Professional Documents

Culture Documents

Caterpillarя┐╜ AP-655C and Barber Greeneя┐╜ BG-2255C Asphalt Paver Hydraulic System 245-0849

Caterpillarя┐╜ AP-655C and Barber Greeneя┐╜ BG-2255C Asphalt Paver Hydraulic System 245-0849

Uploaded by

Kelvin CarrionCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caterpillarя┐╜ AP-655C and Barber Greeneя┐╜ BG-2255C Asphalt Paver Hydraulic System 245-0849

Caterpillarя┐╜ AP-655C and Barber Greeneя┐╜ BG-2255C Asphalt Paver Hydraulic System 245-0849

Uploaded by

Kelvin CarrionCopyright:

Available Formats

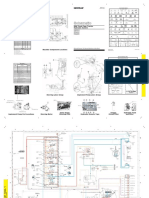

Component Locations

FLUID POWER SYMBOLS

Part Schematic

Item Description

Number Location

AUXILIARY BANK VALVE KENR5024-02 BASIC COMPONENT SYMBOLS

1 Pump Gp - (Propel) 190-6480 Sheet 2 January 2009

2 Motor Gp - (Propel) 190-6479 Sheet 2

MAIN AUX.

PUMP: VARIABLE and

3 Filter Gp - (Propel Charge) 196-7614 Sheet 2 AUGER/RAISE PUMP or MOTOR FLUID CONDITIONER SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION 2-SECTION PUMP PRESSURE COMPENSATED

4 Pump Gp - (Material Feed) 199-5718 Sheet 3&4 (FIXED)

5 Motor Gp - (Conveyor) 190-8787 Sheet 3&4

6 Motor Gp - (Auger) 190-8789 Sheet 3&4

7 Filter Gp - (Auger/Conveyor Charge) 192-0717 Sheet 3 VARIABILITY SPRING LINE RESTRICTION PRESSURE HYDRAULIC PNEUMATIC LINE RESTRICTION ATTACHMENT

(ADJUSTABLE) (VARIABLE) COMPENSATION ENERGY TRIANGLES VARIABLE and PRESSURE

8 Valve Gp - (Vibratory) 190-8803 Sheet 5 COMPENSATED

9 Filter Gp - (Vibratory) 196-7615 Sheet 5 AUGER/LOWER VALVES

10 Pump Gp - (N.A. Auxiliary) 190-8790 Sheet 6 VALVE ENVELOPES VALVE PORTS

11 Valve Gp - (Auxiliary) 228-4076 Sheet 6 MAINFRAME SCREED LIFT

12 Valve Gp - (Brake) 193-8539 Sheet 6

13 Manifold Gp - (Screed) 169-0166 Sheet 6 TWO POSITION TWO-WAY FOUR-WAY

ONE POSITION THREE POSITION THREE-WAY

14 Valve Gp - (Oil Cooler) 228-4077 Sheet 1 FLOW CONTROL VALVE

15 Manifold - (Return) 107-0003 Sheet 6 for VENTILATION MOTOR CONTROL VALVES CHECK VALVES

16 Valve Gp - (Accumulator Charging) 215-3511 Sheet 6 AB

AB

17 Accumulator As 209-2659 Sheet 6 RIGHT PROPEL MOTOR

18 Cylinder Gp - (Hopper Hoist) 135-0220 Sheet 6

CHECK VALVE PLANETARY SHIFT P T P T

19 Cylinder Gp - (Screed Hoist) 216-0185 Sheet 6 BASIC SPRING SHUTTLE PILOT

PRESSURE REDUCER NORMAL POSITION SHIFTED POSITION INFINITE POSITION

SYMBOL LOADED CONTROLLED

20 Cylinder Gp - (Auger Hoist-Right) 194-7259 Sheet 6

21 Cylinder Gp - (Auger Hoist-Left) 194-7260 Sheet 6 LEFT PROPEL CHARGE FILTER MEASUREMENT ROTATING SHAFTS

HOPPER/RAISE

22 Valve Gp - Test (Screed) 203-8517 Sheet 6 BB PLANETARY SHIFT

23 Valve Gp - Counterbalance (Towpoint) 195-2880 Sheet 6 SCREED FLOAT

24 Cylinder Gp - (N.A. Towpoint) 195-2884 Sheet 6 RIGHT PROPEL PUMP

HOPPER/LOWER

25 Pump Gp - (Fan) 254-7016 Sheet 5

PARKING BRAKE

PRESSURE TEMPERATURE FLOW UNIDIRECTIONAL BIDIRECTIONAL

RIGHT PROPEL

26 Motor Gp - (Fan) 190-8799 Sheet 5

CHARGE FILTER

27 Valve Gp - (Fan) 190-8800 Sheet 5

COOLER FLUID STORAGE RESERVOIRS

28 Reservoir As - Hydraulic (Tank) 192-6422 Sheet 1 MANIFOLD

29 Filter Gp - (Tank) 176-9415 Sheet 1 AA

30

31

Strainer - Suction (Tank)

