Professional Documents

Culture Documents

ds_pv3540_en_co

ds_pv3540_en_co

Uploaded by

mastersalmanrazzaqCopyright:

Available Formats

You might also like

- Accor - Graphic Guidelines - L050319Document105 pagesAccor - Graphic Guidelines - L050319Mohamed OmariNo ratings yet

- DS_PV3541_en_co_1806Document6 pagesDS_PV3541_en_co_1806mastersalmanrazzaqNo ratings yet

- Ds pv3542 en CoDocument6 pagesDs pv3542 en CoPajnuNo ratings yet

- ds_pv3543_en_coDocument6 pagesds_pv3543_en_comastersalmanrazzaqNo ratings yet

- DS_PV3221_en_co_1844Document6 pagesDS_PV3221_en_co_1844sp.marianNo ratings yet

- Micro Fused: Pressure TransmitterDocument6 pagesMicro Fused: Pressure Transmitterayyalu samyNo ratings yet

- Three-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmDocument12 pagesThree-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmSalaar AnsarNo ratings yet

- PRD Doc Pro 18327-00001 Sen Ain V2Document2 pagesPRD Doc Pro 18327-00001 Sen Ain V2Rabetto Juanre Pahlevi Goklas HutasoitNo ratings yet

- SAP4825DDocument4 pagesSAP4825DbhizartNo ratings yet

- SQM48T20025 NBB0Document33 pagesSQM48T20025 NBB0Gabriel RacovskyNo ratings yet

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocument12 pagesDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminNo ratings yet

- Wika Ac1Document4 pagesWika Ac1DOUBENo ratings yet

- Gs01c22b03-00en (22) Eja120Document8 pagesGs01c22b03-00en (22) Eja120Nguyen ThuongNo ratings yet

- VG-2W Series: MotienDocument4 pagesVG-2W Series: MotienYonatan RivadeneyraNo ratings yet

- En18068-3-02-18 Eds3300 Plus VdmaDocument4 pagesEn18068-3-02-18 Eds3300 Plus VdmaigorNo ratings yet

- DIN-A-MITE Solid-State Power ControllerDocument21 pagesDIN-A-MITE Solid-State Power Controllermisael123No ratings yet

- Tdf3 NewDocument2 pagesTdf3 NewSơn Lê CaoNo ratings yet

- 3RQ31181AM00 Datasheet enDocument5 pages3RQ31181AM00 Datasheet enDayane CruzNo ratings yet

- 3RN20121BW31 Datasheet enDocument7 pages3RN20121BW31 Datasheet enAmir YuliNo ratings yet

- CONTRINEX Safety RelaysDocument2 pagesCONTRINEX Safety RelaysMarcos AldrovandiNo ratings yet

- Limit-Switch For Standard Signals: AD-MK 330 GSDocument2 pagesLimit-Switch For Standard Signals: AD-MK 330 GSМихаил БеребердинNo ratings yet

- SBL3030PT, SBL3040PT: Vishay General SemiconductorDocument4 pagesSBL3030PT, SBL3040PT: Vishay General Semiconductorrammstein4445No ratings yet

- Data Sheet: DFS 2 025-2/0,03-A Hz60 V120Document3 pagesData Sheet: DFS 2 025-2/0,03-A Hz60 V120Gustavo GamezNo ratings yet

- 3RN2010 1BW30Document7 pages3RN2010 1BW30dachinicuNo ratings yet

- FTL260 Catalogue EngDocument4 pagesFTL260 Catalogue EngalexkeserNo ratings yet

- PT250R-2004-I2-H1143 Pressure Transmitter - With Current Output (2-Wire)Document2 pagesPT250R-2004-I2-H1143 Pressure Transmitter - With Current Output (2-Wire)Ran DomaNo ratings yet

- Ds pv3331 en CoDocument7 pagesDs pv3331 en Co9033301054No ratings yet

- Ordering Information: PCB RelayDocument6 pagesOrdering Information: PCB RelayManikandan GurunathanNo ratings yet

- 2CDC002137D0201 - Data Sheet S200SDocument8 pages2CDC002137D0201 - Data Sheet S200Sadelone23No ratings yet

- Ashcroft - Pressure Switch PDFDocument2 pagesAshcroft - Pressure Switch PDFAnand SinhaNo ratings yet

- DDR 30 Spec PDFDocument4 pagesDDR 30 Spec PDFencus170785No ratings yet

- Eds3400 Plus VdmaDocument4 pagesEds3400 Plus VdmasunhuynhNo ratings yet

- HV Voltage TransformersDocument4 pagesHV Voltage TransformersSharafatNo ratings yet

- Harmony Electromechanical Relays - RXM2LB2P7Document6 pagesHarmony Electromechanical Relays - RXM2LB2P7ikhsanul islahNo ratings yet

