Professional Documents

Culture Documents

Manual montura ecuatorial Meade

Manual montura ecuatorial Meade

Uploaded by

Dario_1980Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual montura ecuatorial Meade

Manual montura ecuatorial Meade

Uploaded by

Dario_1980Copyright:

Available Formats

INSTRUCTION MANUAL

X-Wedge for LX200 and LX600 telescopes

55-12003_07028_XWedge_InstructionManual.indd 1 8/8/2012 11:07:49 AM

X-WEDGE OPERATING MANUAL

#497 HANDBOX

Manual

This Meade X-Wedge is designed for use with the Meade Giant

Field Tripod.

1

2

Instruction

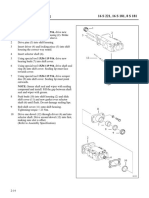

1 Hex wrenches (3)

2 Center mounting

bolt (1) and washer (1)

1!

5 5/16" hex

screws (3)

and

washers (3)

4 3/8" hex screws (3)

AutoStar

and washers (3)

6 Tangent 9 3

arm (1) and

4

X-Wedge

connecting

8-32 hex 5

screws (2)

3 Threaded rod cap (1) 8 6

and threaded rod sleeve insert (1) 7

Figure A. Hardware kit for the X-Wedge.

Warning: If the telescope is placed on the wedge without

the field tripod attached to it, the wedge will be seriously

Figure C. Parts of the X-Wedge. (1) Tilt-plate; (2) Mounting slot

overbalanced and the telescope could tip over.

at top of tilt plate; (3) Latitude lock screw (one on each side);

(4) Vernier pointer; (5) Latitude Scale; (6) Azimuth Control Knob;

(7) Wedge Body; (8) Plate center hole; (9) Latitude control screw

(adjustment knob not shown); (10) Mounting slots; (11) Center

1 8 bolt hole.

2

3 X-Wedge Assembly

4 The required wedge hardware is shipped within the wedge

carton (Fig. A).

7 6 1. Locate the two 8-32 hex screws and the tangent

arm (Fig. A, 6).

5

1 Tripod Head 5 Leg Lock Knobs

2 Threaded Rod 6 Extension Strut

3 T-handle 7 Tension Hub

Tension Knob 8 Retaining clip

4 Spreader (not visible)

Figure B. Fully assembled tripod.

The X-Wedge instructions are written for use with either the

Meade Standard Field or Giant Field Tripod. The assembly

procedure requires two people who can lift about 55 pounds

each.

Figure D. Attach the tangent arm with the flat surface facing up.

2. Attach the tangent arm to the tripod using the

supplied 8-32 hex screws. Note: the flat surface

of the tangent arm should face upwards (Fig. D).

55-12003_07028_XWedge_InstructionManual.indd 1 8/8/2012 11:07:51 AM

X-Wedge Instruction Manual

Azimuth thrust bar pin

Figure E. The azimuth thrust bar pin positioned in the

tangent arm. Figure G. X-Wedge with threaded rod cap and 5/16" hex screws

secured.

3. Place the wedge on the tripod head, sliding the

65°, unthread the lock screw with the supplied

azimuth thrust bar pin into the tangent arm slot

hex key wrench and move the screw to the

(Fig. E).

optional mounting hole.

4. Push the tripod threaded rod (Fig. B, 2) up so

that the rod extends through the X-Wedge plate

center hole (Fig C, 8).

5. Screw the threaded rod insert onto the threaded

rod until it is seated firmly on the X-Wedge base Latitude lock screw

(in 25˚ to 57˚ position

plate, fitted in plate center hole (Fig. F).

Latitude lock screw

hole for 32˚ to 65˚

Figure H. Latitude screw with multiple lock screw positions.

Mounting the Telescope

on the X-Wedge

1. Thread one of the provided 3/8" hex screws into

the hole on the underside of the telescope drive

Figure F. The Threaded rod insert properly positioned on the

threaded rod and X-Wedge base plate. base. The desired hole is located at the curved

6. Align the tripod spreader bar with the tripod legs

as shown in Fig, B. Tighten the tripod t-handle

tension knob to a snug fit. Screw the threaded

rod cap onto the end of the threaded rod.

