Professional Documents

Culture Documents

05-12 (HTH600 Cylinders)

05-12 (HTH600 Cylinders)

Uploaded by

muriloCopyright:

Available Formats

You might also like

- 4w105 sPARE PARTS CATALOGUEDocument63 pages4w105 sPARE PARTS CATALOGUEsxturbo100% (3)

- Manual de Partes Ç 890.2Document523 pagesManual de Partes Ç 890.2luis melloNo ratings yet

- Physics1100 Lab Manual (Iolab Revision)Document105 pagesPhysics1100 Lab Manual (Iolab Revision)Tri NguyenNo ratings yet

- LOG-001-T-01 WORKSHOP 2021-04-14 MANUAL REQUISITION HYD21WR 0232 - 0234Document381 pagesLOG-001-T-01 WORKSHOP 2021-04-14 MANUAL REQUISITION HYD21WR 0232 - 0234Ernest Ngosa SawasawaNo ratings yet

- Zifeng Tower - Ramazan SariDocument2 pagesZifeng Tower - Ramazan SariNadya Pricilia100% (1)

- SCADAPack 334 Hardware ManualDocument165 pagesSCADAPack 334 Hardware ManualFeri HandoyoNo ratings yet

- Knowing God Study Guide - Section TwoDocument56 pagesKnowing God Study Guide - Section Twomercab15100% (2)

- Spare Parts List VM 80Document16 pagesSpare Parts List VM 80Wilson Orlando Salinas SalinasNo ratings yet

- 30 1347 06-43RotatorftSupportDocument2 pages30 1347 06-43RotatorftSupportmuriloNo ratings yet

- Resumes Umber DanaDocument18 pagesResumes Umber DanaAhmad Agit PatriantoNo ratings yet

- Motor 3114: 4 7e5213 JG AneisDocument50 pagesMotor 3114: 4 7e5213 JG AneisJoice CostaNo ratings yet

- STOPE MATE - S36 Cross Over List GOOD ONEDocument12 pagesSTOPE MATE - S36 Cross Over List GOOD ONEFelipe BernalNo ratings yet

- PROSIS Part InformationDocument4 pagesPROSIS Part InformationElie AbisaadNo ratings yet

- Qy55v532.2201541 (1) (1) - 3 PDFDocument30 pagesQy55v532.2201541 (1) (1) - 3 PDFismaelNo ratings yet

- 09 Unit, DiggingDocument27 pages09 Unit, DiggingUbeimar RiveraNo ratings yet

- CT65 Parts ListDocument26 pagesCT65 Parts ListJayakrishnaNo ratings yet

- PROSIS Part InformationDocument2 pagesPROSIS Part InformationElie AbisaadNo ratings yet

- BW332 12.13 101583441003 101583449999 EngineDocument10 pagesBW332 12.13 101583441003 101583449999 Engineeshopmanual TigaNo ratings yet

- E110a - Cylinder BlockDocument6 pagesE110a - Cylinder BlockbennieNo ratings yet

- 【4】RT35-1 Hydraulic schematic diagramDocument25 pages【4】RT35-1 Hydraulic schematic diagramym0224382856No ratings yet

- Materiale Excess ObsDocument452 pagesMateriale Excess ObsLuchian MarinelaNo ratings yet

- Concrete Mixture: Cement Silo With Pneumatic Conveying SysDocument6 pagesConcrete Mixture: Cement Silo With Pneumatic Conveying Sysamal dasNo ratings yet

- VK2 December 2023 + PDVDocument1,916 pagesVK2 December 2023 + PDVSara FusekNo ratings yet

- 54.01 101490900101 101490900144 Operator's PlatformDocument6 pages54.01 101490900101 101490900144 Operator's PlatformMbahdiro KolenxNo ratings yet

- 61.01 101490900101 101490900144 Roller Drum PDFDocument3 pages61.01 101490900101 101490900144 Roller Drum PDFMbahdiro KolenxNo ratings yet

- 12.41 101870341001 101870349999 Radiator SystemDocument5 pages12.41 101870341001 101870349999 Radiator Systemeshopmanual EnamNo ratings yet

- 53.01 101490900101 101490900144 Engine HoodDocument3 pages53.01 101490900101 101490900144 Engine HoodMbahdiro KolenxNo ratings yet

- 15-Drawing and Part List-01Document8 pages15-Drawing and Part List-01Grisha Mari KosoyanNo ratings yet

- 245Document2 pages245Elie AbisaadNo ratings yet

- PROSIS Part Information: Date: Image Id: Catalogue: ModelDocument2 pagesPROSIS Part Information: Date: Image Id: Catalogue: ModelAMIT SINGHNo ratings yet