- Zelio Relay - RXM2LB2BDDocument7 pagesZelio Relay - RXM2LB2BDTrần Anh LuậtNo ratings yet

- K3ma L PDFDocument16 pagesK3ma L PDFsydifiaNo ratings yet

- Ordering Information: Power RelayDocument6 pagesOrdering Information: Power RelayAndrei Ponce WongNo ratings yet

- Datasheet - XN-322-16DI-PD: Part No. Article No. Catalog NoDocument10 pagesDatasheet - XN-322-16DI-PD: Part No. Article No. Catalog NocristianoNo ratings yet

- 8567 RelayDocument3 pages8567 RelayAmandaNo ratings yet

- Va-0.5w DatasheetDocument5 pagesVa-0.5w Datasheetbruno buinNo ratings yet

- 09 FCS084 A09 1 PDFDocument2 pages09 FCS084 A09 1 PDFsaurabh kumarNo ratings yet

- D 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleDocument7 pagesD 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleadrianioantomaNo ratings yet

- Pressure Transmitter For Refrigeration and HVAC Applications Model AC-1Document4 pagesPressure Transmitter For Refrigeration and HVAC Applications Model AC-1Kumphala LuahrNo ratings yet

- Lm2825n Datasheet PDF AipcbaDocument21 pagesLm2825n Datasheet PDF AipcbaBarth XaosNo ratings yet

- Electronic Pressure Switch EDS 8000: Description: Technical SpecificationsDocument2 pagesElectronic Pressure Switch EDS 8000: Description: Technical Specificationsclaudinei alves fonsecaNo ratings yet

- High Current Relay 200Document3 pagesHigh Current Relay 200ShiaTVfanNo ratings yet

- Pressure Switch CQ21Document7 pagesPressure Switch CQ21محمد امين التشغيل الآليNo ratings yet

- LED Driver. Xitanium. 30W 1.2A 0-10V Dimming XI030C120V040BSJ1. Specifications. Wiring DiagramDocument8 pagesLED Driver. Xitanium. 30W 1.2A 0-10V Dimming XI030C120V040BSJ1. Specifications. Wiring DiagramRicardo LopezNo ratings yet

- Epsitron - Capacitive Buffer Modules: DescriptionDocument1 pageEpsitron - Capacitive Buffer Modules: DescriptionHector bonillaNo ratings yet

- MCB DBDocument36 pagesMCB DBRAVIKANT SINDHENo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- DBM20 DatasheetDocument6 pagesDBM20 DatasheetMohammed BenzaidiNo ratings yet

- Siemens CLS 200Document16 pagesSiemens CLS 200Stenio LanzaNo ratings yet

- D5C Touch SwitchDocument8 pagesD5C Touch SwitchMuhamad PriyatnaNo ratings yet

- Nivoswitch: Vibrating Fork Level SwitchesDocument6 pagesNivoswitch: Vibrating Fork Level SwitchesArnaldo BenitezNo ratings yet

- Monitoring Relays 1-Phase True RMS AC/DC Over or Under Current Types DIB02, PIB02Document4 pagesMonitoring Relays 1-Phase True RMS AC/DC Over or Under Current Types DIB02, PIB02ShiaTVfanNo ratings yet

- Edb - 6836591 - GBR - en ASP 1000Document2 pagesEdb - 6836591 - GBR - en ASP 1000Ana NedeljkovicNo ratings yet

- NL Limit Touch SwitchDocument9 pagesNL Limit Touch SwitchMuhamad PriyatnaNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Ethics in Engineering, 2005, 339 Pages, Mike Martin, Roland Schinzinger, 0072831154, 9780072831153, Mcgraw-Hill Education, 2005Document17 pagesEthics in Engineering, 2005, 339 Pages, Mike Martin, Roland Schinzinger, 0072831154, 9780072831153, Mcgraw-Hill Education, 2005Zakir HossenNo ratings yet

- An Wallis Earthing Lightning ProtectionDocument117 pagesAn Wallis Earthing Lightning Protectiongoitom01No ratings yet

- Bangalore University: "Student Attendance Management"Document10 pagesBangalore University: "Student Attendance Management"Rohit VilliersNo ratings yet

- Man and SupermanDocument4 pagesMan and SupermanSrestha Kar100% (1)

- SD220511 01Document1 pageSD220511 01Minh TranNo ratings yet

- A Methodology To Develop Computer Vision Systems in Civil Engineering - Applications in Material Testing and Fish Tracking PDFDocument309 pagesA Methodology To Develop Computer Vision Systems in Civil Engineering - Applications in Material Testing and Fish Tracking PDFMicrodigital WareNo ratings yet