Pump Gp - (Generator)

1G-7663

241-8646

Sheet 1

Sheet 7 Caterpillar® AP-655C and VENTED PRESSURIZED RETURN ABOVE FLUID LEVEL RETURN BELOW FLUID LEVEL

32 Valve Gp - (Generator) 227-5105 Sheet 7

33

34

Motor Gp - (Fumes)

Cylinder Gp - (Truck Hitch)

216-4936

166-7676

Sheet 6

Sheet 6

SUCTION LINE

FROM HYD TANK

PORT 2

PUMP DRIVE

(RIGHT MOUNT)

Barber Greene® BG-2255C COMBINATION CONTROLS

SUCTION LINE

Asphalt Paver

35 Valve Gp - (Truck Hitch) 230-9160 Sheet 6

FROM HYD TANK

36 Pump Gp - (Tamper) 190-8792 Sheet 5 PORT 8 PROPEL SOLENOID SOLENOID SOLENOID SOLENOID and SERVO THERMAL DETENT

37 Radiator Gp - (Oil Cooler) 222-2617 Sheet 1

PUMP or MANUAL and PILOT PILOT or MANUAL

38

39

40

Pump Gp - (European Auxiliary)

Cylinder Gp - (European Towpoint)

Cylinder Gp - (Track Tensioner)

198-3023

195-2883

209-0513

Sheet 6

Sheet 6

Sheet 6 UPP

Hydraulic System MANUAL CONTROL SYMBOLS

ER

41 Motor Gp - (Generator) 227-5104 Sheet 7 PUM

P ST

42 Filter Gp - (Tamper) 196-7614 Sheet 5 ACK AP-655C: BG-2255C:

PUSH-PULL LEVER MANUAL SHUTOFF GENERAL MANUAL PUSH BUTTON PEDAL SPRING

CDG1-UP CKR1-UP

Tap Locations PILOT CONTROL SYMBOLS

AYP1-UP RELEASED PRESSURE REMOTE SUPPLY PRESSURE

Pressure, Sampling, and Sensor

Tap Schematic

Description

Number Location

EXTERNAL RETURN INTERNAL RETURN SIMPLIFIED COMPLETE INTERNAL

SUPPLY PRESSURE

AA Left Charge Filter Pressure Sheet 2 TO LEFT

PROPEL MOTOR

BB Right Charge Filter Pressure Sheet 2 ACCUMULATORS CROSSING AND JOINING LINES HYDRAULIC AND PNEUMATIC CYLINDERS

CC Propulsion Circuit (Forward Side) Sheet 2

DD Propulsion Circuit (Reverse Side) Sheet 2

EE Oil Cooler Inlet Pressure Sheet 1 SPRING LOADED GAS CHARGED LINES CROSSING LINES JOINING SINGLE ACTING DOUBLE ACTING

FF Generator Pump Pressure Sheet 7 LEFT PROPEL PUMP D PUMP DRIVE

GG Generator Manifold Signal Pressure Sheet 7 FW (LOWER MOUNT) CHARGE PUMP

HYDRAULIC PUMPS HYDRAULIC MOTORS INTERNAL PASSAGEWAYS

HH S.O.S. Tap Sheet 3 PISTON PUMP

JJ Material Feed Charge Filter Pressure Sheet 3 (LEFT DRAG CONVEYOR) FIXED VARIABLE DISPLACEMENT FIXED VARIABLE DISPLACEMENT INFINITE THREE TWO

DISPLACEMENT NON-COMPENSATED DISPLACEMENT NON-COMPENSATED POSITIONING POSITION

KK Left Conveyor Motor Pressure Sheet 3 POSITION

PROPEL PUMP

LL Right Auger Motor Pressure Sheet 3 UNIDIRECTIONAL UNIDIRECTIONAL

MM Right Conveyor Motor Pressure Sheet 4 PISTON PUMP

NN Left Auger Motor Pressure Sheet 4 (RIGHT DRAG CONVEYOR) FLOW IN ONE PARALLEL CROSS FLOW ALLOWED IN

BIDIRECTIONAL BIDIRECTIONAL DIRECTION FLOW FLOW EITHER DIRECTION

PP Left Track Tension Pressure Sheet 6

QQ Right Track Tension Pressure Sheet 6

LO

RR Auxiliary Manifold Shift Pressure Sheet 6 WE

RP

SS Brake Release Pressure Sheet 6 UM

PS

TT Truck Hitch Pressure Sheet 6 TAC

K

UU Vibratory System Pressure Sheet 5 © 2009 Caterpillar Printed in U.S.A.