- LD LDEP ManualDocument12 pagesLD LDEP ManualJoaquin RomeroNo ratings yet

- U441d - Brake - Rear (Air)Document6 pagesU441d - Brake - Rear (Air)bennieNo ratings yet

- RF Spare Part ListDocument3 pagesRF Spare Part ListVignesh NagarajanNo ratings yet

- General Filters and 407,709 & Taurus FiltersDocument7 pagesGeneral Filters and 407,709 & Taurus Filterspuneet.joshi7No ratings yet

- 1621 9386 00Document2 pages1621 9386 00Godel KHolikNo ratings yet

- Catalogo 4S Torito 2016Document27 pagesCatalogo 4S Torito 2016Inversiones RinocellNo ratings yet

- 10 Mechanical Equipment, Attachment PDFDocument8 pages10 Mechanical Equipment, Attachment PDFPeter BrickNo ratings yet

- Parts List: Model 541Document15 pagesParts List: Model 541AstraluxNo ratings yet

- Howo WD615 Euro II Part IDocument25 pagesHowo WD615 Euro II Part IYo Yo LiNo ratings yet

- Bom Cai835153Document19 pagesBom Cai835153Yuvraj BappiNo ratings yet

- 248Document2 pages248Elie AbisaadNo ratings yet

- 8000-4 Parts ListDocument19 pages8000-4 Parts ListAstraluxNo ratings yet

- Valmet 645 DSBILDocument58 pagesValmet 645 DSBILAlexey petrovichNo ratings yet

- 06 Steering PDFDocument42 pages06 Steering PDFPeter BrickNo ratings yet

- My Hino - Co.idDocument491 pagesMy Hino - Co.idAman Ichwan100% (1)

- EDL Bolt CatalogueDocument50 pagesEDL Bolt CatalogueCY LiuNo ratings yet

- 61.01 101582431002 101582431052 Roller DrumDocument5 pages61.01 101582431002 101582431052 Roller DrumNidya Wardah JuhanaNo ratings yet

- 132kV ND BOM (1.3 MTR BASE)Document24 pages132kV ND BOM (1.3 MTR BASE)ramudureddyNo ratings yet

- TECALEMIT Rubber-hoses-Tecalemit-FlexiblesDocument1 pageTECALEMIT Rubber-hoses-Tecalemit-FlexiblesAlexNo ratings yet

- Bom Cno201763Document20 pagesBom Cno201763Yuvraj BappiNo ratings yet

- Catalogo de Metales Cigueñal-Biela PDFDocument43 pagesCatalogo de Metales Cigueñal-Biela PDFAlex Xavier Malasquez LeónNo ratings yet

- Air Intake and Exhaust System 13-20-2 (Hino Engine Type J08etm-Ksda)Document4 pagesAir Intake and Exhaust System 13-20-2 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNo ratings yet

- HOT Manual Slips enDocument6 pagesHOT Manual Slips enMarcialgonzalezpNo ratings yet

- Model V45 Manual Assembly DisassemblyDocument51 pagesModel V45 Manual Assembly Disassemblyysabel martinezNo ratings yet

- Bom Cno169727Document15 pagesBom Cno169727Yuvraj BappiNo ratings yet

- UtilityDocument3 pagesUtilitymizquiNo ratings yet

- 06 Steering PDFDocument33 pages06 Steering PDFDaniel NavasNo ratings yet

- 2900SF SPL 660005034 Rev6Document34 pages2900SF SPL 660005034 Rev6Иван Сергеевич ЛатошаNo ratings yet

- Volunteer Inventory Collection Detailed Report - 2 30 PM @16.04.2024Document28 pagesVolunteer Inventory Collection Detailed Report - 2 30 PM @16.04.2024ranimomminaNo ratings yet

- Sinotruck Parts To Be OrderdDocument16 pagesSinotruck Parts To Be OrderdTavongasheMaddTMagwati100% (1)

- Halliburton Otis B Positioning (Shifting) Tool: Slickline Services Mechanical InterventionDocument2 pagesHalliburton Otis B Positioning (Shifting) Tool: Slickline Services Mechanical InterventionBsd CityNo ratings yet

- troubleshooting TJ3000Document44 pagestroubleshooting TJ3000muriloNo ratings yet

- Service Manual TJ430Document256 pagesService Manual TJ430muriloNo ratings yet

- Manual serv transm LOK96ebDocument29 pagesManual serv transm LOK96ebmuriloNo ratings yet

- HTH616 PartsManual F350810Document196 pagesHTH616 PartsManual F350810muriloNo ratings yet

- HTH620 MasterDocument482 pagesHTH620 MastermuriloNo ratings yet

- HTH620 Parts ManualDocument174 pagesHTH620 Parts ManualmuriloNo ratings yet

- 30.513.04_11HTH measuring arm modificationDocument1 page30.513.04_11HTH measuring arm modificationmuriloNo ratings yet