- Salleh2021 Article TheEmergenceOfVeryLargeContainDocument21 pagesSalleh2021 Article TheEmergenceOfVeryLargeContainSajid KhanNo ratings yet

- "W.C. Asorio's ASC Me' Model of Care": NAME: Asorio, Wendale Claire G. Student ID#: 18-0972-39Document3 pages"W.C. Asorio's ASC Me' Model of Care": NAME: Asorio, Wendale Claire G. Student ID#: 18-0972-39Wendale Claire G. ASORIONo ratings yet

- Lead Acid BatteryDocument23 pagesLead Acid BatteryBrahmpal BhardwajNo ratings yet

- Linear Programming TheoryDocument99 pagesLinear Programming TheoryRamez SafwatNo ratings yet

- Ansys Fluent Brings CFD Performance With Intel Processors and FabricsDocument8 pagesAnsys Fluent Brings CFD Performance With Intel Processors and FabricsSaid FerdjallahNo ratings yet

- ME ListDocument3 pagesME ListAltoNo ratings yet

- Erp Case StudyDocument2 pagesErp Case StudymehakNo ratings yet

- ART300Document45 pagesART300Gerlyn OrdonioNo ratings yet

- UntitledDocument27 pagesUntitledFlavio MagelaNo ratings yet

- Better Graphics r10 PDFDocument45 pagesBetter Graphics r10 PDFdocsmsNo ratings yet

- J4500 Basic Electrical Schematics (Epa2017, Gen V) W/Parker VMM, Effective With Unit 68229Document91 pagesJ4500 Basic Electrical Schematics (Epa2017, Gen V) W/Parker VMM, Effective With Unit 68229HamiltonNo ratings yet

- 6ulsc Sample AbDocument2 pages6ulsc Sample Absana AshrafNo ratings yet

- Ethernet Transport Over PDH Networks With Virtual Concatenation TutorialDocument15 pagesEthernet Transport Over PDH Networks With Virtual Concatenation TutorialAnovar_ebooksNo ratings yet

- Population Control Measures in India Explained PointwiseDocument8 pagesPopulation Control Measures in India Explained PointwiseGAUTAM NATHNo ratings yet

- Course OutlineDocument5 pagesCourse OutlinesafdarnazeerNo ratings yet

- TAbles Bending Moments Shear Forces and Deflection TAbles PDFDocument25 pagesTAbles Bending Moments Shear Forces and Deflection TAbles PDFAhmed ShakerNo ratings yet

- Act1102 - Cfas - Course SyllabusDocument19 pagesAct1102 - Cfas - Course SyllabusFrancein CequenaNo ratings yet

- Hot Pumps & Thermal ExpansionDocument3 pagesHot Pumps & Thermal ExpansionMahmoud Al Homran100% (1)

- TLE6 Module5 Propagating Tress and Fruit-Bearing TreesDocument29 pagesTLE6 Module5 Propagating Tress and Fruit-Bearing TreesLorranne Maice D. Morano100% (1)

- KirkDocument6 pagesKirkSwinlife WinlifeNo ratings yet

- TrackersDocument14 pagesTrackersSabahudinBuroNo ratings yet

- Resume - Shubhanjali Srivastava - Component Dev. - UpdateDocument3 pagesResume - Shubhanjali Srivastava - Component Dev. - Updatesurjitrajput8No ratings yet

- Ls1eng Elem Las21 To-Las31-MergedDocument31 pagesLs1eng Elem Las21 To-Las31-MergedJaypee AturoNo ratings yet

ds_pv3540_en_co

ds_pv3540_en_co

Uploaded by

mastersalmanrazzaqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ds_pv3540_en_co

ds_pv3540_en_co

Uploaded by

mastersalmanrazzaqCopyright:

Available Formats

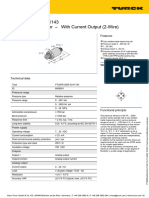

Pressure

Compact differential pressure switch

Models DC, DCC

WIKA data sheet PV 35.40

Process Compact Series

Applications

■ Pressure monitoring and control of processes

■ Safety-critical applications in general process instrumen-

tation, especially in the chemical and petrochemical indus-

tries, oil and gas industries, power generation incl. nuclear

power plants, water/wastewater industries, mining

■ For gaseous,liquid and aggressive media, also in

aggressive ambience

■ Filter and level monitoring

Special features

■ No power supply needed for switching of electrical loads

■ Robust switch enclosure from aluminium alloy or stainless

steel 316L, IP66, NEMA 4X

■ Setting ranges from 0 ... 160 mbar to 0 ... 40 bar with high

static and high one-sided pressure up to 250 bar

■ Ex ia version available

■ 1 set point, SPDT or DPDT, high switching power up to Differential pressure switch, model DC

AC 250 V, 15 A

Description

These high-quality pressure switches have been developed All wetted materials are from stainless steel as a standard.