7. Using the three 5/16" hex screws and washers

(Fig. A, 5) pass the hex screws through the oval

slots on the wedge floor and thread them into the

tripod head (Fig. G).

8. The latitude lock screw (Fig. H) is installed at the

factory to allow the tilt plate to be adjusted for

any latitude greater than 25° and less than 57°.

If viewing in a region with a latitude from 57° to Figure I. Attach one of the 3/8" hex screws to the curved part of

the telescope drive base.

55-12003_07028_XWedge_InstructionManual.indd 2 8/8/2012 11:07:51 AM

#497 HANDBOX

Manual

end of the telescope drive base (see Fig. I). Be not overtighten.

sure to leave approx, 3/4" of the screw exposed

The telescope is now fully mounted onto the wedge and field

to allow for clearance of the wedge tilt plate.

2. Grasp the two fork arms of the telescope firmly,

with the control panel toward the floor, place the

Instruction

telescope onto the wedge tilt plate (Fig. A, 1) by

sliding the mounting screw on the telescope base

into the slot at the top tilt plate (Fig. J).

3. Insert the center mounting bolt (Fig. K) through

AutoStar

X-Wedge

Figure L. Use the provided hex wrench to secure the three 3/8"

hex screws into the telescope drive base.

tripod. Adjustments in wedge latitude angle and/or azimuth

orientation may be made with the telescope in place.

Figure J. The telescope drive base placed on the Setting the Observing Latitude

X-Wedge tilt plate.

Look up the latitude of the desired observing site (most road

the center of the underside of the tilt plate and maps show latitude lines). Then, loosen the latitude lock screws

into the underside of the drive base. Firmly (Fig. C, 3) and rotate the fine latitude control knob (Fig. C, 9)

tighten the bolt. Do not overtighten. while reading the latitude scale (Fig. C, 5). The latitude pointer

Note: It is important to insert the center mounting bolt into the is a vernier scale (Fig. C, 4) which will allow the tilt angle to be

wedge-telescope assembly. The center mounting bolt insures the set to within 0.25°. When the tilt plate is aligned with the desired

precise pointing accuracy of the X-Wedge. latitude, tighten the latitude locking screws.

4. Insert the two remaining 3/8" hex screws

Aligning on Polaris

Begin aligning the telescope by locating Polaris. Finding Polaris

is simple. Most people recognize the “Big Dipper. The Big Dipper

has two stars that point the way. Polaris is the last star in the

“handle” of the Little Dipper (Fig. M).

Once you have located Polaris in the sky, orient your telescope

Figure K. Attaching the center mounting bolt.

through the underside of the tilt plate (Fig. L)

and into the underside of the drive base. Firmly

tighten all three 3/8" hex screws at this time. Do Fig. M. Locating Polaris

55-12003_07028_XWedge_InstructionManual.indd 3 8/8/2012 11:07:52 AM

X-Wedge Instruction Manual

so that the control panel faces north (towards Polaris). You may

need to pick-up and rotate the telescope on its tripod to achieve

this orientation. The telescope and X-Wedge are now pointing

very near to the celestial north. Loosen the DEC lock, rotate the

OTA so that it is 90 degrees to the base (pointing towards Polaris)

and then relock the DEC. If you were to have performed this

maneuver perfectly, you would be able to see Polaris through the

finder scope (make sure that you aligned the finderscope to the

OTA). If you cannot, rotate the entire telescope/tripod assembly

until you can.

You are now ready to perform one of the AutoStar equatorial

alignment procedures. Consult your telescope’s instruction

manual for exact details.

Aligning the Magnetic Compass Figure N. Compass level placed on the X-Wedge.

With the aid of the magnetic compass, a telescope can be polar

of the X-Wedge as shown in Fig N. Verify the

aligned in locations where the view of Polaris is obstructed or

compass is still pointing toward Magnetic North

even before the skies get dark. The compass face has an angular

and the bubble level is properly centered. If the

scale from 0 to 360 degrees which will be useful in adjusting for

bubble is not centered, adjust the tripod legs

the local angle of Magnetic Declination—the difference between

until centered.

