Professional Documents

Culture Documents

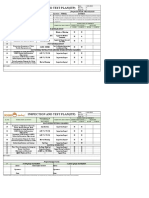

Inspection Test Plan-Q manifold-Rev01

Inspection Test Plan-Q manifold-Rev01

Uploaded by

wassimwalha2016Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Test Plan-Q manifold-Rev01

Inspection Test Plan-Q manifold-Rev01

Uploaded by

wassimwalha2016Copyright:

Available Formats

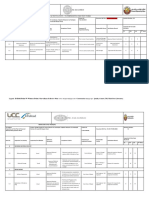

Contractor:

Client: Project : Installation a new filter skid At Q-manifold

PO :

Document Number:

Revision : 01

Inspection Test Plan Date : 03/06/2024

Page 1 of 6

Inspection Test Plan

01 03-06-2024 Issue for Review A. BEN AMOR Dh. BEN Ali

00 25-04-2024 Issue for Review A. BEN AMOR Dh. BEN Ali

Rev : Date REVISION TITLE PREPARED CHECKED APPROVED

Contractor Document Number: Rev : 00

Contractor:

Client: Project : Installation a new filter skid At Q-manifold

PO :

Document Number:

Revision : 01

Inspection Test Plan Date : 03/06/2024

Page 2 of 6

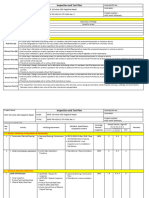

Definition of Inspection & Test Plan acronyms

- H Hold Point Presence of the inspector (QA/QC) is mandatory

A Hold Point is a point in a construction activity where formal written notification is given of an

inspection and work shall not proceed until the inspection is performed. Mandatory attendance is

required.

- W Witness Point Presence of the inspector is preferred but not mandatory.

A point in a construction activity where inspection must take place. CONTRACTOR QC shall be

formally notified of the inspection in advance notice and will normally attend the inspection. If

COMPANY does not attend, activity can proceed.

- P Random Point Random presence of the inspector. In process activity random check

- R Documentation Review Review of documentation only

Contractor Document Number: Rev : 00

Contractor:

Client: Project : Installation a new filter skid At Q-manifold

PO :

Document Number:

Revision : 01

Inspection Test Plan Date : 03/06/2024

Page 3 of 6

Surveillance Point

ITEM Operation Description Reference document Acceptance Criteria TPI External Remarks/Comments

CONTRACTOR SOO

3rd Party 3rd Party

1. CIVIL ACTIVITIES

1.1 EARTHWORKS SERVICE

SOW & App. Drawing (foundation

1.1.1 Topographic Survey H H H

SOW & App. Drawing details)

(foundation details) SOW &App. Drawing (foundation

1.1.2 Excavation H W W

EZAR Civil work procedure details)

or method statement SOW & App. Drawing (foundation

1.1.3 Backfilling H W W

details)

1.2 FORMWORK

SOW & App. Drawing

Check formwork placing and (foundation details) SOW & App .Drawing (foundation

1.1 H W W

formwork stability EZAR Civil work procedure details)

or method statement

1.3 COATING APPLICATION

SOW EZAR Bitumen

Check the crossed layers of bitumen

coating procedure Approved EZAR Bitumen coating

1.3.1 coating on all surfaces in direct contact H H H

Bitumen coating technical procedure

with soil.

data sheet

1.4 DIMENSIONAL

SOW + ISO Drawing +

1.4.1 Final dimensional survey App. Approved ISO Drawing H H H

Dimensional procedure

Contractor Document Number: Rev : 00

Contractor:

Client: Project : Installation a new filter skid At Q-manifold

PO :

Document Number:

