Professional Documents

Culture Documents

coolmax

coolmax

Uploaded by

nando00xCopyright:

Available Formats

You might also like

- 0F9765Mnl: Engine Parts ManualDocument28 pages0F9765Mnl: Engine Parts ManualMartin Valdez100% (2)

- Wintech ProfileDocument42 pagesWintech ProfilenurkolipNo ratings yet

- Savage Worlds - Combat Options Chart (Adventure Edition)Document2 pagesSavage Worlds - Combat Options Chart (Adventure Edition)Sturm Novahl0% (1)

- Boiler InspectionDocument115 pagesBoiler InspectionKanphong.sm100% (1)

- General: AP-A203169A Technical Specification Rev.00Document4 pagesGeneral: AP-A203169A Technical Specification Rev.00Honesto BautistaNo ratings yet

- Champion Spiral Wound Gasket-CatalogDocument2 pagesChampion Spiral Wound Gasket-Catalogsaravanaa212No ratings yet

- Alfacond Range: Plate CondensersDocument2 pagesAlfacond Range: Plate Condensersandres mNo ratings yet

- Sample Cooler Catalogue-SeplDocument2 pagesSample Cooler Catalogue-SeplHANIF AKBARNo ratings yet

- High Temperature Service Equipment and Piping Maintenance in PlantDocument22 pagesHigh Temperature Service Equipment and Piping Maintenance in Plantvaratharajan g rNo ratings yet

- Installation of Ammonia Pre-HeaterDocument24 pagesInstallation of Ammonia Pre-HeaterSAJIDSATTARNo ratings yet

- Air Fin Cooler CatalougeDocument14 pagesAir Fin Cooler Catalougesammar_10No ratings yet

- 01heat Exchanger-FOPE05Document30 pages01heat Exchanger-FOPE05kuldeep mohiteNo ratings yet

- Air Fin CoolerDocument14 pagesAir Fin Coolersaurabh shukla100% (1)

- AlfaNova 76Document2 pagesAlfaNova 76antonio carlos colombaraNo ratings yet

- AlfaNova 76Document2 pagesAlfaNova 76Celio CostaNo ratings yet

- Boa-S PN6 DN40Document14 pagesBoa-S PN6 DN40melaNo ratings yet

- K050 DMDocument1 pageK050 DMvitor4santos_6No ratings yet

- AFT Trolley 50-02Document2 pagesAFT Trolley 50-02Forum PompieriiNo ratings yet

- Boiler InspectionDocument115 pagesBoiler InspectionKanphong.sm100% (1)

- Steam System Q&ADocument115 pagesSteam System Q&Atajshah283No ratings yet

- Evaporators: Dry-ExpansionDocument4 pagesEvaporators: Dry-ExpansionghilesNo ratings yet

- SelectPHE TenderText Bphe 2024-03-15T14 24 01Document2 pagesSelectPHE TenderText Bphe 2024-03-15T14 24 01Hakan ÜçokNo ratings yet

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeViraj ShiroleNo ratings yet

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeAgniva DuttaNo ratings yet

- Vortex CNC Cooler System HBWDocument7 pagesVortex CNC Cooler System HBWHannan RizqiNo ratings yet

- Bronze BrassDocument13 pagesBronze Brassnvhoang0185No ratings yet

- Model MVE: DescriptionDocument2 pagesModel MVE: DescriptionDaniel SanNo ratings yet

- Seal Gas Heater: Typical ApplicationsDocument1 pageSeal Gas Heater: Typical Applicationsmatteo2009No ratings yet

- Life Enhancement of Hot-Forging Dies by Plasma-NitridingDocument7 pagesLife Enhancement of Hot-Forging Dies by Plasma-NitridingAli AhmadNo ratings yet

- Alfa Laval M10-BW: Gasketed Plate-And-Frame Heat ExchangerDocument4 pagesAlfa Laval M10-BW: Gasketed Plate-And-Frame Heat Exchangersandor terceroNo ratings yet

- AlfaNova 14Document2 pagesAlfaNova 14Celio CostaNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument4 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Alfa CondDocument2 pagesAlfa CondKillol ShahNo ratings yet

- The Process IGSDocument8 pagesThe Process IGSFaiz Ziafumi Kura'No ratings yet

- Stripper Low EfficiencyDocument14 pagesStripper Low EfficiencyMuhammad Irfaan MeoNo ratings yet