VV Fan Motor Inlet Pressure Sheet 5 All Rights Reserved

AA

39 24 16 17 14 8

27

37 26 Electrical Symbols Table

19

16

BB Hydraulic Symbols (Electrical)

23

20

QQ PP

G M

18 33 14

3 Transducer Transducer Generator Electric Motor

6 (Fluid) (Gas / Air)

(Dimensions: 39 inches x 28 inches)

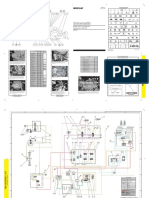

The left charge filter (3) and right charge filter (3) The oil cooler manifold (14) is located behind the The right track tension manifold (16) is mounted to the

25

32 are located in front of the hydraulic tank. The base of engine,under the center console. The ports of the oil floor of the engine compartment, on the right side of

34 15 each filter contains a pressure tap (AA & BB). cooler manifold are marked for identification. The B-port machine. The left track tension manifold (16) is in the

KENR5024-02

ON FRONT OF

TRACTOR FRAME of the manifold is equipped with a pressure tap (EE). same relative position on the left side of the machine. Electrical Wire

Pressure Switch Pressure Switch Temperature Switch

Right track tension pressure can be tested at the (Adjustable)

41 pressure tap (QQ). Left track tension pressure can be

35

tested at the pressure tap (PP).

15 32

Electrical Symbols (Electrical)

6

17

18 11 T

6

16 Pressure Temperature Level Flow

Symbol Symbol Symbol Symbol

21

RR

Wire Number Identification Codes

The generator control manifold (32) is located to the LL NN

left of the cooling package. The center console must be Electrical Schematic Example Hydraulic Schematic Example

tilted to gain access to this compartment. Inlet pressure The left auger motor (6) is are mounted to the rear

13 19 from the generator pump can be measured at the of the tractor. The pressure in the forward circuit of Current Standard Current Standard

23 3 9 12 11 pressure tap (FF) at the TP port, and signal pressure the left auger can be measured at the pressure tap (NN). The auxiliary manifold (11) is located on the left side Harness identification code

24 39 29 22

can be measured at the pressure tap (GG) at the TA port. The right auger motor (6) is identical to the left motor machine, behind the hydraulic tank. The shift pressure This example indicates

30 Page,

3 7 wire 135 in harness "AG". Wire

and is mounted to the rear of the tractor. The pressure can be tested at the pressure tap (RR) in the G-port of Circuit Number Wire Color

tap (LL) in the right auger motor is identical to the left Identification

the auxiliary manifold.

pressure tap (NN). 325-AG135 PK-14

Vibratory Control Valve

325-PK

Circuit Identification Wire Color Wire Gauge

Number

11 27 HH

22 13 JJ 12 Previous Standard

SS

Wire Color

Wire

12

325-PK-14

7

7 B A

19 UU

23 Circuit Number Wire Gauge

3 Identification (EXAMPLE VALVE)

NORHTH AMERICAN VERSION

MOUNTS TO

The base of the material charge filter (7) contains a

DRIVE BOX

SOS tap (HH) and a pressure tap (JJ).

EUROPEAN VERSION 10 31 The brake release manifold (12) is mounted to the The vibratory control valve is mounted on the left side

MOUNTS TO

DRIVE BOX

rear of the hydraulic tank, on the left side of the machine. of the screed. The pressure in the vibratory system

36 38 31 The brake release pressure can be tested at the pressure can be tested at the pressure tap (UU) in the G-port of

20 21 AP-655C PROPULSION PUMPS

tap (SS) in the B-port of the brake release manifold. the auxiliary manifold.

FORWARD EDC

14 L1-PORT REVERSE EDC

CHARGE RELIEF VALVE

FORWARD MULTIFUNCTION VALVE CC

M1-PORT (FORWARD PRESSURE)

B-PORT

32 6 TO/FROM CHARGE FILTER

18 S-PORT

REVERSE MULTIFUNCTION VALVE

KK MM 35 27 M2-PORT (REVERSE PRESSURE) RIGHT

PUMP

5 A-PORT A-PORT

39 24 VV S-PORT

REVERSE MULTIFUNCTION VALVE

B-PORT

DD LEFT

PUMP

FORWARD MULTIFUNCTION VALVE

34 The left conveyor motor (5) is located between the

hydraulic tank and the rear bulkhead. Pressure in the FORWARD EDC REVERSE EDC

left conveyor hydrostatic loop can be measured at the

pressure tap (KK). The right conveyor motor (5) is Pressure in the forward side of the propulsion circuits can be

15

30 5 The truck hitch manifold (35) is mounted to the bottom The cooling fan manifold (27) is located on the right side measured at the pressure tap (CC) in the M1-port, and pressure

8 2 identical to the left motor and is located on the right of the machine. The fan motor inlet pressure can be

1 4

33

of the front engine mounting bracket.Hitch supply in the reverse side of the propulsion circuits can be measured

28 side of the machine. Pressure in the right conveyor tested at the pressure tap (VV) which is located in the

16 17 pressure can be tested at the pressure tap (TT) which at the pressure tap (DD) in the M2-port.

hydrostatic loop can be measured at the pressure P-port of the cooling fan manifold.