Revision : 01

Inspection Test Plan Date : 03/06/2024

Page 4 of 6

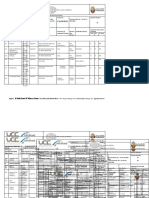

2. LIFTING ACTIVITIES

2.1 LOWERING IN ACTIVITIES

2.1.1 Equipment Certificates SOW Calibration Certificates SOW & SOO HSE Dep. Approval H W W

Check the orientation, levelling EZAR lifting procedure &

2.1.2 SOW & Approved Drawing H H H

alignment lifting plan

3. PIPING ACTIVITIES

2.2 PREREQUISITE / DOCUMENTS REVIEW

Welding Procedures & records SOW + PQR + WPS

2.2.1 SOW & ASME B31.3 H/R R R

(WPS/PQR) PQR + WPS

EZAR general procedure for site EZAR general procedure for site

2.2.2 R R

welding welding

SOW + pressure test

2.2.3 EZAR pressure test procedure EZAR pressure test procedure R R

procedure

2.2.4 NDT PROCEDURE SOW + NDT PROCEUDRE SOW & ASME B31.3 R R

SOW + ISO drawing +

SOW & ASME B31.3

2.2.5 Visual & dimensional check procedure Visual & dimensional check R R

Approved Isometric drawing

procedure

SOW+ WELDER

2.2.6 Welders Qualification SOW & ASME B31.3 H/R R R

QUALIFICATION

ASNT SNT-TC-1A, ASNT ACCP,

or ISO EN 9712 or any other

SOW + NDT Personnel

2.2.7 NDT Personnel Qualification recognized national certification H/R R R

Qualification

program that shall be acceptable to

the company for the method used.

SOW+ Bitumen coating

EZAR coating procedure

2.2.8 Coating Procedure procedure R R R

Bitumen coating procedure

Coating technical Data sheet

2.2.9 Pipe Isometric ISO Drawing Approved Isometric Drawing R R R

Contractor Document Number: Rev : 00

Contractor:

Client: Project : Installation a new filter skid At Q-manifold

PO :

Document Number:

Revision : 01

Inspection Test Plan Date : 03/06/2024

Page 5 of 6

2.3 MATERIAL RECEIVING

2.3.1 Pipes and fittings SOW + PIPE CERTIFICATE PIPE CERTIFICATE EN10204-3.1 H P P

SOW + MATERIAL MATERIAL CERTIFICATE

2.3.2 Welding Consumables H P P

CERTIFICATE EN10204-3.1

SOW+MATERIAL MATERIAL CERTIFICATE

2.3.3 Coating Material H P P

CERTIFICATE EN10204-3.1

2.3 WELDING ACTIVITIES

SOW + ISO Drawing

Verification of:

Approved Visual procedure

2.3.1 Joint identification, SOW & ASME B31.3 H/R P P

Approved Site welding

beveling, cleaning & fit up

procedure

SOW & Approved VT

PROCEDURE

2.3.2 Visual Inspection of Welds SOW & ASME B31.3 H H H

Approved SITE WELDING

PROCEDURE

2.3.3 RT SOW + RT PROCEDURE SOW & ASME B31.3 H+R R R H

2.4 HYDROSTATIC PRESSURE T EST

SOW + Approved Hydro. SOW + Approved Hydro.

2.4.1 Verification of test pack H/W R R

Procedure Procedure

SOW + Approved Hydro. SOW + Approved Hydro.

2.4.2 Gauges & recorder verification W H H

Procedure Procedure

SOW + Approved Hydro. SOW + Approved Hydro.

2.4.3 Pre flushing of flow line Hydro test H/W R R

Procedure Procedure

Confirm the end of the assembly work

2.4.4 SOW + EZAR Procedure SOW + CONTRACT Doc H/W H H

piping

Contractor Document Number: Rev : 00

Contractor:

Client: Project : Installation a new filter skid At Q-manifold

PO :

Document Number:

Revision : 01

Inspection Test Plan Date : 03/06/2024

Page 6 of 6

3.1 COATING

SOW + Approved

3.1.1 Final Coating Application H H H

Procedure

4. AS BUILT DRAWINGS & DOCUMENTATION

Check Red ark As-built Drawings &

4.1 Project Specification Project Specification R R R

Documentation

4.2 Punch List Project Specification Project Specification R R R

4.3 Quality Record Book Project Specification Project Specification R R R

Contractor Document Number: Rev : 00

You might also like

- ITP For Asphalt WorksDocument3 pagesITP For Asphalt WorksBleep News100% (1)

- Planned Maintenance SystemDocument22 pagesPlanned Maintenance SystemJakee Bucol50% (2)

- Inspection & Test Plan For 16 Inch Pipeline (R0)Document13 pagesInspection & Test Plan For 16 Inch Pipeline (R0)Nilesh Kabade100% (1)

- Process Piping Inspection Procedure Rev.2 PDFDocument34 pagesProcess Piping Inspection Procedure Rev.2 PDFLevi Porter100% (8)