Magnetic North (which the compass shows) and true north

(where the telescope should be pointed). 2. Finding True North:

The magnetic compass is now ready for use.

Note: Magnetic Declination should not be confused with the

Follow these simple steps for a quick and easy

astronomical term “Declination” which, when used with “Right

azimuth alignment.

Ascension,” describes the celestial coordinate system.

a. Slightly loosen the three 5/16" hex screws

1. Setting Magnetic Declination:

in the wedge floor to allow for rotation of the

a. In order to obtain an accurate reading using X-Wedge.

the compass, you first need to determine the

b. Using the Azimuth Control Knob (Fig C,

Magnetic Declination of the observing area by

6), manually adjust the X-wedge around the

referring to the Magnetic Declination Map (Fig

O). Locate this value on the compass face for

future reference.

NOTE: East Magnetic Declination means True North is to the right

of the Magnetic North position and West Magnetic Declination

means True North is left of the Magnetic North position. For

example, Fig. O shows the correct setting for 13.5° East

Declination which covers Irvine, CA. The compass scale markings

range from 0 to 360 degrees azimuth so for East Magnetic

Declinations subtract the East Magnetic Declination value from

360 to obtain the correct reference mark on the compass face.

b. While holding the compass, rotate it so the

red compass arrow points in the direction of

Magnetic North. The arrow should be directly

over the "N" marking on the compass face.

Figure O. Compass bearing adjusted for Irvine, CA's

c. Now place the compass onto the flat base magnetic declination.

55-12003_07028_XWedge_InstructionManual.indd 4 8/8/2012 11:07:52 AM

#497 HANDBOX

Manual

threaded rod (without moving the compass)

until the red compass arrow points toward the

observing sites Magnetic Declination found in

step 1.

c. Tighten the t-handle tension knob, locking the

Instruction

X-Wedge into place.

d. Retighten the 5/16" hex screws on the wedge

floor. Do not over tighten.

AutoStar

The tripod and X-Wedge are now pointed very near celestial

north and ready to run one of the alignment procedures.

X-Wedge

55-12003_07028_XWedge_InstructionManual.indd 5 8/8/2012 11:07:52 AM

X-Wedge Instruction Manual

Figure P. Magnetic declination map of North America.

55-12003_07028_XWedge_InstructionManual.indd 6 8/8/2012 11:07:52 AM

#497 HANDBOX

Manual

MEADE LIMITED WARRANTY

Every Meade telescope, spotting scope, and telescope accessory is warranted by Meade Instruments Corp. (“Meade”) to be free of

defects in materials and workmanship for a period of ONE YEAR from the date of original purchase in the U.S.A. and Canada. Meade will

repair or replace a product, or part thereof, found by Meade to be defective, provided the defective part is returned to Meade, freight-

AutoStarX-Wedge

prepaid, with proof of purchase. This warranty applies to the original purchaser only and is non-transferable. Meade products purchased

outside North America are not included in this warranty, but are covered under separate warranties issued by Meade international

distributors.

RGA Number Required: Prior to the return of any product or part, a Return Goods Authorization (RGA) number must be obtained from

Meade by writing, or calling (800) 626-3233. Each returned part or product must include a written statement detailing the nature of the

claimed defect, as well as the owner’s name, address, and phone number.

This warranty is not valid in cases where the product has been abused or mishandled, where unauthorized repairs have been attempted

or performed, or where depreciation of the product is due to normal wear-and-tear. Meade specifically disclaims special, indirect,

or consequential damages or lost profit which may result from a breach of this warranty. Any implied warranties which cannot be

disclaimed are hereby limited to a term of one year from the date of original retail purchase.

This warranty gives you specific rights. You may have other rights which vary from state to state.

Meade reserves the right to change product specifications or to discontinue products without notice.

Meade Instruments Corp.

27 Hubble

Irvine, CA 92618 14-2118-00 071112

800-626-3233 55-12003

www.meade.com

Follow us on facebook and twitter for updates.

