNo ratings yet

- Metal Duct WorkDocument9 pagesMetal Duct WorkSyed Waqas HussainNo ratings yet

- Hazard BeaconDocument6 pagesHazard BeaconDevrim GürselNo ratings yet

- مواصفات التكييفDocument54 pagesمواصفات التكييفoth369No ratings yet

- Va 09 51 00Document16 pagesVa 09 51 00Hana KaedeNo ratings yet

- Fluid Applied WaterproofingDocument8 pagesFluid Applied WaterproofingHamza MamiNo ratings yet

- 00 ISOL 2282 Technical Specification Pipe InsulationDocument10 pages00 ISOL 2282 Technical Specification Pipe InsulationNesta RobertNo ratings yet

- Section 078200 - Board FireproofingDocument5 pagesSection 078200 - Board FireproofingWENDING HUNo ratings yet

- Rockwool R1 PDFDocument55 pagesRockwool R1 PDFczarina caranguian0% (1)

- Volume-Ia Part - I Chapter - Ii: Scope of WorksDocument4 pagesVolume-Ia Part - I Chapter - Ii: Scope of WorksMirhasan GaziNo ratings yet

- Guide - Foam Glass InsulationDocument25 pagesGuide - Foam Glass InsulationChristian DoriaNo ratings yet

- Technobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFDocument5 pagesTechnobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFJohn SmithNo ratings yet

- 60-8001 - Check List For E-House & Topside Switchgear RFQDocument3 pages60-8001 - Check List For E-House & Topside Switchgear RFQDinesh RajNo ratings yet

- SECTION 07 81 00 Applied FireproofingDocument10 pagesSECTION 07 81 00 Applied FireproofingJuanPaoloYbañezNo ratings yet

- Air CurtainsDocument5 pagesAir Curtainsadel rihanaNo ratings yet

- HE-GS-Blueskin WP 200-Waterproof-E5 CSI 07 11 13Document5 pagesHE-GS-Blueskin WP 200-Waterproof-E5 CSI 07 11 13bernardo.vidalNo ratings yet

- Sea Roses Technical Specification - Ffps & Fad SystemDocument70 pagesSea Roses Technical Specification - Ffps & Fad SystemK. CHANDRASEKHARNo ratings yet

- Project Standard Specification: Equipment Insulation 15082 - Page 1/7Document7 pagesProject Standard Specification: Equipment Insulation 15082 - Page 1/7adel rihanaNo ratings yet

- SECTION 07 24 00 Exterior Insulation and Finish SystemsDocument12 pagesSECTION 07 24 00 Exterior Insulation and Finish SystemsJuanPaoloYbañezNo ratings yet

- Proforma Spec_Drainage_2014Document7 pagesProforma Spec_Drainage_2014kylechan.hwNo ratings yet

- Section 08630 Metal-Framed SkylightDocument4 pagesSection 08630 Metal-Framed SkylightMØhãmmed ØwięsNo ratings yet

- Underground Piping SystemsDocument5 pagesUnderground Piping SystemsBinodh DanielNo ratings yet

- E3 Epoxy Mastic Polyurethane Top Coat On Steel or Cast IronDocument5 pagesE3 Epoxy Mastic Polyurethane Top Coat On Steel or Cast IronTricolor C ANo ratings yet

- Saes N 004 PDFDocument5 pagesSaes N 004 PDFRampal Rahul Rampal RahulNo ratings yet

- SECTION 07 54 23 Thermoplastic Polyolefin (Tpo) RoofingDocument23 pagesSECTION 07 54 23 Thermoplastic Polyolefin (Tpo) RoofingJuanPaoloYbañezNo ratings yet

- C0306-S02-ECB-FS-30000-00- Section-11Document6 pagesC0306-S02-ECB-FS-30000-00- Section-11Virgo RajaNo ratings yet

- 09 22 00 Acoustical CeilingsDocument9 pages09 22 00 Acoustical CeilingsKiran D AnvekarNo ratings yet

- Repsol Oil Operations: Nc-115 Field DevelopmentDocument11 pagesRepsol Oil Operations: Nc-115 Field DevelopmentYangui AliNo ratings yet