especially for safety-critical applications. The high quality of For applications with special requirements on the wetted

the products and manufacturing in accordance with ISO 9001 parts, a version with Monel is available.

ensure reliable monitoring of your plant. In production, the

switches are traced by quality assurance software at every By using a diaphragm measuring system, the model DC

step and subsequently are 100 % tested. differential pressure switch is extremely robust and guaran-

tees optimal operating characteristics and the highest

In order to ensure as flexible operation as possible, measuring performances, with repeatability lower than 1 %

the pressure switches are fitted with micro switches, of span.

which enable the switching of an electrical load of up to

AC 250 V, 20 A directly. The process connection with a centre distance of 54 mm

For lower switching power ratings, such as for PLC appli- lower mount allows an easy and comfortable mounting of a

cations, argon gas-filled micro switches with gold-plated standard valve manifold.

contacts can be selected.

WIKA data sheet PV 35.40 ∙ 03/2021 Page 1 of 6

Data sheets showing similar products:

Compact differential pressure switch, flameproof enclosure Ex d; models DE, DEC; see data sheet PV 35.41

Standard version Ignition protection type (option)

■ Ex ia I Ma (mines), only available for model DC with stain-

Measuring system less steel switch enclosure

Double diaphragm with transmission shaft, without sealing ■ Ex ia IIC T6/T4 1) Ga (gas)

elements ■ Ex ia IIIC T85/T135 1) Da (dust)

1) The temperature class is related to the ambient temperature range. See the type exami-

Switch enclosure nation certificate for further details.

■ Aluminium alloy, copper-free, epoxy resin coated

Safety-related maximum values

■ Stainless steel 316L (only available for model DC)

(only for optional Ex ia versions)

Tamper-proof Maximum values

Laser-engraved product label from stainless steel Voltage Ui DC 30 V

Current li 100 mA

Ingress protection

IP66 per EN/lEC 60529, NEMA 4X Power Pi 0.75 W

Internal capacitance Ci 0 μF

Permissible temperature Internal inductance Li 0 mH

Ambient Tamb: -30 ... +85 °C

Medium T M: -30 ... +85 °C

Switch contact

Micro switches with fixed dead band

■ 1 x SPDT (single pole double throw)

■ 1 x DPDT (double pole double throw)

The DPDT function is realised with 2 simultaneously trigger-

ing SPDT micro switches within 2 % of the span.

Contact version Electrical rating (resistive load) Suitable for

AC DC Ex ia option

A 1 x SPDT, silver 250 V, 15 A 24 V, 2 A, 125 V, 0.5 A, 220 V, 0.25 A No

B 1 x SPDT, silver, hermetically sealed, argon gas filling 2) 250 V, 15 A 24 V, 2 A, 220 V, 0.5 A Yes

C 1 x SPDT, gold-plated, hermetically sealed, argon gas filling 2) 125 V, 1 A 24 V, 0.5 A Yes

G 1 x DPDT, silver 250 V, 1 A 24 V, 0.5 A No

2) Permissible ambient temperature range: -30 ... +70 °C

Set point adjustment Example

The set point can be specified by the customer or factory-set Setting range: 0 ... 10 bar with one switch contact

within the setting range. Subsequent adjustment of the set Repeatability: 1 % of 10 bar = 0.1 bar

point on site is made using the adjustment screw, which is Dead band: (see table setting ranges)

covered by the access cover plate with lead seal option. 2 x repeatability + dead band = 2 x 0.1 bar + 0.3 bar = 0.5 bar

Rising pressure: Adjust set point between 0.5 ...10 bar.

Repeatability of the set point Falling pressure: Adjust set point between 0 ... 9.5 bar.

≤ 1 % of span

Process connection

Please specify: Stainless steel, lower mount (LM)

Set point, switching direction for the contact, e.g.: ■ ¼ NPT female (standard)

Set point: 5 bar, rising ■ ½ NPT, G ½ A, G ¼ A male via adapter

■ ½ NPT, G ¼ female via adapter

For optimal performance we suggest to adjust the set point ■ M20 x 1.5 male via adapter

between 25 ... 75 % of the setting range.

WIKA data sheet PV 35.40 ∙ 03/2021 Page 2 of 6

Electrical connection For cable connections to the internal terminal block use wire

■ ½ NPT female (standard) cross-sections between 0.5 ... 2.5 mm2.

■ ¾ NPT, M20 x 1.5, G ½, G ¾ female For the grounding cable connection to the protective conduc-

■ Cable gland non-armoured, nickel-plated brass tor screws use max. 2.5 mm2 for the internal screw and max.

■ Cable gland non-armoured, stainless steel (AISI 304) 4 mm2 for the external screw.