- HTH600 relief valve PVG32Document3 pagesHTH600 relief valve PVG32muriloNo ratings yet

- 30.517.04_13 waratah reliefsDocument2 pages30.517.04_13 waratah reliefsmuriloNo ratings yet

- 30 1347 06-43RotatorftSupportDocument2 pages30 1347 06-43RotatorftSupportmuriloNo ratings yet

- Lockup Torque Converter OperationDocument2 pagesLockup Torque Converter OperationmuriloNo ratings yet

- 5195 Training Presentation REV 1.0Document150 pages5195 Training Presentation REV 1.0muriloNo ratings yet

- 38486AENG OPERATOR AND SERVICE MANUAL BAR SAW FELLING HEAD 51950101 - 51950500Document190 pages38486AENG OPERATOR AND SERVICE MANUAL BAR SAW FELLING HEAD 51950101 - 51950500muriloNo ratings yet

- 30 1291 06-27H480FeedRollerDocument1 page30 1291 06-27H480FeedRollermuriloNo ratings yet

- MANUAL DO OPERADOR - 85503001 TO 85503500Document326 pagesMANUAL DO OPERADOR - 85503001 TO 85503500muriloNo ratings yet

- MAX14871 4.5V To 36V Full-Bridge DC Motor Driver: General Description Benefits and FeaturesDocument15 pagesMAX14871 4.5V To 36V Full-Bridge DC Motor Driver: General Description Benefits and FeaturesUdit AgrawalNo ratings yet

- Ex No: 1 DateDocument4 pagesEx No: 1 DateVignesh AadhiNo ratings yet

- CAT-5002 MRP-NPB6AS Remote Power SupplyDocument2 pagesCAT-5002 MRP-NPB6AS Remote Power SupplyEddi Pelaez SalinasNo ratings yet

- A Meta Model of ChangeDocument25 pagesA Meta Model of Changeraminabk100% (1)

- Stress in Soil MassDocument14 pagesStress in Soil MassJanith ChamilkaNo ratings yet

- Behavior and Design of Double Tees With Web OpeningsDocument17 pagesBehavior and Design of Double Tees With Web Openingsunix0123100% (1)

- Comparative Evaluation of Antibacterial Efficacy.9Document6 pagesComparative Evaluation of Antibacterial Efficacy.9Shivani DubeyNo ratings yet

- Cementing BasicsDocument79 pagesCementing BasicsAngel PadillaNo ratings yet

- Inta Commercial Collection April 2011Document59 pagesInta Commercial Collection April 2011Robin FisherNo ratings yet

- Ts 23 Hardox600workshop Uk 02-4Document1 pageTs 23 Hardox600workshop Uk 02-40005No ratings yet

- Miniature Bioreactors Current Practices and Future Opportunities PDFDocument14 pagesMiniature Bioreactors Current Practices and Future Opportunities PDFLuisNo ratings yet

- Global Technical Campus: Global Institute of Technology Global College of TechnologyDocument19 pagesGlobal Technical Campus: Global Institute of Technology Global College of TechnologyGlobal Technical Campus, JaipurNo ratings yet

- Note EjiogbeDocument13 pagesNote EjiogbeIfadayo Alabi50% (2)

- 3254 IEC ACCC Spec Sheets HelsinkiDocument1 page3254 IEC ACCC Spec Sheets HelsinkiRicardo Hernandez MoralesNo ratings yet

- 2021-22 B.E Mechanical EngineeringDocument84 pages2021-22 B.E Mechanical EngineeringTejas Galu PatilNo ratings yet

- NilkamalDocument31 pagesNilkamalAshwin GkNo ratings yet

- MA1101R Chapter1Document54 pagesMA1101R Chapter1le trung hieuNo ratings yet

- CHE34 Centrifugation Lab Report FinalDocument6 pagesCHE34 Centrifugation Lab Report FinalChristy Joy RetanalNo ratings yet

- MoldovaDocument13 pagesMoldovaCroitoruDanaNo ratings yet

- STAT1012 Ch4 Continuous Probability DistributionDocument53 pagesSTAT1012 Ch4 Continuous Probability Distributionmakabigail7No ratings yet

- B.Tech (ME) 7th SemDocument16 pagesB.Tech (ME) 7th SemPravind JrNo ratings yet

- HYDROPOWER MCQsDocument9 pagesHYDROPOWER MCQsAlexis MUHIRWANo ratings yet

- Study Design IDocument28 pagesStudy Design IKareem DarwishNo ratings yet

- METHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFDocument5 pagesMETHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFCarlos ImmanuelNo ratings yet

- X-Ray For BoneDocument2 pagesX-Ray For BoneLILISNo ratings yet

05-12 (HTH600 Cylinders)