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 pagesPig Receiver Data Sheet 91303 - 8 InchSinaNo ratings yet

- Task 5.1 MAINTAIN TRAINING FACILITIESDocument21 pagesTask 5.1 MAINTAIN TRAINING FACILITIEShvti siayan100% (3)

- ITP For Sub-Base and Road Base WorksDocument3 pagesITP For Sub-Base and Road Base WorksBleep News0% (1)

- Itp For Fitp For Hdpe Pipes InstallationDocument3 pagesItp For Fitp For Hdpe Pipes InstallationBleep NewsNo ratings yet

- Overhaul of PSVDocument5 pagesOverhaul of PSVmeeraksam42100% (2)

- Astm B69Document3 pagesAstm B69Muhammad NaumanNo ratings yet

- Saudi Aramco Typical Inspection Plan: RH/ H RH/ HDocument2 pagesSaudi Aramco Typical Inspection Plan: RH/ H RH/ HZuhaib KhanNo ratings yet

- 3.1.3.5 Phase I Report ColleferroDocument25 pages3.1.3.5 Phase I Report Colleferrofanta calcioNo ratings yet

- Module 3 PDFDocument10 pagesModule 3 PDFAangela Del Rosario CorpuzNo ratings yet

- Engine Room ManualDocument32 pagesEngine Room ManualSarm1s100% (8)

- Project Name:-: Inspection Test Plan (ITP)Document6 pagesProject Name:-: Inspection Test Plan (ITP)TchoboNo ratings yet

- Inspection and Test Plan (Itp)Document2 pagesInspection and Test Plan (Itp)Abdul Gafoor ShaikhNo ratings yet

- Pt. Chuck Engineering Batam: Inspection Test Plan-MachiningDocument4 pagesPt. Chuck Engineering Batam: Inspection Test Plan-MachiningFuaz SukaryaNo ratings yet

- Quality Control Form "Sample"Document23 pagesQuality Control Form "Sample"BernathTurnip100% (1)

- Pressure Test Procedure Rev 0 0 06 05 2024Document8 pagesPressure Test Procedure Rev 0 0 06 05 2024wassimwalha2016No ratings yet

- ITP-Application of PaintingDocument2 pagesITP-Application of PaintingMuthu Saravanan100% (1)

- Painting Procedure Rev0.0Document8 pagesPainting Procedure Rev0.0wassimwalha2016No ratings yet

- S-000-1679-0001V Itp For Insulation PDFDocument5 pagesS-000-1679-0001V Itp For Insulation PDFPhuoc PhuNo ratings yet

- Vessel ItpDocument3 pagesVessel ItpVineet KhanduriNo ratings yet

- QCQF04-Concrete Pre-Pour Inspection ChecklistDocument2 pagesQCQF04-Concrete Pre-Pour Inspection ChecklistPrasanthCsadasivanNo ratings yet

- ITP_GROUTING.Rev.01[1]Document3 pagesITP_GROUTING.Rev.01[1]IKRIMA SABRINo ratings yet

- ITP Civil and Structure Moly ProjectDocument34 pagesITP Civil and Structure Moly ProjectYosses Sang NahkodaNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- ITP - Al Daayen Reservoir Patching & Plugging WorksDocument3 pagesITP - Al Daayen Reservoir Patching & Plugging WorksBleep NewsNo ratings yet

- RFI-14, House Connection Survey, Sewer Network (PESSCM - 1-W-1), Block-K, Zone-C (Updated)Document4 pagesRFI-14, House Connection Survey, Sewer Network (PESSCM - 1-W-1), Block-K, Zone-C (Updated)mainur mechanical engineerNo ratings yet

- KEPL MR 12 - Corrective Action RequestDocument1 pageKEPL MR 12 - Corrective Action RequestAvijit SenNo ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanReduddboy100% (1)

- Site Audit Report - VeoliaDocument2 pagesSite Audit Report - VeoliaBALAKRISHANANNo ratings yet

- ITP ErectionDocument3 pagesITP Erectionjanpaul2481No ratings yet

- Lps-01-Hti-Itp-Me-024 - Fan Coil UnitDocument5 pagesLps-01-Hti-Itp-Me-024 - Fan Coil UnitJomy JohnyNo ratings yet

