Professional Documents

Culture Documents

JSA for Dewatering

JSA for Dewatering

Uploaded by

Abdul WahabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA for Dewatering

JSA for Dewatering

Uploaded by

Abdul WahabCopyright:

Available Formats

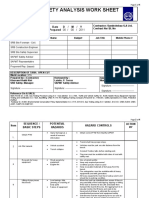

Element 6 – Safe Operation

Job Safety Analysis (JSA)

SMS 6.17.3 JSA Record sheet

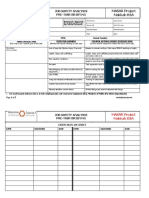

JOB SAFETY ANALYSIS RECORD SHEET

DATE PREPARED: DATE ISSUED:

DEPARTMENT:

12/09/2020

PLANT/EQUIPMENT:

Unit: JSA NO:

DESCRIPTION OF JOB/TASK: JSA for Dewatering work

Reviewed By: Name: Signature: Date:

SAPMT

PREPARED BY: APPROVED BY:

SAPMT

Unit Foreman.

REFERENCES:

CSM chapter II-1.6,1.7, III-4, SAEP 327 , Construction of on-land and near shore pipelines,) Work Permits GIs 2.100(TIM Work Permit#103101 and SMS-E6.2 toE-

6.6) Electrical Isolation, lockout #103104(SMS-E-6.7), vacuum tanker utilization GI163205, Mobile equipment ground TIM GI #109001, PPE TIM GI#101101, fire

watch TIM GI#101003.

SA Construction Safety Manual (SACSM), SA Medical Minimum Standards Requirements Manual (MMSR Manual), SA Safety Handbook, Minimum Safety

Rules, SA Safety Management System (SASMS).

All other applicable Saudi Aramco Programs, Processes, Procedures, and Standards including Schedule “D” of the Contract shall be strictly followed during

the execution of site activities.

TSP - CSSP, HIP, ERP, EMP etc.

SAFETY EQUIPMENT REQUIRED: Personnel protective equipment (PPE): Required to wear Personal Protection Equipment (PPE), including safety helmet, safety glasses,

gloves, and safety shoes. Equipment shall be grounded, upwind and valid fire extinguisher beside.

Saudi Aramco: Company General Use

JOB

To check

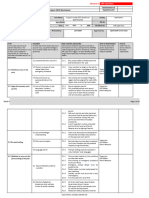

STEP SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS REQUIRED HAZARD CONTROLS/SAFE WORK PROCEDURES

(Ticked)

NO.

1 Obtain work permit – conduct a Presence of other Make sure all employees have attended proper safety Supervisor/ WPR/ SAPMT

joint site inspection. known & unknown induction from Saudi Aramco and TSP. Fully familiar

Permit Application. hazards with site safety requirements and enforce requirements

Mobilization Unfamiliarity of the to wear hard hats, safety shoes, safety glasses, FRC and

site road/access other appropriate PPE for the site conditions.

Heat stress The permit issuer and receiver will conduct a joint site

inspection to discuss the hazards and precautions

required for conducting the job safely.

A toolbox meeting shall be conducted also informing

the location of assembly area for emergency & contact

numbers to be posted.

All work permit requirements shall be followed under the GI

2.100 Work Permit System.

Prior to using, all vehicles shall be duly inspected and maintained

in accordance with Saudi Aramco Standards

Personnel shall wear full body harness with 100% tie-off, if ever

working at height

JSA and Work permit shall be communicated to all personnel

during daily TBT prior to start the activity.

2 Entry in to Excavation deeper than Oxygen Personnel entering confined spaces will be required to have the Supervisor/ Competent

1.2 meter Deficiency/Toxic Gas confined space training class prior to entry. Person/ Civil

TSP shall comply to Saudi AramcoGI 2.100 work permit Engineer/safety Officer

Atmospheric gas testing shall be done with an accordance with GI

2.709.

Standby men shall be provided with adequate means of

communication (e.g., two-way radio) to ensure continuous

communication with entrants and with the proper personnel

(e.g., CSES, rescue team) in event of an emergency.

All personal work in the Confined space shall have their own T-40

H2S monitor with them & all personal shall understand how to

read the reading in T-40 and must understand SA emergency

evacuation procedure.

Shoring/sloping or shoring shall be provided according to soil

Saudi Aramco: Company General Use

condition.