■ Cable gland armoured, nickel-plated brass

■ Cable gland armoured, stainless steel (AISI 304) Dielectric strength

■ MIL connector, 7-pin, DTL 5015 Safety class I (IEC 61298-2: 2008)

Wetted parts, model DC

Setting range Stainless steel version NACE version (option) 1) Monel version (option)

Diaphragm Process con- Diaphragm Process con- Diaphragm Process

nection nection connection

0 ... 160 mbar AISI 316 AISI 316L Monel® 400 AISI 316L Monel® 400

0 ... 250 mbar

0 ... 400 mbar

0 ... 600 mbar

0 ... 1 bar

0 ... 2.5 bar

0 ... 4 bar AISI 304

0 ... 6 bar

0 ... 10 bar

0 ... 16 bar Inconel® 718 Inconel® 718 -

0 ... 25 bar

0 ... 40 bar

1) NACE compliant to MR 0175, ISO 15156 and MR 0103

Wetted parts, model DCC

Setting range Diaphragm Process con-

nection

0 ... 160 mbar Inconel® 718 Aluminium alloy

(EN AW-5082 per

0 ... 250 mbar

EN 573-3)

0 ... 400 mbar

0 ... 600 mbar

0 ... 1 bar

0 ... 1.6 bar

0 ... 2.5 bar

0 ... 4 bar

0 ... 6 bar

Sealing material for all models and versions: NBR

Mounting

■ Mounting fixture from stainless steel (AISI 304)

■ Option: Mounting bracket for 2" pipe mounting (AISI 304)

Weight

■ approx. 5.4 kg, switch enclosure aluminium alloy

■ approx. 5.9 kg, switch enclosure stainless steel

WIKA data sheet PV 35.40 ∙ 03/2021 Page 3 of 6

Setting range, model DC

Δp-cell Setting range Fixed dead band Static / One-sided pressure

for contact version

in bar 1 contact 1 contact in bar

A, B, C G

in mbar in mbar

L 0 ... 0.16 ≤6 ≤ 12 ≤ 40, ≤ 100 or ≤ 160

0 ...0.25 ≤8 ≤ 20

H 0 ... 0.4 ≤ 20 ≤ 40

0 ... 0.6 ≤ 25 ≤ 50

0 ... 1 ≤ 40 ≤ 80

0 ... 2.5 ≤ 70 ≤ 170 ≤ 40, ≤ 100, ≤ 160 or ≤ 250

0 ... 4 ≤ 120 ≤ 200

0 ... 6 ≤ 180 ≤ 250

0 ... 10 ≤ 300 ≤ 400

0 ... 16 ≤ 480 ≤ 600

0 ... 25 ≤ 700 ≤ 1,000

V 0 ... 40 ≤ 1,200 ≤ 1,800 ≤ 40, ≤ 100 or ≤ 160

Other available setting ranges:

■ -40 ... +120 mbar, -60 ... +190 mbar, -200 ... +200 mbar, -300 ... +300 mbar, -500 ... +500 mbar

■ -1.25 ... +1.25 bar, -2 ... +2 bar, -3 ... +3 bar, -5 ... +5 bar, -8 ... +8 bar, -12.5 ... +12.5 bar

Setting range, model DCC 1)

Δp-cell Setting range Fixed dead band Static / One-sided pressure

for contact version

in bar 1 contact 1 contact in bar

A, B, C G

in mbar in mbar

L 0 ... 0.25 ≤5 ≤ 10 ≤ 25

H 0 ... 1 ≤ 30 ≤ 50

0 ... 1.6 ≤ 50 ≤ 110

0 ... 2.5 ≤ 80 ≤ 170

0 ... 4 ≤ 120 ≤ 200

0 ... 6 ≤ 120 ≤ 200

1) For clean gas or non-condensing vapour only

Other setting ranges on request.

Other Versions Assembly

■ Ex ia version ■ Valve manifold for differential pressure measuring

■ Cleaned for oxygen service instruments, models IV30, IV31 and IV50 und IV51

■ Drying of wetted parts see data sheet AC 09.23

■ Offshore version 2) ■ Diaphragm seals, see website

■ NACE compliant to MR 0175, ISO 15156 and MR 0103 2) ■ Differential pressure gauge

■ Wetted parts from Monel

2) WIKA recommends argon gas-filled contact versions

3) Only available for model DC

WIKA data sheet PV 35.40 ∙ 03/2021 Page 4 of 6

Approvals

Logo Description Country

EU declaration of conformity European Community

■ Pressure equipment directive

■ Low voltage directive

■ RoHS directive

■ ATEX directive 1) (option)