MOUNTS TO is located in the G-port of the truck hitch manifold.

DRIVE BOX tap (MM).

TO HYD TANK IN TANK RETURN

FILTER, SEE SHEET 1

FROM FAN MOTOR RETURN,

SEE SHEET 5

27

FROM MATERIAL FEED

FROM HYD TANK PORT 6

SEE SHEET 1

39 VV

P CHARGE FILTER SEE SHEET 3

T

L1 S 24 34 TRUCK HITCH 25

LEFT GRADE CONTROL RIGHT GRADE CONTROL

OPTIONAL SYSTEM

M4 23 FROM HYD TANK

PORT 1

SEE SHEET 1

C2 C1 C2 C1

FROM GENERATOR PUMP TT

CASE DRAIN, SEE SHEET 5

FAN PUMP

C G D 15 G C1 C2 R

M2 FAN PILOT

RETURN

L1 M1 A M6 C M1 L2 P

A B A B

A B CIRCUIT TO RETURN

A L2

FROM TAMPER PUMP

CASE DRAIN, SEE SHEET 5 MANIFOLD PORT G,

SEE SHEET 6

B L2

RETURN

MANIFOLD

P A

6

10 P T P T F H E 26

38

LEFT AUGER MOTOR

40 23 T L3

PP

16 PRESSURE MANIFOLD

A

D F RIGHT CONVEYOR PUMP LEFT AUGER PUMP VIBE PUMP

FROM GENERATOR MOTOR

RETURN, SEE SHEET 5 B

H G M4

35 TO AUXILIARY VALVE

DRAIN "T" SEE SHEET 6

A M1 M2 B

B B L1

LEFT TRACK TAKEUP E C M5 TO COOLER BYPASS

MANIFOLD PORT D

A C SEE SHEET 1

B

NN

PS

15 L.BRAKE 12 L2 S

PRESSURE R.BRAKE SS

17 SWITCH

HOPPER HOIST

B

RIGHT

N M4

20 21 RIGHT

LEFT L1 M5

FROM HYD TANK PORT 4

SEE SHEET 1

L2

LEFT UU TO RETURN MANIFOLD

QQ V2 V3 V7 V8 42 PORT B, SEE SHEET 6

40 AUGER HOIST

18 SCREED HOIST V9

D

B

5

GAUGE V4

19 V5

M3 S

FROM HYD TANK

PORT 5 SEE SHEET 1 RIGHT CONVEYOR MOTOR

B

RIGHT TRACK TAKEUP

L3

A C

33 REMOTE MOUNTED

E

PS

TO HYD TANK

SEE SHEET 1

RIGHT LEFT AUX T FROM HYD TANK

SEE SHEET 1

VIBRATOR CHARGE FILTER

M4

PRESSURE

16

TO HYD TANK

CIRCUIT TAMPER PUMP

M5

M2 B M6 M2 D A

SWITCH SEE SHEET 1

V1 V6

FUMES RR

17

MOTOR

L.SHIFT 22 TAMPER L1

R.SHIFT GAGE

TO COOLER BYPASS MANIFOLD

B A C1 C2 C3 C4 G D E

SCREED

8 FROM VIBE PUMP

SEE SHEET 4

CIRCUIT 4 MM

PORT A, SEE SHEET 1

COUNTERBALANCE IN

#4

VALVE GA

#3

M7 M8

#2

P CYL

9

OUT X1 X2 X1 X2

PRESSURE

36

#1 #5 #6 #7 #8 13

DRAIN

ALTERNATE

PRESSURE TO COOLER BYPASS

MANIFOLD PORT E

ALTERNATE SEE SHEET 1

TANK

TANK

LEFT

SCREED EXTENDERS RIGHT

11

SCREED CIRCUIT FAN / VIBRATOR / TAMPER CIRCUIT CONVEYOR / AUGER / VIBE LOWER PUMP STACK

FROM TAMPER MOTOR CASE

DRAIN, SEE SHEET 5

TO HYD TANK IN TANK RETURN

FILTER, SEE SHEET 1

TO COOLER BYPASS MANIFOLD

PORT C SEE SHEET 1

LEFT PROPEL PUMP RIGHT PROPEL PUMP 37

TO COOLER BYPASS

MANIFOLD PORT B

SEE SHEET 1

BRAKE BRAKE

14 L1

L2

L2 L1 FROM BRAKE HAND PUMP L2 FROM BRAKE

TO COOLER

BYPASS MANIFOLD

TO PORT M6 CHARGE INLET

ON CONVEYOR/AUGER/VIBE

PORT B, SEE SHEET 6

L1 HAND PUMP

PORT B,

OIL COOLER

HYD OIL

PORT H SEE SHEET 1 PUMP GP SEE SHEET 4

SEE SHEET 6 TC SOS PORT

FC

HH JJ

(Dimensions: 39 inches x 28 inches)