- Lps 01 Hti Itp Me 007 GRP Water TankDocument7 pagesLps 01 Hti Itp Me 007 GRP Water TankJomy JohnyNo ratings yet

- Arabian Industries Projects LLC: Doc No: AIP-C3100000175-ITP-09 Rev.0Document6 pagesArabian Industries Projects LLC: Doc No: AIP-C3100000175-ITP-09 Rev.0Mohammed AmorNo ratings yet

- CP05 - Procedure For Three Layer Polyethylene Coating (CP Liquid Coating, Dan Polymeric Sheet Coating)Document10 pagesCP05 - Procedure For Three Layer Polyethylene Coating (CP Liquid Coating, Dan Polymeric Sheet Coating)herdiansyahNo ratings yet

- DD-QC-XK-ITP-23-004 - El DaBaa NPP Unit 3 - R6Document5 pagesDD-QC-XK-ITP-23-004 - El DaBaa NPP Unit 3 - R6Minh NguyễnNo ratings yet

- Itp UbpDocument10 pagesItp UbpMarco ValerianNo ratings yet

- Shopee E-Commerce Hub-Bogor Project: Inspection and Test PlanDocument5 pagesShopee E-Commerce Hub-Bogor Project: Inspection and Test PlanANWAR PERANGINANGINNo ratings yet

- New Fire Water System Project Bontang Kalimantan Timur: Site Inspection and Test Plan (ITP) For Fire Water Tank WorksDocument34 pagesNew Fire Water System Project Bontang Kalimantan Timur: Site Inspection and Test Plan (ITP) For Fire Water Tank WorksTim JalurNo ratings yet

- Material Inspection SheetDocument3 pagesMaterial Inspection Sheetrahid iqubalNo ratings yet

- LPS-01-HTI-ITP-EL-009 - Light FixturesDocument6 pagesLPS-01-HTI-ITP-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Toaz - Info Itp For PVC Conduits PRDocument6 pagesToaz - Info Itp For PVC Conduits PRehtesham khanNo ratings yet

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 pagesLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNo ratings yet

- Piping Erection ItpDocument22 pagesPiping Erection ItpHaythem Ben Zid100% (1)

- Third Party Inspection Report: Material / Subject of InspectionDocument6 pagesThird Party Inspection Report: Material / Subject of InspectionBrijithNo ratings yet

- By Akhilesh CHECKLIST - For AllDocument15 pagesBy Akhilesh CHECKLIST - For AllankurNo ratings yet

- Contractor Inspection RequestDocument2 pagesContractor Inspection Requestsheeko123ofhNo ratings yet

- ITP For Pipeline Repair Works - by Using Belzona Superwrap IIDocument4 pagesITP For Pipeline Repair Works - by Using Belzona Superwrap IIAhmedNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- Lps 01 Hti Itp Me 022 Chemical Dosing SystemDocument9 pagesLps 01 Hti Itp Me 022 Chemical Dosing SystemJomy JohnyNo ratings yet

- WQIP-H3-ILF-T-0448 V0, Third-Party Inspection Notification (TPI) For DI Pipes 11th Dec. 2023Document29 pagesWQIP-H3-ILF-T-0448 V0, Third-Party Inspection Notification (TPI) For DI Pipes 11th Dec. 2023Mohamed AliNo ratings yet

- QWP 010 AuditDocument4 pagesQWP 010 AuditJerry Roy DeytoNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpDocument5 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpRami KsidaNo ratings yet

- Inspection Test Plan For Fabrication PDF FreeDocument4 pagesInspection Test Plan For Fabrication PDF Freesam paulNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURK100% (1)

- QAQC Form - ArchitechtureDocument42 pagesQAQC Form - ArchitechtureMohammad Hadoumi SaldanNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- Inspection & Test Plan (Itp) : Mechanical (Machine & Equipment)Document2 pagesInspection & Test Plan (Itp) : Mechanical (Machine & Equipment)ikramNo ratings yet

- Inspection Test Plan For Stat XDocument4 pagesInspection Test Plan For Stat XGinish KumarNo ratings yet

- Civil Quality Control Plan EarthworksDocument3 pagesCivil Quality Control Plan Earthworksroekyat hendrawanNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Calculation: B02 11-Jan-15 5 LC AS US Issued For Company ApprovalDocument5 pagesCalculation: B02 11-Jan-15 5 LC AS US Issued For Company Approvaljay2kay5793No ratings yet