05-12 (HTH600 Cylinders)

Uploaded by

muriloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05-12 (HTH600 Cylinders)

05-12 (HTH600 Cylinders)

Uploaded by

muriloCopyright:

Available Formats

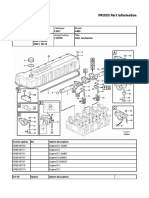

Parts & Service Bulletin

MODEL: HTH600 Series Harvesters Bulletin No. 05/12

AFFECTS: Hydraulic April, 2005

ACTION: For your information

FACTORY: Waratah New Zealand Limited

TITLE: NEW CYLINDERS

Units Involved: HTH616 Harvester Serial number 228144 onward

HTH620 Harvester Serial number 231682 onward

HTH622 Harvester Serial number 232286 onward

HTH622B Harvester Serial number 622368 onward

HTH624 Harvester Serial number 233358 onward

HTH626 Harvester Serial number 234135 onward

SITUATION: Waratah has a new supplier of hydraulic cylinders.

SOLUTION: The new cylinders are interchangeable with existing cylinders. No new plumbing is required as

port thread diameters are the same as existing cylinders.

NOTE: Internal components of the cylinders are not interchangeable with existing cylinders. When

replacing a complete cylinder, please advise customer that a different seal kit is used.

Original equipment cylinders and parts for are available at WPI.

COMMENT: The following documents are attached for reference:

Cylinder conversion list

Cylinder compenent list

Service manual extract - Cylinder Piston Replacement Up To, and Including 3" Cylinders.

Service manual extract - Cylinder Piston Replacement 4" Cylinders and Over.

Cylinder conversion list:

Harvester Old Cylinder New Cylinder

616 delimb WA102011 WA109017

drive WA103608 WA109019

harvester WA103393 WA109018

main saw F350531 WA109012

measuring WA101976 WA109015

top saw F350528 WA109010

620 231 delimb F350536 WA109022

drive F350538 WA109023

harvester F350540 WA109025

main saw WA105266 WA109016

measuring F350533 WA109014

top saw F350528 WA109010

622 232 delimb F350536 WA109022

drive F350541 WA109026

harvester F350540 WA109025

main saw WA105266 WA109016

measuring F350533 WA109014

top saw F350528 WA109010

622B 622 delimb F350536 WA109022

drive F350538 WA109023

harvester WA106411 WA109027

main saw F350531 WA109012

measuring F350533 WA109014

top saw F350528 WA109010

624 233 delimb F350535 WA109021

drive F350534 WA109020

harvester F350539 WA109024

main saw F350530 WA109011

measuring F350532 WA109013

top saw F350528 WA109010

626 234 delimb F350542 WA109028

drive F350543 WA109029

harvester F350544 WA109030

main saw F350530 WA109011

measuring F350532 WA109013

top saw F350530 WA109011

Cylinder component list:

Cylinder Size Barrel Piston Gland Rod Seal Kit

WA109010 1 1/2" WA109154 WA109175 WA109205 WA109210 WA109031

WA109011 WA109155 WA109211

WA109012 WA109156 WA109212

WA109013 WA109157 WA109213

2" WA109176 WA109206 WA109032

WA109014 WA109158 WA109214

WA109015 WA109159 WA109215

WA109016 WA109160 WA109216

WA109017 WA109161 WA109217

WA109018 2 1/2" WA109162 WA109177 WA109207 WA109218 WA109033

WA109019 WA109162 WA109219

WA109020 WA109164 WA109220

WA109021 WA109165 WA109221

WA109022 WA109166 WA109222

WA109023 WA109167 WA109223

WA109024 3" WA109168 WA109178 WA109208 WA109224 WA109034

WA109025 WA109169 WA109225

WA109026 WA109170 WA109226

WA109027 WA109171 WA109227

WA109028 WA109172 WA109228

WA109029 4" WA109173 WA109179 WA109209 WA109229 WA109035

WA109030 WA109174 WA109230

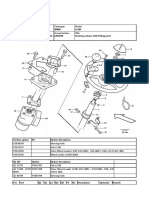

Cylinder Piston Replacement

Up To, and Including 3" Cylinders

Cleanliness

Bore Diameter is critical,Less

washThan

all parts4"

and ensure all

traces of solvent are removed. Check seals, rod and

bore of tubeisforcritical,

Cleanliness damage wash all parts and ensure all

3 traces of solvent are removed. Check seals, rod and

It is essential

bore thatdamage

of tube for the piston to rod connection is

correctly tightened during assembly, or the cylinder

will fail.

It is essential that the piston to rod connection is

correctly tightened during assembly, or the cylinder

2 •will fail.

Thoroughly clean and dry all parts.

