Professional Documents

Culture Documents

Bitupaint FR.TDS

Bitupaint FR.TDS

Uploaded by

Boopathi RaghavanCopyright:

Available Formats

You might also like

- CallRecord LogDocument17 pagesCallRecord LogLela SokhateriNo ratings yet

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- Bituprimer-S TDSDocument1 pageBituprimer-S TDSazharh535No ratings yet

- Acrilem ST190: Product DescriptionDocument2 pagesAcrilem ST190: Product DescriptionMachidon OanaNo ratings yet

- LIPATON SB 5843Document2 pagesLIPATON SB 5843trabelsicyrine53No ratings yet

- 1 Cipothane SLDocument3 pages1 Cipothane SLpremieragencies22No ratings yet

- Sika SanisilDocument4 pagesSika SanisilA GlaumNo ratings yet

- ACR01Document2 pagesACR01s_omeone4usNo ratings yet

- Bitumen Emulsion TDSDocument1 pageBitumen Emulsion TDSSagar MishraNo ratings yet

- Tritosil W70-TDSDocument4 pagesTritosil W70-TDSRANo ratings yet

- Concrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoDocument2 pagesConcrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoVincent JavateNo ratings yet

- JTCC - Ultrapower MP - EditedDocument2 pagesJTCC - Ultrapower MP - EditedAdhigana QSNo ratings yet

- Myk Arment Sealarm Pu Sealant 600mlDocument2 pagesMyk Arment Sealarm Pu Sealant 600mlpraveenpatel.pp7143No ratings yet

- Alcolin Fire Stop Neutral Silicone: Technical Data SheetDocument6 pagesAlcolin Fire Stop Neutral Silicone: Technical Data SheetTonyNo ratings yet

- 1 Component KiiltoDocument2 pages1 Component KiiltoMantas ButrimaviciusNo ratings yet

- Weberep 360 FFRDocument2 pagesWeberep 360 FFRBasemNo ratings yet

- ZNT 1000hasDocument2 pagesZNT 1000hasSugi. masco.proteksiNo ratings yet

- Polycrete FC: Polymer Modified Cementitious Fairing CoatDocument2 pagesPolycrete FC: Polymer Modified Cementitious Fairing Coatmohamed ragabNo ratings yet

- Masterprotect 190 TdsDocument3 pagesMasterprotect 190 Tdsjonte kimondioNo ratings yet

- Luxaprime1801 Chromate Free Etch PrimerDocument2 pagesLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraNo ratings yet

- Sika Monotop®-610: Product Data SheetDocument3 pagesSika Monotop®-610: Product Data SheetViet LeNo ratings yet

- Sika Polysulphide GG PDS GCCDocument3 pagesSika Polysulphide GG PDS GCCsilver rayNo ratings yet

- Cr-Durapatch - TDSDocument3 pagesCr-Durapatch - TDSMurali PokkunuriNo ratings yet

- Solvent-Free, Low Viscosity Epoxy ResinDocument2 pagesSolvent-Free, Low Viscosity Epoxy ResinYASHICA VAITTIANATHANNo ratings yet

- TDS Bitulastic BituflexDocument3 pagesTDS Bitulastic Bituflexd TjonasanNo ratings yet

- Xylan 80-018-g6706 Black - BeDocument2 pagesXylan 80-018-g6706 Black - BeSYED MAZHARNo ratings yet

- Syncoat: Description PrecautionsDocument2 pagesSyncoat: Description Precautionss_omeone4usNo ratings yet

- VT-638FC MS Seam Sealant: Vital Technical Sdn. BHDDocument2 pagesVT-638FC MS Seam Sealant: Vital Technical Sdn. BHDal varezNo ratings yet

- Mastertile 530: Description Coverage / YieldDocument2 pagesMastertile 530: Description Coverage / Yieldbassem muhannaNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- Single Component Shrink-Free Structural Grout: FeaturesDocument2 pagesSingle Component Shrink-Free Structural Grout: Featuresmathewsujith31No ratings yet

- ZNT 500Document2 pagesZNT 500Faisal FaizNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- Kansai ZNT - 1000Document2 pagesKansai ZNT - 1000Sugi. masco.proteksiNo ratings yet