- SECTION 07 54 19 Polyvinyl-Chloride (PVC) RoofingDocument23 pagesSECTION 07 54 19 Polyvinyl-Chloride (PVC) RoofingJuanPaoloYbañezNo ratings yet

- Tremco-Section-07148-Fluid-Applied-Elastomeric-Waterproofing-for-Planters-Guide-Specifications-201453Document7 pagesTremco-Section-07148-Fluid-Applied-Elastomeric-Waterproofing-for-Planters-Guide-Specifications-201453Beau HumeNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- proforma_spec_lpg_20_12_2004Document9 pagesproforma_spec_lpg_20_12_2004kylechan.hwNo ratings yet

- Proforma Spec_Rainwater Recycling System_29_09_2010Document19 pagesProforma Spec_Rainwater Recycling System_29_09_2010kylechan.hwNo ratings yet

- proforma_spec_fsf_2007versionDocument25 pagesproforma_spec_fsf_2007versionkylechan.hwNo ratings yet

- Proforma Spec - EE (Draft 1)Document16 pagesProforma Spec - EE (Draft 1)kylechan.hwNo ratings yet

- proforma_spec_cater_20_12_2004Document15 pagesproforma_spec_cater_20_12_2004kylechan.hwNo ratings yet

- Proforma Spec_Solar LED LumDocument6 pagesProforma Spec_Solar LED Lumkylechan.hwNo ratings yet

- Proforma Spec_Drainage_2014Document7 pagesProforma Spec_Drainage_2014kylechan.hwNo ratings yet

- proforma_spec_IAQ 140110Document2 pagesproforma_spec_IAQ 140110kylechan.hwNo ratings yet

- Proforma spec for Medical Gas Installation_20100414Document126 pagesProforma spec for Medical Gas Installation_20100414kylechan.hwNo ratings yet

- lift proforma ps & es (22Jan13)Document60 pageslift proforma ps & es (22Jan13)kylechan.hwNo ratings yet

- Proforma Spec_PV and BIPV_10_08_2011Document28 pagesProforma Spec_PV and BIPV_10_08_2011kylechan.hwNo ratings yet

- cir1403-2015 TESDocument6 pagescir1403-2015 TESkylechan.hwNo ratings yet

- ProSpecLift_ BLCBDocument2 pagesProSpecLift_ BLCBkylechan.hwNo ratings yet

- proforma_spec_Food_Waste_Composting_System_15June2011rev1Document8 pagesproforma_spec_Food_Waste_Composting_System_15June2011rev1kylechan.hwNo ratings yet

- Proforma Spec - Burglar Alarm (2007)-rev 1aDocument39 pagesProforma Spec - Burglar Alarm (2007)-rev 1akylechan.hwNo ratings yet

- Proforma Spec_GSM_05_09_2011Document4 pagesProforma Spec_GSM_05_09_2011kylechan.hwNo ratings yet

- Proforma Spec_Plumbing_2014Document11 pagesProforma Spec_Plumbing_2014kylechan.hwNo ratings yet

- Proforma BSER_Particular Requirements_12_12_2011Document9 pagesProforma BSER_Particular Requirements_12_12_2011kylechan.hwNo ratings yet

- Proforma BSER_General Requirements_12_12_2011Document21 pagesProforma BSER_General Requirements_12_12_2011kylechan.hwNo ratings yet

- Proforma Spec - BRI 2007 11 BDocument7 pagesProforma Spec - BRI 2007 11 Bkylechan.hwNo ratings yet

- Proforma Spec - LVSB (Draft 6)Document11 pagesProforma Spec - LVSB (Draft 6)kylechan.hwNo ratings yet

- 3 TekniFloor LDPDocument2 pages3 TekniFloor LDPAndy100% (1)

- Product Catalogue: Welding ConsumablesDocument44 pagesProduct Catalogue: Welding ConsumablesSerhan AysanNo ratings yet

- Gradia Direct Clinical Guide enDocument24 pagesGradia Direct Clinical Guide enGeorgi AnaNo ratings yet

- He Design Report Group 2Document29 pagesHe Design Report Group 2Aji PratamaNo ratings yet