Access shall be provided every 7.5 meter of an excavation. Both

sides shall be provided with adequate handrails.

3 Installation of dewatering Fuel Spills due to Fire extinguisher shall be kept visible and ready to use.

System Supervisor/ Competent

inappropriate re-fuelling Shut off the equipment and let it cool off prior refueling. Proper

of air compressor or Person/ Civil

Grounding of fuel truck shall be observed.

dewatering pump/ Fire Engineer/safety Officer

Check the engine for fuel leaks. Commeasure/Pump to be installed

hazards on site with adequate drip tray to contain any possible spill.

Wear appropriate coverall, long safety boot, respiratory protection

and working gloves during dewatering pump installation and

Contact of hot surface in excavation.

machine Burns, Hand

Injury Allow compressor or pump to cool down before handling or

servicing.

Caught in rotating Do not operate when safety devices (guards) are not in place.

machinery Hand injury. Secure pump in its operating position so it cannot tip over or fall.

Severe laceration

Inhalation of fumes Health Do not wear loose clothing that may become entangled in the

Hazards Respiratory impeller or other moving parts.

problem, Noise hazards, Keep clear of suction and discharge openings. Do not insert fingers

Temporary to permanent in hoses.

impairment on hearing

Environment hazards Provide dust masks and ear plugs.

/misuse of equipment Ensure good ventilation and smoke muffler of air compressor or

water pump is pointed upside away from operator’s harm.

Ear plugs must be worn by operator all the time.

Warning signs shall be posted prohibiting unauthorized entry.

Falls into excavation both Do not exceed manufacturer’s recommendation for maximum

personnel and performance, as this can cause the motor to overheat.

equipment.

Hard barricades shall be installed 1.5 meters away from the

excavation and Warning Signs posted.

Provide adequate lighting in case of night works.

Workers will be advised not to go near excavation edges

4 Installation of well system using Damage underground Ensure that all underground utilities are identified.

Supervisor/ Competent

Saudi Aramco: Company General Use

mechanical excavator spiral utilities Excavation should be hard barricaded and ‘DEEP EXCAVATION

drill. Physical injury from Person/ Civil

SIGNS’ posted.

moving parts of Engineer/safety

Ensure that heavy equipment have valid 3rd party inspection Officer/WPR

Equipment

sticker.

Inhalation of dirt or dust

during work Activities Ensure that heavy equipment operator have valid SA certificate

Cave-in to operate the machine.

Potential for Flag man should be always present to control heavy equipment

Flooding movement.

Falling of equipment or Sloping or benching of the sides of excavations to be used to

worker into excavation protect workers from cave-ins.

Toxic gases

Have a competent person to evaluate the excavation and

Traffic accident

complete excavation checklist. Excavations over 4-foot-deep

requires confined space permit. Always utilize a H2S detector

while employees are in ditch.

Ensure that the dewatering hose and pipes and heavy

equipment are kept away from the edge of the excavation.

Proper access (ramp) for personnel to be arranged.

Unauthorized personnel shall be kept away.

5 Operation of Dewatering System Emergencies stop button Test the emergency stop for its functionality prior start of work.

Foreman shall ensure that equipment is in full operable condition. Supervisor/ Competent

not functional.

Person/ Civil

Hit by high pressure air Inspect air housed fitting, installed whip arrester with all joint,

Engineer/safety

maintain pressure as per pneumatic pump requirement.

house. Officer/WPR

Only pneumatic pump shall be use until presence of crude with

Fire/explosion due to water.

presence of crude with

Hot work activity shall not do near dewatering area.

water,

Adequate protection shall be provided to header pipes when

Damage of Pipe Header crossing access roads. It shall be buried and installed with cover.

due to run down by Do not block or restrict discharge hose, as discharge hose may

equipment, whip under pressure and can cause damage to equipment.

Hoses shall be arranged properly and not to obstruct access.

Slips, trips, Warning signs shall be posted

Cave In (collapse of Approved Excavation and shoring plan shall be followed. WPR/Supervisor

Saudi Aramco: Company General Use

side walls) Have competent person/civil engineer to inspect the excavation

before work starts and as often as necessary during the shift.

Unauthorized personnel are not allowed to enter the work

location.