CHARGE

G PRESSURE PORT

2 SPARE

AUXILIARY AUXILIARY

2 COOLER

MANIFOLD

C

PORT A PORT B

MOTOR CASE

L PROPEL

AUGER/CONVEYOR 7

SEE SHEET 2 CHARGE FILTER

GEAR GEAR F TO COOLER BYPASS

M3 M3 SHIFT

KENR5024-02

SHIFT CASE DRAIN LEFT

MANIFOLD PORT H

SEE SHEET 1

PROPEL PUMP PORT A PORT B

FROM AUXILIARY VALVE FROM AUXILIARY

PORT D, SEE SHEET 6 VALVE PORT D,

SEE SHEET 6 E

SEE SHEET 2

41 GG

P

L1 M1 A M6 C M1 L2

M1 M2 M1 M2 FROM VIBE CIRCUIT

SEE SHEET 5 CASE DRAIN LEFT B L2

CONVEYOR MOTOR TA A B

LOOP FLUSHING LOOP FLUSHING SEE SHEET 3

B 6

B A A B CASE DRAIN LEFT

AUGER MOTOR

AUGER / CONVEYOR

D SEE SHEET 4

CHARGE PUMP

GENERATOR VALVE

CC DD

A RIGHT AUGER MOTOR L3

CASE DRAIN RIGHT

R PROPEL AUGER MOTOR

B A B A MOTOR CASE SEE SHEET 3

A

B SEE SHEET 2

EE LEFT CONVEYOR PUMP RIGHT AUGER PUMP

M1 M2 M1 M2 A

CASE DRAIN RIGHT

CONVEYOR MOTOR

32 M4

J H SEE SHEET 4

B

MATERIAL FEED

PUMPS CASE DRAIN A L1

SEE SHEET 3 & 4 M5

1 1

RIGHT PROPEL PUMP

CASE DRAIN

SEE SHEET 2

TO COOLER BYPASS MANIFOLD

PORT A SEE SHEET 1

LL

FROM AUXILIARY VALVE / SCREED EXTENDERS

TP P T LS

SEE SHEET 6

M4 S

FROM RETURN MANIFOLD TO HYDRAULIC M5

FROM HYD TANK PORT 3

SEE SHEET 1

L2

SEE SHEET 6 FF

TANK FILTER

L1 B X

E E #1

A

TO FAN PUMP

5

AA BB SEE SHEET 5

LEFT CONVEYOR MOTOR

3 #2

30 Page,

M3 3 M3 29 TO R.H. PROPEL

CHARGE PUMP

CHARGE CHARGE LOAD SENSE L3

FILTER D FILTER

D SEE SHEET 2

#3

TO AUGER/CONVEY

CHARGE PUMP

FUMES MOTOR RETURN SEE SHEET 3 M2 OPTIONAL

S S SEE SHEET 6

B

X1 X1 GENERATOR MOTOR 30 #4 M2 B M6 M2 D

FROM HYDRAULIC TANK

PORT 8 SEE SHEET 1

FROM HYDRAULIC

TANK PORT 2 SEE

SHEET 1

CASE DRAIN

SEE SHEET 7

TO VIBE PUMP

SEE SHEET 4 31

#5

L1

SCREED C/B GAGE TO COOLER BYPASS MANIFOLD

VALVE DRAIN TO TAMPER PORT D, SEE SHEET 1

SEE SHEET 6 CHARGE PUMP

SEE SHEET 5

FAN MOTOR CASE/ #6

4 KK

CONTROL VALVE

L1 SEE SHEET 5 TO AUXILIARY PUMP

L1 TO COOLER BYPASS

SEE SHEET 6

TO COOLER BYPASS

MANIFOLD PORT J SEE #7 S M4

MANIFOLD PORT F SHEET 1

M5 M4 L2 SEE SHEET 1

M5 M4 L2 LEFT SCREED TO GENERATOR PUMP

LIFT CYLINDER SEE SHEET 7

SEE SHEET 6

#8

X1 X2 X1 X2

SCREED C/B

VALVE DRAIN TO L.H. PROPEL L2 TO RETURN MANIFOLD

SEE SHEET 6 CHARGE PUMP PORT D SEE SHEET 6

SEE SHEET 2

X2 X2 RIGHT SCREED LIFT CYLINDER

SEE SHEET 6 28

BRAKE HAND PUMP SUCTION

SEE SHEET 6

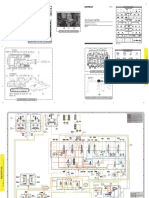

PROPEL PUMP CIRCUITS TANK AND COOLER GENERATOR CIRCUIT CONVEYOR / AUGER / CHARGE UPPER PUMP STACK

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS LINE PATTERNS

AUGER/CONVEYOR CHARGE PUMP OUTPUT

AUXILIARY PUMP OUTPUT Pressure Line

FAN PUMP OUTPUT

VIBRATORY PROPEL PUMP OUTPUT Pilot / Load Sensing Pressure

RIGHT PROPEL PUMP OUTPUT

LEFT PROPEL PUMP OUTPUT Drain / Return Lines

SUPPLY LINE