- SealArm PU 2K PF-Ver6Document2 pagesSealArm PU 2K PF-Ver6Rajesh GiriNo ratings yet

- Primer TC PDFDocument3 pagesPrimer TC PDFFrancois-No ratings yet

- PDS - 340 Deck Protect BC Body Coat (February 2014)Document2 pagesPDS - 340 Deck Protect BC Body Coat (February 2014)Sphesihle MagubaneNo ratings yet

- Mrf Dampproof ExteriorDocument5 pagesMrf Dampproof Exterioranishbnair24No ratings yet

- THMT SCDocument2 pagesTHMT SCZaheer Ahmad RazaNo ratings yet

- Sikatop - 107 Sealid 221102 105735Document4 pagesSikatop - 107 Sealid 221102 105735Andre SitumeangNo ratings yet

- Pumast 600: Polyurethane Based, One Component, Joint SealantDocument3 pagesPumast 600: Polyurethane Based, One Component, Joint SealantLulzim BeqirajNo ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- Brimo-Thane Gun Grade Sealant: More Color, More ChoiceDocument2 pagesBrimo-Thane Gun Grade Sealant: More Color, More Choiceمحمد عزتNo ratings yet

- G - Documentacio - FITXA TECNICA - FITXES TCNIQUES PROVEDORS PAPERS - RITRAMA - 801 F.T RI-6493-180 PET-V GLOSS CLEAR AR827B PET30CR2XDocument1 pageG - Documentacio - FITXA TECNICA - FITXES TCNIQUES PROVEDORS PAPERS - RITRAMA - 801 F.T RI-6493-180 PET-V GLOSS CLEAR AR827B PET30CR2XDavidNo ratings yet

- Sikatop 107 Seal - Pds en PDFDocument3 pagesSikatop 107 Seal - Pds en PDFMarthinus Tonny PangemananNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- SikaMonoTop 620MY en MY (11 2018) 1 1Document3 pagesSikaMonoTop 620MY en MY (11 2018) 1 1chanqiming51No ratings yet

- TDS - Penguard Midcoat Mio 80Document4 pagesTDS - Penguard Midcoat Mio 80GunarsyahNo ratings yet

- Isolith-M: Waterproof Marble & Tile AdhesiveDocument2 pagesIsolith-M: Waterproof Marble & Tile AdhesiveContracting and Trading CompanyNo ratings yet

- Masterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembraneDocument3 pagesMasterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembranehemantrulzNo ratings yet

- Sikabit Pro P 30 0peDocument3 pagesSikabit Pro P 30 0peSlamet Tri UsadhaNo ratings yet

- Clay Bitumen EmulsionDocument2 pagesClay Bitumen EmulsionCharles LangatNo ratings yet

- Fosroc-Brushbond (Waterproofing Coating)Document2 pagesFosroc-Brushbond (Waterproofing Coating)Boy GalihNo ratings yet

- Ficha Inscripcion SSDocument2 pagesFicha Inscripcion SSalexNo ratings yet

- Asmaco PU SealantDocument3 pagesAsmaco PU SealantJoseph EzekielNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- Sika Construction Data SheetDocument4 pagesSika Construction Data SheetsathiyanNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- b_1_10_lawsDocument1 pageb_1_10_lawsBoopathi RaghavanNo ratings yet

- b_1_9_paymentDocument2 pagesb_1_9_paymentBoopathi RaghavanNo ratings yet

- b_1_8_control_of_the_worksDocument3 pagesb_1_8_control_of_the_worksBoopathi RaghavanNo ratings yet

- b_1_7_the_works_unlockedDocument2 pagesb_1_7_the_works_unlockedBoopathi RaghavanNo ratings yet

- Building and Engineering WorksDocument132 pagesBuilding and Engineering WorksBoopathi RaghavanNo ratings yet

- LT-OP-012 General Adoption ManualDocument176 pagesLT-OP-012 General Adoption ManualBoopathi RaghavanNo ratings yet

- PROJECT GUIDILINESDocument7 pagesPROJECT GUIDILINESBoopathi RaghavanNo ratings yet

- North Country AutoDocument9 pagesNorth Country AutoSamu BorgesNo ratings yet

- FDA Letter To IndustryDocument2 pagesFDA Letter To IndustryFrank HerreraNo ratings yet