•• Clamp

Thoroughly rod inclean

a solid

andvice

dryby allthe pin eye on

parts.

the end using soft jaws and place a stand

• under

Clampthe rodshaft

in a near

solidthe

vicepiston

by theend.

pin eye on

the end using soft jaws and place a stand

Note. Do notthe

under undershaftany circumstances

near the piston end. clamp or

grip any tool on the chrome plated area of the rod

as thisDo

Note. willnotinstantly

under any destroy the rod by clamp

circumstances damagingor

1

the

gripchrome

any toolplate.

on the chrome plated area of the rod

as this will instantly destroy the rod by damaging

•the chrome

Fit gland

plate.(1) on to shaft. Lightly coat all

surfaces with oil.

• Fit gland (1) on to shaft. Lightly coat all

• Position

surfaces piston

with oil. (2) on rod. Lightly oil socket

head cap screw (3) and initially torque to

• 25Nm

Position (4)piston

to obtain therod.

(2) on starting

Lightlypoint

oilfor

socket

"torque

head capbyscrew angle"(3) and initially torque to

25Nm (4) to obtain the starting point for

• Mark

"torque thebyrod (5) with a maker pen (reference

angle"

point for hex key) and tighten the socket

• head

Markcap the screw

rod (5)a with

further 60° from

a maker pen this mark.

(reference

This

pointmay require

for hex key)aand

1.4m long extension

tighten the socket

head cap

handle onscrew a further

the larger 60° from this mark.

size cylinders.

4 This may require a 1.4m long extension

• Tighten

handle on gland bolts in

the larger crisscross

size cylinders.pattern

Torque 8 bolts (M8) to 39 Nm or

Torque

Note. The socket8 bolts

head(M10) to 76must

cap screw Nm be replaced

Do not

every time theover

piston tighten.

is removed

Note. Piston will head

The socket need tocapbescrew

removed

musttobechange

replaced

gland seals.the

every time The glandis and

piston tube contacting

removed

surfaces should be lightly oiled too.

Note. Piston will need to be removed to change

5 gland seals. The gland and tube contacting

surfaces should be lightly oiled too.

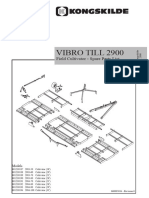

Cylinder Piston Replacement

Cylinder

4" Cylinders

Piston

andReplacement

over

Cleanliness

Bore Diameter is critical,Less

washThan

all parts4"

and ensure all

traces of solvent are removed. Check seals, rod and

bore of tubeisforcritical,

Cleanliness damage wash all parts and ensure all

traces of solvent are removed. Check seals, rod and

It is essential

bore thatdamage

of tube for the piston to rod connection is

correctly tightened during assembly, or the cylinder

will fail.

It is essential that the piston to rod connection is

correctly tightened during assembly, or the cylinder

•will fail.

Thoroughly clean and dry all parts.

•• Clamp

Thoroughlyrod inclean

a solid

andvice

drybyallthe pin eye on

parts.

the end using soft jaws and place a stand

• under

Clampthe rodshaft

in a near

solidthe

vicepiston

by theend.

pin eye on

the end using soft jaws and place a stand

Note. Do notthe

under under any

shaft circumstances

near the piston end. clamp or

grip any tool on the chrome plated area of the rod

2 as thisDo

Note. willnot

instantly

under anydestroy the rod by clamp

circumstances damaging or

the

gripchrome

any toolplate.

on the chrome plated area of the rod

as this will instantly destroy the rod by damaging

•the chrome

Fit gland (1) on to shaft. Lightly coat all

plate.

1 surfaces with oil.

• Fit gland (1) on to shaft. Lightly coat all

Note. Wrap

surfacestapewith

around

oil. the rod thread to avoid

damaging gland seals.

• Position piston (2) on rod. Lightly oil socket

• Position

head cappiston

screw (2)

(3) on

androd. and turn

initially untilto

torque

hand tight.

25Nm (4) to obtain the starting point for

"torque by angle"

• Tighten piston to 800 to 1000 Nm.

• This

Markwill the require: tool aWA109965

rod (5) with maker pen (3),

(reference

6point

boltsfor

M10 x 30 (4), and

hex key) and tighten an extension

the socket

handle

head cap 1.4m long.

screw a further 60° from this mark.

This may require a 1.4m long extension

• Tighten gland bolts in crisscross pattern

handle on the larger size cylinders.

Torque 14 bolts (M8) to 39 Nm or

Torque

Note. The 14 head

socket bolts cap

(M10) to 76

screw Nmbe replaced

must

Do not over tighten.

every time the piston is removed

4

Note. Piston

Note. The piston

will lock

needring

to bemust be replaced

removed every

to change

3 time the

gland piston

seals. Theisgland

removed.

and tube contacting

surfaces should be lightly oiled too.