IM1

II 1 GD

IECEx 1) (option) IECEx member states

Ex ia I Ma

Ex ia IIC T6/T4 2) Ga

Ex ia IIIC T85/T135 2) Da

EAC (option) Eurasian Economic

Hazardous areas Community

Ex-Ukraine (option) Ukraine

Hazardous areas

CCC (option) China

Hazardous areas

KOSHA (option) South Korea

Hazardous areas

1) Double marking ATEX and IECEx on the same product label

2) The temperature class is related to the ambient temperature range

Manufacturer‘s information and certifications

Logo Description

SIL 2 rating (option), per IEC 61508

Functional safety

Only available with contact version B or C

Certificates (option)

■ 2.2 test report per EN 10204

■ 3.1 inspection certificate per EN 10204

Approvals and certificates, see website

WIKA data sheet PV 35.40 ∙ 03/2021 Page 5 of 6

Dimensions in mm

Switch enclosure: Aluminium alloy Switch enclosure: Stainless steel 316L

Legend

A ⊖ Process connection C Electrical connection

B ⊕ Process connection V Vent

Assembly examples

Direct mounting with valve manifold Mounting via capillary to diaphragm seals

Ordering information

Model / Static - One-sided pressure / Δp-cell / Switch enclosure / Contact version / Setting range / Process connection /

Electrical connection / Options

© 12/2010 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

03/2021 EN

WIKA data sheet PV 35.40 ∙ 03/2021 Page 6 of 6

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Accor - Graphic Guidelines - L050319Document105 pagesAccor - Graphic Guidelines - L050319Mohamed OmariNo ratings yet

- DS_PV3541_en_co_1806Document6 pagesDS_PV3541_en_co_1806mastersalmanrazzaqNo ratings yet

- Ds pv3542 en CoDocument6 pagesDs pv3542 en CoPajnuNo ratings yet

- ds_pv3543_en_coDocument6 pagesds_pv3543_en_comastersalmanrazzaqNo ratings yet

- DS_PV3221_en_co_1844Document6 pagesDS_PV3221_en_co_1844sp.marianNo ratings yet

- Micro Fused: Pressure TransmitterDocument6 pagesMicro Fused: Pressure Transmitterayyalu samyNo ratings yet

- Three-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmDocument12 pagesThree-Phase Voltage and Phase-Sequence Phase-Loss Relay: K8Ds-PmSalaar AnsarNo ratings yet

- PRD Doc Pro 18327-00001 Sen Ain V2Document2 pagesPRD Doc Pro 18327-00001 Sen Ain V2Rabetto Juanre Pahlevi Goklas HutasoitNo ratings yet

- SAP4825DDocument4 pagesSAP4825DbhizartNo ratings yet

- SQM48T20025 NBB0Document33 pagesSQM48T20025 NBB0Gabriel RacovskyNo ratings yet

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocument12 pagesDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminNo ratings yet

- Wika Ac1Document4 pagesWika Ac1DOUBENo ratings yet

- Gs01c22b03-00en (22) Eja120Document8 pagesGs01c22b03-00en (22) Eja120Nguyen ThuongNo ratings yet

- VG-2W Series: MotienDocument4 pagesVG-2W Series: MotienYonatan RivadeneyraNo ratings yet

- En18068-3-02-18 Eds3300 Plus VdmaDocument4 pagesEn18068-3-02-18 Eds3300 Plus VdmaigorNo ratings yet

- DIN-A-MITE Solid-State Power ControllerDocument21 pagesDIN-A-MITE Solid-State Power Controllermisael123No ratings yet

- Tdf3 NewDocument2 pagesTdf3 NewSơn Lê CaoNo ratings yet

- 3RQ31181AM00 Datasheet enDocument5 pages3RQ31181AM00 Datasheet enDayane CruzNo ratings yet

- 3RN20121BW31 Datasheet enDocument7 pages3RN20121BW31 Datasheet enAmir YuliNo ratings yet

- CONTRINEX Safety RelaysDocument2 pagesCONTRINEX Safety RelaysMarcos AldrovandiNo ratings yet

- Limit-Switch For Standard Signals: AD-MK 330 GSDocument2 pagesLimit-Switch For Standard Signals: AD-MK 330 GSМихаил БеребердинNo ratings yet

- SBL3030PT, SBL3040PT: Vishay General SemiconductorDocument4 pagesSBL3030PT, SBL3040PT: Vishay General Semiconductorrammstein4445No ratings yet

- Data Sheet: DFS 2 025-2/0,03-A Hz60 V120Document3 pagesData Sheet: DFS 2 025-2/0,03-A Hz60 V120Gustavo GamezNo ratings yet

- 3RN2010 1BW30Document7 pages3RN2010 1BW30dachinicuNo ratings yet

- FTL260 Catalogue EngDocument4 pagesFTL260 Catalogue EngalexkeserNo ratings yet

- PT250R-2004-I2-H1143 Pressure Transmitter - With Current Output (2-Wire)Document2 pagesPT250R-2004-I2-H1143 Pressure Transmitter - With Current Output (2-Wire)Ran DomaNo ratings yet