- Qlik Certification Program FAQ enDocument6 pagesQlik Certification Program FAQ ensmederevac1977No ratings yet

- Billet RhomboidityDocument2 pagesBillet RhomboidityLowerclown Romanes100% (1)

- Verfication Performa PDFDocument1 pageVerfication Performa PDFAhmad JamalNo ratings yet

- How To Get Work Items From Workflow in Your Outlook Inbox PDFDocument9 pagesHow To Get Work Items From Workflow in Your Outlook Inbox PDFismailimran09No ratings yet

- Midyear 23 24.t1 t3Document3 pagesMidyear 23 24.t1 t3mylinafabi5No ratings yet

- CHAPTER-4 Masonry Wall DesignDocument16 pagesCHAPTER-4 Masonry Wall DesignMohammed AwadNo ratings yet

- Lecture No. 9 Basic Principles of CT ScanDocument24 pagesLecture No. 9 Basic Principles of CT ScanMohammed Khalil SaeedNo ratings yet

- Specifications of VCB With AccessoriesDocument2 pagesSpecifications of VCB With AccessoriesMuhammad NaveedNo ratings yet

- Akbar2015Document33 pagesAkbar2015DEDY KURNIAWANNo ratings yet

- Sustainable Tourism Development ProjectDocument4 pagesSustainable Tourism Development ProjectKularajah ThuthirajNo ratings yet

- Mercedes CatalogDocument84 pagesMercedes CatalogJeffrey Cunningham100% (9)

- Unit 1 - LL 2 - 3Document24 pagesUnit 1 - LL 2 - 3Hegde2626No ratings yet

- TM Promo NameDocument10 pagesTM Promo NameCristel Simbol TinguhaNo ratings yet

- Entity Framework Net CoreDocument74 pagesEntity Framework Net Corerdslinkac100% (1)

- Chapter 1 - Managing Human Resources: Learning ObjectivesDocument8 pagesChapter 1 - Managing Human Resources: Learning ObjectivesĐức NguyễnNo ratings yet

- LO 2 Apply Java Advanced Class Design and Object Oriented Design PrinciplesDocument24 pagesLO 2 Apply Java Advanced Class Design and Object Oriented Design PrinciplesLJames SacuezaNo ratings yet

- OooooobbbbbbDocument134 pagesOooooobbbbbbAmedin TemamNo ratings yet

- 2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Document4 pages2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Progress QueensNo ratings yet

- Data Collection Timeline FinalDocument4 pagesData Collection Timeline Finalapi-631736561No ratings yet

- HRM 822 Group Assignment 1Document12 pagesHRM 822 Group Assignment 1Dhruvi RajNo ratings yet

- Eaton Vacuum Interruption (EVI) Technology - BR - 03 - 2013Document8 pagesEaton Vacuum Interruption (EVI) Technology - BR - 03 - 2013Venna Karthik ReddyNo ratings yet

- Transient and Steady-State Analysis of A SEPIC Converter by An Average State-Space ModellingDocument5 pagesTransient and Steady-State Analysis of A SEPIC Converter by An Average State-Space ModellingPablo PulacheNo ratings yet

- Concert: Certified Installer Plus - Enterprise Solutions Partner (Cip-Esp)Document2 pagesConcert: Certified Installer Plus - Enterprise Solutions Partner (Cip-Esp)AndresNo ratings yet

- AE211 Final ExamDocument10 pagesAE211 Final ExamMariette Alex AgbanlogNo ratings yet

- Harbin Culture Centre Final Draft 02Document6 pagesHarbin Culture Centre Final Draft 02Shamoon ZubairNo ratings yet

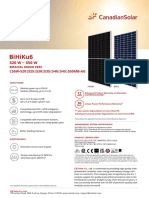

- CS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)Document2 pagesCS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)AlejandraNo ratings yet

- Nslookup For Dns CacheDocument31 pagesNslookup For Dns Cacheapi-418424782No ratings yet

Bitupaint FR.TDS

Bitupaint FR.TDS

Uploaded by

Boopathi RaghavanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bitupaint FR.TDS

Bitupaint FR.TDS

Uploaded by

Boopathi RaghavanCopyright:

Available Formats

CAT No.