6 Discharging of Water Environmental Hazard YCOT/SA Operation compliance shall be followed. WPR/WP

due to Contaminated Issuer/SAPMT/

Water / Soil, Damage to

Supervisor/Env.

environment

Coordinator

7 Vacuum truck/vacuum Damage truck, Prior to using, vacuum truck shall be duly inspected using vacuum Vacuum Truck

Excavator operation No inspection truck pre use checklist & Vacuum truck safe operation checklist (as Driver/Operator

(Oily Water/water or Fire per API recommended practice 2219).

sewage/Sludge/soil removal) Safety Officer/WPR

Only drivers with valid Saudi licensed and certified

drivers/operator shall be allowed to handle and operate to drive. /Supervisor

Ensure availability of Fire Extinguisher in truck.

Exhaust hose shall be sufficient to reach an area that is away from

the source of liquid, at least 50ft downwind of the truck and free

from hazardous exposure.

Operator shall be aware of source of ignition include vacuum truck

engine and exhaust heat, pump overheat, faulty or improper

electrical devices, smoking etc.

Truck shall be positioned, if possible, on level ground at least 7.6

m (25 ft) upwind from the material to be loaded or 15.2 m (50

ft) upwind if inside a dike.

Operator shall be aware of emergency contact 911 or 014-397-

0911.

Explosion of tank Valve must be leak free, Vacuum tank pressure and level gauges to

be in working condition.

There must be a means to manually depressurize the truck.

cargo tank shall have a nameplate that contains the minimum

design (25 psi) and test pressure (40 psi).

Do not stand near vacuum truck, Only Authorized personnel

allowed.

Ensure Vacuum relief valve or remote shut down is available &

operational.

Saudi Aramco: Company General Use

Toxic gas inhalation Full PPE, including chemical gloves, cartage respirator shall be

(H2S Biological Hazards used.

Sewer gases) Conduct air quality monitoring at the work site is continuous at

locations.

Vacuum truck shall position in a safe, identified place, at least 25 ft

upwind or cross wind from the source of sump pit or possible toxic

gases area.

Chemical Reaction Train workers on the hazards associated with the liquids or

between different substances to be vacuumed or transferred.

waste types

Overflow cause Spill Be sure all equipment – including tank and vacuum trucks, and

pumping equipment – is in safe working condition.

Never transfer fluids from one truck to another

Gas test shall conduct prior to Vacuum operation.

Open manholes/toilets Close manholes/toilets after the operation

Static electricity Grounding for the tank

Unknown chemicals Discharge shall only be done in a SA approved area & shall be in-

Discharges illegally accordance with SA environmental health code, waste manifest to

secure with each discharge.

Conduct air quality monitoring at the work site is continuous at

locations where vacuum trucks are

Fall of truck in Ensure work area is barricaded and that appropriate signage is

excavation, installed. assign trained flagman to guide the truck,

Vacuum truck must move or park on compacted area.

8 Working in adverse weather Heat stress Supervisors to take decisions while continuing work during WPR/WP

condition/welfare/Emergency Strong wind adverse weather.

Issuer/SAPMT/

Rain / lighting Ensure adequate supply of cold water and ORS during working

High humidity hours. Supervisor/

Non-Establishment of During peak summer season all workforces must be aware about

Emergency heat stress symptoms.

Response effort If required job rotation of the workers will be done, divided the

team of two.

It must be ensuring that rest shelters are available at site for rest

and other welfare facilities.

Aramco emergency numbers along with contractor emergency

Saudi Aramco: Company General Use

numbers should be displayed at prominent location.

ERT including ambulance shall be active during dewatering

activity. Call SA ERT in case of emergency.

For in case of any emergency exit routes & master assembly area

should be marked and known to all personnel involved in the

task.

Enough fresh and cold drinking water must be available during

execution of the job.

9 Installation of Lightings/Night work. Harm to personnel due to Only Flood Light shall be installed on site for Night work.

Supervisor/ WPR/ Safety

usage of defective or Always wear appropriate PPE.

homemade tools Officer, Electrician

Electrical installation and maintenance shall only be performed by

certified electricians.

Harm to personnel due to All electrical equipment shall have ground fault circuit interrupters

failure to properly (GFCI) or assured equipment grounding.

disconnect power from Conductive items of jewelry or clothing shall not be worn unless

main line. they are rendered non-conductive by covering, wrapping or other

Electric shock serious insulating means.

burns or injury to body Adequate grounding must be provided and installed and all

Equipment not properly generators, tower lights etc. It must be properly buried onto

grounded ground.