55-12003_07028_XWedge_InstructionManual.indd 7 8/8/2012 11:07:53 AM

You might also like

- Service Manual Singer 9100 - 2010Document46 pagesService Manual Singer 9100 - 2010Alejo Rozo67% (3)

- SainSmart Genmitsu CNC Router 3018-User ManualDocument26 pagesSainSmart Genmitsu CNC Router 3018-User ManualFernando MarcanoNo ratings yet

- Horizontal "Flatbed" Router Table: MLCS Manual For #9767Document11 pagesHorizontal "Flatbed" Router Table: MLCS Manual For #9767teromandosNo ratings yet

- B.6.23 - STD SPECS - For Plum Concrete & Plum MasonaryDocument3 pagesB.6.23 - STD SPECS - For Plum Concrete & Plum MasonaryBijay Krishna Das100% (3)

- Primacoustic Stratus ManualDocument4 pagesPrimacoustic Stratus ManualJay JayNo ratings yet

- Installation Instruction: 0.3m AntennaDocument8 pagesInstallation Instruction: 0.3m AntennaDan MereanuNo ratings yet

- Escaladores Magnética. ManualDocument20 pagesEscaladores Magnética. ManualMiguel Alberto Renderos AlfaroNo ratings yet

- Activator 903-CIS0185-CDocument8 pagesActivator 903-CIS0185-CmahdimecarniNo ratings yet

- Inner Bearing Race Puller Snemalec Notranjih Ležajnih ObročevDocument2 pagesInner Bearing Race Puller Snemalec Notranjih Ležajnih ObročevWijaya TeknikNo ratings yet

- Orbitrek PlatinumDocument10 pagesOrbitrek Platinumjesusleo02No ratings yet

- Group 8 Turning JointDocument5 pagesGroup 8 Turning Jointdeniden2013No ratings yet

- 8 12 PDFDocument6 pages8 12 PDFTaha RdmanNo ratings yet

- WH TT60, TT70 e - 9. Differential Locks, Front DifferentialDocument6 pagesWH TT60, TT70 e - 9. Differential Locks, Front DifferentialVedran HrastovićNo ratings yet

- Group 4 Disassembly and AssemblyDocument30 pagesGroup 4 Disassembly and Assemblymãi bên emNo ratings yet

- Kit de Montaje para CilindrosDocument2 pagesKit de Montaje para CilindrossandraNo ratings yet

- 4535 Rower CobraDocument20 pages4535 Rower CobraDaniel H.No ratings yet

- Bus Broc Bus Eng 1263 4Document1 pageBus Broc Bus Eng 1263 4vijender07No ratings yet

- ChainDriveVise 1-25-19 WebDocument14 pagesChainDriveVise 1-25-19 WebEliseu ChereneNo ratings yet

- 5-4 Disassembly and AssemblyDocument31 pages5-4 Disassembly and AssemblyGustavo Alonso Cappa SalasNo ratings yet

- D FTP Media Manuals 330185 ManualDocument82 pagesD FTP Media Manuals 330185 ManualPETER LOCKNo ratings yet

- GS-430E Elliptical TrainerDocument26 pagesGS-430E Elliptical TrainerpaulmauriceNo ratings yet

- Group 8 Turning Joint: 1. Removal and InstallDocument5 pagesGroup 8 Turning Joint: 1. Removal and InstallDavidNo ratings yet

- Cylinder Adjust 349D Prefijo Jgb.Document2 pagesCylinder Adjust 349D Prefijo Jgb.Enso E Rosales FNo ratings yet

- Free hand sketchesDocument9 pagesFree hand sketcheslalalxla22No ratings yet

- Owner'S Manual: Important!Document9 pagesOwner'S Manual: Important!Fidio RodriguezNo ratings yet

- KSM01 Installation InstructionsDocument17 pagesKSM01 Installation InstructionsHybrid RacingNo ratings yet

- Activator 80 GHZ 903-CIS0163-PC6Document8 pagesActivator 80 GHZ 903-CIS0163-PC6mahdimecarniNo ratings yet

- User Manual 17284Document9 pagesUser Manual 17284unitlatihanspNo ratings yet

- Group 10 Undercarriage: 1. Track LinkDocument12 pagesGroup 10 Undercarriage: 1. Track LinkDavidNo ratings yet