WP-06-2305

BITUPAINT – FR

Fiber-Reinforced Bituminous Coating

BITUPAINT-FR is a medium viscosity, high build brushing consistency asphalt designed as a permanent, waterproof

barrier to protect concrete against entry of water. It consist of asphalt cement, solvents and non -asbestos fibrous

reinforcements. It can also be applied on steel as an anti-corrosion protection.

USES

BITUPAINT-FR is used for waterproofing of below grade concrete structures such as structural foundation walls,

floor slabs, blinding, footings and other concrete in contact with the ground. BITUPAINT-FR can also be used for

repairing worn felt asphalt roofs, parapets, flashings.

ADVANTAGES

Resistant to water, alkalies, chlorides, sulfates, mild acids and organic matter in soils.

Non-asbestos fibers provide reinforcement against cracking or blistering.

Single component, excellent flexibility, cold applied.

Brushing, high-build consistency for thicker application.

Excellent adhesion to steel and cement bound substrates.

Can be applied by brush, roller or trowel.

SPECIFICATION

BITUPAINT-FR conforms with the requirements of BS 3416 Type 2, Class C.

TYPICAL PROPERTIES

Specific gravity 1.0 – 1.20

Solid Content, by volume 78 +/- 2%

Bend Test (10mm mandrel) Pass. No cracking

Surface Dry time* Within 8 hours

(* BS 3416 Appendix C)

Full cure Within 72 hours

DIRECTIONS FOR USE

SURFACE PREPARATION

Surface should be clean, dry and free from rust, mill scale, dust, dirt, sealers, curing compounds, grease oil and

other foreign matters. For cleaning of oil or grease deposits, use ISOLA CHEMICAL DEGREASER. Substrate should

first be treated with BITUPRIMER-S applied at the rate of 5 – 5.5 square meters, per liter, one coat. This should

An ISO 9001: 2015 Certified Company

be allowed to dry for at least 4 hours prior to coating with BITUPAINT – FR. (Note: It is always advisable to prime

surface to ease brushing and to bind loose dust particles).

APPLICATION

Mix the material manually until homogeneous in appearance. Apply BITUPAINT – FR by brush or trowel on the

surface to be waterproofed in a continuous unbroken fillm free from surface breaks and pinholes. Additional

coats are highly recommended especially on above ground structures. However, each coat should be allowed to

dry until tack free for at least 24 hours. Once dry, BITUPAINT – FR should be protected from getting damaged

using protection boards.

PACKING / COVERAGE

BITUPAINT-FR is packed in 18 liter metal pail. Theoretical coverages are given below for guidance.

250 microns Dry film thickness 3 sq. mtr/ liter

500 microns Dry film thickness 1.5 sq. mtr/ liter

750 microns Dry film thickness 1.0 sq. mtr/ liter

1000 microns Dry film thickness 0.8 sq. mtr/ liter

This coverage only applies to a smooth, level surface and will be lesser depending on surface profile and

irregularities. It is always advisable to maintain the minimum coating thickness regardless of the nature of the

substrate. The use of wet-film thickness gauge to check the coating thickness is highly recommended.

CAUTION

BITUPAINT-FR contains solvent. Keep away from open flames. In case of fire, extinguish with sand or carbon

dioxide extinguisher. Always store in full shade. Keep away from direct sunlight.

HEALTH/ SAFETY

Always use protective clothing, hand gloves and eye goggles when using this product. Always ensure adequate

ventilation when working on confined spaces. When accidentally spilled on the skin, wash immediately with water

and soap. Refer to MSDS for more instructions.

SHELF LIFE

Eighteen (18) months in original unopened container stored in warehouse condition.