- Ds pv3331 en CoDocument7 pagesDs pv3331 en Co9033301054No ratings yet

- Ordering Information: PCB RelayDocument6 pagesOrdering Information: PCB RelayManikandan GurunathanNo ratings yet

- 2CDC002137D0201 - Data Sheet S200SDocument8 pages2CDC002137D0201 - Data Sheet S200Sadelone23No ratings yet

- Ashcroft - Pressure Switch PDFDocument2 pagesAshcroft - Pressure Switch PDFAnand SinhaNo ratings yet

- DDR 30 Spec PDFDocument4 pagesDDR 30 Spec PDFencus170785No ratings yet

- Eds3400 Plus VdmaDocument4 pagesEds3400 Plus VdmasunhuynhNo ratings yet

- HV Voltage TransformersDocument4 pagesHV Voltage TransformersSharafatNo ratings yet

- Harmony Electromechanical Relays - RXM2LB2P7Document6 pagesHarmony Electromechanical Relays - RXM2LB2P7ikhsanul islahNo ratings yet

- Zelio Relay - RXM2LB2BDDocument7 pagesZelio Relay - RXM2LB2BDTrần Anh LuậtNo ratings yet

- K3ma L PDFDocument16 pagesK3ma L PDFsydifiaNo ratings yet

- Ordering Information: Power RelayDocument6 pagesOrdering Information: Power RelayAndrei Ponce WongNo ratings yet

- Datasheet - XN-322-16DI-PD: Part No. Article No. Catalog NoDocument10 pagesDatasheet - XN-322-16DI-PD: Part No. Article No. Catalog NocristianoNo ratings yet

- 8567 RelayDocument3 pages8567 RelayAmandaNo ratings yet

- Va-0.5w DatasheetDocument5 pagesVa-0.5w Datasheetbruno buinNo ratings yet

- 09 FCS084 A09 1 PDFDocument2 pages09 FCS084 A09 1 PDFsaurabh kumarNo ratings yet

- D 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleDocument7 pagesD 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleadrianioantomaNo ratings yet

- Pressure Transmitter For Refrigeration and HVAC Applications Model AC-1Document4 pagesPressure Transmitter For Refrigeration and HVAC Applications Model AC-1Kumphala LuahrNo ratings yet

- Lm2825n Datasheet PDF AipcbaDocument21 pagesLm2825n Datasheet PDF AipcbaBarth XaosNo ratings yet

- Electronic Pressure Switch EDS 8000: Description: Technical SpecificationsDocument2 pagesElectronic Pressure Switch EDS 8000: Description: Technical Specificationsclaudinei alves fonsecaNo ratings yet

- High Current Relay 200Document3 pagesHigh Current Relay 200ShiaTVfanNo ratings yet

- Pressure Switch CQ21Document7 pagesPressure Switch CQ21محمد امين التشغيل الآليNo ratings yet

- LED Driver. Xitanium. 30W 1.2A 0-10V Dimming XI030C120V040BSJ1. Specifications. Wiring DiagramDocument8 pagesLED Driver. Xitanium. 30W 1.2A 0-10V Dimming XI030C120V040BSJ1. Specifications. Wiring DiagramRicardo LopezNo ratings yet

- Epsitron - Capacitive Buffer Modules: DescriptionDocument1 pageEpsitron - Capacitive Buffer Modules: DescriptionHector bonillaNo ratings yet

- MCB DBDocument36 pagesMCB DBRAVIKANT SINDHENo ratings yet

- Pressure Transducer: SpecificationsDocument9 pagesPressure Transducer: SpecificationsWILLIAM AGUDELONo ratings yet

- DBM20 DatasheetDocument6 pagesDBM20 DatasheetMohammed BenzaidiNo ratings yet

- Siemens CLS 200Document16 pagesSiemens CLS 200Stenio LanzaNo ratings yet

- D5C Touch SwitchDocument8 pagesD5C Touch SwitchMuhamad PriyatnaNo ratings yet

- Nivoswitch: Vibrating Fork Level SwitchesDocument6 pagesNivoswitch: Vibrating Fork Level SwitchesArnaldo BenitezNo ratings yet

- Monitoring Relays 1-Phase True RMS AC/DC Over or Under Current Types DIB02, PIB02Document4 pagesMonitoring Relays 1-Phase True RMS AC/DC Over or Under Current Types DIB02, PIB02ShiaTVfanNo ratings yet

- Edb - 6836591 - GBR - en ASP 1000Document2 pagesEdb - 6836591 - GBR - en ASP 1000Ana NedeljkovicNo ratings yet