Electrocution

Good cable management must be observed. Cables must be

Poor cable management

hanged or properly buried to avoid tripping or damaging the cable.

Slip, Trip and Fall

Fire extinguisher must be in Place.

Poor elimination Only licensed and certified drivers/operator shall be allowed to

operate or drive.

Only approved routes shall be used for access to and egress from

the site.

All personnel must wear clear safety glasses.

Provide enough illumination (Flood light) to work area.

Saudi Aramco: Company General Use

10 Spread of Infectious disease COVID-19 Health ill, Workers shall be trained to practice social distancing of minimum HSE dep, SAPMT,

pandemic, 2-meter distance during work and rest, wear face mask at all the

time, wash hand frequently or use frequently hand sanitizer. Supervisor, WPR.

Sunshade/rest shelter shall be extended which can accommodate

workers in maintaining 2-meter distance,

Work shall be trained to avoid gathering. Avoid using shared

items, like water bottle, cups etc.,

TSP shall Provide separate drinking flask to each worker.

Develop shift work to minimize gathering.

Additional water cooler shall be provided, workers shall maintain

two-meter distance while using drinking station, provide hand

sanitizer, Face mask, washing station on workplace.

Repot to Site clinic for any health ill.

Adequate and trained medical staff, ambulance equipped as per

MMSR shall be available on workplace.

Educate the worker on 7 moment of hand hygiene,

Disinfection procedures shall be implemented in Sunshade/rest

shelter buses etc.

11 Closing of activity Poor housekeeping. After completing activity WPR & supervisor ensure that area

Safety/ Supervisor

Fire hazard. must be cleaned form any unattended materials.

Permit must be closed by proponent.

All equipment & tools must be removed from the activity area.

Equipment must be locked / isolated from the access of

unauthorized personnel.

No combustible / flammable materials left at activity area.

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- JSA Blasting and Coating KP 69.4Document5 pagesJSA Blasting and Coating KP 69.4shinto Lawrence100% (7)

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- ARK-JSA - Installation of Form Works, Rebars & Concrete PouringDocument7 pagesARK-JSA - Installation of Form Works, Rebars & Concrete PouringREMYA100% (3)

- Welding, Cutting and GrindingDocument6 pagesWelding, Cutting and GrindingMohammed MinhajNo ratings yet

- Coating and Painting Work.Document9 pagesCoating and Painting Work.MOHNISHKUMARJHANo ratings yet

- Flow Chart - Prisoner Re-Entry ProgramDocument7 pagesFlow Chart - Prisoner Re-Entry ProgramUrbanistRuralsNo ratings yet

- Mutants&Masterminds Condition CardsDocument32 pagesMutants&Masterminds Condition CardsTalos2912100% (2)

- JSA - ELLECTRICAL AINDAR LAYING TERMINATION - CompressedDocument8 pagesJSA - ELLECTRICAL AINDAR LAYING TERMINATION - Compressedmalikshoaib8528No ratings yet

- Element 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetDocument14 pagesElement 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetGurumoorthy Rajavijayan100% (2)

- JSA Asphalt PavingDocument10 pagesJSA Asphalt PavingMohammad Al Masa'dehNo ratings yet

- ARK JSA Manual Excavation A 3Document9 pagesARK JSA Manual Excavation A 3REMYANo ratings yet

- JSA Excavation For Lighting Pole FoundationDocument18 pagesJSA Excavation For Lighting Pole FoundationMohammad Al Masa'deh100% (1)

- ARK-JSA-06 Concrete FDN PDFDocument8 pagesARK-JSA-06 Concrete FDN PDFREMYA100% (1)

- ARK-JSA-08 Manual Tie-In Welding Rev-3Document9 pagesARK-JSA-08 Manual Tie-In Welding Rev-3REMYANo ratings yet

- JSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00Document9 pagesJSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00DLPS HSENo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- JSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00Document7 pagesJSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00DLPS HSENo ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationMohammed Ali QaziNo ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationREMYA50% (2)

- JSA #4 Concrete WorksDocument7 pagesJSA #4 Concrete Worksahmed Otaif100% (1)