- 6016-60C Pneumatic Actuation Kit For The 6010 & 6016 Emergency Shut-Off ValvesDocument2 pages6016-60C Pneumatic Actuation Kit For The 6010 & 6016 Emergency Shut-Off ValvesJuan Carlos Pardo RimachiNo ratings yet

- Auxiliary Valve Kit For NEW HOLLAND NEW MODEL HARRITAGE 3600 3230 3037 4710 1Document2 pagesAuxiliary Valve Kit For NEW HOLLAND NEW MODEL HARRITAGE 3600 3230 3037 4710 1Manoj YadavNo ratings yet

- InspectForm A Pre 2013 1Document1 pageInspectForm A Pre 2013 1mr.manker.mlbbNo ratings yet

- Stream DocumentDocument4 pagesStream DocumentalphonseduculotNo ratings yet

- Service Manual SM17 - 002 - 083.00: Latching Boom Mechanism RetrofitDocument24 pagesService Manual SM17 - 002 - 083.00: Latching Boom Mechanism RetrofitErissonNo ratings yet

- Penholder Instruction EgDocument33 pagesPenholder Instruction EgJoao MendesNo ratings yet

- Ms Ins 83Document2 pagesMs Ins 83Alexyz33No ratings yet

- MS Cap2Document19 pagesMS Cap2alazhar laisonNo ratings yet

- Juki HZL-30Z Sewing Machine Service ManualDocument20 pagesJuki HZL-30Z Sewing Machine Service ManualiliiexpugnansNo ratings yet

- VOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFDocument16 pagesVOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFfjjsjekdmme67% (3)

- Kstand Assembly Instructions_11192018Document10 pagesKstand Assembly Instructions_11192018lefol88027No ratings yet

- Baker A-5 SemidisassenblyDocument7 pagesBaker A-5 SemidisassenblyabodolkuhaaNo ratings yet

- Excavadora HiundayDocument12 pagesExcavadora HiundayHenry HuayhuaNo ratings yet

- Classic 60 Deck Service Kit 902415Document3 pagesClassic 60 Deck Service Kit 902415pwoody571No ratings yet

- ELME 817 Manual PDFDocument20 pagesELME 817 Manual PDFniko67% (3)

- Group 4 Main Control Valve: 1. Removal and InstallDocument14 pagesGroup 4 Main Control Valve: 1. Removal and InstallDavidNo ratings yet

- Instruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsDocument2 pagesInstruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsJonNo ratings yet

- Mini Scierie MontageDocument4 pagesMini Scierie Montagen_bernardNo ratings yet

- Group 6 Turning Joint: 1. Disassembly and AssemblyDocument4 pagesGroup 6 Turning Joint: 1. Disassembly and AssemblySaidi JalelNo ratings yet

- GEARWRENCH - 80949 232 Piece SAE/Metric Mechanics Tool Set: What's Included QuantityDocument6 pagesGEARWRENCH - 80949 232 Piece SAE/Metric Mechanics Tool Set: What's Included Quantitykamran shahNo ratings yet

- Installation Instructions Service Kit - 28453: Monsoon Universal Part NoDocument28 pagesInstallation Instructions Service Kit - 28453: Monsoon Universal Part NonicehornetNo ratings yet

- Group 3 Gear Box: 1. StructureDocument4 pagesGroup 3 Gear Box: 1. StructureTaha RdmanNo ratings yet

- MX-DR Series Product Installation Diagram - ICENDocument9 pagesMX-DR Series Product Installation Diagram - ICENjose peñaNo ratings yet

- ErhethrthdDocument2 pagesErhethrthdThylaneNo ratings yet

- Group 10 UndercarriageDocument12 pagesGroup 10 Undercarriagedeniden2013No ratings yet

- EsrhstrhdrtjDocument2 pagesEsrhstrhdrtjThylaneNo ratings yet

- BRX100 ERGO - GB - Rev00Document18 pagesBRX100 ERGO - GB - Rev00Németh BalázsNo ratings yet

- V-Slot Corexy 3D Printer: Assembly InstructionsDocument21 pagesV-Slot Corexy 3D Printer: Assembly InstructionsCuong Nguyen VanNo ratings yet