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionDocument2 pagesInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- Check Sheet Testing of Drainage PipesDocument1 pageCheck Sheet Testing of Drainage PipesMurtada OmerNo ratings yet

- ITP Instrument-Cover EXAMPLEDocument6 pagesITP Instrument-Cover EXAMPLECharles RobiansyahNo ratings yet

- CIM ITP 2017023 - Rev.00Document6 pagesCIM ITP 2017023 - Rev.00daus nasNo ratings yet

- Nmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)Document8 pagesNmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)parangkilalakitaNo ratings yet

- Pressure Test Procedure Rev 0 0 06 05 2024Document8 pagesPressure Test Procedure Rev 0 0 06 05 2024wassimwalha2016No ratings yet

- 6 Drawing SiteDocument1 page6 Drawing Sitewassimwalha2016No ratings yet

- 6 3D DrawingDocument1 page6 3D Drawingwassimwalha2016No ratings yet

- WPS 04 05 06 07 v2Document12 pagesWPS 04 05 06 07 v2wassimwalha2016No ratings yet

- WPS 08 09 10 11 v2Document12 pagesWPS 08 09 10 11 v2wassimwalha2016No ratings yet

- Visual and Dimensional ROBE TK2701BDocument1 pageVisual and Dimensional ROBE TK2701Bwassimwalha2016No ratings yet

- Clause by Clause Based On The ISO 9001 - 2015Document21 pagesClause by Clause Based On The ISO 9001 - 2015PrashanthPrashanth100% (1)

- JIG Standards Session G ODonnell N MasonDocument40 pagesJIG Standards Session G ODonnell N Masonsamson anyumbaNo ratings yet

- LED SPOT LIGHT-ReprotDocument15 pagesLED SPOT LIGHT-ReprotIsrael BelaynhNo ratings yet

- Upgrade of Damaged Gamesa G90 Nose Cone StructureDocument3 pagesUpgrade of Damaged Gamesa G90 Nose Cone StructureNorbertoNo ratings yet

- TCVN 5318-2001 Mobile Offshore Installation-Welding (EN) PDFDocument9 pagesTCVN 5318-2001 Mobile Offshore Installation-Welding (EN) PDFPushkar GopalNo ratings yet

- 01 ISA-Skill RequirementDocument1 page01 ISA-Skill RequirementJack LaksmanaNo ratings yet

- C-4100NC 524-11323 To 524-13337 Instruction ManualDocument49 pagesC-4100NC 524-11323 To 524-13337 Instruction ManualMuhammad FarabiNo ratings yet

- Section 23 A The Practice of Visual Welding InspectionDocument14 pagesSection 23 A The Practice of Visual Welding InspectionS GoudaNo ratings yet

- Andt Thank AlgerieDocument28 pagesAndt Thank AlgerieChristian BarNo ratings yet

- KSV KishoreDocument9 pagesKSV KishoreGanesan RamamoorthyNo ratings yet

- Certificate of Conformance 01Document4 pagesCertificate of Conformance 01Magesh WaranNo ratings yet

- Pratik Patil 2021Document3 pagesPratik Patil 2021Pratik PatilNo ratings yet

- A Comparison of Quality Management For Bored PiledDocument10 pagesA Comparison of Quality Management For Bored PiledKhin Sandi KoNo ratings yet

- STA Notes (Unit 5)Document13 pagesSTA Notes (Unit 5)Shashank chowdary DaripineniNo ratings yet

- Cimtas Precision Company Overview - 2022Document21 pagesCimtas Precision Company Overview - 2022FatihNo ratings yet

- Hse Plan: Ahts Peteka 5401Document29 pagesHse Plan: Ahts Peteka 5401megaNo ratings yet

- Astm B209Document26 pagesAstm B209Elias Cruz100% (2)

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- Inspection and Testing of Production WeldsDocument22 pagesInspection and Testing of Production WeldsAmmar ČabaravdićNo ratings yet

- MCC Landscape Pre Commencement and Construction Hold PointsDocument3 pagesMCC Landscape Pre Commencement and Construction Hold PointsBillyNo ratings yet

![ITP_GROUTING.Rev.01[1]](https://imgv2-2-f.scribdassets.com/img/document/747758954/149x198/707bc32ee7/1720061209?v=1)