Note. Piston will need to be removed to change

gland seals. The gland and tube contacting

surfaces should be lightly oiled too.

You might also like

- 4w105 sPARE PARTS CATALOGUEDocument63 pages4w105 sPARE PARTS CATALOGUEsxturbo100% (3)

- Manual de Partes Ç 890.2Document523 pagesManual de Partes Ç 890.2luis melloNo ratings yet

- Physics1100 Lab Manual (Iolab Revision)Document105 pagesPhysics1100 Lab Manual (Iolab Revision)Tri NguyenNo ratings yet

- LOG-001-T-01 WORKSHOP 2021-04-14 MANUAL REQUISITION HYD21WR 0232 - 0234Document381 pagesLOG-001-T-01 WORKSHOP 2021-04-14 MANUAL REQUISITION HYD21WR 0232 - 0234Ernest Ngosa SawasawaNo ratings yet

- Zifeng Tower - Ramazan SariDocument2 pagesZifeng Tower - Ramazan SariNadya Pricilia100% (1)

- SCADAPack 334 Hardware ManualDocument165 pagesSCADAPack 334 Hardware ManualFeri HandoyoNo ratings yet

- Knowing God Study Guide - Section TwoDocument56 pagesKnowing God Study Guide - Section Twomercab15100% (2)

- Spare Parts List VM 80Document16 pagesSpare Parts List VM 80Wilson Orlando Salinas SalinasNo ratings yet

- 30 1347 06-43RotatorftSupportDocument2 pages30 1347 06-43RotatorftSupportmuriloNo ratings yet

- Resumes Umber DanaDocument18 pagesResumes Umber DanaAhmad Agit PatriantoNo ratings yet

- Motor 3114: 4 7e5213 JG AneisDocument50 pagesMotor 3114: 4 7e5213 JG AneisJoice CostaNo ratings yet

- STOPE MATE - S36 Cross Over List GOOD ONEDocument12 pagesSTOPE MATE - S36 Cross Over List GOOD ONEFelipe BernalNo ratings yet

- PROSIS Part InformationDocument4 pagesPROSIS Part InformationElie AbisaadNo ratings yet

- Qy55v532.2201541 (1) (1) - 3 PDFDocument30 pagesQy55v532.2201541 (1) (1) - 3 PDFismaelNo ratings yet

- 09 Unit, DiggingDocument27 pages09 Unit, DiggingUbeimar RiveraNo ratings yet

- CT65 Parts ListDocument26 pagesCT65 Parts ListJayakrishnaNo ratings yet

- PROSIS Part InformationDocument2 pagesPROSIS Part InformationElie AbisaadNo ratings yet

- BW332 12.13 101583441003 101583449999 EngineDocument10 pagesBW332 12.13 101583441003 101583449999 Engineeshopmanual TigaNo ratings yet

- E110a - Cylinder BlockDocument6 pagesE110a - Cylinder BlockbennieNo ratings yet

- 【4】RT35-1 Hydraulic schematic diagramDocument25 pages【4】RT35-1 Hydraulic schematic diagramym0224382856No ratings yet

- Materiale Excess ObsDocument452 pagesMateriale Excess ObsLuchian MarinelaNo ratings yet

- Concrete Mixture: Cement Silo With Pneumatic Conveying SysDocument6 pagesConcrete Mixture: Cement Silo With Pneumatic Conveying Sysamal dasNo ratings yet

- VK2 December 2023 + PDVDocument1,916 pagesVK2 December 2023 + PDVSara FusekNo ratings yet

- 54.01 101490900101 101490900144 Operator's PlatformDocument6 pages54.01 101490900101 101490900144 Operator's PlatformMbahdiro KolenxNo ratings yet

- 61.01 101490900101 101490900144 Roller Drum PDFDocument3 pages61.01 101490900101 101490900144 Roller Drum PDFMbahdiro KolenxNo ratings yet

- 12.41 101870341001 101870349999 Radiator SystemDocument5 pages12.41 101870341001 101870349999 Radiator Systemeshopmanual EnamNo ratings yet

- 53.01 101490900101 101490900144 Engine HoodDocument3 pages53.01 101490900101 101490900144 Engine HoodMbahdiro KolenxNo ratings yet

- 15-Drawing and Part List-01Document8 pages15-Drawing and Part List-01Grisha Mari KosoyanNo ratings yet

- 245Document2 pages245Elie AbisaadNo ratings yet

- PROSIS Part Information: Date: Image Id: Catalogue: ModelDocument2 pagesPROSIS Part Information: Date: Image Id: Catalogue: ModelAMIT SINGHNo ratings yet