- MODEL 1900D Airliner: Maintenance ManualDocument3 pagesMODEL 1900D Airliner: Maintenance ManualAdel KhelifiNo ratings yet

- Cee-2027 AntirollDocument6 pagesCee-2027 Antirollalexi calatayudNo ratings yet

- Quick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesFrom EverandQuick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesRating: 3 out of 5 stars3/5 (2)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Web Lab PDFDocument6 pagesWeb Lab PDFDevesh PandeyNo ratings yet

- SkillsDocument7 pagesSkillsRufus RajNo ratings yet

- Experiencing Postsocialist CapitalismDocument251 pagesExperiencing Postsocialist CapitalismjelisNo ratings yet

- DeforestationDocument1 pageDeforestationzaineb chzkibNo ratings yet

- Wa0004.Document15 pagesWa0004.Sudhir RoyNo ratings yet

- SoftOne BlackBook ENG Ver.3.3 PDFDocument540 pagesSoftOne BlackBook ENG Ver.3.3 PDFLiviu BuliganNo ratings yet

- GACAL vs. PALDocument2 pagesGACAL vs. PALKathleen Valencia100% (1)

- 8DIO Claire Oboe Virtuoso ManualDocument10 pages8DIO Claire Oboe Virtuoso ManualNiskaNo ratings yet

- Adverb ExerciseDocument22 pagesAdverb ExerciseLộc NguyễnNo ratings yet

- Testbank: Applying Ifrs Standards 4eDocument11 pagesTestbank: Applying Ifrs Standards 4eSyed Bilal AliNo ratings yet

- File Handling in JavaDocument8 pagesFile Handling in JavaDipendra KmNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Error Message Reference: Oracle® Hyperion Tax GovernanceDocument6 pagesError Message Reference: Oracle® Hyperion Tax GovernanceAbayneh AssefaNo ratings yet

- A Movie Recommendation System (Amrs)Document27 pagesA Movie Recommendation System (Amrs)shanmukhaNo ratings yet

- Channel DecisionsDocument30 pagesChannel Decisionsuzmatabassum1996No ratings yet

- Microsoft Project TOCDocument5 pagesMicrosoft Project TOCali_zulfikarNo ratings yet

- Tic EbookDocument215 pagesTic EbookTaju Deen100% (1)

- BdwtvdytwDocument11 pagesBdwtvdytwharshit kuchhalNo ratings yet

- Case 4.2 Comptronic CorporationDocument2 pagesCase 4.2 Comptronic CorporationThao NguyenNo ratings yet

- Ent Secretory Otitis MediaDocument3 pagesEnt Secretory Otitis MediaIrena DayehNo ratings yet

- Anti-Friction Bearings FundamentalsDocument21 pagesAnti-Friction Bearings FundamentalssubrataNo ratings yet

- Ozone Therapy Is Safest Known TherapyDocument35 pagesOzone Therapy Is Safest Known Therapyherdin2008100% (1)

- Effective Phone and Door Scripts 0Document6 pagesEffective Phone and Door Scripts 0Kaso MuseNo ratings yet

- (Human Behavior and Environment 8) Carol M. Werner, Irwin Altman, Diana Oxley (Auth.), Irwin Altman, Carol M. Werner (Eds.) - Home Environments-Springer US (1985)Document355 pages(Human Behavior and Environment 8) Carol M. Werner, Irwin Altman, Diana Oxley (Auth.), Irwin Altman, Carol M. Werner (Eds.) - Home Environments-Springer US (1985)Carlos Roberto JúniorNo ratings yet

- Tera Spin PK-1500 Series PK-1600 40 Weighting Arms Jul-2018Document14 pagesTera Spin PK-1500 Series PK-1600 40 Weighting Arms Jul-2018deepakNo ratings yet

- Setting GuideDocument12 pagesSetting GuideJamesNo ratings yet

- Edc 2Document103 pagesEdc 2abhi_engg06No ratings yet

- Transistor 2n3904 DatasheetDocument2 pagesTransistor 2n3904 DatasheetAlex ZXNo ratings yet

- Jyotish - Hindu Panchangam & MuhurtasDocument40 pagesJyotish - Hindu Panchangam & MuhurtasSamir Kadiya100% (1)