Revised: 30.05.2023

Technical information, data are to be considered as typical values and not sales specification. Actual measured values may vary due to factors beyond our control. Indications concerning function and

application of the products are empirical. Although the information is believed to be accurate, there is no warranty by ISOLA. None of the recommendations becomes part of the warranted quality of

the products. Due to the fact that the conditions of individual use are beyond ISOLA’s direct and continuous control, ISOLA disclaims all responsibility in connection with the use of its products and does

not warrant against any loss direct or consequential

ISOLA SOLUTIONS W.L.L

P.O. Box 530, Manama, Kingdom of Bahrain, Tel: 17784777, Fax:17911422, Email: isola@hajihassan.com, web: www.isolasolutions.com

An ISO 9001: 2015 Certified Company

You might also like

- CallRecord LogDocument17 pagesCallRecord LogLela SokhateriNo ratings yet

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- Bituprimer-S TDSDocument1 pageBituprimer-S TDSazharh535No ratings yet

- Acrilem ST190: Product DescriptionDocument2 pagesAcrilem ST190: Product DescriptionMachidon OanaNo ratings yet

- LIPATON SB 5843Document2 pagesLIPATON SB 5843trabelsicyrine53No ratings yet

- 1 Cipothane SLDocument3 pages1 Cipothane SLpremieragencies22No ratings yet

- Sika SanisilDocument4 pagesSika SanisilA GlaumNo ratings yet

- ACR01Document2 pagesACR01s_omeone4usNo ratings yet

- Bitumen Emulsion TDSDocument1 pageBitumen Emulsion TDSSagar MishraNo ratings yet

- Tritosil W70-TDSDocument4 pagesTritosil W70-TDSRANo ratings yet

- Concrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoDocument2 pagesConcrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoVincent JavateNo ratings yet

- JTCC - Ultrapower MP - EditedDocument2 pagesJTCC - Ultrapower MP - EditedAdhigana QSNo ratings yet

- Myk Arment Sealarm Pu Sealant 600mlDocument2 pagesMyk Arment Sealarm Pu Sealant 600mlpraveenpatel.pp7143No ratings yet

- Alcolin Fire Stop Neutral Silicone: Technical Data SheetDocument6 pagesAlcolin Fire Stop Neutral Silicone: Technical Data SheetTonyNo ratings yet

- 1 Component KiiltoDocument2 pages1 Component KiiltoMantas ButrimaviciusNo ratings yet

- Weberep 360 FFRDocument2 pagesWeberep 360 FFRBasemNo ratings yet

- ZNT 1000hasDocument2 pagesZNT 1000hasSugi. masco.proteksiNo ratings yet

- Polycrete FC: Polymer Modified Cementitious Fairing CoatDocument2 pagesPolycrete FC: Polymer Modified Cementitious Fairing Coatmohamed ragabNo ratings yet

- Masterprotect 190 TdsDocument3 pagesMasterprotect 190 Tdsjonte kimondioNo ratings yet

- Luxaprime1801 Chromate Free Etch PrimerDocument2 pagesLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraNo ratings yet

- Sika Monotop®-610: Product Data SheetDocument3 pagesSika Monotop®-610: Product Data SheetViet LeNo ratings yet

- Sika Polysulphide GG PDS GCCDocument3 pagesSika Polysulphide GG PDS GCCsilver rayNo ratings yet

- Cr-Durapatch - TDSDocument3 pagesCr-Durapatch - TDSMurali PokkunuriNo ratings yet

- Solvent-Free, Low Viscosity Epoxy ResinDocument2 pagesSolvent-Free, Low Viscosity Epoxy ResinYASHICA VAITTIANATHANNo ratings yet

- TDS Bitulastic BituflexDocument3 pagesTDS Bitulastic Bituflexd TjonasanNo ratings yet

- Xylan 80-018-g6706 Black - BeDocument2 pagesXylan 80-018-g6706 Black - BeSYED MAZHARNo ratings yet

- Syncoat: Description PrecautionsDocument2 pagesSyncoat: Description Precautionss_omeone4usNo ratings yet

- VT-638FC MS Seam Sealant: Vital Technical Sdn. BHDDocument2 pagesVT-638FC MS Seam Sealant: Vital Technical Sdn. BHDal varezNo ratings yet

- Mastertile 530: Description Coverage / YieldDocument2 pagesMastertile 530: Description Coverage / Yieldbassem muhannaNo ratings yet

- G4258 Silver - Pds-EnDocument3 pagesG4258 Silver - Pds-EnuraliNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- Single Component Shrink-Free Structural Grout: FeaturesDocument2 pagesSingle Component Shrink-Free Structural Grout: Featuresmathewsujith31No ratings yet