- LD LDEP ManualDocument12 pagesLD LDEP ManualJoaquin RomeroNo ratings yet

- U441d - Brake - Rear (Air)Document6 pagesU441d - Brake - Rear (Air)bennieNo ratings yet

- RF Spare Part ListDocument3 pagesRF Spare Part ListVignesh NagarajanNo ratings yet

- General Filters and 407,709 & Taurus FiltersDocument7 pagesGeneral Filters and 407,709 & Taurus Filterspuneet.joshi7No ratings yet

- 1621 9386 00Document2 pages1621 9386 00Godel KHolikNo ratings yet

- Catalogo 4S Torito 2016Document27 pagesCatalogo 4S Torito 2016Inversiones RinocellNo ratings yet

- 10 Mechanical Equipment, Attachment PDFDocument8 pages10 Mechanical Equipment, Attachment PDFPeter BrickNo ratings yet

- Parts List: Model 541Document15 pagesParts List: Model 541AstraluxNo ratings yet

- Howo WD615 Euro II Part IDocument25 pagesHowo WD615 Euro II Part IYo Yo LiNo ratings yet

- Bom Cai835153Document19 pagesBom Cai835153Yuvraj BappiNo ratings yet

- 248Document2 pages248Elie AbisaadNo ratings yet

- 8000-4 Parts ListDocument19 pages8000-4 Parts ListAstraluxNo ratings yet

- Valmet 645 DSBILDocument58 pagesValmet 645 DSBILAlexey petrovichNo ratings yet

- 06 Steering PDFDocument42 pages06 Steering PDFPeter BrickNo ratings yet

- My Hino - Co.idDocument491 pagesMy Hino - Co.idAman Ichwan100% (1)

- EDL Bolt CatalogueDocument50 pagesEDL Bolt CatalogueCY LiuNo ratings yet

- 61.01 101582431002 101582431052 Roller DrumDocument5 pages61.01 101582431002 101582431052 Roller DrumNidya Wardah JuhanaNo ratings yet

- 132kV ND BOM (1.3 MTR BASE)Document24 pages132kV ND BOM (1.3 MTR BASE)ramudureddyNo ratings yet

- TECALEMIT Rubber-hoses-Tecalemit-FlexiblesDocument1 pageTECALEMIT Rubber-hoses-Tecalemit-FlexiblesAlexNo ratings yet

- Bom Cno201763Document20 pagesBom Cno201763Yuvraj BappiNo ratings yet

- Catalogo de Metales Cigueñal-Biela PDFDocument43 pagesCatalogo de Metales Cigueñal-Biela PDFAlex Xavier Malasquez LeónNo ratings yet

- Air Intake and Exhaust System 13-20-2 (Hino Engine Type J08etm-Ksda)Document4 pagesAir Intake and Exhaust System 13-20-2 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNo ratings yet

- HOT Manual Slips enDocument6 pagesHOT Manual Slips enMarcialgonzalezpNo ratings yet

- Model V45 Manual Assembly DisassemblyDocument51 pagesModel V45 Manual Assembly Disassemblyysabel martinezNo ratings yet

- Bom Cno169727Document15 pagesBom Cno169727Yuvraj BappiNo ratings yet

- UtilityDocument3 pagesUtilitymizquiNo ratings yet

- 06 Steering PDFDocument33 pages06 Steering PDFDaniel NavasNo ratings yet

- 2900SF SPL 660005034 Rev6Document34 pages2900SF SPL 660005034 Rev6Иван Сергеевич ЛатошаNo ratings yet

- Volunteer Inventory Collection Detailed Report - 2 30 PM @16.04.2024Document28 pagesVolunteer Inventory Collection Detailed Report - 2 30 PM @16.04.2024ranimomminaNo ratings yet

- Sinotruck Parts To Be OrderdDocument16 pagesSinotruck Parts To Be OrderdTavongasheMaddTMagwati100% (1)

- Halliburton Otis B Positioning (Shifting) Tool: Slickline Services Mechanical InterventionDocument2 pagesHalliburton Otis B Positioning (Shifting) Tool: Slickline Services Mechanical InterventionBsd CityNo ratings yet

- troubleshooting TJ3000Document44 pagestroubleshooting TJ3000muriloNo ratings yet

- Service Manual TJ430Document256 pagesService Manual TJ430muriloNo ratings yet

- Manual serv transm LOK96ebDocument29 pagesManual serv transm LOK96ebmuriloNo ratings yet

- HTH616 PartsManual F350810Document196 pagesHTH616 PartsManual F350810muriloNo ratings yet

- HTH620 MasterDocument482 pagesHTH620 MastermuriloNo ratings yet

- HTH620 Parts ManualDocument174 pagesHTH620 Parts ManualmuriloNo ratings yet

- 30.513.04_11HTH measuring arm modificationDocument1 page30.513.04_11HTH measuring arm modificationmuriloNo ratings yet