- Air Fin CoolersDocument43 pagesAir Fin Coolersbharatbellad100% (2)

- M33V Iso Full Bore Ball Valve API 6D DN50 To DN200 ASME (ANSI) 150 and 300Document4 pagesM33V Iso Full Bore Ball Valve API 6D DN50 To DN200 ASME (ANSI) 150 and 300mateuNo ratings yet

- AlfaNova 27Document2 pagesAlfaNova 27Celio CostaNo ratings yet

- High Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicsDocument12 pagesHigh Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicscivicbladeNo ratings yet

- UntitledDocument2 pagesUntitledRuslan SlusarNo ratings yet

- Sample Gas Compressor CoolerDocument4 pagesSample Gas Compressor CoolerAnish KarthikeyanNo ratings yet

- Thermatrac Air-To-Water Heat Pump Water HeaterDocument15 pagesThermatrac Air-To-Water Heat Pump Water Heatercodefinder100% (1)

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- ALFA LAVAL Compact Heat Exchangers in HVAC SystemsDocument27 pagesALFA LAVAL Compact Heat Exchangers in HVAC SystemsvickersNo ratings yet

- Shell & Tube Heat ExchangersDocument16 pagesShell & Tube Heat ExchangersShawala AzharNo ratings yet

- Thermodynamic Steam TrapsDocument12 pagesThermodynamic Steam TrapsbuddhansamratNo ratings yet

- 2/2-Way Solenoid Valve With Servo-Diaphragm, G 1/2 - G 2 1/2Document4 pages2/2-Way Solenoid Valve With Servo-Diaphragm, G 1/2 - G 2 1/2MacakafkaNo ratings yet

- Gem Chiller Catalogue Proof - 27 4 13Document4 pagesGem Chiller Catalogue Proof - 27 4 13abianshbaralNo ratings yet

- FURNACEDocument74 pagesFURNACESonam Bijaya100% (2)

- 05A - Fired Heaters 2UPsDocument38 pages05A - Fired Heaters 2UPsAhmed ElhadyNo ratings yet

- 14 July CR PaperDocument3 pages14 July CR PaperPNo ratings yet

- Datasheet Hydraulic Radiator AOCHMDocument5 pagesDatasheet Hydraulic Radiator AOCHMLauraNo ratings yet

- Direct Contact Desuperheaters TI-P475-01Document9 pagesDirect Contact Desuperheaters TI-P475-01LucasZanaNo ratings yet

- Trampas de Vapor FFTDocument5 pagesTrampas de Vapor FFTAndrés ChuquillaNo ratings yet

- 4 Eng Induction Welded Small Diameter TubeDocument22 pages4 Eng Induction Welded Small Diameter TubeDimitri PanagiotouNo ratings yet

- Design of Liquid Nitrogen (Ln2) Cryogenic TankDocument19 pagesDesign of Liquid Nitrogen (Ln2) Cryogenic Tankraviteja tankalaNo ratings yet

- 200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationDocument2 pages200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationbhaskarbabaiNo ratings yet

- bite-type-tube-fittings-2015Document62 pagesbite-type-tube-fittings-2015Vaibhav KotnalaNo ratings yet

- DK DIN Bite Type Tube FittingDocument62 pagesDK DIN Bite Type Tube FittingLuisFranciscoMarinMedranoNo ratings yet

- Vacuum DegasserDocument6 pagesVacuum Degasserreza haghjooNo ratings yet

- Project On Design of Plate Heat Exchanger: Submitted by Ambarish Phatak Ninad Laturkar Ravi AwadeDocument32 pagesProject On Design of Plate Heat Exchanger: Submitted by Ambarish Phatak Ninad Laturkar Ravi AwadeMiguel ParraNo ratings yet

- Big Data Analytics: By: Syed Nawaz Pasha at SR Univeristy Professional Elective-5 B.Tech Iv-Ii SemDocument31 pagesBig Data Analytics: By: Syed Nawaz Pasha at SR Univeristy Professional Elective-5 B.Tech Iv-Ii SemShushanth munna100% (1)

- UML复习Document14 pagesUML复习xinrui.zhang77No ratings yet

- FLEXELEC English Complet PDFDocument99 pagesFLEXELEC English Complet PDFDaniel100% (1)