DRAIN / RETURN LINE Component Group

LEFT CONVEYOR/RIGHT AUGER PUMP OUTPUT

TAMPER PUMP OUTPUT Attachment

SCREED HOIST CONTROL CIRCUIT

AUGER HOIST CONTROL CIRCUIT Air Line

RIGHT CONVEYOR/LEFT AUGER PUMP OUTPUT

HOPPER HOIST CONTROL CIRCUIT

THIS SCHEMATIC IS FOR THE AP-655C AND BG-2255C ASPHALT PAVER

CALLOUTS

TRUCK HITCH CONTROL CIRCUIT PART NUMBER: 245-0849

GRADE CONTROL CIRCUIT YY Taps (Pressure, Sampling,Sensor) by letter Components are shown installed on a fully operable machine with the key and engine off and transmission shifter in neutral.

GENERATOR PUMP OUTPUT

BRAKE RELEASE CONTROL CIRCUIT

52 Components by number Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations.

SCREED EXTENDERS CONTROL CIRCUIT

You might also like

- Hydraulic System Schematic 914-g PDFDocument2 pagesHydraulic System Schematic 914-g PDFpupoz100% (7)

- d6n Hydraulic Ds PilotDocument2 pagesd6n Hydraulic Ds PilotEmmanuel solomonNo ratings yet

- Diagrama Hidraulico Caterpillar 345cDocument2 pagesDiagrama Hidraulico Caterpillar 345cJose Miguel Gary Vargas100% (1)

- 321d Esquema Hidraulico Excavadora CatDocument2 pages321d Esquema Hidraulico Excavadora CatWilson CamachitoNo ratings yet

- TH360B TH560B - CAT - Hydr System.Document2 pagesTH360B TH560B - CAT - Hydr System.Zeck33% (3)

- Procedure For Isolation of Screw PumpDocument7 pagesProcedure For Isolation of Screw PumpManoj Kumar SawNo ratings yet

- RENR8305-02 Esquematico Hidraulico 777FDocument4 pagesRENR8305-02 Esquematico Hidraulico 777FEIDER LEYESNo ratings yet

- 777F PDFDocument4 pages777F PDFIgnacio Lazo JhsúsNo ratings yet

- 320dlrr HydraulicDocument2 pages320dlrr HydraulicEmmanuel solomonNo ratings yet

- 324D Excavator Hydraulic System: Control Manifold Main Pump & Filter Circuits Main Control ValveDocument2 pages324D Excavator Hydraulic System: Control Manifold Main Pump & Filter Circuits Main Control ValveKJDNKJZEFNo ratings yet

- 422e 428e Hydo PDFDocument2 pages422e 428e Hydo PDFdenis100% (1)

- 785C Plano Hidraulico PDFDocument2 pages785C Plano Hidraulico PDFChristian Vásquez BasilioNo ratings yet

- Component Locations: Hydraulic System 730 Ejector Articulated TruckDocument2 pagesComponent Locations: Hydraulic System 730 Ejector Articulated Truckmrcruzito_2099No ratings yet

- 323D Excavator Hydraulic System: Machine Component LocationsDocument2 pages323D Excavator Hydraulic System: Machine Component LocationsKJDNKJZEF100% (1)

- 345C ExcavatorDocument2 pages345C ExcavatorAdhittyaz D SaputraNo ratings yet

- Cat 330dDocument2 pagesCat 330dShahreyar KhanNo ratings yet

- So Do Thuy Luc 345C PDFDocument2 pagesSo Do Thuy Luc 345C PDFdoxuanquylcNo ratings yet

- Plano Hidraulico Sistema 17 Convinacion de FlujoDocument2 pagesPlano Hidraulico Sistema 17 Convinacion de Flujonilton ac100% (1)