- ZNT 500Document2 pagesZNT 500Faisal FaizNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- Kansai ZNT - 1000Document2 pagesKansai ZNT - 1000Sugi. masco.proteksiNo ratings yet

- SealArm PU 2K PF-Ver6Document2 pagesSealArm PU 2K PF-Ver6Rajesh GiriNo ratings yet

- Primer TC PDFDocument3 pagesPrimer TC PDFFrancois-No ratings yet

- PDS - 340 Deck Protect BC Body Coat (February 2014)Document2 pagesPDS - 340 Deck Protect BC Body Coat (February 2014)Sphesihle MagubaneNo ratings yet

- Mrf Dampproof ExteriorDocument5 pagesMrf Dampproof Exterioranishbnair24No ratings yet

- THMT SCDocument2 pagesTHMT SCZaheer Ahmad RazaNo ratings yet

- Sikatop - 107 Sealid 221102 105735Document4 pagesSikatop - 107 Sealid 221102 105735Andre SitumeangNo ratings yet

- Pumast 600: Polyurethane Based, One Component, Joint SealantDocument3 pagesPumast 600: Polyurethane Based, One Component, Joint SealantLulzim BeqirajNo ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- Brimo-Thane Gun Grade Sealant: More Color, More ChoiceDocument2 pagesBrimo-Thane Gun Grade Sealant: More Color, More Choiceمحمد عزتNo ratings yet

- G - Documentacio - FITXA TECNICA - FITXES TCNIQUES PROVEDORS PAPERS - RITRAMA - 801 F.T RI-6493-180 PET-V GLOSS CLEAR AR827B PET30CR2XDocument1 pageG - Documentacio - FITXA TECNICA - FITXES TCNIQUES PROVEDORS PAPERS - RITRAMA - 801 F.T RI-6493-180 PET-V GLOSS CLEAR AR827B PET30CR2XDavidNo ratings yet

- Sikatop 107 Seal - Pds en PDFDocument3 pagesSikatop 107 Seal - Pds en PDFMarthinus Tonny PangemananNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- SikaMonoTop 620MY en MY (11 2018) 1 1Document3 pagesSikaMonoTop 620MY en MY (11 2018) 1 1chanqiming51No ratings yet

- TDS - Penguard Midcoat Mio 80Document4 pagesTDS - Penguard Midcoat Mio 80GunarsyahNo ratings yet

- Isolith-M: Waterproof Marble & Tile AdhesiveDocument2 pagesIsolith-M: Waterproof Marble & Tile AdhesiveContracting and Trading CompanyNo ratings yet

- Masterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembraneDocument3 pagesMasterseal M 635: Flexible and Elastic Single Component Polyurethane Waterproofing MembranehemantrulzNo ratings yet

- Sikabit Pro P 30 0peDocument3 pagesSikabit Pro P 30 0peSlamet Tri UsadhaNo ratings yet

- Clay Bitumen EmulsionDocument2 pagesClay Bitumen EmulsionCharles LangatNo ratings yet

- Fosroc-Brushbond (Waterproofing Coating)Document2 pagesFosroc-Brushbond (Waterproofing Coating)Boy GalihNo ratings yet

- Ficha Inscripcion SSDocument2 pagesFicha Inscripcion SSalexNo ratings yet

- Asmaco PU SealantDocument3 pagesAsmaco PU SealantJoseph EzekielNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- Sika Construction Data SheetDocument4 pagesSika Construction Data SheetsathiyanNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- b_1_10_lawsDocument1 pageb_1_10_lawsBoopathi RaghavanNo ratings yet

- b_1_9_paymentDocument2 pagesb_1_9_paymentBoopathi RaghavanNo ratings yet

- b_1_8_control_of_the_worksDocument3 pagesb_1_8_control_of_the_worksBoopathi RaghavanNo ratings yet

- b_1_7_the_works_unlockedDocument2 pagesb_1_7_the_works_unlockedBoopathi RaghavanNo ratings yet

- Building and Engineering WorksDocument132 pagesBuilding and Engineering WorksBoopathi RaghavanNo ratings yet

- LT-OP-012 General Adoption ManualDocument176 pagesLT-OP-012 General Adoption ManualBoopathi RaghavanNo ratings yet