- HTH600 relief valve PVG32Document3 pagesHTH600 relief valve PVG32muriloNo ratings yet

- 30.517.04_13 waratah reliefsDocument2 pages30.517.04_13 waratah reliefsmuriloNo ratings yet

- 30 1347 06-43RotatorftSupportDocument2 pages30 1347 06-43RotatorftSupportmuriloNo ratings yet

- Lockup Torque Converter OperationDocument2 pagesLockup Torque Converter OperationmuriloNo ratings yet

- 5195 Training Presentation REV 1.0Document150 pages5195 Training Presentation REV 1.0muriloNo ratings yet

- 38486AENG OPERATOR AND SERVICE MANUAL BAR SAW FELLING HEAD 51950101 - 51950500Document190 pages38486AENG OPERATOR AND SERVICE MANUAL BAR SAW FELLING HEAD 51950101 - 51950500muriloNo ratings yet

- 30 1291 06-27H480FeedRollerDocument1 page30 1291 06-27H480FeedRollermuriloNo ratings yet

- MANUAL DO OPERADOR - 85503001 TO 85503500Document326 pagesMANUAL DO OPERADOR - 85503001 TO 85503500muriloNo ratings yet

- MAX14871 4.5V To 36V Full-Bridge DC Motor Driver: General Description Benefits and FeaturesDocument15 pagesMAX14871 4.5V To 36V Full-Bridge DC Motor Driver: General Description Benefits and FeaturesUdit AgrawalNo ratings yet

- Ex No: 1 DateDocument4 pagesEx No: 1 DateVignesh AadhiNo ratings yet

- CAT-5002 MRP-NPB6AS Remote Power SupplyDocument2 pagesCAT-5002 MRP-NPB6AS Remote Power SupplyEddi Pelaez SalinasNo ratings yet

- A Meta Model of ChangeDocument25 pagesA Meta Model of Changeraminabk100% (1)

- Stress in Soil MassDocument14 pagesStress in Soil MassJanith ChamilkaNo ratings yet

- Behavior and Design of Double Tees With Web OpeningsDocument17 pagesBehavior and Design of Double Tees With Web Openingsunix0123100% (1)

- Comparative Evaluation of Antibacterial Efficacy.9Document6 pagesComparative Evaluation of Antibacterial Efficacy.9Shivani DubeyNo ratings yet

- Cementing BasicsDocument79 pagesCementing BasicsAngel PadillaNo ratings yet

- Inta Commercial Collection April 2011Document59 pagesInta Commercial Collection April 2011Robin FisherNo ratings yet

- Ts 23 Hardox600workshop Uk 02-4Document1 pageTs 23 Hardox600workshop Uk 02-40005No ratings yet

- Miniature Bioreactors Current Practices and Future Opportunities PDFDocument14 pagesMiniature Bioreactors Current Practices and Future Opportunities PDFLuisNo ratings yet

- Global Technical Campus: Global Institute of Technology Global College of TechnologyDocument19 pagesGlobal Technical Campus: Global Institute of Technology Global College of TechnologyGlobal Technical Campus, JaipurNo ratings yet

- Note EjiogbeDocument13 pagesNote EjiogbeIfadayo Alabi50% (2)

- 3254 IEC ACCC Spec Sheets HelsinkiDocument1 page3254 IEC ACCC Spec Sheets HelsinkiRicardo Hernandez MoralesNo ratings yet

- 2021-22 B.E Mechanical EngineeringDocument84 pages2021-22 B.E Mechanical EngineeringTejas Galu PatilNo ratings yet

- NilkamalDocument31 pagesNilkamalAshwin GkNo ratings yet

- MA1101R Chapter1Document54 pagesMA1101R Chapter1le trung hieuNo ratings yet

- CHE34 Centrifugation Lab Report FinalDocument6 pagesCHE34 Centrifugation Lab Report FinalChristy Joy RetanalNo ratings yet

- MoldovaDocument13 pagesMoldovaCroitoruDanaNo ratings yet

- STAT1012 Ch4 Continuous Probability DistributionDocument53 pagesSTAT1012 Ch4 Continuous Probability Distributionmakabigail7No ratings yet

- B.Tech (ME) 7th SemDocument16 pagesB.Tech (ME) 7th SemPravind JrNo ratings yet

- HYDROPOWER MCQsDocument9 pagesHYDROPOWER MCQsAlexis MUHIRWANo ratings yet

- Study Design IDocument28 pagesStudy Design IKareem DarwishNo ratings yet

- METHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFDocument5 pagesMETHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFCarlos ImmanuelNo ratings yet

- X-Ray For BoneDocument2 pagesX-Ray For BoneLILISNo ratings yet