- Exchange Rate Volatility and International TR - 2023 - Journal of Business ReseaDocument19 pagesExchange Rate Volatility and International TR - 2023 - Journal of Business ReseaNgọc Hân NgôNo ratings yet

- Cause and Effect MatrixDocument5 pagesCause and Effect Matrixjashaggy100No ratings yet

- Installation Users Guide 200-X Rev A2Document28 pagesInstallation Users Guide 200-X Rev A2Jean-Claude DNo ratings yet

- Advanced Control Solutions For Enhanced Resilience of Modern Power-Electronic-Interfaced Distribution SystemsDocument15 pagesAdvanced Control Solutions For Enhanced Resilience of Modern Power-Electronic-Interfaced Distribution Systemsndaryanto 92No ratings yet

- RWC 2: Jetblue Airways, Westjet Airlines, and OthersDocument9 pagesRWC 2: Jetblue Airways, Westjet Airlines, and Othersriya7sen67% (3)

- Guide To Syncsort PDFDocument41 pagesGuide To Syncsort PDFblueniluxNo ratings yet

- October 2020 P4Document32 pagesOctober 2020 P4Momen YasserNo ratings yet

- GROUP 4 REPORT (Ethical Dilemmas Google Clip & Sentencing Software)Document22 pagesGROUP 4 REPORT (Ethical Dilemmas Google Clip & Sentencing Software)Cathrena DequinaNo ratings yet

- Improved Particle Swarm Optimization Based MPPT For PV Systems Under Partial Shading ConditionsDocument6 pagesImproved Particle Swarm Optimization Based MPPT For PV Systems Under Partial Shading ConditionsNazrul HaqemNo ratings yet

- Chap6 - Engineering Measurements and EstimationsDocument36 pagesChap6 - Engineering Measurements and EstimationsalsinanhananNo ratings yet

- Supplier Selection in Procurement Logistics Using Ahp-Qfd and Anp-Qfd ApproachDocument14 pagesSupplier Selection in Procurement Logistics Using Ahp-Qfd and Anp-Qfd ApproachEng.shadid1 Sh123456No ratings yet

- Home Automation SystemDocument5 pagesHome Automation SystemdaniaNo ratings yet

- Unit 6 PII MACHINE LEARNINGDocument43 pagesUnit 6 PII MACHINE LEARNINGSakshi ChoudharyNo ratings yet

- Lesson Plan MechatronicsDocument2 pagesLesson Plan MechatronicsChetan GhatageNo ratings yet

- 25NB To 65NB Duplex Basket StrainerDocument1 page25NB To 65NB Duplex Basket Straineraloke2mondalNo ratings yet

- Famous Entrepreneur Scavenger Hunt 1Document3 pagesFamous Entrepreneur Scavenger Hunt 1Alyssa marie BuenoNo ratings yet

- Etsi Ttcn3 TutorialDocument32 pagesEtsi Ttcn3 TutorialSaumyadip GhoshNo ratings yet

- Primus Iron MachineDocument67 pagesPrimus Iron MachineKonstantinos Politis100% (1)

- Flyers DesignDocument4 pagesFlyers DesignRamdas M NambisanNo ratings yet

- 2102 - PGA Labs Report - Internet First BrandsDocument31 pages2102 - PGA Labs Report - Internet First BrandsGanesh Mahidhar100% (1)

- Ansys Exercise PDFDocument14 pagesAnsys Exercise PDFRajesh Choudhary0% (1)

- SFP XG Combo PON OLT Class D 20km OM5270AX301 Databrief Rev1-0Document4 pagesSFP XG Combo PON OLT Class D 20km OM5270AX301 Databrief Rev1-0Alexey VurdiNo ratings yet

- Ug 146 PDFDocument36 pagesUg 146 PDFTrần LinhNo ratings yet

- Company ListDocument180 pagesCompany ListleoNo ratings yet

- BSCADocument39 pagesBSCAROOMA SALEEMNo ratings yet

coolmax

coolmax

Uploaded by

nando00xCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

coolmax

coolmax

Uploaded by

nando00xCopyright:

Available Formats

CoolMax

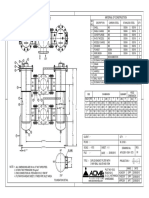

Coil-in-Coil Type Sample Cooler

Mounting plate Outer shell tube

Inner tube

Process

Fluid In

Coolant Out

CoolMax D

Special 'T’

connector

Process

Fluid Out

A number of industrial processes Features

require sampling of various process

Available in different material to suit process conditions like multiphase

fluids like diesel, LCO, ULSD, low

slurries and petrochemical mixtures

pressure steam, water and alcohol to

the required uniform temperature. Fully drainable inner and outer tubes

Improper design of heat exchangers Rugged design, highly resistant to thermal and hydraulic shocks

can severely erode product quality

and profitability. Single continuous tube to avoid leaks

The “CoolMAX” series from Forbes Enhanced turbulence to avoid deposits

Marshall, is a range of compact heat Easy to install

exchangers with wide ranging

benefits. These offer high heat High precision engineered product

transfer rates, low pressure drops, a

close approach temperature with Manufactured as per ASME BPE 2007

minimal cooling water requirements. Suitable for clean steam and WFI (water for injection) processes

A high turbulence of fluid ensures self-

cleaning and longer life of the product. Stringent safety/ cleanliness norms incorporated which are especially

required for pharmaceutical industry

Electro-polished models (Ra<0.6 micrometer) are available for

pharmaceutical applications

Benefits

High heat transfer rates.

Very close approach temperature - upto 2°C

More compact due to increased overall heat transfer coefficient

Suitable for high heat duty application

Minimal cooling water requirement

Suitable for low flow rates at high pressure/high temperature application

Maximum counter current coefficient

Eliminates the tendency of dead spot formations

Low pressure drop on outer tube side

Size(MM) Dimension Dimension Dimension Dimension Weight High Temperature

(Sq. meter) 'A' 'B' 'C' 'D' (kg) Area (square meter)

CoolMax-50H 143 139 229 313 5 0.12

CoolMax-100H 176 148 273 320 7 0.18

CoolMax-200H 226 153 279 426 14 0.24

Recommended Parameters for Operation Ordering Information

Cooling water

Forbes Marshall CoolMax Series

Inlet temperature 35° C (max)

Inlet pressure 3.5 bar Series

50H-1/4" OD inner tube

Outlet pressure Open to atmosphere 100H-3/8" OD inner tube

200H-1/2" OD inner tube

Quality/ chloride content Less than 25 ppm Sanitary**

Inner Tube Material

Copper

SS316

Inconel

Monel

Outer Tube Material

Copper

SS316

Inconel

Monel

CM X Y Z

Sample side (Inner tube)

Tube Material Pressure Temperature

Copper 140 kg/cm² @ 148°C

SS 316 250kg/cm² @ 560°C

Inconel 400kg/cm² @ 600°C

Monel 140kg/cm² @ 148°C

Cooling side (Outer tube)

Tube Material Pressure Temperature

Copper 86 kg/cm² @ 148°C

SS316 160kg/cm² @ 560°C

CoolMax - Sanitary

Features

Manufactured as per ASME BPE 2007

Suitable for clean steam and WFI (water for injection)

processes

Electro-polished models (Ra<0.6 micrometer) are

available for pharmaceutical applications

Specifications

Stainless steel (SS 316) housing

Sanitary tri-clamps: approved for pharmaceutical application

Surface finish (0.6<micrometer).

TIG welded

Single length SS tube to avoid any joints

Opp 106th Milestone B-85, Phase II, Chakan Indl Area A-34/35, MIDC H Block

Bombay Poona Road Sawardari, Chakan, Tal. Khed Pimpri, Pune - 411 018. INDIA.

Kasarwadi, Pune - 411 034. INDIA Dist. Pune - 410 501. INDIA Tel : 91(0)20-27442020, 39851199

Forbes Marshall Tel : 91(0)20-27145595, 39858555 Tel : 91(0)2135-393400 Fax : 91(0)20-27442040

Krohne Marshall Fax : 91(0)20-27147413 CIN No.: U28996PN1985PTC037806

Forbes Marshall Arca Email : swasmktg@forbesmarshall.com, ccmidc@forbesmarshall.com www.forbesmarshall.com

Codel International

Forbes Solar © All rights reserved. Any reproduction or distribution in part or as a whole without written permission of Forbes Marshall Pvt Ltd, its

associate companies or its subsidiaries (“FM Group”) is prohibited.