- 04-MOBIL Aero HF EnglishDocument2 pages04-MOBIL Aero HF EnglishKheireddine AounallahNo ratings yet

- The SAC Programme Is Managed by Enterprise SingaporeDocument4 pagesThe SAC Programme Is Managed by Enterprise Singaporeমেহেদী MehediNo ratings yet

- TDS Ardrox 9881 09 25 2013Document3 pagesTDS Ardrox 9881 09 25 2013PP043No ratings yet

- MMJ 300/500 V: Installation CablesDocument2 pagesMMJ 300/500 V: Installation CablesQC ĐNNo ratings yet

- Safecon Builders and Trading: Warehouse Detailed Cost EstimateDocument21 pagesSafecon Builders and Trading: Warehouse Detailed Cost EstimateJessybel Acosta MendozaNo ratings yet

- BS4449/1997 & BS 4449/2005/ASTM A 615/A 615/M: Reinforcement Steel SpecificationsDocument1 pageBS4449/1997 & BS 4449/2005/ASTM A 615/A 615/M: Reinforcement Steel Specificationsgreat_triskelionNo ratings yet

- Dental Material MCQ Test Bank Chapter 1Document17 pagesDental Material MCQ Test Bank Chapter 1Táláát ÄlsuroriNo ratings yet

- Comdiflex Spiral Wound Gaskets Technical CatalogueDocument7 pagesComdiflex Spiral Wound Gaskets Technical CatalogueSugianto BarusNo ratings yet

- 2018grandeacs Iecr 8b01483Document7 pages2018grandeacs Iecr 8b01483Alberto TousNo ratings yet

- SDS - Diversey Emerel Multi-Surface Creme Cleanser PDFDocument5 pagesSDS - Diversey Emerel Multi-Surface Creme Cleanser PDFNdega Ya ChumaNo ratings yet

- Proconnect H05 - H07-BQ-FDocument1 pageProconnect H05 - H07-BQ-FPaul ScottNo ratings yet

- Gordon P. Bierwagen Eds. Organic Coatings For Corrosion Control PDFDocument445 pagesGordon P. Bierwagen Eds. Organic Coatings For Corrosion Control PDFHuyen Trang LeNo ratings yet

- MatterDocument112 pagesMatterjoshsiquig12No ratings yet

- Water Spray + Additive: E9 A1 EvDocument2 pagesWater Spray + Additive: E9 A1 EvMusyrif YusoffNo ratings yet

- Shale-Oil Resource Systems - AAPG WikiDocument35 pagesShale-Oil Resource Systems - AAPG WikiAmrNo ratings yet

- Technical Data: Ethacure 300Document2 pagesTechnical Data: Ethacure 300sriatul2006No ratings yet

- Sil - PT - Sunil Vaishnav - 1st-Slabl - FWK - R0 PDFDocument1 pageSil - PT - Sunil Vaishnav - 1st-Slabl - FWK - R0 PDFamit_saxena_10No ratings yet

- H432-01-Periodic Table, Elements and Physical Chemistry/a Level Chemistry A H432 - H432-01 - QS13Document5 pagesH432-01-Periodic Table, Elements and Physical Chemistry/a Level Chemistry A H432 - H432-01 - QS13Altay ShawNo ratings yet

- EM 311 Principles of MiningDocument90 pagesEM 311 Principles of MiningAldrene GiligNo ratings yet

- Dgca Module 11 Part 02 PDFDocument21 pagesDgca Module 11 Part 02 PDFBhaskerNegiNo ratings yet

- Spring Design Ii: Prepared and Presented byDocument11 pagesSpring Design Ii: Prepared and Presented byDhiraj NayakNo ratings yet

- Chevron Base OilDocument3 pagesChevron Base OilNeha AntimonyNo ratings yet

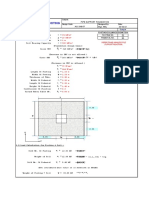

- Design FootingsDocument9 pagesDesign FootingsRupesh KhandekarNo ratings yet

- What Is Slurry SealDocument5 pagesWhat Is Slurry SealEmmanuel Mends FynnNo ratings yet