- PROJECT GUIDILINESDocument7 pagesPROJECT GUIDILINESBoopathi RaghavanNo ratings yet

- North Country AutoDocument9 pagesNorth Country AutoSamu BorgesNo ratings yet

- FDA Letter To IndustryDocument2 pagesFDA Letter To IndustryFrank HerreraNo ratings yet

- Qlik Certification Program FAQ enDocument6 pagesQlik Certification Program FAQ ensmederevac1977No ratings yet

- Billet RhomboidityDocument2 pagesBillet RhomboidityLowerclown Romanes100% (1)

- Verfication Performa PDFDocument1 pageVerfication Performa PDFAhmad JamalNo ratings yet

- How To Get Work Items From Workflow in Your Outlook Inbox PDFDocument9 pagesHow To Get Work Items From Workflow in Your Outlook Inbox PDFismailimran09No ratings yet

- Midyear 23 24.t1 t3Document3 pagesMidyear 23 24.t1 t3mylinafabi5No ratings yet

- CHAPTER-4 Masonry Wall DesignDocument16 pagesCHAPTER-4 Masonry Wall DesignMohammed AwadNo ratings yet

- Lecture No. 9 Basic Principles of CT ScanDocument24 pagesLecture No. 9 Basic Principles of CT ScanMohammed Khalil SaeedNo ratings yet

- Specifications of VCB With AccessoriesDocument2 pagesSpecifications of VCB With AccessoriesMuhammad NaveedNo ratings yet

- Akbar2015Document33 pagesAkbar2015DEDY KURNIAWANNo ratings yet

- Sustainable Tourism Development ProjectDocument4 pagesSustainable Tourism Development ProjectKularajah ThuthirajNo ratings yet

- Mercedes CatalogDocument84 pagesMercedes CatalogJeffrey Cunningham100% (9)

- Unit 1 - LL 2 - 3Document24 pagesUnit 1 - LL 2 - 3Hegde2626No ratings yet

- TM Promo NameDocument10 pagesTM Promo NameCristel Simbol TinguhaNo ratings yet

- Entity Framework Net CoreDocument74 pagesEntity Framework Net Corerdslinkac100% (1)

- Chapter 1 - Managing Human Resources: Learning ObjectivesDocument8 pagesChapter 1 - Managing Human Resources: Learning ObjectivesĐức NguyễnNo ratings yet

- LO 2 Apply Java Advanced Class Design and Object Oriented Design PrinciplesDocument24 pagesLO 2 Apply Java Advanced Class Design and Object Oriented Design PrinciplesLJames SacuezaNo ratings yet

- OooooobbbbbbDocument134 pagesOooooobbbbbbAmedin TemamNo ratings yet

- 2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Document4 pages2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Progress QueensNo ratings yet

- Data Collection Timeline FinalDocument4 pagesData Collection Timeline Finalapi-631736561No ratings yet

- HRM 822 Group Assignment 1Document12 pagesHRM 822 Group Assignment 1Dhruvi RajNo ratings yet

- Eaton Vacuum Interruption (EVI) Technology - BR - 03 - 2013Document8 pagesEaton Vacuum Interruption (EVI) Technology - BR - 03 - 2013Venna Karthik ReddyNo ratings yet

- Transient and Steady-State Analysis of A SEPIC Converter by An Average State-Space ModellingDocument5 pagesTransient and Steady-State Analysis of A SEPIC Converter by An Average State-Space ModellingPablo PulacheNo ratings yet

- Concert: Certified Installer Plus - Enterprise Solutions Partner (Cip-Esp)Document2 pagesConcert: Certified Installer Plus - Enterprise Solutions Partner (Cip-Esp)AndresNo ratings yet

- AE211 Final ExamDocument10 pagesAE211 Final ExamMariette Alex AgbanlogNo ratings yet

- Harbin Culture Centre Final Draft 02Document6 pagesHarbin Culture Centre Final Draft 02Shamoon ZubairNo ratings yet

- CS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)Document2 pagesCS Datasheet BiHiKu6 - CS6W MB AG - v2.1 - EN (Canadise)AlejandraNo ratings yet

- Nslookup For Dns CacheDocument31 pagesNslookup For Dns Cacheapi-418424782No ratings yet