- JSA Backfilling, Leveling, (Night Shift)Document14 pagesJSA Backfilling, Leveling, (Night Shift)Mohammad Al Masa'dehNo ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- Soft Cut Saw Operations (Generic) : Job Safety AnalysisDocument1 pageSoft Cut Saw Operations (Generic) : Job Safety AnalysisBorislav VulićNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970100% (1)

- Jsa For Confined Space EntryDocument5 pagesJsa For Confined Space EntrythennarasuNo ratings yet

- JSA-soil StablizingDocument6 pagesJSA-soil StablizingshahbazchafekarNo ratings yet

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- Manual Excavation For Identified Depth and Elevation of Existing PipelineDocument15 pagesManual Excavation For Identified Depth and Elevation of Existing PipelineshahbazchafekarNo ratings yet

- JSA Road ConstructionDocument17 pagesJSA Road ConstructionMohammad Al Masa'dehNo ratings yet

- Up Dated Job Safety Analysis Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis Gypsum Plastering WorksshahbazchafekarNo ratings yet

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- ARK JSA 0 Rev 00 Crane LiftingDocument6 pagesARK JSA 0 Rev 00 Crane LiftingREMYANo ratings yet

- Red Tile Placing JSADocument5 pagesRed Tile Placing JSAShahid BhattiNo ratings yet

- Jsa-Rp-005 Concrete WorksDocument19 pagesJsa-Rp-005 Concrete Worksibaig1970No ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Construction of New Telecom BuildingDocument6 pagesConstruction of New Telecom BuildingZubair Ahmed KhaskheliNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 pagesPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponNo ratings yet

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentDocument4 pagesJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanNo ratings yet

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 pagesJsa-Rp-001 Site Preparation and General Earthworksibaig1970No ratings yet

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- JSA New Mohan SirDocument23 pagesJSA New Mohan Sirsyed khaja misbhuddinNo ratings yet

- Safety: AnalysisDocument23 pagesSafety: AnalysisshahbazchafekarNo ratings yet

- JSA 03 Manual Excavation and TrenchingDocument11 pagesJSA 03 Manual Excavation and TrenchingArt MayoresNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- JSA 03 Gate Entrance Traffic ProposalDocument10 pagesJSA 03 Gate Entrance Traffic Proposalrahul tkNo ratings yet

- SAR.JSA FOR Geophysical studyDocument7 pagesSAR.JSA FOR Geophysical studyRizwan KhanNo ratings yet

- JSA For SSSP-1Document7 pagesJSA For SSSP-1thennarasuNo ratings yet

- Jsa_installation Fire Water Pump_upgrade Existing Fire Pumps North Parking Ac Plant1,2,3 Building-330 DhahranDocument7 pagesJsa_installation Fire Water Pump_upgrade Existing Fire Pumps North Parking Ac Plant1,2,3 Building-330 DhahranAltaf HassainNo ratings yet

- EWPL-PS5-37 Temporary Power Supply For Spacer Heater With Portable - Gen JSA (PS5)Document12 pagesEWPL-PS5-37 Temporary Power Supply For Spacer Heater With Portable - Gen JSA (PS5)fahadNo ratings yet

- Crane Lifting ActivitiesDocument18 pagesCrane Lifting Activitiestaimoorzafar4676No ratings yet

- Construction of New Overflow Drain ChannelDocument14 pagesConstruction of New Overflow Drain ChannelZubair Ahmed KhaskheliNo ratings yet

- Job Safety Analysis: Abqaiq Plants OperationDocument5 pagesJob Safety Analysis: Abqaiq Plants OperationZia ur RehmanNo ratings yet

- AIR CRASH INVESTIGATIONS – THE CRASH OF VIRGIN GALACTIC SPACESHIP 2From EverandAIR CRASH INVESTIGATIONS – THE CRASH OF VIRGIN GALACTIC SPACESHIP 2No ratings yet

- AMBULANCE MEDICAL CHECK LISTDocument1 pageAMBULANCE MEDICAL CHECK LISTAbdul WahabNo ratings yet

- ENNIRONMENTAL DAY PRESENTATION 5 JUNE 2024Document22 pagesENNIRONMENTAL DAY PRESENTATION 5 JUNE 2024Abdul WahabNo ratings yet