Forbes Vyncke

Information, designs or specifications in this document are subject to change without notice. Responsibility for suitability, selection,

Forbes Marshall Steam Systems installation, use, operation or maintenance of the product(s) rests solely with the purchaser and/or user. The contents of this document are

presented for informational purposes only. FM Group disclaims liabilities or losses that may be incurred as a consequence of the use of this

information.

DOC#FMSWAS/1216/2211/V3.R0

You might also like

- 0F9765Mnl: Engine Parts ManualDocument28 pages0F9765Mnl: Engine Parts ManualMartin Valdez100% (2)

- Wintech ProfileDocument42 pagesWintech ProfilenurkolipNo ratings yet

- Savage Worlds - Combat Options Chart (Adventure Edition)Document2 pagesSavage Worlds - Combat Options Chart (Adventure Edition)Sturm Novahl0% (1)

- Boiler InspectionDocument115 pagesBoiler InspectionKanphong.sm100% (1)

- General: AP-A203169A Technical Specification Rev.00Document4 pagesGeneral: AP-A203169A Technical Specification Rev.00Honesto BautistaNo ratings yet

- Champion Spiral Wound Gasket-CatalogDocument2 pagesChampion Spiral Wound Gasket-Catalogsaravanaa212No ratings yet

- Alfacond Range: Plate CondensersDocument2 pagesAlfacond Range: Plate Condensersandres mNo ratings yet

- Sample Cooler Catalogue-SeplDocument2 pagesSample Cooler Catalogue-SeplHANIF AKBARNo ratings yet

- High Temperature Service Equipment and Piping Maintenance in PlantDocument22 pagesHigh Temperature Service Equipment and Piping Maintenance in Plantvaratharajan g rNo ratings yet

- Installation of Ammonia Pre-HeaterDocument24 pagesInstallation of Ammonia Pre-HeaterSAJIDSATTARNo ratings yet

- Air Fin Cooler CatalougeDocument14 pagesAir Fin Cooler Catalougesammar_10No ratings yet

- 01heat Exchanger-FOPE05Document30 pages01heat Exchanger-FOPE05kuldeep mohiteNo ratings yet

- Air Fin CoolerDocument14 pagesAir Fin Coolersaurabh shukla100% (1)

- AlfaNova 76Document2 pagesAlfaNova 76antonio carlos colombaraNo ratings yet

- AlfaNova 76Document2 pagesAlfaNova 76Celio CostaNo ratings yet

- Boa-S PN6 DN40Document14 pagesBoa-S PN6 DN40melaNo ratings yet

- K050 DMDocument1 pageK050 DMvitor4santos_6No ratings yet

- AFT Trolley 50-02Document2 pagesAFT Trolley 50-02Forum PompieriiNo ratings yet

- Boiler InspectionDocument115 pagesBoiler InspectionKanphong.sm100% (1)

- Steam System Q&ADocument115 pagesSteam System Q&Atajshah283No ratings yet

- Evaporators: Dry-ExpansionDocument4 pagesEvaporators: Dry-ExpansionghilesNo ratings yet

- SelectPHE TenderText Bphe 2024-03-15T14 24 01Document2 pagesSelectPHE TenderText Bphe 2024-03-15T14 24 01Hakan ÜçokNo ratings yet

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeViraj ShiroleNo ratings yet

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeAgniva DuttaNo ratings yet

- Vortex CNC Cooler System HBWDocument7 pagesVortex CNC Cooler System HBWHannan RizqiNo ratings yet

- Bronze BrassDocument13 pagesBronze Brassnvhoang0185No ratings yet

- Model MVE: DescriptionDocument2 pagesModel MVE: DescriptionDaniel SanNo ratings yet

- Seal Gas Heater: Typical ApplicationsDocument1 pageSeal Gas Heater: Typical Applicationsmatteo2009No ratings yet

- Life Enhancement of Hot-Forging Dies by Plasma-NitridingDocument7 pagesLife Enhancement of Hot-Forging Dies by Plasma-NitridingAli AhmadNo ratings yet

- Alfa Laval M10-BW: Gasketed Plate-And-Frame Heat ExchangerDocument4 pagesAlfa Laval M10-BW: Gasketed Plate-And-Frame Heat Exchangersandor terceroNo ratings yet