- Sistema Hidráulico BynDocument2 pagesSistema Hidráulico BynRoyer MamaniNo ratings yet

- Plano Huidráulico Itm 324DDocument2 pagesPlano Huidráulico Itm 324DTONINo ratings yet

- Hydraulic 992G - Azx PDFDocument2 pagesHydraulic 992G - Azx PDFGuztiNo ratings yet

- Diagrama Hidraulico Del 980HDocument2 pagesDiagrama Hidraulico Del 980HMiguel GonzalezNo ratings yet

- 420D, 432D and 442D Hydraulic System Backhoe Loader: Fluid Power SymbolsDocument4 pages420D, 432D and 442D Hydraulic System Backhoe Loader: Fluid Power Symbolsmilton murillo100% (1)

- Retro 420D PDFDocument4 pagesRetro 420D PDFelmerNo ratings yet

- RENR81230001Document2 pagesRENR81230001ANDRESNo ratings yet

- D3K, D4K, and D5K Track-Type Tractor Hydraulic and Power Train SystemDocument2 pagesD3K, D4K, and D5K Track-Type Tractor Hydraulic and Power Train Systemjulio peña limaNo ratings yet

- 329D Excavator Hydraulic System - Attachment: EE AADocument2 pages329D Excavator Hydraulic System - Attachment: EE AAyonatan sullon sosaNo ratings yet

- Cat - Dcs.sis - Controller Shema Hydrolic de TH 360 SleDocument2 pagesCat - Dcs.sis - Controller Shema Hydrolic de TH 360 SleLhsan Rajawi100% (1)

- Main Control Valve: 345C Excavator Hydraulic System - AttachmentDocument2 pagesMain Control Valve: 345C Excavator Hydraulic System - AttachmentVladimirNo ratings yet

- Kenr7125kenr7125-01 Sis PDFDocument2 pagesKenr7125kenr7125-01 Sis PDFHector Dongo ArrayanNo ratings yet

- 216B, 226B, 236B, 246B, 232B, 242B, Hydraulic System 252B & 262B Skid Steer LoadersDocument2 pages216B, 226B, 236B, 246B, 232B, 242B, Hydraulic System 252B & 262B Skid Steer LoadersLiliana Rebeca Santos santosNo ratings yet

- Diagrama Electrico PM200 PerfiladoraDocument2 pagesDiagrama Electrico PM200 PerfiladoraPlstina Rams100% (2)

- 143H and 163H Motor Grader Hydraulic System Ripper AttachmentDocument2 pages143H and 163H Motor Grader Hydraulic System Ripper AttachmentMohamed Harb100% (1)

- Schéma Hy 227B 01Document2 pagesSchéma Hy 227B 01Juju100% (1)

- 416 eDocument2 pages416 earmando vara chavezNo ratings yet

- Hyd 246C KENR5117KENR5117-03 - SISDocument4 pagesHyd 246C KENR5117KENR5117-03 - SISmizaelNo ratings yet

- 232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerDocument2 pages232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerPablo Porras100% (1)

- 319D Excavator Hydraulic System - Attachment Filter 6: Fluid Power SymbolsDocument2 pages319D Excavator Hydraulic System - Attachment Filter 6: Fluid Power SymbolsANDREI26No ratings yet

- 825H Soil Compactor Hydraulic SystemDocument2 pages825H Soil Compactor Hydraulic SystemTom SouzaNo ratings yet

- Pump GP - Main Hydraulic: 325D and 329D Excavator Hydraulic System - AttachmentDocument2 pagesPump GP - Main Hydraulic: 325D and 329D Excavator Hydraulic System - AttachmentDennis OlayaNo ratings yet

- Plano Hidraulico 834HDocument2 pagesPlano Hidraulico 834HRicardo OjedaNo ratings yet

- 1 5121063547685568656Document2 pages1 5121063547685568656lucio100% (1)

- Minicat 236B Plano HidraulicoDocument4 pagesMinicat 236B Plano HidraulicoHumberto Andrés Mantilla V.No ratings yet

- 950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocument2 pages950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringTeofilo Paredes CosmeNo ratings yet

- NF SD FF NS 001Document1 pageNF SD FF NS 001Adnan AkhtarNo ratings yet

- Fluid Power Symbols: A B C D E F G H JDocument2 pagesFluid Power Symbols: A B C D E F G H JGabino Gaytán100% (2)

- Plano Hidraulico d8tDocument2 pagesPlano Hidraulico d8tJonathan HenriNo ratings yet

- Diagrama Hidráulico 277Document4 pagesDiagrama Hidráulico 277Eduardo SainzNo ratings yet