- WARNING LETTERDocument1 pageWARNING LETTERAbdul WahabNo ratings yet

- 操作工安全交底记录Construction Safety TBT Record (1) (1)Document5 pages操作工安全交底记录Construction Safety TBT Record (1) (1)Abdul WahabNo ratings yet

- Pro-Choice Violence in VirginiaDocument11 pagesPro-Choice Violence in VirginiaHuman Life InternationalNo ratings yet

- HEC's Policy On Drugs and Tobacco Control at HEIsDocument12 pagesHEC's Policy On Drugs and Tobacco Control at HEIsArsalan SidikiNo ratings yet

- Makassar Workshop - BeneFusion 5 Series 20190626Document49 pagesMakassar Workshop - BeneFusion 5 Series 20190626wahyu bunha rNo ratings yet

- Healthcare Business Alliance Newsletter - FinalDocument4 pagesHealthcare Business Alliance Newsletter - Finalmg658No ratings yet

- Exercise On Rational ClozeDocument50 pagesExercise On Rational Clozealongita311No ratings yet

- Difference Between Developed Countries and Developing Countries (With Comparison Chart) - Key DifferencesDocument1 pageDifference Between Developed Countries and Developing Countries (With Comparison Chart) - Key DifferencesHeather ClarchickNo ratings yet

- Request For Refund or Test Date Transfer Form: Personal DetailsDocument2 pagesRequest For Refund or Test Date Transfer Form: Personal DetailsKendra FouetsopNo ratings yet

- CFNP TAP Review - AtropineDocument43 pagesCFNP TAP Review - AtropineJunmajNo ratings yet

- Method of Statement PCDocument8 pagesMethod of Statement PCAbada SaadNo ratings yet

- Saudi Pharmaceutical JournalDocument10 pagesSaudi Pharmaceutical JournalDiky ArdianNo ratings yet

- 2024 MSDocument38 pages2024 MS6vnh5z7fnjNo ratings yet

- Applying Taguchi Methods To Health CareDocument12 pagesApplying Taguchi Methods To Health CarehamzaabdalameerNo ratings yet

- 11 кл 1 четверть 472Document54 pages11 кл 1 четверть 472Еркегуль ЖауенNo ratings yet

- Random Presentation!Document37 pagesRandom Presentation!georgeNo ratings yet

- Bronchial Asthma Careplan BBDocument26 pagesBronchial Asthma Careplan BBKshayna 1234No ratings yet

- Mweheyo Andew Handover ReportDocument4 pagesMweheyo Andew Handover ReportDaphne christineNo ratings yet

- Parental Substance AbuseDocument10 pagesParental Substance Abuseapi-360330020No ratings yet

- Detail Information - PHARMACIST AND CLINIC ASSISTANTDocument4 pagesDetail Information - PHARMACIST AND CLINIC ASSISTANTSahil AgnihotriNo ratings yet

- WHO Lab Quality Management SystemDocument246 pagesWHO Lab Quality Management SystemMigori Art100% (1)

- Homework 2Document9 pagesHomework 2Alexis R. CamargoNo ratings yet

- Cardiopulmonary Resuscitation (CPR) : First Aid: UntrainedDocument7 pagesCardiopulmonary Resuscitation (CPR) : First Aid: UntrainedCharles Dominique Nikko LabraNo ratings yet

- Andrews Powergrab Dictatorial Powers BillDocument116 pagesAndrews Powergrab Dictatorial Powers BillMichael SmithNo ratings yet

- Slewing Jib Cranes SI 18.3Document2 pagesSlewing Jib Cranes SI 18.3reda mesbahNo ratings yet

- Spent WashDocument8 pagesSpent WashSuresh Kumar MittapalliNo ratings yet

- PST Inspection Report MS Leisure Company IncDocument2 pagesPST Inspection Report MS Leisure Company IncRyan MackeyNo ratings yet

- Prevalence of Child ABuseDocument20 pagesPrevalence of Child ABuseMarvin Cabantac100% (1)

- 2017-06-06 Scott County AgendaDocument63 pages2017-06-06 Scott County AgendaBrad TabkeNo ratings yet

- 5431 Titanium Console Manual TT1.0 2.0 3.0 ENGLISH PRINTDocument19 pages5431 Titanium Console Manual TT1.0 2.0 3.0 ENGLISH PRINTMilos VujasinovicNo ratings yet