- NL Limit Touch SwitchDocument9 pagesNL Limit Touch SwitchMuhamad PriyatnaNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Ethics in Engineering, 2005, 339 Pages, Mike Martin, Roland Schinzinger, 0072831154, 9780072831153, Mcgraw-Hill Education, 2005Document17 pagesEthics in Engineering, 2005, 339 Pages, Mike Martin, Roland Schinzinger, 0072831154, 9780072831153, Mcgraw-Hill Education, 2005Zakir HossenNo ratings yet

- An Wallis Earthing Lightning ProtectionDocument117 pagesAn Wallis Earthing Lightning Protectiongoitom01No ratings yet

- Bangalore University: "Student Attendance Management"Document10 pagesBangalore University: "Student Attendance Management"Rohit VilliersNo ratings yet

- Man and SupermanDocument4 pagesMan and SupermanSrestha Kar100% (1)

- SD220511 01Document1 pageSD220511 01Minh TranNo ratings yet

- A Methodology To Develop Computer Vision Systems in Civil Engineering - Applications in Material Testing and Fish Tracking PDFDocument309 pagesA Methodology To Develop Computer Vision Systems in Civil Engineering - Applications in Material Testing and Fish Tracking PDFMicrodigital WareNo ratings yet

- Salleh2021 Article TheEmergenceOfVeryLargeContainDocument21 pagesSalleh2021 Article TheEmergenceOfVeryLargeContainSajid KhanNo ratings yet

- "W.C. Asorio's ASC Me' Model of Care": NAME: Asorio, Wendale Claire G. Student ID#: 18-0972-39Document3 pages"W.C. Asorio's ASC Me' Model of Care": NAME: Asorio, Wendale Claire G. Student ID#: 18-0972-39Wendale Claire G. ASORIONo ratings yet

- Lead Acid BatteryDocument23 pagesLead Acid BatteryBrahmpal BhardwajNo ratings yet

- Linear Programming TheoryDocument99 pagesLinear Programming TheoryRamez SafwatNo ratings yet

- Ansys Fluent Brings CFD Performance With Intel Processors and FabricsDocument8 pagesAnsys Fluent Brings CFD Performance With Intel Processors and FabricsSaid FerdjallahNo ratings yet

- ME ListDocument3 pagesME ListAltoNo ratings yet

- Erp Case StudyDocument2 pagesErp Case StudymehakNo ratings yet

- ART300Document45 pagesART300Gerlyn OrdonioNo ratings yet

- UntitledDocument27 pagesUntitledFlavio MagelaNo ratings yet

- Better Graphics r10 PDFDocument45 pagesBetter Graphics r10 PDFdocsmsNo ratings yet

- J4500 Basic Electrical Schematics (Epa2017, Gen V) W/Parker VMM, Effective With Unit 68229Document91 pagesJ4500 Basic Electrical Schematics (Epa2017, Gen V) W/Parker VMM, Effective With Unit 68229HamiltonNo ratings yet

- 6ulsc Sample AbDocument2 pages6ulsc Sample Absana AshrafNo ratings yet

- Ethernet Transport Over PDH Networks With Virtual Concatenation TutorialDocument15 pagesEthernet Transport Over PDH Networks With Virtual Concatenation TutorialAnovar_ebooksNo ratings yet

- Population Control Measures in India Explained PointwiseDocument8 pagesPopulation Control Measures in India Explained PointwiseGAUTAM NATHNo ratings yet

- Course OutlineDocument5 pagesCourse OutlinesafdarnazeerNo ratings yet

- TAbles Bending Moments Shear Forces and Deflection TAbles PDFDocument25 pagesTAbles Bending Moments Shear Forces and Deflection TAbles PDFAhmed ShakerNo ratings yet

- Act1102 - Cfas - Course SyllabusDocument19 pagesAct1102 - Cfas - Course SyllabusFrancein CequenaNo ratings yet

- Hot Pumps & Thermal ExpansionDocument3 pagesHot Pumps & Thermal ExpansionMahmoud Al Homran100% (1)

- TLE6 Module5 Propagating Tress and Fruit-Bearing TreesDocument29 pagesTLE6 Module5 Propagating Tress and Fruit-Bearing TreesLorranne Maice D. Morano100% (1)

- KirkDocument6 pagesKirkSwinlife WinlifeNo ratings yet

- TrackersDocument14 pagesTrackersSabahudinBuroNo ratings yet

- Resume - Shubhanjali Srivastava - Component Dev. - UpdateDocument3 pagesResume - Shubhanjali Srivastava - Component Dev. - Updatesurjitrajput8No ratings yet

- Ls1eng Elem Las21 To-Las31-MergedDocument31 pagesLs1eng Elem Las21 To-Las31-MergedJaypee AturoNo ratings yet