- KENR7618KENR7618-02 Cargador 924HDocument2 pagesKENR7618KENR7618-02 Cargador 924HEliceo PalominoNo ratings yet

- 319D Excavator Hydraulic System - Attachment Filter: Fluid Power SymbolsDocument2 pages319D Excavator Hydraulic System - Attachment Filter: Fluid Power SymbolsANDREI26No ratings yet

- Machine Component Locations: 793D Off-Highway Truck Hydraulic SystemDocument2 pagesMachine Component Locations: 793D Off-Highway Truck Hydraulic SystemИгорь Иванов0% (1)

- Esquema Hidráulico (793D)Document2 pagesEsquema Hidráulico (793D)Oswaldo Ayma VisaNo ratings yet

- Component Locations: Hydraulic System - Attachment 321D LCR ExcavatorDocument2 pagesComponent Locations: Hydraulic System - Attachment 321D LCR ExcavatorKarlOs Junco SichaNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- 12H Frein TestDocument13 pages12H Frein TestaniriNo ratings yet

- Calculation of Planetary Gear FrequenciesDocument6 pagesCalculation of Planetary Gear Frequenciesdongcsun100% (1)

- MAT-p eDocument4 pagesMAT-p eedark2009No ratings yet

- SO - Pilot Hydraulic SystemDocument8 pagesSO - Pilot Hydraulic Systemisaac989No ratings yet

- Chapter Thirty-Five: ClutchesDocument24 pagesChapter Thirty-Five: ClutchesKkbhuvan KkNo ratings yet

- Import SampleDocument15 pagesImport Samplesuhana.aliroNo ratings yet

- Acs Lab ManualDocument59 pagesAcs Lab ManualAanshu SinghNo ratings yet

- John Deere Tractor Service Manual JD S Tm4336Document14 pagesJohn Deere Tractor Service Manual JD S Tm4336oscarNo ratings yet

- SK330 Trouble Shoot (By Trouble)Document36 pagesSK330 Trouble Shoot (By Trouble)ferdyak1No ratings yet

- Plano Hidraulico R220Document2 pagesPlano Hidraulico R220Renato SanchezNo ratings yet

- CRP Operation ChecklistDocument4 pagesCRP Operation ChecklistveemandalNo ratings yet

- Air Arms S410 EXPDocument3 pagesAir Arms S410 EXPapi-3695814No ratings yet

- Installation and Operating Instructions: Horizontal Split Case Fire PumpsDocument16 pagesInstallation and Operating Instructions: Horizontal Split Case Fire Pumpsyesid rodriguezNo ratings yet

- Tsubaki Emerson Gearmotor HypoidDocument228 pagesTsubaki Emerson Gearmotor HypoidDillan Stwart Quintero ParraNo ratings yet

- Cluth k2 ReconditioningDocument16 pagesCluth k2 ReconditioningPetrus Kanisius WiratnoNo ratings yet

- 7 Cicutos Del Bucket y Boom Stick PDFDocument55 pages7 Cicutos Del Bucket y Boom Stick PDFjorgemegok1860100% (2)

- Assignment No 4 GearsDocument3 pagesAssignment No 4 GearsKaren GedalangaNo ratings yet

- Bombas Shimadzu 2Document33 pagesBombas Shimadzu 2GilbertoNo ratings yet

- Installation Operation Man GTXDocument20 pagesInstallation Operation Man GTXNguyễn LinhNo ratings yet

- 3-Spool Control Valve (2 - 2) - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsDocument2 pages3-Spool Control Valve (2 - 2) - Wheel Loader Komatsu Wa20-1 - Work Equipment Control System 777partsashraf elsayedNo ratings yet

- Cat 320CDocument2 pagesCat 320CДмитрий100% (1)

- Helical GearDocument18 pagesHelical GearNitin B maskeNo ratings yet

- Tecnord - Application ExamplesDocument24 pagesTecnord - Application ExamplesRıfat BingülNo ratings yet

- Critical Wear Areas & Vacuum Test Locations: Control Valve Body Assembly - Front - Gen. 2 6T40 ShownDocument4 pagesCritical Wear Areas & Vacuum Test Locations: Control Valve Body Assembly - Front - Gen. 2 6T40 ShownМихаил БолотинNo ratings yet

- Hydraulic PumpsDocument35 pagesHydraulic PumpsMohammed Al-Odat100% (1)

- Công Ty Cổ Phần Rtc Technology Việt Nam: Check Lable Máy Giặt Tên sản phẩmDocument21 pagesCông Ty Cổ Phần Rtc Technology Việt Nam: Check Lable Máy Giặt Tên sản phẩmMinh tuan Nguyên nhưNo ratings yet

- 9108Document2 pages9108ramiro alvarezNo ratings yet

- ActuatorsDocument6 pagesActuatorsFam ChumNo ratings yet