- AlfaNova 14Document2 pagesAlfaNova 14Celio CostaNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument4 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Alfa CondDocument2 pagesAlfa CondKillol ShahNo ratings yet

- The Process IGSDocument8 pagesThe Process IGSFaiz Ziafumi Kura'No ratings yet

- Stripper Low EfficiencyDocument14 pagesStripper Low EfficiencyMuhammad Irfaan MeoNo ratings yet

- Air Fin CoolersDocument43 pagesAir Fin Coolersbharatbellad100% (2)

- M33V Iso Full Bore Ball Valve API 6D DN50 To DN200 ASME (ANSI) 150 and 300Document4 pagesM33V Iso Full Bore Ball Valve API 6D DN50 To DN200 ASME (ANSI) 150 and 300mateuNo ratings yet

- AlfaNova 27Document2 pagesAlfaNova 27Celio CostaNo ratings yet

- High Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicsDocument12 pagesHigh Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicscivicbladeNo ratings yet

- UntitledDocument2 pagesUntitledRuslan SlusarNo ratings yet

- Sample Gas Compressor CoolerDocument4 pagesSample Gas Compressor CoolerAnish KarthikeyanNo ratings yet

- Thermatrac Air-To-Water Heat Pump Water HeaterDocument15 pagesThermatrac Air-To-Water Heat Pump Water Heatercodefinder100% (1)

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- ALFA LAVAL Compact Heat Exchangers in HVAC SystemsDocument27 pagesALFA LAVAL Compact Heat Exchangers in HVAC SystemsvickersNo ratings yet

- Shell & Tube Heat ExchangersDocument16 pagesShell & Tube Heat ExchangersShawala AzharNo ratings yet

- Thermodynamic Steam TrapsDocument12 pagesThermodynamic Steam TrapsbuddhansamratNo ratings yet

- 2/2-Way Solenoid Valve With Servo-Diaphragm, G 1/2 - G 2 1/2Document4 pages2/2-Way Solenoid Valve With Servo-Diaphragm, G 1/2 - G 2 1/2MacakafkaNo ratings yet

- Gem Chiller Catalogue Proof - 27 4 13Document4 pagesGem Chiller Catalogue Proof - 27 4 13abianshbaralNo ratings yet

- FURNACEDocument74 pagesFURNACESonam Bijaya100% (2)

- 05A - Fired Heaters 2UPsDocument38 pages05A - Fired Heaters 2UPsAhmed ElhadyNo ratings yet

- 14 July CR PaperDocument3 pages14 July CR PaperPNo ratings yet

- Datasheet Hydraulic Radiator AOCHMDocument5 pagesDatasheet Hydraulic Radiator AOCHMLauraNo ratings yet

- Direct Contact Desuperheaters TI-P475-01Document9 pagesDirect Contact Desuperheaters TI-P475-01LucasZanaNo ratings yet

- Trampas de Vapor FFTDocument5 pagesTrampas de Vapor FFTAndrés ChuquillaNo ratings yet

- 4 Eng Induction Welded Small Diameter TubeDocument22 pages4 Eng Induction Welded Small Diameter TubeDimitri PanagiotouNo ratings yet

- Design of Liquid Nitrogen (Ln2) Cryogenic TankDocument19 pagesDesign of Liquid Nitrogen (Ln2) Cryogenic Tankraviteja tankalaNo ratings yet

- 200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationDocument2 pages200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationbhaskarbabaiNo ratings yet

- bite-type-tube-fittings-2015Document62 pagesbite-type-tube-fittings-2015Vaibhav KotnalaNo ratings yet

- DK DIN Bite Type Tube FittingDocument62 pagesDK DIN Bite Type Tube FittingLuisFranciscoMarinMedranoNo ratings yet

- Vacuum DegasserDocument6 pagesVacuum Degasserreza haghjooNo ratings yet

- Project On Design of Plate Heat Exchanger: Submitted by Ambarish Phatak Ninad Laturkar Ravi AwadeDocument32 pagesProject On Design of Plate Heat Exchanger: Submitted by Ambarish Phatak Ninad Laturkar Ravi AwadeMiguel ParraNo ratings yet

- Big Data Analytics: By: Syed Nawaz Pasha at SR Univeristy Professional Elective-5 B.Tech Iv-Ii SemDocument31 pagesBig Data Analytics: By: Syed Nawaz Pasha at SR Univeristy Professional Elective-5 B.Tech Iv-Ii SemShushanth munna100% (1)

- UML复习Document14 pagesUML复习xinrui.zhang77No ratings yet

- FLEXELEC English Complet PDFDocument99 pagesFLEXELEC English Complet PDFDaniel100% (1)

- Exchange Rate Volatility and International TR - 2023 - Journal of Business ReseaDocument19 pagesExchange Rate Volatility and International TR - 2023 - Journal of Business ReseaNgọc Hân NgôNo ratings yet

- Cause and Effect MatrixDocument5 pagesCause and Effect Matrixjashaggy100No ratings yet

- Installation Users Guide 200-X Rev A2Document28 pagesInstallation Users Guide 200-X Rev A2Jean-Claude DNo ratings yet

- Advanced Control Solutions For Enhanced Resilience of Modern Power-Electronic-Interfaced Distribution SystemsDocument15 pagesAdvanced Control Solutions For Enhanced Resilience of Modern Power-Electronic-Interfaced Distribution Systemsndaryanto 92No ratings yet

- RWC 2: Jetblue Airways, Westjet Airlines, and OthersDocument9 pagesRWC 2: Jetblue Airways, Westjet Airlines, and Othersriya7sen67% (3)

- Guide To Syncsort PDFDocument41 pagesGuide To Syncsort PDFblueniluxNo ratings yet

- October 2020 P4Document32 pagesOctober 2020 P4Momen YasserNo ratings yet

- GROUP 4 REPORT (Ethical Dilemmas Google Clip & Sentencing Software)Document22 pagesGROUP 4 REPORT (Ethical Dilemmas Google Clip & Sentencing Software)Cathrena DequinaNo ratings yet

- Improved Particle Swarm Optimization Based MPPT For PV Systems Under Partial Shading ConditionsDocument6 pagesImproved Particle Swarm Optimization Based MPPT For PV Systems Under Partial Shading ConditionsNazrul HaqemNo ratings yet

- Chap6 - Engineering Measurements and EstimationsDocument36 pagesChap6 - Engineering Measurements and EstimationsalsinanhananNo ratings yet

- Supplier Selection in Procurement Logistics Using Ahp-Qfd and Anp-Qfd ApproachDocument14 pagesSupplier Selection in Procurement Logistics Using Ahp-Qfd and Anp-Qfd ApproachEng.shadid1 Sh123456No ratings yet

- Home Automation SystemDocument5 pagesHome Automation SystemdaniaNo ratings yet

- Unit 6 PII MACHINE LEARNINGDocument43 pagesUnit 6 PII MACHINE LEARNINGSakshi ChoudharyNo ratings yet

- Lesson Plan MechatronicsDocument2 pagesLesson Plan MechatronicsChetan GhatageNo ratings yet

- 25NB To 65NB Duplex Basket StrainerDocument1 page25NB To 65NB Duplex Basket Straineraloke2mondalNo ratings yet

- Famous Entrepreneur Scavenger Hunt 1Document3 pagesFamous Entrepreneur Scavenger Hunt 1Alyssa marie BuenoNo ratings yet

- Etsi Ttcn3 TutorialDocument32 pagesEtsi Ttcn3 TutorialSaumyadip GhoshNo ratings yet

- Primus Iron MachineDocument67 pagesPrimus Iron MachineKonstantinos Politis100% (1)

- Flyers DesignDocument4 pagesFlyers DesignRamdas M NambisanNo ratings yet

- 2102 - PGA Labs Report - Internet First BrandsDocument31 pages2102 - PGA Labs Report - Internet First BrandsGanesh Mahidhar100% (1)

- Ansys Exercise PDFDocument14 pagesAnsys Exercise PDFRajesh Choudhary0% (1)

- SFP XG Combo PON OLT Class D 20km OM5270AX301 Databrief Rev1-0Document4 pagesSFP XG Combo PON OLT Class D 20km OM5270AX301 Databrief Rev1-0Alexey VurdiNo ratings yet

- Ug 146 PDFDocument36 pagesUg 146 PDFTrần LinhNo ratings yet

- Company ListDocument180 pagesCompany ListleoNo ratings yet

- BSCADocument39 pagesBSCAROOMA SALEEMNo ratings yet